College+of+Engineering

-

KAIST Researchers Introduce New and Improved, Next-Generation Perovskite Solar Cell

- KAIST-Yonsei university researchers developed innovative dipole technology to maximize near-infrared photon harvesting efficiency

- Overcoming the shortcoming of existing perovskite solar cells that cannot utilize approximately 52% of total solar energy

- Development of next-generation solar cell technology with high efficiency and high stability that can absorb near-infrared light beyond the existing visible light range with a perovskite-dipole-organic semiconductor hybrid structure

< Photo. (From left) Professor Jung-Yong Lee, Ph.D. candidate Min-Ho Lee, and Master’s candidate Min Seok Kim of the School of Electrical Engineering >

Existing perovskite solar cells, which have the problem of not being able to utilize approximately 52% of total solar energy, have been developed by a Korean research team as an innovative technology that maximizes near-infrared light capture performance while greatly improving power conversion efficiency. This greatly increases the possibility of commercializing next-generation solar cells and is expected to contribute to important technological advancements in the global solar cell market.

The research team of Professor Jung-Yong Lee of the School of Electrical Engineering at KAIST (President Kwang-Hyung Lee) and Professor Woojae Kim of the Department of Chemistry at Yonsei University announced on October 31st that they have developed a high-efficiency and high-stability organic-inorganic hybrid solar cell production technology that maximizes near-infrared light capture beyond the existing visible light range.

The research team suggested and advanced a hybrid next-generation device structure with organic photo-semiconductors that complements perovskite materials limited to visible light absorption and expands the absorption range to near-infrared.

In addition, they revealed the electronic structure problem that mainly occurs in the structure and announced a high-performance solar cell device that dramatically solved this problem by introducing a dipole layer*.

*Dipole layer: A thin material layer that controls the energy level within the device to facilitate charge transport and forms an interface potential difference to improve device performance.

Existing lead-based perovskite solar cells have a problem in that their absorption spectrum is limited to the visible light region with a wavelength of 850 nanometers (nm) or less, which prevents them from utilizing approximately 52% of the total solar energy.

To solve this problem, the research team designed a hybrid device that combined an organic bulk heterojunction (BHJ) with perovskite and implemented a solar cell that can absorb up to the near-infrared region.

In particular, by introducing a sub-nanometer dipole interface layer, they succeeded in alleviating the energy barrier between the perovskite and the organic bulk heterojunction (BHJ), suppressing charge accumulation, maximizing the contribution to the near-infrared, and improving the current density (JSC) to 4.9 mA/cm².

The key achievement of this study is that the power conversion efficiency (PCE) of the hybrid device has been significantly increased from 20.4% to 24.0%. In particular, this study achieved a high internal quantum efficiency (IQE) compared to previous studies, reaching 78% in the near-infrared region.

< Figure. The illustration of the mechanism of improving the electronic structure and charge transfer capability through Perovskite/organic hybrid device structure and dipole interfacial layers (DILs). The proposed dipole interfacial layer forms a strong interfacial dipole, effectively reducing the energy barrier between the perovskite and organic bulk heterojunction (BHJ), and suppressing hole accumulation. This technology improves near-infrared photon harvesting and charge transfer, and as a result, the power conversion efficiency of the solar cell increases to 24.0%. In addition, it achieves excellent stability by maintaining performance for 1,200 hours even in an extremely humid environment. >

In addition, this device showed high stability, showing excellent results of maintaining more than 80% of the initial efficiency in the maximum output tracking for more than 800 hours even under extreme humidity conditions.

Professor Jung-Yong Lee said, “Through this study, we have effectively solved the charge accumulation and energy band mismatch problems faced by existing perovskite/organic hybrid solar cells, and we will be able to significantly improve the power conversion efficiency while maximizing the near-infrared light capture performance, which will be a new breakthrough that can solve the mechanical-chemical stability problems of existing perovskites and overcome the optical limitations.”

This study, in which KAIST School of Electrical Engineering Ph.D. candidate Min-Ho Lee and Master's candidate Min Seok Kim participated as co-first authors, was published in the September 30th online edition of the international academic journal Advanced Materials. (Paper title: Suppressing Hole Accumulation Through Sub-Nanometer Dipole Interfaces in Hybrid Perovskite/Organic Solar Cells for Boosting Near-Infrared Photon Harvesting).

This study was conducted with the support of the National Research Foundation of Korea.

2024.10.31 View 116

KAIST Researchers Introduce New and Improved, Next-Generation Perovskite Solar Cell

- KAIST-Yonsei university researchers developed innovative dipole technology to maximize near-infrared photon harvesting efficiency

- Overcoming the shortcoming of existing perovskite solar cells that cannot utilize approximately 52% of total solar energy

- Development of next-generation solar cell technology with high efficiency and high stability that can absorb near-infrared light beyond the existing visible light range with a perovskite-dipole-organic semiconductor hybrid structure

< Photo. (From left) Professor Jung-Yong Lee, Ph.D. candidate Min-Ho Lee, and Master’s candidate Min Seok Kim of the School of Electrical Engineering >

Existing perovskite solar cells, which have the problem of not being able to utilize approximately 52% of total solar energy, have been developed by a Korean research team as an innovative technology that maximizes near-infrared light capture performance while greatly improving power conversion efficiency. This greatly increases the possibility of commercializing next-generation solar cells and is expected to contribute to important technological advancements in the global solar cell market.

The research team of Professor Jung-Yong Lee of the School of Electrical Engineering at KAIST (President Kwang-Hyung Lee) and Professor Woojae Kim of the Department of Chemistry at Yonsei University announced on October 31st that they have developed a high-efficiency and high-stability organic-inorganic hybrid solar cell production technology that maximizes near-infrared light capture beyond the existing visible light range.

The research team suggested and advanced a hybrid next-generation device structure with organic photo-semiconductors that complements perovskite materials limited to visible light absorption and expands the absorption range to near-infrared.

In addition, they revealed the electronic structure problem that mainly occurs in the structure and announced a high-performance solar cell device that dramatically solved this problem by introducing a dipole layer*.

*Dipole layer: A thin material layer that controls the energy level within the device to facilitate charge transport and forms an interface potential difference to improve device performance.

Existing lead-based perovskite solar cells have a problem in that their absorption spectrum is limited to the visible light region with a wavelength of 850 nanometers (nm) or less, which prevents them from utilizing approximately 52% of the total solar energy.

To solve this problem, the research team designed a hybrid device that combined an organic bulk heterojunction (BHJ) with perovskite and implemented a solar cell that can absorb up to the near-infrared region.

In particular, by introducing a sub-nanometer dipole interface layer, they succeeded in alleviating the energy barrier between the perovskite and the organic bulk heterojunction (BHJ), suppressing charge accumulation, maximizing the contribution to the near-infrared, and improving the current density (JSC) to 4.9 mA/cm².

The key achievement of this study is that the power conversion efficiency (PCE) of the hybrid device has been significantly increased from 20.4% to 24.0%. In particular, this study achieved a high internal quantum efficiency (IQE) compared to previous studies, reaching 78% in the near-infrared region.

< Figure. The illustration of the mechanism of improving the electronic structure and charge transfer capability through Perovskite/organic hybrid device structure and dipole interfacial layers (DILs). The proposed dipole interfacial layer forms a strong interfacial dipole, effectively reducing the energy barrier between the perovskite and organic bulk heterojunction (BHJ), and suppressing hole accumulation. This technology improves near-infrared photon harvesting and charge transfer, and as a result, the power conversion efficiency of the solar cell increases to 24.0%. In addition, it achieves excellent stability by maintaining performance for 1,200 hours even in an extremely humid environment. >

In addition, this device showed high stability, showing excellent results of maintaining more than 80% of the initial efficiency in the maximum output tracking for more than 800 hours even under extreme humidity conditions.

Professor Jung-Yong Lee said, “Through this study, we have effectively solved the charge accumulation and energy band mismatch problems faced by existing perovskite/organic hybrid solar cells, and we will be able to significantly improve the power conversion efficiency while maximizing the near-infrared light capture performance, which will be a new breakthrough that can solve the mechanical-chemical stability problems of existing perovskites and overcome the optical limitations.”

This study, in which KAIST School of Electrical Engineering Ph.D. candidate Min-Ho Lee and Master's candidate Min Seok Kim participated as co-first authors, was published in the September 30th online edition of the international academic journal Advanced Materials. (Paper title: Suppressing Hole Accumulation Through Sub-Nanometer Dipole Interfaces in Hybrid Perovskite/Organic Solar Cells for Boosting Near-Infrared Photon Harvesting).

This study was conducted with the support of the National Research Foundation of Korea.

2024.10.31 View 116 -

KAIST Proposes AI Training Method that will Drastically Shorten Time for Calculations in Quantum Mechanics

- Professor Yong-Hoon Kim's team from the School of Electrical Engineering succeeded in accelerating calculations for electronic structure in quantum mechanics for the first time in the world using a convolutional neural network (CNN) model

- Presenting the learning principle of quantum mechanical 3D chemical bonding information through AI, expected to be applied to next-generation material and device computer design fields

The close relationship between AI and highly complicated scientific computing can be seen in the fact that both the 2024 Nobel Prizes in Physics and Chemistry were awarded to scientists for devising the AI for their respective fields of study. KAIST researchers succeeded in dramatically reducing the computation time for highly sophisticated computer simulations for quantum mechanics by predicting atomic-level chemical bonding information distributed in 3D space using a novel approach to teach AI.

KAIST (President Kwang-Hyung Lee) announced on the 30th of October that Professor Yong-Hoon Kim's team from the School of Electrical Engineering developed a 3D computer vision artificial neural network-based computation methodology that bypasses the complex algorithms required for atomic-level quantum mechanical calculations traditionally performed using supercomputers to derive the properties of materials.

< Figure 1. Various methodologies are utilized in the simulation of materials and materials, such as quantum mechanical calculations at the nanometer (nm) level, classical mechanical force fields at the scale of tens to hundreds of nanometers, continuum dynamics calculations at the macroscopic scale, and calculations that mix simulations at different scales. These simulations are already playing a key role in a wide range of basic research and application development fields in combination with informatics techniques. Recently, there have been active efforts to introduce machine learning techniques to radically accelerate simulations, but research on introducing machine learning techniques to quantum mechanical electronic structure calculations, which form the basis of high-scale simulations, is still insufficient. >

The density functional theory (DFT) calculations in quantum mechanics using supercomputers have become an essential and standard tool in a wide range of research and development fields, including advanced materials and drug design, as they allow for fast and accurate prediction of quantum properties.

*Density functional theory (DFT): A representative theory of ab initio (first principles) calculations that calculate quantum mechanical properties from the atomic level.

However, practical DFT calculations require generating 3D electron density and solving quantum mechanical equations through a complex, iterative self-consistent field (SCF)* process that must be repeated tens to hundreds of times. This restricts its application to systems with only a few hundred to a few thousand atoms.

*Self-consistent field (SCF): A scientific computing method widely used to solve complex many-body problems that must be described by a number of interconnected simultaneous differential equations.

Professor Yong-Hoon Kim’s research team questioned whether recent advancements in AI techniques could be used to bypass the SCF process. As a result, they developed the DeepSCF model, which accelerates calculations by learning chemical bonding information distributed in a 3D space using neural network algorithms from the field of computer vision.

< Figure 2. The deepSCF methodology developed in this study provides a way to rapidly accelerate DFT calculations by avoiding the self-consistent field process (orange box) that had to be performed repeatedly in traditional quantum mechanical electronic structure calculations through artificial neural network techniques (green box). The self-consistent field process is a process of predicting the 3D electron density, constructing the corresponding potential, and then solving the quantum mechanical Cohn-Sham equations, repeating tens to hundreds of times. The core idea of the deepSCF methodology is that the residual electron density (δρ), which is the difference between the electron density (ρ) and the sum of the electron densities of the constituent atoms (ρ0), corresponds to chemical bonding information, so the self-consistent field process is replaced with a 3D convolutional neural network model. >

The research team focused on the fact that, according to density functional theory, electron density contains all quantum mechanical information of electrons, and that the residual electron density — the difference between the total electron density and the sum of the electron densities of the constituent atoms — contains chemical bonding information. They used this as the target for machine learning.

They then adopted a dataset of organic molecules with various chemical bonding characteristics, applying random rotations and deformations to the atomic structures of these molecules to further enhance the model’s accuracy and generalization capabilities. Ultimately, the research team demonstrated the validity and efficiency of the DeepSCF methodology on large, complex systems.

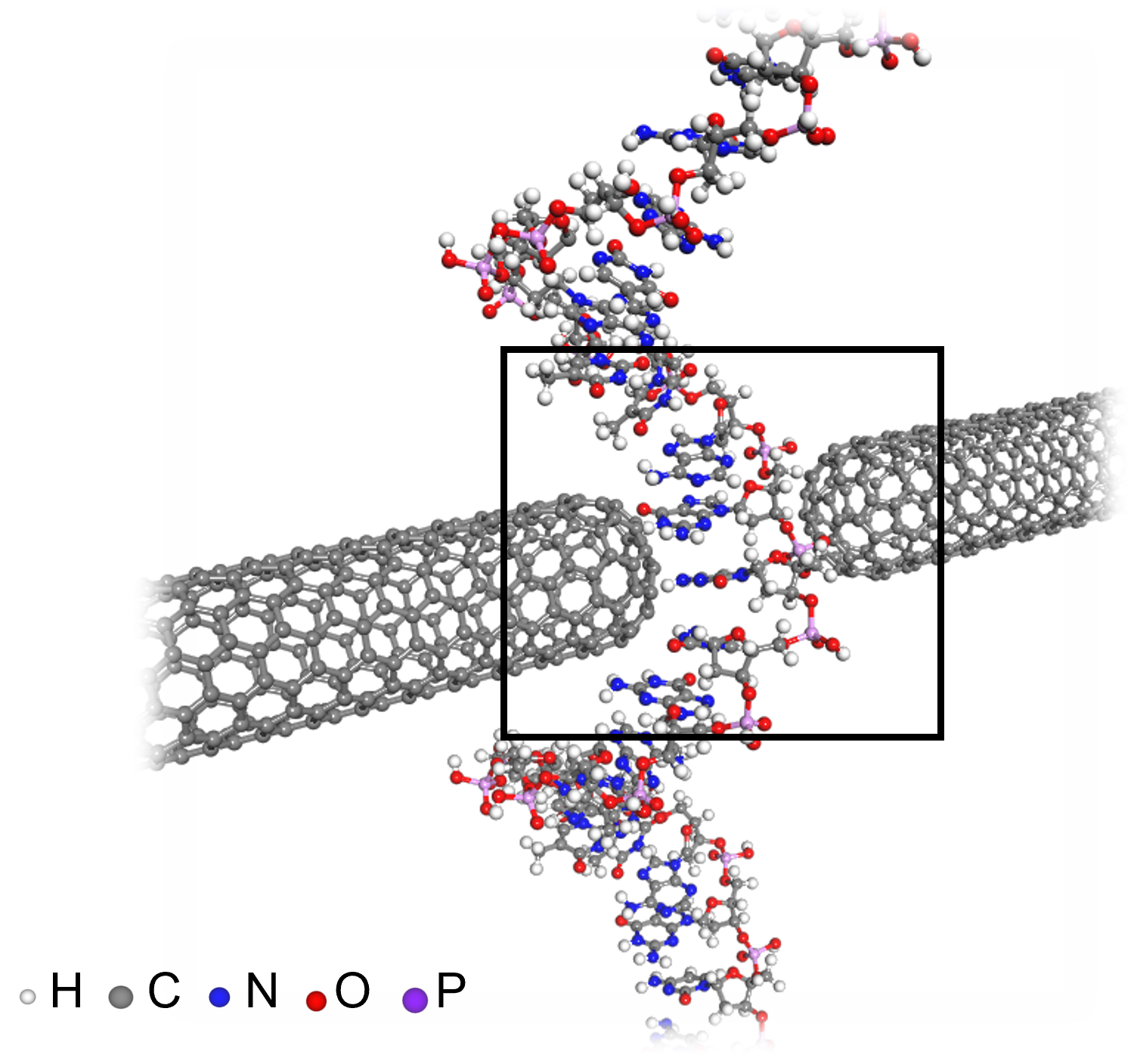

< Figure 3. An example of applying the deepSCF methodology to a carbon nanotube-based DNA sequence analysis device model (top left). In addition to classical mechanical interatomic forces (bottom right), the residual electron density (top right) and quantum mechanical electronic structure properties such as the electronic density of states (DOS) (bottom left) containing information on chemical bonding are rapidly predicted with an accuracy corresponding to the standard DFT calculation results that perform the SCF process. >

Professor Yong-Hoon Kim, who supervised the research, explained that his team had found a way to map quantum mechanical chemical bonding information in a 3D space onto artificial neural networks. He noted, “Since quantum mechanical electron structure calculations underpin property simulations at all scales, this research establishes a foundational principle for accelerating material calculations using artificial intelligence.”

Ryong-Gyu Lee, a PhD candidate in the School of Electrical Engineering, served as the first author of this research, which was published online on October 24 in Npj Computational Materials, a prestigious journal in the field of material computation. (Paper title: “Convolutional network learning of self-consistent electron density via grid-projected atomic fingerprints”)

This research was conducted with support from the KAIST Venture Research Program for Graduate and PhD Students and the National Research Foundation of Korea’s Mid-career Researcher Support Program.

2024.10.30 View 147

KAIST Proposes AI Training Method that will Drastically Shorten Time for Calculations in Quantum Mechanics

- Professor Yong-Hoon Kim's team from the School of Electrical Engineering succeeded in accelerating calculations for electronic structure in quantum mechanics for the first time in the world using a convolutional neural network (CNN) model

- Presenting the learning principle of quantum mechanical 3D chemical bonding information through AI, expected to be applied to next-generation material and device computer design fields

The close relationship between AI and highly complicated scientific computing can be seen in the fact that both the 2024 Nobel Prizes in Physics and Chemistry were awarded to scientists for devising the AI for their respective fields of study. KAIST researchers succeeded in dramatically reducing the computation time for highly sophisticated computer simulations for quantum mechanics by predicting atomic-level chemical bonding information distributed in 3D space using a novel approach to teach AI.

KAIST (President Kwang-Hyung Lee) announced on the 30th of October that Professor Yong-Hoon Kim's team from the School of Electrical Engineering developed a 3D computer vision artificial neural network-based computation methodology that bypasses the complex algorithms required for atomic-level quantum mechanical calculations traditionally performed using supercomputers to derive the properties of materials.

< Figure 1. Various methodologies are utilized in the simulation of materials and materials, such as quantum mechanical calculations at the nanometer (nm) level, classical mechanical force fields at the scale of tens to hundreds of nanometers, continuum dynamics calculations at the macroscopic scale, and calculations that mix simulations at different scales. These simulations are already playing a key role in a wide range of basic research and application development fields in combination with informatics techniques. Recently, there have been active efforts to introduce machine learning techniques to radically accelerate simulations, but research on introducing machine learning techniques to quantum mechanical electronic structure calculations, which form the basis of high-scale simulations, is still insufficient. >

The density functional theory (DFT) calculations in quantum mechanics using supercomputers have become an essential and standard tool in a wide range of research and development fields, including advanced materials and drug design, as they allow for fast and accurate prediction of quantum properties.

*Density functional theory (DFT): A representative theory of ab initio (first principles) calculations that calculate quantum mechanical properties from the atomic level.

However, practical DFT calculations require generating 3D electron density and solving quantum mechanical equations through a complex, iterative self-consistent field (SCF)* process that must be repeated tens to hundreds of times. This restricts its application to systems with only a few hundred to a few thousand atoms.

*Self-consistent field (SCF): A scientific computing method widely used to solve complex many-body problems that must be described by a number of interconnected simultaneous differential equations.

Professor Yong-Hoon Kim’s research team questioned whether recent advancements in AI techniques could be used to bypass the SCF process. As a result, they developed the DeepSCF model, which accelerates calculations by learning chemical bonding information distributed in a 3D space using neural network algorithms from the field of computer vision.

< Figure 2. The deepSCF methodology developed in this study provides a way to rapidly accelerate DFT calculations by avoiding the self-consistent field process (orange box) that had to be performed repeatedly in traditional quantum mechanical electronic structure calculations through artificial neural network techniques (green box). The self-consistent field process is a process of predicting the 3D electron density, constructing the corresponding potential, and then solving the quantum mechanical Cohn-Sham equations, repeating tens to hundreds of times. The core idea of the deepSCF methodology is that the residual electron density (δρ), which is the difference between the electron density (ρ) and the sum of the electron densities of the constituent atoms (ρ0), corresponds to chemical bonding information, so the self-consistent field process is replaced with a 3D convolutional neural network model. >

The research team focused on the fact that, according to density functional theory, electron density contains all quantum mechanical information of electrons, and that the residual electron density — the difference between the total electron density and the sum of the electron densities of the constituent atoms — contains chemical bonding information. They used this as the target for machine learning.

They then adopted a dataset of organic molecules with various chemical bonding characteristics, applying random rotations and deformations to the atomic structures of these molecules to further enhance the model’s accuracy and generalization capabilities. Ultimately, the research team demonstrated the validity and efficiency of the DeepSCF methodology on large, complex systems.

< Figure 3. An example of applying the deepSCF methodology to a carbon nanotube-based DNA sequence analysis device model (top left). In addition to classical mechanical interatomic forces (bottom right), the residual electron density (top right) and quantum mechanical electronic structure properties such as the electronic density of states (DOS) (bottom left) containing information on chemical bonding are rapidly predicted with an accuracy corresponding to the standard DFT calculation results that perform the SCF process. >

Professor Yong-Hoon Kim, who supervised the research, explained that his team had found a way to map quantum mechanical chemical bonding information in a 3D space onto artificial neural networks. He noted, “Since quantum mechanical electron structure calculations underpin property simulations at all scales, this research establishes a foundational principle for accelerating material calculations using artificial intelligence.”

Ryong-Gyu Lee, a PhD candidate in the School of Electrical Engineering, served as the first author of this research, which was published online on October 24 in Npj Computational Materials, a prestigious journal in the field of material computation. (Paper title: “Convolutional network learning of self-consistent electron density via grid-projected atomic fingerprints”)

This research was conducted with support from the KAIST Venture Research Program for Graduate and PhD Students and the National Research Foundation of Korea’s Mid-career Researcher Support Program.

2024.10.30 View 147 -

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 406

A KAIST Team Develops Face-Conforming LED Mask Showing 340% Improved Efficacy in Deep Skin Elasticity

- A KAIST research team led by Professor Keon Jae Lee has developed a deep skin-stimulating LED mask which has been verified in clinical trials to improve dermis elasticity by 340%.

< Figure 1. Overall concept of face-fit surface-lighting micro-LEDs (FSLED) mask. a. Optical image of the FSLED mask showing uniform surface-lighting. schematic illustration of the FSLED mask. The 2D to 3D transformation procedure b. Difference in cosmetic effect on deep skin elasticity, wrinkles, and sagging between FSLED mask and CLED mask. (improvement percentage in eight weeks) >

Conventional LED masks, with their rigid design, fail to conform closely to the skin's contours. This limitation causes substantial light reflection, with up to 90% reflected over a distance of 2 cm, reducing light penetration and limiting stimulation of the deep skin layers essential for effective skin rejuvenation.

To address these challenges, Professor Lee's team developed a face-conforming surface lighting micro-LED (FSLED) mask, which can provide uniform photostimulation to the dermis. The key technology lies in the mask's ability to deliver uniform light to deep skin tissues while maintaining a conformal skin attachment. This is achieved through a 3D origami structure, integrated with 3,770 micro-LEDs and flexible surface light-diffusion layer, minimizing the gaps between the light source and the skin.

In clinical trials involving 33 participants, the FSLED mask demonstrated a 340% improvement in deep skin elasticity compared to conventional LED masks, proving its efficacy in significantly reducing skin wrinkles, sagging and aging.

Professor Keon Jae Lee said, “The FSLED mask provides cosmetic benefits to the entire facial dermis without the side effects of low-temperature burns, making home-care anti-aging treatment that enhances the quality of human life possible. The product is being manufactured by Fronics, KAIST startup company, and will be distributed globally through Amorepacific's network, with sales starting in November.”

This result titled “Clinical Validation of Face-fit Surface-lighting Micro Light-emitting Diode Mask for Skin Anti-aging Treatment”, in which Min Seo Kim, a student of the Master-Doctorate integrated program, and Jaehun An, a Ph.D. candidate, in the Department of Materials Science and Engineering of KAIST, took part as co-first authors, was published in Advanced Materials on October 22nd, 2024 (DOI: 10.1002/adma.202411651).

Introductory Video: Face-conforming surface LED mask for skin anti-aging ( https://www.youtube.com/watch?v=kSccLwx8N_w )

2024.10.29 View 406 -

Team KAIST Crowned Champion for their World’s Best Ironman, Winning their 2nd Consecutive Win at the Cyborg Olympics

< Group photo of our research team participating in the 3rd Cybathlon >

The Cybathlon is an international competition, which aims to help overcome disabilities through the use of robotics technology. KAIST researchers came in third, winning the bronze medal, at their 1st participation in 2016, won their first gold medal at the 2nd competition in 2020, and took back the gold medal at this year’s 3rd competition, successfully defending their champion title.

KAIST (President Kwang-Hyung Lee) announced on the 28th of October that the wearable robot ‘WalkON Suit F1’ developed by the joint research team of KAIST EXO-Lab, Move Lab, and Angel Robotics, led by Professor Kyoungchul Kong of the Department of Mechanical Engineering (Chairman of Angel Robotics), won gold medal in Cybathlon 2024 held on the 27th.

< Seunghwan Kim, the Paraplegic Pilot of Team KAIST, cheering after completing all the missions >

Cybathlon is an international competition first held in Switzerland that challenges teams to develop assistive technologies with the purpose of overcoming disabilities, and is also called the Cyborg Olympics. Right after each competition, the missions for the next competition are announced, and research teams from around the world research and develop the right assistive technology for next four years to accomplish the given mission.

Aside from the Exoskeleton Race, competitions in a total of eight disciplines are held, including Arm Prosthesis Race, Leg Prosthesis Race, and Wheelchair Race. A total of 71 teams from 26 countries participated in the 3rd Cybathlon event. Professor Kyoungchul Kong’s research team participated in the Exoskeleton Race, the same discipline they took part in the previous competition.

The Exoskeleton Race is the highlight of the event that can be called the core of the Cybathlon. In the prosthetic arm or leg events, disabled athletes wearing traditional assistive devices instead of powered devices often win depending more on the ability of the athletes rather than the technology behind the tools.

However, the exoskeleton event requires individuals with paraplegic disability to walk completely dependent on the robotic device to perform various missions, so the technical difficulty and the dependence on robotics technology is high.

In fact, many teams gave up on participating after seeing the missions for this competition, and more than half of the research teams declared withdrawal during the developmental process. In the end, only six teams from Korea, Thailands, Switzerland, Germany, and the Netherlands participated in the actual competition. Even the research team from the Swiss headquarters declared forfeiture midway as the competition date drew nearer.

< Cybathlon 2024 – Exoskeleton Race Mission Description >

The reason why many teams gave up in the exoskeleton discipline was because the difficulty of the missions was unusually high. Most research teams have the skills to make paraplegic athletes walk, but there were many other difficult tasks, such as making them walk without crutches or using both hands, while standing free on both legs on the exoskeleton, to cut a lump of sponge block, as in imitating food preparing process.

The reason why the difficulty of the missions increased like this is because Professor Kong's research team completed all the missions given to them too quickly in the last competition. In fact, in the last competition, there was even a question asked whether Kim Byeong-Uk (paraplegic) wearing the WalkON Suit F1 was really disabled.

Professor Kong's research team developed WalkON Suit F1 to successfully complete the missions. The number of motorized joints increased from six to twelve, and the output of the motor itself was more than doubled compared to the previous model that ran in the competition back in 2020. The 6-channel ground reaction force sensor on the foot measured the robot's balance 1,000 times per second to maintain balance. Cameras were installed to detect obstacles, and an AI board for implementation of AI neural network was also installed.

On top of the technologies required to complete the competition missions, a function was implemented that allows the users to wear the robot by themselves and dock on to it right from their wheelchair. In the process, all parts were domestically produced and all basic technologies were internalized. The outer design of the robot was done by Professor Hyunjoon Park of KAIST, and the harmony between people and robots was pursued.

In the end, the results of the competition were as expected. The only team that could successfully perform all of the mission tasks, which were originally designed to challenge Professor Kong's research team, was Professor Kong's team. They successfully completed missions such as moving by sidesteps between narrow chairs, moving boxes, walking freely unassisted by crutches, passing through a narrow door and closing it behind, and working on food preparation in the kitchen, recording 6 minutes and 41 seconds to complete all six tasks.

The Swiss and Thai teams that took 2nd and 3rd places were all given 10 minutes, but only were able to perform two missions, each earning twenty points. It was an unevenly matched race to begin with. The Cybathlon broadcast team was more surprised and interested in the performance of WalkON Suit F1 than in result of the race.

< Team KAIST’s Paraplegic Pilot Seunghwan Kim (left), and Professor Kyoungchul Kong (right) >

Researcher Jeongsu Park, the captain of Team KAIST, said, “We came into this competition thinking of it as a competition against ourselves to begin with and focused on showing the technological gap. Now, we are very happy and proud that our endeavors achieved such good result as well.” He added, “We plan to continue to showcase various functions of the WalkON Suit F1 that have not yet been publicly introduced.”

Researcher Seunghwan Kim, the paraplegic athlete of the team, said, “I am so touched that I was able to introduce the world’s best wearable robot technology of Korea with my own body.”

On a different note, Professor Kong’s research team has successfully commercialized wearable robots through Angel Robotics Co., Ltd. since the 2020 competition. In 2022, they began distributing “ANGEL LEGS M20,” the first wearable robot to be covered by health insurance, and as a result, Angel Robotics Co., Ltd. was successfully listed on KOSDAQ this March.

The various know-how and core technologies accumulated while preparing for this competition is to contribute to further development and propagation of wearable robots, provoking imagination to draw on the future of wearable robots and on how it may change our daily lives.

Final Match (Self-filmed): https://youtu.be/3ASAtvkiOhw

Final Match and Interview (Official Video): https://youtu.be/FSfxOTpDjSE

Final Match and Interview (Summary): https://youtu.be/Sb_vd5-3f_0

2024.10.28 View 493

Team KAIST Crowned Champion for their World’s Best Ironman, Winning their 2nd Consecutive Win at the Cyborg Olympics

< Group photo of our research team participating in the 3rd Cybathlon >

The Cybathlon is an international competition, which aims to help overcome disabilities through the use of robotics technology. KAIST researchers came in third, winning the bronze medal, at their 1st participation in 2016, won their first gold medal at the 2nd competition in 2020, and took back the gold medal at this year’s 3rd competition, successfully defending their champion title.

KAIST (President Kwang-Hyung Lee) announced on the 28th of October that the wearable robot ‘WalkON Suit F1’ developed by the joint research team of KAIST EXO-Lab, Move Lab, and Angel Robotics, led by Professor Kyoungchul Kong of the Department of Mechanical Engineering (Chairman of Angel Robotics), won gold medal in Cybathlon 2024 held on the 27th.

< Seunghwan Kim, the Paraplegic Pilot of Team KAIST, cheering after completing all the missions >

Cybathlon is an international competition first held in Switzerland that challenges teams to develop assistive technologies with the purpose of overcoming disabilities, and is also called the Cyborg Olympics. Right after each competition, the missions for the next competition are announced, and research teams from around the world research and develop the right assistive technology for next four years to accomplish the given mission.

Aside from the Exoskeleton Race, competitions in a total of eight disciplines are held, including Arm Prosthesis Race, Leg Prosthesis Race, and Wheelchair Race. A total of 71 teams from 26 countries participated in the 3rd Cybathlon event. Professor Kyoungchul Kong’s research team participated in the Exoskeleton Race, the same discipline they took part in the previous competition.

The Exoskeleton Race is the highlight of the event that can be called the core of the Cybathlon. In the prosthetic arm or leg events, disabled athletes wearing traditional assistive devices instead of powered devices often win depending more on the ability of the athletes rather than the technology behind the tools.

However, the exoskeleton event requires individuals with paraplegic disability to walk completely dependent on the robotic device to perform various missions, so the technical difficulty and the dependence on robotics technology is high.

In fact, many teams gave up on participating after seeing the missions for this competition, and more than half of the research teams declared withdrawal during the developmental process. In the end, only six teams from Korea, Thailands, Switzerland, Germany, and the Netherlands participated in the actual competition. Even the research team from the Swiss headquarters declared forfeiture midway as the competition date drew nearer.

< Cybathlon 2024 – Exoskeleton Race Mission Description >

The reason why many teams gave up in the exoskeleton discipline was because the difficulty of the missions was unusually high. Most research teams have the skills to make paraplegic athletes walk, but there were many other difficult tasks, such as making them walk without crutches or using both hands, while standing free on both legs on the exoskeleton, to cut a lump of sponge block, as in imitating food preparing process.

The reason why the difficulty of the missions increased like this is because Professor Kong's research team completed all the missions given to them too quickly in the last competition. In fact, in the last competition, there was even a question asked whether Kim Byeong-Uk (paraplegic) wearing the WalkON Suit F1 was really disabled.

Professor Kong's research team developed WalkON Suit F1 to successfully complete the missions. The number of motorized joints increased from six to twelve, and the output of the motor itself was more than doubled compared to the previous model that ran in the competition back in 2020. The 6-channel ground reaction force sensor on the foot measured the robot's balance 1,000 times per second to maintain balance. Cameras were installed to detect obstacles, and an AI board for implementation of AI neural network was also installed.

On top of the technologies required to complete the competition missions, a function was implemented that allows the users to wear the robot by themselves and dock on to it right from their wheelchair. In the process, all parts were domestically produced and all basic technologies were internalized. The outer design of the robot was done by Professor Hyunjoon Park of KAIST, and the harmony between people and robots was pursued.

In the end, the results of the competition were as expected. The only team that could successfully perform all of the mission tasks, which were originally designed to challenge Professor Kong's research team, was Professor Kong's team. They successfully completed missions such as moving by sidesteps between narrow chairs, moving boxes, walking freely unassisted by crutches, passing through a narrow door and closing it behind, and working on food preparation in the kitchen, recording 6 minutes and 41 seconds to complete all six tasks.

The Swiss and Thai teams that took 2nd and 3rd places were all given 10 minutes, but only were able to perform two missions, each earning twenty points. It was an unevenly matched race to begin with. The Cybathlon broadcast team was more surprised and interested in the performance of WalkON Suit F1 than in result of the race.

< Team KAIST’s Paraplegic Pilot Seunghwan Kim (left), and Professor Kyoungchul Kong (right) >

Researcher Jeongsu Park, the captain of Team KAIST, said, “We came into this competition thinking of it as a competition against ourselves to begin with and focused on showing the technological gap. Now, we are very happy and proud that our endeavors achieved such good result as well.” He added, “We plan to continue to showcase various functions of the WalkON Suit F1 that have not yet been publicly introduced.”

Researcher Seunghwan Kim, the paraplegic athlete of the team, said, “I am so touched that I was able to introduce the world’s best wearable robot technology of Korea with my own body.”

On a different note, Professor Kong’s research team has successfully commercialized wearable robots through Angel Robotics Co., Ltd. since the 2020 competition. In 2022, they began distributing “ANGEL LEGS M20,” the first wearable robot to be covered by health insurance, and as a result, Angel Robotics Co., Ltd. was successfully listed on KOSDAQ this March.

The various know-how and core technologies accumulated while preparing for this competition is to contribute to further development and propagation of wearable robots, provoking imagination to draw on the future of wearable robots and on how it may change our daily lives.

Final Match (Self-filmed): https://youtu.be/3ASAtvkiOhw

Final Match and Interview (Official Video): https://youtu.be/FSfxOTpDjSE

Final Match and Interview (Summary): https://youtu.be/Sb_vd5-3f_0

2024.10.28 View 493 -

KAIST Professor Uichin Lee Receives Distinguished Paper Award from ACM

< Photo. Professor Uichin Lee (left) receiving the award >

KAIST (President Kwang Hyung Lee) announced on the 25th of October that Professor Uichin Lee’s research team from the School of Computing received the Distinguished Paper Award at the International Joint Conference on Pervasive and Ubiquitous Computing and International Symposium on Wearable Computing (Ubicomp / ISWC) hosted by the Association for Computing Machinery (ACM) in Melbourne, Australia on October 8.

The ACM Ubiquitous Computing Conference is the most prestigious international conference where leading universities and global companies from around the world present the latest research results on ubiquitous computing and wearable technologies in the field of human-computer interaction (HCI).

The main conference program is composed of invited papers published in the Proceedings of the ACM (PACM) on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT), which covers the latest research in the field of ubiquitous and wearable computing.

The Distinguished Paper Award Selection Committee selected eight papers among 205 papers published in Vol. 7 of the ACM Proceedings (PACM IMWUT) that made outstanding and exemplary contributions to the research community. The committee consists of 16 prominent experts who are current and former members of the journal's editorial board which made the selection after a rigorous review of all papers for a period that stretched over a month.

< Figure 1. BeActive mobile app to promote physical activity to form active lifestyle habits >

The research that won the Distinguished Paper Award was conducted by Dr. Junyoung Park, a graduate of the KAIST Graduate School of Data Science, as the 1st author, and was titled “Understanding Disengagement in Just-in-Time Mobile Health Interventions”

Professor Uichin Lee’s research team explored user engagement of ‘Just-in-Time Mobile Health Interventions’ that actively provide interventions in opportune situations by utilizing sensor data collected from health management apps, based on the premise that these apps are aptly in use to ensure effectiveness.

< Figure 2. Traditional user-requested digital behavior change intervention (DBCI) delivery (Pull) vs. Automatic transmission (Push) for Just-in-Time (JIT) mobile DBCI using smartphone sensing technologies >

The research team conducted a systematic analysis of user disengagement or the decline in user engagement in digital behavior change interventions. They developed the BeActive system, an app that promotes physical activities designed to help forming active lifestyle habits, and systematically analyzed the effects of users’ self-control ability and boredom-proneness on compliance with behavioral interventions over time.

The results of an 8-week field trial revealed that even if just-in-time interventions are provided according to the user’s situation, it is impossible to avoid a decline in participation. However, for users with high self-control and low boredom tendency, the compliance with just-in-time interventions delivered through the app was significantly higher than that of users in other groups.

In particular, users with high boredom proneness easily got tired of the repeated push interventions, and their compliance with the app decreased more quickly than in other groups.

< Figure 3. Just-in-time Mobile Health Intervention: a demonstrative case of the BeActive system: When a user is identified to be sitting for more than 50 mins, an automatic push notification is sent to recommend a short active break to complete for reward points. >

Professor Uichin Lee explained, “As the first study on user engagement in digital therapeutics and wellness services utilizing mobile just-in-time health interventions, this research provides a foundation for exploring ways to empower user engagement.” He further added, “By leveraging large language models (LLMs) and comprehensive context-aware technologies, it will be possible to develop user-centered AI technologies that can significantly boost engagement."

< Figure 4. A conceptual illustration of user engagement in digital health apps. Engagement in digital health apps consists of (1) engagement in using digital health apps and (2) engagement in behavioral interventions provided by digital health apps, i.e., compliance with behavioral interventions. Repeated adherences to behavioral interventions recommended by digital health apps can help achieve the distal health goals. >

This study was conducted with the support of the 2021 Biomedical Technology Development Program and the 2022 Basic Research and Development Program of the National Research Foundation of Korea funded by the Ministry of Science and ICT.

< Figure 5. A conceptual illustration of user disengagement and engagement of digital behavior change intervention (DBCI) apps. In general, user engagement of digital health intervention apps consists of two components: engagement in digital health apps and engagement in behavioral interventions recommended by such apps (known as behavioral compliance or intervention adherence). The distinctive stages of user can be divided into adoption, abandonment, and attrition. >

< Figure 6. Trends of changes in frequency of app usage and adherence to behavioral intervention over 8 weeks, ● SC: Self-Control Ability (High-SC: user group with high self-control, Low-SC: user group with low self-control) ● BD: Boredom-Proneness (High-BD: user group with high boredom-proneness, Low-BD: user group with low boredom-proneness). The app usage frequencies were declined over time, but the adherence rates of those participants with High-SC and Low-BD were significantly higher than other groups. >

2024.10.25 View 334

KAIST Professor Uichin Lee Receives Distinguished Paper Award from ACM

< Photo. Professor Uichin Lee (left) receiving the award >

KAIST (President Kwang Hyung Lee) announced on the 25th of October that Professor Uichin Lee’s research team from the School of Computing received the Distinguished Paper Award at the International Joint Conference on Pervasive and Ubiquitous Computing and International Symposium on Wearable Computing (Ubicomp / ISWC) hosted by the Association for Computing Machinery (ACM) in Melbourne, Australia on October 8.

The ACM Ubiquitous Computing Conference is the most prestigious international conference where leading universities and global companies from around the world present the latest research results on ubiquitous computing and wearable technologies in the field of human-computer interaction (HCI).

The main conference program is composed of invited papers published in the Proceedings of the ACM (PACM) on Interactive, Mobile, Wearable and Ubiquitous Technologies (IMWUT), which covers the latest research in the field of ubiquitous and wearable computing.

The Distinguished Paper Award Selection Committee selected eight papers among 205 papers published in Vol. 7 of the ACM Proceedings (PACM IMWUT) that made outstanding and exemplary contributions to the research community. The committee consists of 16 prominent experts who are current and former members of the journal's editorial board which made the selection after a rigorous review of all papers for a period that stretched over a month.

< Figure 1. BeActive mobile app to promote physical activity to form active lifestyle habits >

The research that won the Distinguished Paper Award was conducted by Dr. Junyoung Park, a graduate of the KAIST Graduate School of Data Science, as the 1st author, and was titled “Understanding Disengagement in Just-in-Time Mobile Health Interventions”

Professor Uichin Lee’s research team explored user engagement of ‘Just-in-Time Mobile Health Interventions’ that actively provide interventions in opportune situations by utilizing sensor data collected from health management apps, based on the premise that these apps are aptly in use to ensure effectiveness.

< Figure 2. Traditional user-requested digital behavior change intervention (DBCI) delivery (Pull) vs. Automatic transmission (Push) for Just-in-Time (JIT) mobile DBCI using smartphone sensing technologies >

The research team conducted a systematic analysis of user disengagement or the decline in user engagement in digital behavior change interventions. They developed the BeActive system, an app that promotes physical activities designed to help forming active lifestyle habits, and systematically analyzed the effects of users’ self-control ability and boredom-proneness on compliance with behavioral interventions over time.

The results of an 8-week field trial revealed that even if just-in-time interventions are provided according to the user’s situation, it is impossible to avoid a decline in participation. However, for users with high self-control and low boredom tendency, the compliance with just-in-time interventions delivered through the app was significantly higher than that of users in other groups.

In particular, users with high boredom proneness easily got tired of the repeated push interventions, and their compliance with the app decreased more quickly than in other groups.

< Figure 3. Just-in-time Mobile Health Intervention: a demonstrative case of the BeActive system: When a user is identified to be sitting for more than 50 mins, an automatic push notification is sent to recommend a short active break to complete for reward points. >

Professor Uichin Lee explained, “As the first study on user engagement in digital therapeutics and wellness services utilizing mobile just-in-time health interventions, this research provides a foundation for exploring ways to empower user engagement.” He further added, “By leveraging large language models (LLMs) and comprehensive context-aware technologies, it will be possible to develop user-centered AI technologies that can significantly boost engagement."

< Figure 4. A conceptual illustration of user engagement in digital health apps. Engagement in digital health apps consists of (1) engagement in using digital health apps and (2) engagement in behavioral interventions provided by digital health apps, i.e., compliance with behavioral interventions. Repeated adherences to behavioral interventions recommended by digital health apps can help achieve the distal health goals. >

This study was conducted with the support of the 2021 Biomedical Technology Development Program and the 2022 Basic Research and Development Program of the National Research Foundation of Korea funded by the Ministry of Science and ICT.

< Figure 5. A conceptual illustration of user disengagement and engagement of digital behavior change intervention (DBCI) apps. In general, user engagement of digital health intervention apps consists of two components: engagement in digital health apps and engagement in behavioral interventions recommended by such apps (known as behavioral compliance or intervention adherence). The distinctive stages of user can be divided into adoption, abandonment, and attrition. >

< Figure 6. Trends of changes in frequency of app usage and adherence to behavioral intervention over 8 weeks, ● SC: Self-Control Ability (High-SC: user group with high self-control, Low-SC: user group with low self-control) ● BD: Boredom-Proneness (High-BD: user group with high boredom-proneness, Low-BD: user group with low boredom-proneness). The app usage frequencies were declined over time, but the adherence rates of those participants with High-SC and Low-BD were significantly higher than other groups. >

2024.10.25 View 334 -

KAIST Introduces a Wearable Robot that Walks and Puts itself on to Disabled Persons

< Photo 1. WalkON Suit F1 - walking demonstration >

KAIST researchers have unveiled a new wearable robot developed for completely paralyzed persons that can walk to them so that the user can wear it right out of their wheelchairs without the help from others. Also, it was announced that Professor Kyoungchul Kong's team from KAIST will be participating in the wearable robot category of the 3rd Cybathlon, which is being held four years after the team’s gold medal win in 2020.

KAIST (President Kwang-Hyung Lee) announced this new version of the wearable robot for paraplegic people, WalkON Suit F1, by Professor Kyoungchul Kong (CEO and founder of Angel Robotics) of KAIST Department of Mechanical Engineering on the 24th of October.

< Photo 2. (From left) Professor Kyoungchul Kong of the Department of Mechanical Engineering, Researcher Seunghwan Kim (the competing athlete), and PhD candidate Jeongsu Park (the leader of Team KAIST) >

WalkON Suit is a wearable robot for people suffering with paraplegic disabilities that the research team has been continuously researching since 2015. This robot targets to assist persons with American Spinal Injury Association (ASIA) Impairment Scale – A (complete paralysis) grade injury, the most severe level of paraplegia. Therefore, its development purpose is different from that of other rehabilitation therapy and muscle strength assisting robots currently being supplied nationally by Angel Robotics.

Professor Kong's research team first announced WalkON Suit 1 in 2016, and then introduced WalkON Suit 4 in 2020, increasing the walking speed to 3.2 km/h, achieving the normal walking speed of people with no disabilities. In addition, it demonstrated the ability to pass through obstacles such as narrow passages, doors, and stairs that can be encountered in daily life.

However, it had the same fundamental problem all wearable robots have, which is that they require the help of others to wear the robot. While you can walk without help from others once you are wearing the robot, you needed someone's help to put it on to begin with.

The newly released WalkON Suit F1 presented a technical solution to this fundamental problem. It applied a frontal-docking method instead of a rear-sitting method so that you can wear the robot right away without getting out of the wheelchair and into the robot, which would require help from others mid-transition.

< Photo 3. WalkON Suit F1 - suiting-up demonstration >

In addition, before wearing the robot, it can walk on its own like a humanoid robot and approaches the user. It is also implemented a function that actively controls the center of its weight against the pull of gravity so that it maintains balance without falling over even if the user pushes the robot otherwise. The outer design of the WalkON Suit F1, which crosses between a humanoid and a wearable robot, was done by Professor Hyunjoon Park of the Department of Industrial Design at KAIST.

The original function of the wearable robot has also been greatly improved. The performance of the balance control was improved to allow the free use of both hands in upright state, as well as the freedom to take several steps without a cane.

Technological advancements at the components level are also noteworthy. Through close collaboration with Angel Robotics, all core components of the robot, such as the motor, reducer, motor driver, and main circuit, have been domestically produced. The output density of the motor and reducer modules has been improved by about two folds (based on power per weight) compared to the research team's existing technology, and the control performance of the motor driver has been improved by about three times (based on frequency response speed) compared to the best overseas technology.

In particular, the embedded software technology of the motor driver has been significantly improved so that advanced motion control algorithms can be stably implemented without using expensive higher-level controllers. In addition, visual recognition system for obstacle detection and an AI board for neural network application have been installed.

< Figure 1. WalkON Suit F1 shape and main specifications >

Professor Kong explained, “WalkON Suit is the culmination of wearable robot technology for the disabled,” and added, “The numerous components, control, and module technologies derived from WalkON Suit are setting the standard for the entire wearable robot industry.”

Professor Kong’s research team revealed WalkON Suit F1 and announced that they will be participating in the 3rd Cybathlon, which is being held after four years since the last event. In this competition, which will be held on October 27, Professor Kong’s lab, the Exo Lab will be participating with Jeongsu Park, a Ph.D. Student, as the leader and Seunghwan Kim, the lab’s staff researcher with complete paralysis, as the competing athlete.

The difficulty of the missions in this competition has been significantly increased compared to the previous competition, and the number of missions has increased from six to ten. Some missions have been criticized for being overly challenging, going beyond the level that can be encountered in everyday life.

< Photo 4. Cybathlon stadium (Angel Robotics Asia Hub) >

Regarding this, the team leader Jeongsu Park expressed his ambition, saying, “Since we already won first place in the previous competition, our goal in this competition is to show the technological gap rather than competing for rankings.”

The Cybathlon is a cyborg Olympics held every four years in Switzerland. This competition will be held in a hybrid format, with some participants taking part in Switzerland while others broadcasting live from stadiums in their own country on October 27. Professor Kong's research team will be participating via live broadcast from the competition facilities installed in Angel Robotics' Advanced Research Institute (Planet Daejeon).

< Photo 5. Photo of Team KAIST participating in Cybathlon 2024 >

The demonstration video of WalkON Suit F1 can be viewed through the link below.

Link: https://www.youtube.com/@KyoungchulKong_EXO-Lab

2024.10.24 View 1278

KAIST Introduces a Wearable Robot that Walks and Puts itself on to Disabled Persons

< Photo 1. WalkON Suit F1 - walking demonstration >

KAIST researchers have unveiled a new wearable robot developed for completely paralyzed persons that can walk to them so that the user can wear it right out of their wheelchairs without the help from others. Also, it was announced that Professor Kyoungchul Kong's team from KAIST will be participating in the wearable robot category of the 3rd Cybathlon, which is being held four years after the team’s gold medal win in 2020.

KAIST (President Kwang-Hyung Lee) announced this new version of the wearable robot for paraplegic people, WalkON Suit F1, by Professor Kyoungchul Kong (CEO and founder of Angel Robotics) of KAIST Department of Mechanical Engineering on the 24th of October.

< Photo 2. (From left) Professor Kyoungchul Kong of the Department of Mechanical Engineering, Researcher Seunghwan Kim (the competing athlete), and PhD candidate Jeongsu Park (the leader of Team KAIST) >

WalkON Suit is a wearable robot for people suffering with paraplegic disabilities that the research team has been continuously researching since 2015. This robot targets to assist persons with American Spinal Injury Association (ASIA) Impairment Scale – A (complete paralysis) grade injury, the most severe level of paraplegia. Therefore, its development purpose is different from that of other rehabilitation therapy and muscle strength assisting robots currently being supplied nationally by Angel Robotics.

Professor Kong's research team first announced WalkON Suit 1 in 2016, and then introduced WalkON Suit 4 in 2020, increasing the walking speed to 3.2 km/h, achieving the normal walking speed of people with no disabilities. In addition, it demonstrated the ability to pass through obstacles such as narrow passages, doors, and stairs that can be encountered in daily life.

However, it had the same fundamental problem all wearable robots have, which is that they require the help of others to wear the robot. While you can walk without help from others once you are wearing the robot, you needed someone's help to put it on to begin with.

The newly released WalkON Suit F1 presented a technical solution to this fundamental problem. It applied a frontal-docking method instead of a rear-sitting method so that you can wear the robot right away without getting out of the wheelchair and into the robot, which would require help from others mid-transition.

< Photo 3. WalkON Suit F1 - suiting-up demonstration >

In addition, before wearing the robot, it can walk on its own like a humanoid robot and approaches the user. It is also implemented a function that actively controls the center of its weight against the pull of gravity so that it maintains balance without falling over even if the user pushes the robot otherwise. The outer design of the WalkON Suit F1, which crosses between a humanoid and a wearable robot, was done by Professor Hyunjoon Park of the Department of Industrial Design at KAIST.

The original function of the wearable robot has also been greatly improved. The performance of the balance control was improved to allow the free use of both hands in upright state, as well as the freedom to take several steps without a cane.

Technological advancements at the components level are also noteworthy. Through close collaboration with Angel Robotics, all core components of the robot, such as the motor, reducer, motor driver, and main circuit, have been domestically produced. The output density of the motor and reducer modules has been improved by about two folds (based on power per weight) compared to the research team's existing technology, and the control performance of the motor driver has been improved by about three times (based on frequency response speed) compared to the best overseas technology.

In particular, the embedded software technology of the motor driver has been significantly improved so that advanced motion control algorithms can be stably implemented without using expensive higher-level controllers. In addition, visual recognition system for obstacle detection and an AI board for neural network application have been installed.

< Figure 1. WalkON Suit F1 shape and main specifications >

Professor Kong explained, “WalkON Suit is the culmination of wearable robot technology for the disabled,” and added, “The numerous components, control, and module technologies derived from WalkON Suit are setting the standard for the entire wearable robot industry.”

Professor Kong’s research team revealed WalkON Suit F1 and announced that they will be participating in the 3rd Cybathlon, which is being held after four years since the last event. In this competition, which will be held on October 27, Professor Kong’s lab, the Exo Lab will be participating with Jeongsu Park, a Ph.D. Student, as the leader and Seunghwan Kim, the lab’s staff researcher with complete paralysis, as the competing athlete.

The difficulty of the missions in this competition has been significantly increased compared to the previous competition, and the number of missions has increased from six to ten. Some missions have been criticized for being overly challenging, going beyond the level that can be encountered in everyday life.

< Photo 4. Cybathlon stadium (Angel Robotics Asia Hub) >

Regarding this, the team leader Jeongsu Park expressed his ambition, saying, “Since we already won first place in the previous competition, our goal in this competition is to show the technological gap rather than competing for rankings.”

The Cybathlon is a cyborg Olympics held every four years in Switzerland. This competition will be held in a hybrid format, with some participants taking part in Switzerland while others broadcasting live from stadiums in their own country on October 27. Professor Kong's research team will be participating via live broadcast from the competition facilities installed in Angel Robotics' Advanced Research Institute (Planet Daejeon).

< Photo 5. Photo of Team KAIST participating in Cybathlon 2024 >

The demonstration video of WalkON Suit F1 can be viewed through the link below.

Link: https://www.youtube.com/@KyoungchulKong_EXO-Lab

2024.10.24 View 1278 -

KAIST Develops a Fire-risk Free Self-Powered Hydrogen Production System

KAIST researchers have developed a new hydrogen production system that overcomes the current limitations of green hydrogen production. By using a water-splitting system with an aqueous electrolyte, this system is expected to block fire risks and enable stable hydrogen production.

KAIST (represented by President Kwang Hyung Lee) announced on the 22nd of October that a research team led by Professor Jeung Ku Kang from the Department of Materials Science and Engineering developed a self-powered hydrogen production system based on a high-performance zinc-air battery*.

*Zinc-air battery: A primary battery that absorbs oxygen from the air and uses it as an oxidant. Its advantage is long life, but its low electromotive force is a disadvantage.

Hydrogen (H₂) is a key raw material for synthesizing high-value-added substances, and it is gaining attention as a clean fuel with an energy density (142 MJ/kg) more than three times higher than traditional fossil fuels (gasoline, diesel, etc.). However, most current hydrogen production methods impose environmental burden as they emit carbon dioxide (CO₂).

While green hydrogen can be produced by splitting water using renewable energy sources such as solar cells and wind power, these sources are subject to irregular power generation due to weather and temperature fluctuations, leading to low water-splitting efficiency.

To overcome this, air batteries that can emit sufficient voltage (greater than 1.23V) for water splitting have been gaining attention. However, achieving sufficient capacity requires expensive precious metal catalysts and the performance of the catalyst materials becomes significantly degraded during prolonged charge and discharge cycles. Thus, it is essential to develop catalysts that are effective for the water-splitting reactions (oxygen and hydrogen evolution) and materials that can stabilize the repeated charge and discharge reactions (oxygen reduction and evolution) in zinc-air battery electrodes.

In response, Professor Kang's research team proposed a method to synthesize a non-precious metal catalyst material (G-SHELL) that is effective for three different catalytic reactions (oxygen evolution, hydrogen evolution, and oxygen reduction) by growing nano-sized, metal-organic frameworks on graphene oxide.

The team incorporated the developed catalyst material into the air cathode of a zinc-air battery, confirming that it achieved approximately five times higher energy density (797Wh/kg), high power characteristics (275.8mW/cm²), and long-term stability even under repeated charge and discharge conditions compared to conventional batteries.

Additionally, the zinc-air battery, which operates using an aqueous electrolyte, is safe from fire risks. It is expected that this system can be applied as a next-generation energy storage device when linked with water electrolysis systems, offering an environmentally friendly method for hydrogen production.

< Figure 1. Illustrations of a trifunctional graphene-sandwiched heterojunction-embedded layered lattice (G-SHELL) structure. Schematic representation of a) synthesis procedures of G-SHELL from a zeolitic imidazole framework, b) hollow core-layered shell structure with trifunctional sites for oxygen reduction evolution (ORR), oxygen evolution reaction (OER), and hydrogen evolution reaction (HER), and c) heterojunctions, eterojunction-induced internal electric fields, and the corresponding band structure. >

Professor Kang explained, "By developing a catalyst material with high activity and durability for three different electrochemical catalytic reactions at low temperatures using simple methods, the self-powered hydrogen production system we implemented based on zinc-air batteries presents a new breakthrough to overcome the current limitations of green hydrogen production."

<Figure 2. Electrochemical performance of a ZAB-driven water-splitting cell with G-SHELL. Diagram of a self-driven water-splitting cell integrated by combining a ZAB with an alkaline water electrolyzer.>

PhD candidate Dong Won Kim and Jihoon Kim, a master's student in the Department of Materials Science and Engineering at KAIST, were co-first authors of this research, which was published in the international journal Advanced Science on September 17th in the multidisciplinary field of materials science. (Paper Title: “Trifunctional Graphene-Sandwiched Heterojunction-Embedded Layered Lattice Electrocatalyst for High Performance in Zn-Air Battery-Driven Water Splitting”)

This research was supported by the Nano and Material Technology Development Program of the Ministry of Science and ICT and the National Research Foundation of Korea’s Future Technology Research Laboratory.

2024.10.22 View 519

KAIST Develops a Fire-risk Free Self-Powered Hydrogen Production System

KAIST researchers have developed a new hydrogen production system that overcomes the current limitations of green hydrogen production. By using a water-splitting system with an aqueous electrolyte, this system is expected to block fire risks and enable stable hydrogen production.

KAIST (represented by President Kwang Hyung Lee) announced on the 22nd of October that a research team led by Professor Jeung Ku Kang from the Department of Materials Science and Engineering developed a self-powered hydrogen production system based on a high-performance zinc-air battery*.

*Zinc-air battery: A primary battery that absorbs oxygen from the air and uses it as an oxidant. Its advantage is long life, but its low electromotive force is a disadvantage.

Hydrogen (H₂) is a key raw material for synthesizing high-value-added substances, and it is gaining attention as a clean fuel with an energy density (142 MJ/kg) more than three times higher than traditional fossil fuels (gasoline, diesel, etc.). However, most current hydrogen production methods impose environmental burden as they emit carbon dioxide (CO₂).

While green hydrogen can be produced by splitting water using renewable energy sources such as solar cells and wind power, these sources are subject to irregular power generation due to weather and temperature fluctuations, leading to low water-splitting efficiency.

To overcome this, air batteries that can emit sufficient voltage (greater than 1.23V) for water splitting have been gaining attention. However, achieving sufficient capacity requires expensive precious metal catalysts and the performance of the catalyst materials becomes significantly degraded during prolonged charge and discharge cycles. Thus, it is essential to develop catalysts that are effective for the water-splitting reactions (oxygen and hydrogen evolution) and materials that can stabilize the repeated charge and discharge reactions (oxygen reduction and evolution) in zinc-air battery electrodes.

In response, Professor Kang's research team proposed a method to synthesize a non-precious metal catalyst material (G-SHELL) that is effective for three different catalytic reactions (oxygen evolution, hydrogen evolution, and oxygen reduction) by growing nano-sized, metal-organic frameworks on graphene oxide.

The team incorporated the developed catalyst material into the air cathode of a zinc-air battery, confirming that it achieved approximately five times higher energy density (797Wh/kg), high power characteristics (275.8mW/cm²), and long-term stability even under repeated charge and discharge conditions compared to conventional batteries.

Additionally, the zinc-air battery, which operates using an aqueous electrolyte, is safe from fire risks. It is expected that this system can be applied as a next-generation energy storage device when linked with water electrolysis systems, offering an environmentally friendly method for hydrogen production.

< Figure 1. Illustrations of a trifunctional graphene-sandwiched heterojunction-embedded layered lattice (G-SHELL) structure. Schematic representation of a) synthesis procedures of G-SHELL from a zeolitic imidazole framework, b) hollow core-layered shell structure with trifunctional sites for oxygen reduction evolution (ORR), oxygen evolution reaction (OER), and hydrogen evolution reaction (HER), and c) heterojunctions, eterojunction-induced internal electric fields, and the corresponding band structure. >

Professor Kang explained, "By developing a catalyst material with high activity and durability for three different electrochemical catalytic reactions at low temperatures using simple methods, the self-powered hydrogen production system we implemented based on zinc-air batteries presents a new breakthrough to overcome the current limitations of green hydrogen production."

<Figure 2. Electrochemical performance of a ZAB-driven water-splitting cell with G-SHELL. Diagram of a self-driven water-splitting cell integrated by combining a ZAB with an alkaline water electrolyzer.>

PhD candidate Dong Won Kim and Jihoon Kim, a master's student in the Department of Materials Science and Engineering at KAIST, were co-first authors of this research, which was published in the international journal Advanced Science on September 17th in the multidisciplinary field of materials science. (Paper Title: “Trifunctional Graphene-Sandwiched Heterojunction-Embedded Layered Lattice Electrocatalyst for High Performance in Zn-Air Battery-Driven Water Splitting”)

This research was supported by the Nano and Material Technology Development Program of the Ministry of Science and ICT and the National Research Foundation of Korea’s Future Technology Research Laboratory.

2024.10.22 View 519 -

KAIST Develops Thread-like, Flexible Thermoelectric Materials Applicable in Extreme Environments

A team of Korean researchers developed a thermoelectric material that can be used in wearable devices, such as smart clothing, and while maintaining stable thermal energy performance even in extreme environments. It has dramatically resolved the dilemma of striking the balance between achieving good performance and the mechanical flexibility of thermoelectric materials, which has been a long-standing challenge in the field of thermoelectric materials, and has also proven the possibility of commercialization.