research

(Professor Paik(right) and PhD Candidate Yoon)

Higher resolution display electronic devices increasingly needs ultra-fine pitch assemblies. On that account, display driver interconnection technology has become a major challenge for upscaling display electronics.

Researchers have moved to one step closer to realizing ultra-fine resolution for displays with a novel thermoplastic anchoring polymer layer structure. This new structure can significantly improve the ultra-fine pitch interconnection by effectively suppressing the movement of conductive particles. This film is expected to be applied to various mobile devices, large-sized OLED panels, and VR, among others.

A research team under Professor Kyung-Wook Paik in the Department of Materials developed an anchoring polymer layer structure that can effectively suppress the movement of conductive particles during the bonding process of the anisotropic conductive films (ACFs). The new structure will significantly improve the conductive particle capture rate, addressing electrical short problems in the ultra-fine pitch assembly process.

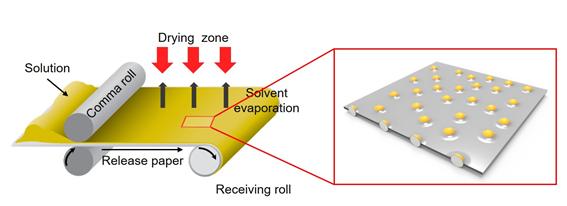

During the ultra-fine pitch bonding process, the conductive particles of conventional ACFs agglomerate between bumps and cause electrical short circuits. To overcome the electrical shortage problem caused by the free movement of conductive particles, higher tensile strength anchoring polymer layers incorporated with conductive particles were introduced into the ACFs to effectively prevent conductive particle movement.

The team used nylon to produce a single layer film with well-distributed and incorporated conductive particles. The higher tensile strength of nylon completely suppressed the movement of conductive particles, raising the capture rate of conductive particles from 33% of the conventional ACFs to 90%. The nylon films showed no short circuit problem during the Chip on Glass assembly. Even more, they obtained excellent electrical conductivity, high reliability, and low cost ACFs during the ultra-fine pitch applications.

Professor Paik believes this new type of ACFs can further be applied not only to VR, 4K and 8K UHD display products, but also to large-size OLED panels and mobile devices.

His team completed a prototype of the film supported by the ‘H&S High-Tech,’ a domestic company and the ‘Innopolis Foundation.’ The study, whose first author is PhD candidate Dal-Jin Yoon, is described in the October issue of IEEE TCPMT.

Figure 1: Schematic process of APL structure fabrication.

Figure 2: Proto-type production of APL ACFs.

-

research KAIST debuts “DreamWaQer” - a quadrupedal robot that can walk in the dark

- The team led by Professor Hyun Myung of the School of Electrical Engineering developed “DreamWaQ”, a deep reinforcement learning-based walking robot control technology that can walk in an atypical environment without visual and/or tactile information - Utilization of “DreamWaQ” technology can enable mass production of various types of “DreamWaQers” - Expected to be used in exploration of atypical environment involving unique circumstances such as disasters

2023-05-18 -

people Professor Sang Kil Cha Receives IEEE Test-of-Time Award

Professor Sang Kil Cha from the Graduate School of Information Security (GSIS) in the School of Computing received the Test-of-Time Award from IEEE Security & Privacy, a top conference in the field of information security. The Test-of-Time Award recognizes the research papers that have influenced the field of information security the most over the past decade. Three papers were selected this year, and Professor Cha is the first Korean winner of the award. The paper by Professor Cha was p

2022-06-13 -

people Professor Hyunjoo Jenny Lee to Co-Chair IEEE MEMS 2025

Professor Hyunjoo Jenny Lee from the School of Electrical Engineering has been appointed General Chair of the 38th IEEE MEMS 2025 (International Conference on Micro Electro Mechanical Systems). Professor Lee, who is 40, is the conference’s youngest General Chair to date and will work jointly with Professor Sheng-Shian Li of Taiwan’s National Tsing Hua University as co-chairs in 2025. IEEE MEMS is a top-tier international conference on microelectromechanical systems and it serves a

2022-04-18 -

people Prof. Changho Suh Named the 2021 James L. Massey Awardee

Professor Changho Suh from the School of Electrical Engineering was named the recipient of the 2021 James L.Massey Award. The award recognizes outstanding achievement in research and teaching by young scholars in the information theory community. The award is named in honor of James L. Massey, who was an internationally acclaimed pioneer in digital communications and revered teacher and mentor to communications engineers. Professor Suh is a recipient of numerous awards, including the 2021 Jam

2021-07-27 -

people Prof. Junil Choi Receives the Neal Shepherd Memorial Award

Professor Junil Choi of the School of Electrical Engineering received the 2021 Neal Shepherd Memorial Award from the IEEE Vehicular Technology Society. The award recognizes the most outstanding paper relating to radio propagation published in major journals over the previous five years. Professor Cho, the recipient of the 2015 IEEE Signal Processing Society’s and the 2019 IEEE Communications Society’s Best Paper Award, was selected as the awardee for his paper titled “The Im

2021-07-26