NI

-

Distinguished Alumni Awardees 2020

The KAIST Alumni Association (KAA) announced the four recipients of the Distinguished Alumni Awards for the year 2020.

The Distinguished Alumni Awards recognize graduates who have achieved outstanding accomplishments in their professional and personal lives, and who have been an inspiration to fellow alumni and students in Korea and around the globe. The four distinguished alumni of the year 2020 are listed below.

President Dong-Won Kim (Department of Industrial and Systems Engineering, M.S., Class of ’82) of Jeonbuk National University is making significant contributions to the advancement of local industrial technology and the cultivation of professional personnel through outstanding research outcomes. As an educational administrator, his leadership is helping to realize long-desired projects at the university, through which he is strengthening the competitiveness of the university and the local community.

Tae-Kyung Yoo (School of Electrical Engineering, M.S. and Ph.D., Class of ’83 and ’85 respectively), CEO and Chairman of Lumens, is a first-generation entrepreneur in the light emitting diode (LED) industry in Korea. He runs Lumens, a globally renowned company specializing in and leading the technological innovation of LEDs. He thereby contributes to strengthening national competitiveness and the advancement of science and technology.

President Nak Kyu Lee (Department of Mechanical Engineering, M.S. and Ph.D., Class of ’85 and ’87 respectively) of the Korea Institute of Industrial Technology (KITECH) has shown excellent results in his research in which he developed core production technologies to lead the nation’s industries. He also focused on supporting on-site technologies involved in field work to apply what he developed into real production processes, and contributed greatly to improving the competitiveness of nationwide manufacturing.

Hyeon-Mo Ku (School of Business and Technology Management, M.S. and Ph.D., Class of ’85 and ’93 respectively), CEO of KT Corporation, helped the nation’s leading communications company roll out the first 5G network in the world. He also strengthened national competitiveness in AI technology through ‘AI One Team,’ an industry-academic corporation project, and took the lead in developing the home-grown cloud industry. His involvement in the innovation of Korea’s ICT technology was highly recognized.

Since the establishment of the award in 1992, a total of 107 alumni at home and abroad have brought distinction to the university and been honored as recipients.

These recipients are playing major roles in society, and some of the notable former awardees include: KAIST President Sung-Chul Shin (2010), Samsung Electronics Vice Chairman Ki-Nam Kim (2012), Nexon Chairman Jung-Ju Kim (2007), and Krafton Chairman Byeong-Gyu Chang (2006).

The President of the KAA and Advisor of Samsung Electronics, Chilhee Chung, said, “The Distinguished Alumni Awards are an honor given to alumni who have contributed to the development of the nation and society, and raised the name of their alma mater.” He added, “We can see the proud position of KAIST in the global arena just by looking at the accomplishments of our awardees.”

(END)

2021.02.04 View 9578

Distinguished Alumni Awardees 2020

The KAIST Alumni Association (KAA) announced the four recipients of the Distinguished Alumni Awards for the year 2020.

The Distinguished Alumni Awards recognize graduates who have achieved outstanding accomplishments in their professional and personal lives, and who have been an inspiration to fellow alumni and students in Korea and around the globe. The four distinguished alumni of the year 2020 are listed below.

President Dong-Won Kim (Department of Industrial and Systems Engineering, M.S., Class of ’82) of Jeonbuk National University is making significant contributions to the advancement of local industrial technology and the cultivation of professional personnel through outstanding research outcomes. As an educational administrator, his leadership is helping to realize long-desired projects at the university, through which he is strengthening the competitiveness of the university and the local community.

Tae-Kyung Yoo (School of Electrical Engineering, M.S. and Ph.D., Class of ’83 and ’85 respectively), CEO and Chairman of Lumens, is a first-generation entrepreneur in the light emitting diode (LED) industry in Korea. He runs Lumens, a globally renowned company specializing in and leading the technological innovation of LEDs. He thereby contributes to strengthening national competitiveness and the advancement of science and technology.

President Nak Kyu Lee (Department of Mechanical Engineering, M.S. and Ph.D., Class of ’85 and ’87 respectively) of the Korea Institute of Industrial Technology (KITECH) has shown excellent results in his research in which he developed core production technologies to lead the nation’s industries. He also focused on supporting on-site technologies involved in field work to apply what he developed into real production processes, and contributed greatly to improving the competitiveness of nationwide manufacturing.

Hyeon-Mo Ku (School of Business and Technology Management, M.S. and Ph.D., Class of ’85 and ’93 respectively), CEO of KT Corporation, helped the nation’s leading communications company roll out the first 5G network in the world. He also strengthened national competitiveness in AI technology through ‘AI One Team,’ an industry-academic corporation project, and took the lead in developing the home-grown cloud industry. His involvement in the innovation of Korea’s ICT technology was highly recognized.

Since the establishment of the award in 1992, a total of 107 alumni at home and abroad have brought distinction to the university and been honored as recipients.

These recipients are playing major roles in society, and some of the notable former awardees include: KAIST President Sung-Chul Shin (2010), Samsung Electronics Vice Chairman Ki-Nam Kim (2012), Nexon Chairman Jung-Ju Kim (2007), and Krafton Chairman Byeong-Gyu Chang (2006).

The President of the KAA and Advisor of Samsung Electronics, Chilhee Chung, said, “The Distinguished Alumni Awards are an honor given to alumni who have contributed to the development of the nation and society, and raised the name of their alma mater.” He added, “We can see the proud position of KAIST in the global arena just by looking at the accomplishments of our awardees.”

(END)

2021.02.04 View 9578 -

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 11811

Highly Deformable Piezoelectric Nanotruss for Tactile Electronics

With the importance of non-contact environments growing due to COVID-19, tactile electronic devices using haptic technology are gaining traction as new mediums of communication.

Haptic technology is being applied in a wide array of fields such as robotics or interactive displays. haptic gloves are being used for augmented information communication technology. Efficient piezoelectric materials that can convert various mechanical stimuli into electrical signals and vice versa are a prerequisite for advancing high-performing haptic technology.

A research team led by Professor Seungbum Hong confirmed the potential of tactile devices by developing ceramic piezoelectric materials that are three times more deformable. For the fabrication of highly deformable nanomaterials, the research team built a zinc oxide hollow nanostructure using proximity field nanopatterning and atomic layered deposition. The piezoelectric coefficient was measured to be approximately 9.2 pm/V and the nanopillar compression test showed an elastic strain limit of approximately 10%, which is more than three times greater than that of the bulk zinc oxide one.

Piezoelectric ceramics have a high piezoelectric coefficient with a low elastic strain limit, whereas the opposite is true for piezoelectric polymers. Therefore, it has been very challenging to obtain good performance in both high piezoelectric coefficients as well as high elastic strain limits. To break the elastic limit of piezoelectric ceramics, the research team introduced a 3D truss-like hollow nanostructure with nanometer-scale thin walls.

According to the Griffith criterion, the fracture strength of a material is inversely proportional to the square root of the preexisting flaw size. However, a large flaw is less likely to occur in a small structure, which, in turn, enhances the strength of the material. Therefore, implementing the form of a 3D truss-like hollow nanostructure with nanometer-scale thin walls can extend the elastic limit of the material. Furthermore, a monolithic 3D structure can withstand large strains in all directions while simultaneously preventing the loss from the bottleneck. Previously, the fracture property of piezoelectric ceramic materials was difficult to control, owing to the large variance in crack sizes. However, the research team structurally limited the crack sizes to manage the fracture properties.

Professor Hong’s results demonstrate the potential for the development of highly deformable ceramic piezoelectric materials by improving the elastic limit using a 3D hollow nanostructure. Since zinc oxide has a relatively low piezoelectric coefficient compared to other piezoelectric ceramic materials, applying the proposed structure to such components promised better results in terms of the piezoelectric activity.

“With the advent of the non-contact era, the importance of emotional communication is increasing. Through the development of novel tactile interaction technologies, in addition to the current visual and auditory communication, mankind will enter a new era where they can communicate with anyone using all five senses regardless of location as if they are with them in person,” Professor Hong said.

“While additional research must be conducted to realize the application of the proposed designs for haptic enhancement devices, this study holds high value in that it resolves one of the most challenging issues in the use of piezoelectric ceramics, specifically opening new possibilities for their application by overcoming their mechanical constraints.

The research was reported in Nano Energy and supported by the Ministry of Science and ICT, the Korea Research Foundation, and the KAIST Global Singularity Research Project.

-Profile: Professor Seungbum Hong

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr/

Department of Materials Science and Engineering

KAIST

2021.02.02 View 11811 -

Top University Leaders Urge Innovation for the Post-COVID Era at the KAIST Summit

- Presidents of KAIST, MIT, Tokyo Tech, and Northwestern to define new roles and responsibilities of universities for the post-COVID and 4IR eras during an online summit in celebration of KAIST’s 50th anniversary. -

Universities are facing ever-mounting pressure to address impacts brought on by COVID-19 and the emerging technologies of the Fourth Industrial Revolution (4IR).

Presidents from MIT, Tokyo Tech, and Northwestern University will join the KAIST Summit to explore new directions for higher education during the post-COVID era intertwined with the 4IR. They agree that addressing these dual challenges requires pushing for innovations to rebuild the competitive edges of universities.

This summit is one of KAIST’s series of events to envision the future of KAIST and higher education in celebration of its 50th anniversary. The online summit will be live streamed on KAIST’s official YouTube channel (https://www.youtube.com/c/KAISTofficial) on February 3, 2021, from 10 a.m. to 12:00 p.m. Korean time (February 2, 7:00-9:00 p.m. CST and 8:00-10:00 p.m. EST, respectively).

The KAIST Summit titled “The Roles and Responsibilities of Universities in a Global Crisis” will discuss a range of issues affecting many aspects of universities in the coming decades.

“This summit will allow us to measure the level of risk that universities face today and will face in the future. Although there will be varying views on what a post-COVID world might look like, one thing for sure is that universities cannot go back to the way they used to exist and operate. Moreover, the 4IR continues to infiltrate and shake up our daily lives. Changes are inevitable, and universities must pursue bold and innovative responses to remain sustainable and relevant to society,” said KAIST President Sung-Chul Shin on the background of hosting the event.

The keynote speakers include KAIST President Shin, MIT President L. Rafael Reif, Tokyo Tech President Kazuya Masu, and Northwestern University President Morton Schapiro. After the keynote speech session, the speakers will take part in a panel discussion on three topics: “The Digital Divide,” “Emerging Challenges in AI,” and “Social Entrepreneurship and University-Industry Collaboration.” A Q&A session with an online audience consisting of KAIST faculty, staff, and students as well as high school students across the nation will follow shortly afterwards.

President Reif of MIT will congratulate KAIST on its successful 50-year journey from meager beginnings to achieving its current status as one of the finest global universities in science and technology. Then he will give a talk titled “Universities as Engines of Change” to present how universities have played a critical role in advancing solutions to humanity’s most urgent problems.

President Masu of Tokyo Tech will stress the importance of universities’ continuous dialogue with society as drivers of innovation. In his speech titled “Designing Our Future—Tokyo Tech DLab’s Approach,” he will introduce the activities of Tokyo Tech’s Laboratory for Design of Social Innovation in Global Networks (DLab) and explain how DLab collaborates for the future with members of society.

President Schapiro of Northwestern University will speak about how universities might incorporate the lessons they learned in dealing with COVID-19 to improve their research, teaching, and public service in the post-pandemic era. He will also look into issues arising from changing labor market needs associated with the 4IR and the aftermath of COVID-19 in his talk titled “The University in the ‘New Normal.’”

Finally, President Shin of KAIST will deliver a presentation on the “Visions & Innovations for the Next Dream of KAIST.” He will reflect on the remarkable track record from KAIST’s first 50 years and how it has contributed significantly to the rapid growth of Korea as a hi-tech powerhouse. Furthermore, he will elaborate on a new vision for the development of KAIST over the next 50 years and roll out a set of strategic innovation plans in the five areas of education, research, technology commercialization, globalization, and future strategy.

In the panel discussion, the four presidents will dive into a more intense conversation on such topics as universities’ role in bridging the increasing digital divide through their research, education, and international cooperation; the socioeconomic implications and ethical challenges of the fast deployment of AI and robotics; 4IR disruptions that will transform higher education; ways to foster social innovation and youth entrepreneurship; and how to build university-industry cooperation.

More information on KAIST’s 50th anniversary celebrations can be found on its special celebratory website at https://50.kaist.ac.kr/eng/. The official anniversary ceremony is scheduled for February 16, 2021, from 10 a.m. Korean time, and live-streaming will also be made available on KAIST’s official YouTube channel at https://www.youtube.com/c/KAISTofficial.

(END)

2021.02.01 View 16512

Top University Leaders Urge Innovation for the Post-COVID Era at the KAIST Summit

- Presidents of KAIST, MIT, Tokyo Tech, and Northwestern to define new roles and responsibilities of universities for the post-COVID and 4IR eras during an online summit in celebration of KAIST’s 50th anniversary. -

Universities are facing ever-mounting pressure to address impacts brought on by COVID-19 and the emerging technologies of the Fourth Industrial Revolution (4IR).

Presidents from MIT, Tokyo Tech, and Northwestern University will join the KAIST Summit to explore new directions for higher education during the post-COVID era intertwined with the 4IR. They agree that addressing these dual challenges requires pushing for innovations to rebuild the competitive edges of universities.

This summit is one of KAIST’s series of events to envision the future of KAIST and higher education in celebration of its 50th anniversary. The online summit will be live streamed on KAIST’s official YouTube channel (https://www.youtube.com/c/KAISTofficial) on February 3, 2021, from 10 a.m. to 12:00 p.m. Korean time (February 2, 7:00-9:00 p.m. CST and 8:00-10:00 p.m. EST, respectively).

The KAIST Summit titled “The Roles and Responsibilities of Universities in a Global Crisis” will discuss a range of issues affecting many aspects of universities in the coming decades.

“This summit will allow us to measure the level of risk that universities face today and will face in the future. Although there will be varying views on what a post-COVID world might look like, one thing for sure is that universities cannot go back to the way they used to exist and operate. Moreover, the 4IR continues to infiltrate and shake up our daily lives. Changes are inevitable, and universities must pursue bold and innovative responses to remain sustainable and relevant to society,” said KAIST President Sung-Chul Shin on the background of hosting the event.

The keynote speakers include KAIST President Shin, MIT President L. Rafael Reif, Tokyo Tech President Kazuya Masu, and Northwestern University President Morton Schapiro. After the keynote speech session, the speakers will take part in a panel discussion on three topics: “The Digital Divide,” “Emerging Challenges in AI,” and “Social Entrepreneurship and University-Industry Collaboration.” A Q&A session with an online audience consisting of KAIST faculty, staff, and students as well as high school students across the nation will follow shortly afterwards.

President Reif of MIT will congratulate KAIST on its successful 50-year journey from meager beginnings to achieving its current status as one of the finest global universities in science and technology. Then he will give a talk titled “Universities as Engines of Change” to present how universities have played a critical role in advancing solutions to humanity’s most urgent problems.

President Masu of Tokyo Tech will stress the importance of universities’ continuous dialogue with society as drivers of innovation. In his speech titled “Designing Our Future—Tokyo Tech DLab’s Approach,” he will introduce the activities of Tokyo Tech’s Laboratory for Design of Social Innovation in Global Networks (DLab) and explain how DLab collaborates for the future with members of society.

President Schapiro of Northwestern University will speak about how universities might incorporate the lessons they learned in dealing with COVID-19 to improve their research, teaching, and public service in the post-pandemic era. He will also look into issues arising from changing labor market needs associated with the 4IR and the aftermath of COVID-19 in his talk titled “The University in the ‘New Normal.’”

Finally, President Shin of KAIST will deliver a presentation on the “Visions & Innovations for the Next Dream of KAIST.” He will reflect on the remarkable track record from KAIST’s first 50 years and how it has contributed significantly to the rapid growth of Korea as a hi-tech powerhouse. Furthermore, he will elaborate on a new vision for the development of KAIST over the next 50 years and roll out a set of strategic innovation plans in the five areas of education, research, technology commercialization, globalization, and future strategy.

In the panel discussion, the four presidents will dive into a more intense conversation on such topics as universities’ role in bridging the increasing digital divide through their research, education, and international cooperation; the socioeconomic implications and ethical challenges of the fast deployment of AI and robotics; 4IR disruptions that will transform higher education; ways to foster social innovation and youth entrepreneurship; and how to build university-industry cooperation.

More information on KAIST’s 50th anniversary celebrations can be found on its special celebratory website at https://50.kaist.ac.kr/eng/. The official anniversary ceremony is scheduled for February 16, 2021, from 10 a.m. Korean time, and live-streaming will also be made available on KAIST’s official YouTube channel at https://www.youtube.com/c/KAISTofficial.

(END)

2021.02.01 View 16512 -

Wirelessly Rechargeable Soft Brain Implant Controls Brain Cells

Researchers have invented a smartphone-controlled soft brain implant that can be recharged wirelessly from outside the body. It enables long-term neural circuit manipulation without the need for periodic disruptive surgeries to replace the battery of the implant. Scientists believe this technology can help uncover and treat psychiatric disorders and neurodegenerative diseases such as addiction, depression, and Parkinson’s.

A group of KAIST researchers and collaborators have engineered a tiny brain implant that can be wirelessly recharged from outside the body to control brain circuits for long periods of time without battery replacement. The device is constructed of ultra-soft and bio-compliant polymers to help provide long-term compatibility with tissue. Geared with micrometer-sized LEDs (equivalent to the size of a grain of salt) mounted on ultrathin probes (the thickness of a human hair), it can wirelessly manipulate target neurons in the deep brain using light.

This study, led by Professor Jae-Woong Jeong, is a step forward from the wireless head-mounted implant neural device he developed in 2019. That previous version could indefinitely deliver multiple drugs and light stimulation treatment wirelessly by using a smartphone. For more, Manipulating Brain Cells by Smartphone.

For the new upgraded version, the research team came up with a fully implantable, soft optoelectronic system that can be remotely and selectively controlled by a smartphone. This research was published on January 22, 2021 in Nature Communications.

The new wireless charging technology addresses the limitations of current brain implants. Wireless implantable device technologies have recently become popular as alternatives to conventional tethered implants, because they help minimize stress and inflammation in freely-moving animals during brain studies, which in turn enhance the lifetime of the devices. However, such devices require either intermittent surgeries to replace discharged batteries, or special and bulky wireless power setups, which limit experimental options as well as the scalability of animal experiments.

“This powerful device eliminates the need for additional painful surgeries to replace an exhausted battery in the implant, allowing seamless chronic neuromodulation,” said Professor Jeong. “We believe that the same basic technology can be applied to various types of implants, including deep brain stimulators, and cardiac and gastric pacemakers, to reduce the burden on patients for long-term use within the body.”

To enable wireless battery charging and controls, researchers developed a tiny circuit that integrates a wireless energy harvester with a coil antenna and a Bluetooth low-energy chip. An alternating magnetic field can harmlessly penetrate through tissue, and generate electricity inside the device to charge the battery. Then the battery-powered Bluetooth implant delivers programmable patterns of light to brain cells using an “easy-to-use” smartphone app for real-time brain control.

“This device can be operated anywhere and anytime to manipulate neural circuits, which makes it a highly versatile tool for investigating brain functions,” said lead author Choong Yeon Kim, a researcher at KAIST.

Neuroscientists successfully tested these implants in rats and demonstrated their ability to suppress cocaine-induced behaviour after the rats were injected with cocaine. This was achieved by precise light stimulation of relevant target neurons in their brains using the smartphone-controlled LEDs. Furthermore, the battery in the implants could be repeatedly recharged while the rats were behaving freely, thus minimizing any physical interruption to the experiments.

“Wireless battery re-charging makes experimental procedures much less complicated,” said the co-lead author Min Jeong Ku, a researcher at Yonsei University’s College of Medicine.

“The fact that we can control a specific behaviour of animals, by delivering light stimulation into the brain just with a simple manipulation of smartphone app, watching freely moving animals nearby, is very interesting and stimulates a lot of imagination,” said Jeong-Hoon Kim, a professor of physiology at Yonsei University’s College of Medicine. “This technology will facilitate various avenues of brain research.”

The researchers believe this brain implant technology may lead to new opportunities for brain research and therapeutic intervention to treat diseases in the brain and other organs.

This work was supported by grants from the National Research Foundation of Korea and the KAIST Global Singularity Research Program.

-Profile

Professor Jae-Woong Jeong

https://www.jeongresearch.org/

School of Electrical Engineering

KAIST

2021.01.26 View 27010

Wirelessly Rechargeable Soft Brain Implant Controls Brain Cells

Researchers have invented a smartphone-controlled soft brain implant that can be recharged wirelessly from outside the body. It enables long-term neural circuit manipulation without the need for periodic disruptive surgeries to replace the battery of the implant. Scientists believe this technology can help uncover and treat psychiatric disorders and neurodegenerative diseases such as addiction, depression, and Parkinson’s.

A group of KAIST researchers and collaborators have engineered a tiny brain implant that can be wirelessly recharged from outside the body to control brain circuits for long periods of time without battery replacement. The device is constructed of ultra-soft and bio-compliant polymers to help provide long-term compatibility with tissue. Geared with micrometer-sized LEDs (equivalent to the size of a grain of salt) mounted on ultrathin probes (the thickness of a human hair), it can wirelessly manipulate target neurons in the deep brain using light.

This study, led by Professor Jae-Woong Jeong, is a step forward from the wireless head-mounted implant neural device he developed in 2019. That previous version could indefinitely deliver multiple drugs and light stimulation treatment wirelessly by using a smartphone. For more, Manipulating Brain Cells by Smartphone.

For the new upgraded version, the research team came up with a fully implantable, soft optoelectronic system that can be remotely and selectively controlled by a smartphone. This research was published on January 22, 2021 in Nature Communications.

The new wireless charging technology addresses the limitations of current brain implants. Wireless implantable device technologies have recently become popular as alternatives to conventional tethered implants, because they help minimize stress and inflammation in freely-moving animals during brain studies, which in turn enhance the lifetime of the devices. However, such devices require either intermittent surgeries to replace discharged batteries, or special and bulky wireless power setups, which limit experimental options as well as the scalability of animal experiments.

“This powerful device eliminates the need for additional painful surgeries to replace an exhausted battery in the implant, allowing seamless chronic neuromodulation,” said Professor Jeong. “We believe that the same basic technology can be applied to various types of implants, including deep brain stimulators, and cardiac and gastric pacemakers, to reduce the burden on patients for long-term use within the body.”

To enable wireless battery charging and controls, researchers developed a tiny circuit that integrates a wireless energy harvester with a coil antenna and a Bluetooth low-energy chip. An alternating magnetic field can harmlessly penetrate through tissue, and generate electricity inside the device to charge the battery. Then the battery-powered Bluetooth implant delivers programmable patterns of light to brain cells using an “easy-to-use” smartphone app for real-time brain control.

“This device can be operated anywhere and anytime to manipulate neural circuits, which makes it a highly versatile tool for investigating brain functions,” said lead author Choong Yeon Kim, a researcher at KAIST.

Neuroscientists successfully tested these implants in rats and demonstrated their ability to suppress cocaine-induced behaviour after the rats were injected with cocaine. This was achieved by precise light stimulation of relevant target neurons in their brains using the smartphone-controlled LEDs. Furthermore, the battery in the implants could be repeatedly recharged while the rats were behaving freely, thus minimizing any physical interruption to the experiments.

“Wireless battery re-charging makes experimental procedures much less complicated,” said the co-lead author Min Jeong Ku, a researcher at Yonsei University’s College of Medicine.

“The fact that we can control a specific behaviour of animals, by delivering light stimulation into the brain just with a simple manipulation of smartphone app, watching freely moving animals nearby, is very interesting and stimulates a lot of imagination,” said Jeong-Hoon Kim, a professor of physiology at Yonsei University’s College of Medicine. “This technology will facilitate various avenues of brain research.”

The researchers believe this brain implant technology may lead to new opportunities for brain research and therapeutic intervention to treat diseases in the brain and other organs.

This work was supported by grants from the National Research Foundation of Korea and the KAIST Global Singularity Research Program.

-Profile

Professor Jae-Woong Jeong

https://www.jeongresearch.org/

School of Electrical Engineering

KAIST

2021.01.26 View 27010 -

Professor Bumjoon Kim Named Scientist of the Month

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering won January’s Scientist of the Month Award presented by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF) on January 6. Professor Kim also received 10 million won in prize money.

Professor Kim was recognized for his research in the field of fuel cells. Since the first paper on fuel cells was published in 1839 by the German chemist Friedrich Schonbein, there has been an increase in the number of fields in which fuel cells are used, including national defense, aerospace engineering, and autonomous vehicles.

Professor Kim developed carbonized block copolymer particles with high durability and a high-performance fuel cell. Block copolymers are two different polymers cross-linked into a chain structure. Various nanostructures can be made effectively by using the attractive and repulsive forces between the chains.

Professor Kim used the membrane emulsification technique, employing a high-performance separation membrane to develop a platform that makes the mass production of highly durable carbonized particles possible, which he then used to develop high-performance energy devices like fuel cells.

The carbonized particles designed by Professor Kim and his research team were used to create the world’s more durable fuel cells that boast outstanding performance while using only five percent of the costly platinum needed for existing commercialized products.

The team’s research results were published in the Journal of the American Chemical Society and Energy Environmental Science in May and July of last year.

“We have developed a fuel cell that ticks all the boxes including performance, durability, and cost,” said Professor Kim. “Related techniques will not be limited to fuel cells, but could also be applied to the development of various energy devices like solar cells and secondary cells,” he added.

(END)

2021.01.22 View 13132

Professor Bumjoon Kim Named Scientist of the Month

Professor Bumjoon Kim from the Department of Chemical and Biomolecular Engineering won January’s Scientist of the Month Award presented by the Ministry of Science and ICT (MSIT) and the National Research Foundation of Korea (NRF) on January 6. Professor Kim also received 10 million won in prize money.

Professor Kim was recognized for his research in the field of fuel cells. Since the first paper on fuel cells was published in 1839 by the German chemist Friedrich Schonbein, there has been an increase in the number of fields in which fuel cells are used, including national defense, aerospace engineering, and autonomous vehicles.

Professor Kim developed carbonized block copolymer particles with high durability and a high-performance fuel cell. Block copolymers are two different polymers cross-linked into a chain structure. Various nanostructures can be made effectively by using the attractive and repulsive forces between the chains.

Professor Kim used the membrane emulsification technique, employing a high-performance separation membrane to develop a platform that makes the mass production of highly durable carbonized particles possible, which he then used to develop high-performance energy devices like fuel cells.

The carbonized particles designed by Professor Kim and his research team were used to create the world’s more durable fuel cells that boast outstanding performance while using only five percent of the costly platinum needed for existing commercialized products.

The team’s research results were published in the Journal of the American Chemical Society and Energy Environmental Science in May and July of last year.

“We have developed a fuel cell that ticks all the boxes including performance, durability, and cost,” said Professor Kim. “Related techniques will not be limited to fuel cells, but could also be applied to the development of various energy devices like solar cells and secondary cells,” he added.

(END)

2021.01.22 View 13132 -

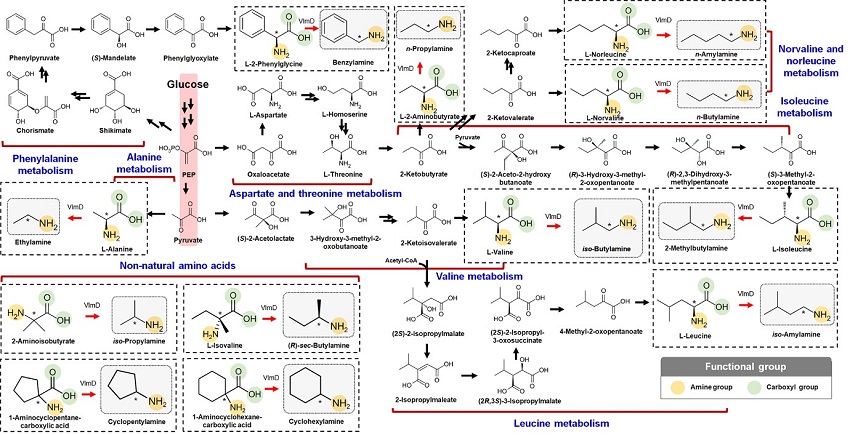

Expanding the Biosynthetic Pathway via Retrobiosynthesis

- Researchers reports a new strategy for the microbial production of multiple short-chain primary amines via retrobiosynthesis. -

KAIST metabolic engineers presented the bio-based production of multiple short-chain primary amines that have a wide range of applications in chemical industries for the first time. The research team led by Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering designed the novel biosynthetic pathways for short-chain primary amines by combining retrobiosynthesis and a precursor selection step.

The research team verified the newly designed pathways by confirming the in vivo production of 10 short-chain primary amines by supplying the precursors. Furthermore, the platform Escherichia coli strains were metabolically engineered to produce three proof-of-concept short-chain primary amines from glucose, demonstrating the possibility of the bio-based production of diverse short-chain primary amines from renewable resources. The research team said this study expands the strategy of systematically designing biosynthetic pathways for the production of a group of related chemicals as demonstrated by multiple short-chain primary amines as examples.

Currently, most of the industrial chemicals used in our daily lives are produced with petroleum-based products. However, there are several serious issues with the petroleum industry such as the depletion of fossil fuel reserves and environmental problems including global warming. To solve these problems, the sustainable production of industrial chemicals and materials is being explored with microorganisms as cell factories and renewable non-food biomass as raw materials for alternative to petroleum-based products. The engineering of these microorganisms has increasingly become more efficient and effective with the help of systems metabolic engineering – a practice of engineering the metabolism of a living organism toward the production of a desired metabolite. In this regard, the number of chemicals produced using biomass as a raw material has substantially increased.

Although the scope of chemicals that are producible using microorganisms continues to expand through advances in systems metabolic engineering, the biological production of short-chain primary amines has not yet been reported despite their industrial importance. Short-chain primary amines are the chemicals that have an alkyl or aryl group in the place of a hydrogen atom in ammonia with carbon chain lengths ranging from C1 to C7. Short-chain primary amines have a wide range of applications in chemical industries, for example, as a precursor for pharmaceuticals (e.g., antidiabetic and antihypertensive drugs), agrochemicals (e.g., herbicides, fungicides and insecticides), solvents, and vulcanization accelerators for rubber and plasticizers. The market size of short-chain primary amines was estimated to be more than 4 billion US dollars in 2014.

The main reason why the bio-based production of short-chain primary amines was not yet possible was due to their unknown biosynthetic pathways. Therefore, the team designed synthetic biosynthetic pathways for short-chain primary amines by combining retrobiosynthesis and a precursor selection step. The retrobiosynthesis allowed the systematic design of a biosynthetic pathway for short-chain primary amines by using a set of biochemical reaction rules that describe chemical transformation patterns between a substrate and product molecules at an atomic level.

These multiple precursors predicted for the possible biosynthesis of each short-chain primary amine were sequentially narrowed down by using the precursor selection step for efficient metabolic engineering experiments.

“Our research demonstrates the possibility of the renewable production of short-chain primary amines for the first time. We are planning to increase production efficiencies of short-chain primary amines. We believe that our study will play an important role in the development of sustainable and eco-friendly bio-based industries and the reorganization of the chemical industry, which is mandatory for solving the environmental problems threating the survival of mankind,” said Professor Lee.

This paper titled “Microbial production of multiple short-chain primary amines via retrobiosynthesis” was published in Nature Communications. This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea.

-Publication

Dong In Kim, Tong Un Chae, Hyun Uk Kim, Woo Dae Jang, and Sang Yup Lee. Microbial production of multiple short-chain primary amines via retrobiosynthesis. Nature Communications ( https://www.nature.com/articles/s41467-020-20423-6)

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

Metabolic &Biomolecular Engineering National Research Laboratory

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2021.01.14 View 13095

Expanding the Biosynthetic Pathway via Retrobiosynthesis

- Researchers reports a new strategy for the microbial production of multiple short-chain primary amines via retrobiosynthesis. -

KAIST metabolic engineers presented the bio-based production of multiple short-chain primary amines that have a wide range of applications in chemical industries for the first time. The research team led by Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering designed the novel biosynthetic pathways for short-chain primary amines by combining retrobiosynthesis and a precursor selection step.

The research team verified the newly designed pathways by confirming the in vivo production of 10 short-chain primary amines by supplying the precursors. Furthermore, the platform Escherichia coli strains were metabolically engineered to produce three proof-of-concept short-chain primary amines from glucose, demonstrating the possibility of the bio-based production of diverse short-chain primary amines from renewable resources. The research team said this study expands the strategy of systematically designing biosynthetic pathways for the production of a group of related chemicals as demonstrated by multiple short-chain primary amines as examples.

Currently, most of the industrial chemicals used in our daily lives are produced with petroleum-based products. However, there are several serious issues with the petroleum industry such as the depletion of fossil fuel reserves and environmental problems including global warming. To solve these problems, the sustainable production of industrial chemicals and materials is being explored with microorganisms as cell factories and renewable non-food biomass as raw materials for alternative to petroleum-based products. The engineering of these microorganisms has increasingly become more efficient and effective with the help of systems metabolic engineering – a practice of engineering the metabolism of a living organism toward the production of a desired metabolite. In this regard, the number of chemicals produced using biomass as a raw material has substantially increased.

Although the scope of chemicals that are producible using microorganisms continues to expand through advances in systems metabolic engineering, the biological production of short-chain primary amines has not yet been reported despite their industrial importance. Short-chain primary amines are the chemicals that have an alkyl or aryl group in the place of a hydrogen atom in ammonia with carbon chain lengths ranging from C1 to C7. Short-chain primary amines have a wide range of applications in chemical industries, for example, as a precursor for pharmaceuticals (e.g., antidiabetic and antihypertensive drugs), agrochemicals (e.g., herbicides, fungicides and insecticides), solvents, and vulcanization accelerators for rubber and plasticizers. The market size of short-chain primary amines was estimated to be more than 4 billion US dollars in 2014.

The main reason why the bio-based production of short-chain primary amines was not yet possible was due to their unknown biosynthetic pathways. Therefore, the team designed synthetic biosynthetic pathways for short-chain primary amines by combining retrobiosynthesis and a precursor selection step. The retrobiosynthesis allowed the systematic design of a biosynthetic pathway for short-chain primary amines by using a set of biochemical reaction rules that describe chemical transformation patterns between a substrate and product molecules at an atomic level.

These multiple precursors predicted for the possible biosynthesis of each short-chain primary amine were sequentially narrowed down by using the precursor selection step for efficient metabolic engineering experiments.

“Our research demonstrates the possibility of the renewable production of short-chain primary amines for the first time. We are planning to increase production efficiencies of short-chain primary amines. We believe that our study will play an important role in the development of sustainable and eco-friendly bio-based industries and the reorganization of the chemical industry, which is mandatory for solving the environmental problems threating the survival of mankind,” said Professor Lee.

This paper titled “Microbial production of multiple short-chain primary amines via retrobiosynthesis” was published in Nature Communications. This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation (NRF) of Korea.

-Publication

Dong In Kim, Tong Un Chae, Hyun Uk Kim, Woo Dae Jang, and Sang Yup Lee. Microbial production of multiple short-chain primary amines via retrobiosynthesis. Nature Communications ( https://www.nature.com/articles/s41467-020-20423-6)

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

Metabolic &Biomolecular Engineering National Research Laboratory

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2021.01.14 View 13095 -

KAIST Mobile Clinic Module to Fill Negative Pressure Ward Shortage

Efficient versatile ready-for-rapid building system of MCM will serve as both a triage unit and bridge center in emergency medical situations

A team from KAIST has developed a low-cost and ready-for-rapid-production negative pressure room called a Mobile Clinic Module (MCM). The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-function panels.

The MCM expects to quickly meet the high demand for negative pressure beds in the nation and eventually many other countries where the third wave of COVID-19 is raging. The module is now ready to be rolled out after a three-week test period at the Korea Cancer Center Hospital.

Professor Tek-Jin Nam’s team swung into action, rapidly working together with researchers, engineers with expertise in mechanical design, and a team of clinical doctors to complete the MCM as one of KAIST’s New Deal R&D initiatives launched last July.

Professor Nam cites ‘expandability’ as the key feature of the MCM. Eventually, it will serve as both a triage unit and bridge center in emergency medical situations.

“The module is a very efficient and versatile unit building system. It takes approximately two hours to build the basic MCM unit, which comprises four negative pressure bed rooms, nurse’s station, locker room, and treatment room. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms,” said Professor Nam.

“It will also be helpful for managing less-severe patients who need to be monitored daily in quarantined rooms or as bridge stations where on-site medical staff can provide treatment and daily monitoring before hospitalization. These wards can be efficiently deployed either inside or outside existing hospitals.”

The research team specially designed the negative pressure frame to ensure safety level A for the negative pressure room, which is made of a multi-function panel wall and roofed with an air tent. The multi-function panels can hold medical appliances such as ventilators, oxygen and bio-signal monitors.

Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air. An internal air information monitoring system efficiently controls room air pressure and purifies the air.

While a conventional negative pressure bed is reported to cost approximately 3.5 billion KRW (50 billion won for a ward), this module is estimated to cost 0.75 billion won each (10 billion won for a ward), cutting the costs by approximately 80%.

The MCM is designed to be easily transported and relocated due to its volume, weight, and maintainability. This module requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

“We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the world.”

Professor Nam’s team is also developing antiviral solutions and devices such as protective gear, sterilizers, and test kits under the KAIST New Deal R&D Initiative that was launched to promptly and proactively respond to the epidemic. More than 45 faculty members and researchers at KAIST are collaborating with industry and clinical hospitals to develop the antiviral technology that will improve preventive measures, diagnoses, and treatment.

2021.01.07 View 12802

KAIST Mobile Clinic Module to Fill Negative Pressure Ward Shortage

Efficient versatile ready-for-rapid building system of MCM will serve as both a triage unit and bridge center in emergency medical situations

A team from KAIST has developed a low-cost and ready-for-rapid-production negative pressure room called a Mobile Clinic Module (MCM). The MCM is expandable, moveable, and easy to store through a combination of negative pressure frames, air tents, and multi-function panels.

The MCM expects to quickly meet the high demand for negative pressure beds in the nation and eventually many other countries where the third wave of COVID-19 is raging. The module is now ready to be rolled out after a three-week test period at the Korea Cancer Center Hospital.

Professor Tek-Jin Nam’s team swung into action, rapidly working together with researchers, engineers with expertise in mechanical design, and a team of clinical doctors to complete the MCM as one of KAIST’s New Deal R&D initiatives launched last July.

Professor Nam cites ‘expandability’ as the key feature of the MCM. Eventually, it will serve as both a triage unit and bridge center in emergency medical situations.

“The module is a very efficient and versatile unit building system. It takes approximately two hours to build the basic MCM unit, which comprises four negative pressure bed rooms, nurse’s station, locker room, and treatment room. We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms,” said Professor Nam.

“It will also be helpful for managing less-severe patients who need to be monitored daily in quarantined rooms or as bridge stations where on-site medical staff can provide treatment and daily monitoring before hospitalization. These wards can be efficiently deployed either inside or outside existing hospitals.”

The research team specially designed the negative pressure frame to ensure safety level A for the negative pressure room, which is made of a multi-function panel wall and roofed with an air tent. The multi-function panels can hold medical appliances such as ventilators, oxygen and bio-signal monitors.

Positive air pressure devices supply fresh air from outside the tent. An air pump and controller maintain air beam pressure, while filtering exhausted air. An internal air information monitoring system efficiently controls room air pressure and purifies the air.

While a conventional negative pressure bed is reported to cost approximately 3.5 billion KRW (50 billion won for a ward), this module is estimated to cost 0.75 billion won each (10 billion won for a ward), cutting the costs by approximately 80%.

The MCM is designed to be easily transported and relocated due to its volume, weight, and maintainability. This module requires only one-fourth of the volume of existing wards and takes up approximately 40% of their weight. The unit can be transported in a 40-foot container truck.

“We believe this will significantly contribute to relieving the drastic need for negative pressure beds and provide a place for monitoring patients with moderate symptoms. We look forward to the MCM upgrading epidemic management resources around the world.”

Professor Nam’s team is also developing antiviral solutions and devices such as protective gear, sterilizers, and test kits under the KAIST New Deal R&D Initiative that was launched to promptly and proactively respond to the epidemic. More than 45 faculty members and researchers at KAIST are collaborating with industry and clinical hospitals to develop the antiviral technology that will improve preventive measures, diagnoses, and treatment.

2021.01.07 View 12802 -

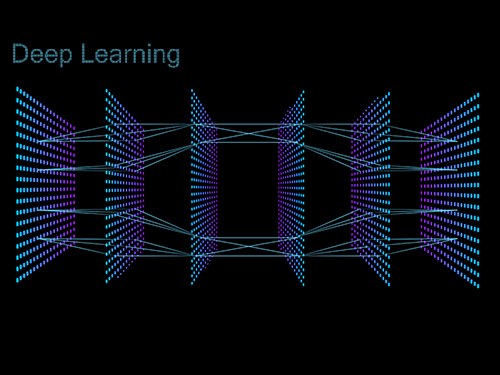

DeepTFactor Predicts Transcription Factors

A deep learning-based tool predicts transcription factors using protein sequences as inputs

A joint research team from KAIST and UCSD has developed a deep neural network named DeepTFactor that predicts transcription factors from protein sequences. DeepTFactor will serve as a useful tool for understanding the regulatory systems of organisms, accelerating the use of deep learning for solving biological problems.

A transcription factor is a protein that specifically binds to DNA sequences to control the transcription initiation. Analyzing transcriptional regulation enables the understanding of how organisms control gene expression in response to genetic or environmental changes. In this regard, finding the transcription factor of an organism is the first step in the analysis of the transcriptional regulatory system of an organism.

Previously, transcription factors have been predicted by analyzing sequence homology with already characterized transcription factors or by data-driven approaches such as machine learning. Conventional machine learning models require a rigorous feature selection process that relies on domain expertise such as calculating the physicochemical properties of molecules or analyzing the homology of biological sequences. Meanwhile, deep learning can inherently learn latent features for the specific task.

A joint research team comprised of Ph.D. candidate Gi Bae Kim and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST, and Ye Gao and Professor Bernhard O. Palsson of the Department of Biochemical Engineering at UCSD reported a deep learning-based tool for the prediction of transcription factors. Their research paper “DeepTFactor: A deep learning-based tool for the prediction of transcription factors” was published online in PNAS.

Their article reports the development of DeepTFactor, a deep learning-based tool that predicts whether a given protein sequence is a transcription factor using three parallel convolutional neural networks. The joint research team predicted 332 transcription factors of Escherichia coli K-12 MG1655 using DeepTFactor and the performance of DeepTFactor by experimentally confirming the genome-wide binding sites of three predicted transcription factors (YqhC, YiaU, and YahB).

The joint research team further used a saliency method to understand the reasoning process of DeepTFactor. The researchers confirmed that even though information on the DNA binding domains of the transcription factor was not explicitly given the training process, DeepTFactor implicitly learned and used them for prediction. Unlike previous transcription factor prediction tools that were developed only for protein sequences of specific organisms, DeepTFactor is expected to be used in the analysis of the transcription systems of all organisms at a high level of performance.

Distinguished Professor Sang Yup Lee said, “DeepTFactor can be used to discover unknown transcription factors from numerous protein sequences that have not yet been characterized. It is expected that DeepTFactor will serve as an important tool for analyzing the regulatory systems of organisms of interest.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea.

-Publication

Gi Bae Kim, Ye Gao, Bernhard O. Palsson, and Sang Yup Lee. DeepTFactor: A deep learning-based tool for the prediction of transcription factors. (https://doi.org/10.1073/pnas202117118)

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

Metabolic &Biomolecular Engineering National Research Laboratory

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2021.01.05 View 10386

DeepTFactor Predicts Transcription Factors

A deep learning-based tool predicts transcription factors using protein sequences as inputs

A joint research team from KAIST and UCSD has developed a deep neural network named DeepTFactor that predicts transcription factors from protein sequences. DeepTFactor will serve as a useful tool for understanding the regulatory systems of organisms, accelerating the use of deep learning for solving biological problems.

A transcription factor is a protein that specifically binds to DNA sequences to control the transcription initiation. Analyzing transcriptional regulation enables the understanding of how organisms control gene expression in response to genetic or environmental changes. In this regard, finding the transcription factor of an organism is the first step in the analysis of the transcriptional regulatory system of an organism.

Previously, transcription factors have been predicted by analyzing sequence homology with already characterized transcription factors or by data-driven approaches such as machine learning. Conventional machine learning models require a rigorous feature selection process that relies on domain expertise such as calculating the physicochemical properties of molecules or analyzing the homology of biological sequences. Meanwhile, deep learning can inherently learn latent features for the specific task.

A joint research team comprised of Ph.D. candidate Gi Bae Kim and Distinguished Professor Sang Yup Lee of the Department of Chemical and Biomolecular Engineering at KAIST, and Ye Gao and Professor Bernhard O. Palsson of the Department of Biochemical Engineering at UCSD reported a deep learning-based tool for the prediction of transcription factors. Their research paper “DeepTFactor: A deep learning-based tool for the prediction of transcription factors” was published online in PNAS.

Their article reports the development of DeepTFactor, a deep learning-based tool that predicts whether a given protein sequence is a transcription factor using three parallel convolutional neural networks. The joint research team predicted 332 transcription factors of Escherichia coli K-12 MG1655 using DeepTFactor and the performance of DeepTFactor by experimentally confirming the genome-wide binding sites of three predicted transcription factors (YqhC, YiaU, and YahB).

The joint research team further used a saliency method to understand the reasoning process of DeepTFactor. The researchers confirmed that even though information on the DNA binding domains of the transcription factor was not explicitly given the training process, DeepTFactor implicitly learned and used them for prediction. Unlike previous transcription factor prediction tools that were developed only for protein sequences of specific organisms, DeepTFactor is expected to be used in the analysis of the transcription systems of all organisms at a high level of performance.

Distinguished Professor Sang Yup Lee said, “DeepTFactor can be used to discover unknown transcription factors from numerous protein sequences that have not yet been characterized. It is expected that DeepTFactor will serve as an important tool for analyzing the regulatory systems of organisms of interest.”

This work was supported by the Technology Development Program to Solve Climate Changes on Systems Metabolic Engineering for Biorefineries from the Ministry of Science and ICT through the National Research Foundation of Korea.

-Publication

Gi Bae Kim, Ye Gao, Bernhard O. Palsson, and Sang Yup Lee. DeepTFactor: A deep learning-based tool for the prediction of transcription factors. (https://doi.org/10.1073/pnas202117118)

-Profile

Distinguished Professor Sang Yup Lee

leesy@kaist.ac.kr

Metabolic &Biomolecular Engineering National Research Laboratory

http://mbel.kaist.ac.kr

Department of Chemical and Biomolecular Engineering

KAIST

2021.01.05 View 10386 -

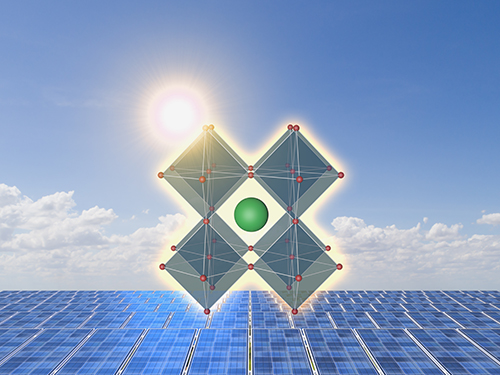

Extremely Stable Perovskite Nanoparticles Films for Next-Generation Displays

Researchers have reported an extremely stable cross-linked perovskite nanoparticle that maintains a high photoluminescence quantum yield (PLQY) for 1.5 years in air and harsh liquid environments. This stable material’s design strategies, which addressed one of the most critical problems limiting their practical application, provide a breakthrough for the commercialization of perovskite nanoparticles in next-generation displays and bio-related applications.

According to the research team led by Professor Byeong-Soo Bae, their development can survive in severe environments such as water, various polar solvents, and high temperature with high humidity without additional encapsulation. This development is expected to enable perovskite nanoparticles to be applied to high color purity display applications as a practical color converting material. This result was published as the inside front cover article in Advanced Materials.

Perovskites, which consist of organics, metals, and halogen elements, have emerged as key elements in various optoelectronic applications. The power conversion efficiency of photovoltaic cells based on perovskites light absorbers has been rapidly increased. Perovskites are also great promise as a light emitter in display applications because of their low material cost, facile wavelength tunability, high (PLQY), very narrow emission band width, and wider color gamut than inorganic semiconducting nanocrystals and organic emitters. Thanks to these advantages, perovskites have been identified as a key color-converting material for next-generation high color-purity displays. In particular, perovskites are the only luminescence material that meets Rec. 2020 which is a new color standard in display industry.

However, perovskites are very unstable against heat, moisture, and light, which makes them almost impossible to use in practical applications. To solve these problems, many researchers have attempted to physically prevent perovskites from coming into contact with water molecules by passivating the perovskite grain and nanoparticle surfaces with organic ligands or inorganic shell materials, or by fabricating perovskite-polymer nanocomposites. These methods require complex processes and have limited stability in ambient air and water. Furthermore, stable perovskite nanoparticles in the various chemical environments and high temperatures with high humidity have not been reported yet.

The research team in collaboration with Seoul National University develops siloxane-encapsulated perovskite nanoparticle composite films. Here, perovskite nanoparticles are chemically crosslinked with thermally stable siloxane molecules, thereby significantly improving the stability of the perovskite nanoparticles without the need for any additional protecting layer.

Siloxane-encapsulated perovskite nanoparticle composite films exhibited a high PLQY (> 70%) value, which can be maintained over 600 days in water, various chemicals (alcohol, strong acidic and basic solutions), and high temperatures with high humidity (85℃/85%). The research team investigated the mechanisms impacting the chemical crosslinking and water molecule-induced stabilization of perovskite nanoparticles through various photo-physical analysis and density-functional theory calculation.

The research team confirmed that displays based on their siloxane-perovskite nanoparticle composite films exhibited higher PLQY and a wider color gamut than those of Cd-based quantum dots and demonstrated perfect color converting properties on commercial mobile phone screens. Unlike what was commonly believed in the halide perovskite field, the composite films showed excellent bio-compatibility because the siloxane matrix prevents the toxicity of Pb in perovskite nanoparticle.

By using this technology, the instability of perovskite materials, which is the biggest challenge for practical applications, is greatly improved through simple encapsulation method.

“Perovskite nanoparticle is the only photoluminescent material that can meet the next generation display color standard. Nevertheless, there has been reluctant to commercialize it due to its moisture vulnerability. The newly developed siloxane encapsulation technology will trigger more research on perovskite nanoparticles as color conversion materials and will accelerate early commercialization,” Professor Bae said.

This work was supported by the Wearable Platform Materials Technology Center (WMC) of the Engineering Research Center (ERC) Project, and the Leadership Research Program funded by the National Research Foundation of Korea.

-Publication:

Junho Jang, Young-Hoon Kim, Sunjoon Park, Dongsuk Yoo, Hyunjin Cho, Jinhyeong Jang, Han Beom Jeong, Hyunhwan Lee, Jong Min Yuk, Chan Beum Park, Duk Young Jeon, Yong-Hyun Kim, Byeong-Soo Bae, and Tae-Woo Lee. “Extremely Stable Luminescent Crosslinked Perovskite Nanoparticles under Harsh Environments over 1.5 Years” Advanced Materials, 2020, 2005255. https://doi.org/10.1002/adma.202005255.

Link to download the full-text paper:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202005255

-Profile: Prof. Byeong-Soo Bae (Corresponding author)

bsbae@kaist.ac.kr

Lab. of Optical Materials & Coating

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

2020.12.29 View 14606

Extremely Stable Perovskite Nanoparticles Films for Next-Generation Displays

Researchers have reported an extremely stable cross-linked perovskite nanoparticle that maintains a high photoluminescence quantum yield (PLQY) for 1.5 years in air and harsh liquid environments. This stable material’s design strategies, which addressed one of the most critical problems limiting their practical application, provide a breakthrough for the commercialization of perovskite nanoparticles in next-generation displays and bio-related applications.

According to the research team led by Professor Byeong-Soo Bae, their development can survive in severe environments such as water, various polar solvents, and high temperature with high humidity without additional encapsulation. This development is expected to enable perovskite nanoparticles to be applied to high color purity display applications as a practical color converting material. This result was published as the inside front cover article in Advanced Materials.

Perovskites, which consist of organics, metals, and halogen elements, have emerged as key elements in various optoelectronic applications. The power conversion efficiency of photovoltaic cells based on perovskites light absorbers has been rapidly increased. Perovskites are also great promise as a light emitter in display applications because of their low material cost, facile wavelength tunability, high (PLQY), very narrow emission band width, and wider color gamut than inorganic semiconducting nanocrystals and organic emitters. Thanks to these advantages, perovskites have been identified as a key color-converting material for next-generation high color-purity displays. In particular, perovskites are the only luminescence material that meets Rec. 2020 which is a new color standard in display industry.

However, perovskites are very unstable against heat, moisture, and light, which makes them almost impossible to use in practical applications. To solve these problems, many researchers have attempted to physically prevent perovskites from coming into contact with water molecules by passivating the perovskite grain and nanoparticle surfaces with organic ligands or inorganic shell materials, or by fabricating perovskite-polymer nanocomposites. These methods require complex processes and have limited stability in ambient air and water. Furthermore, stable perovskite nanoparticles in the various chemical environments and high temperatures with high humidity have not been reported yet.

The research team in collaboration with Seoul National University develops siloxane-encapsulated perovskite nanoparticle composite films. Here, perovskite nanoparticles are chemically crosslinked with thermally stable siloxane molecules, thereby significantly improving the stability of the perovskite nanoparticles without the need for any additional protecting layer.

Siloxane-encapsulated perovskite nanoparticle composite films exhibited a high PLQY (> 70%) value, which can be maintained over 600 days in water, various chemicals (alcohol, strong acidic and basic solutions), and high temperatures with high humidity (85℃/85%). The research team investigated the mechanisms impacting the chemical crosslinking and water molecule-induced stabilization of perovskite nanoparticles through various photo-physical analysis and density-functional theory calculation.

The research team confirmed that displays based on their siloxane-perovskite nanoparticle composite films exhibited higher PLQY and a wider color gamut than those of Cd-based quantum dots and demonstrated perfect color converting properties on commercial mobile phone screens. Unlike what was commonly believed in the halide perovskite field, the composite films showed excellent bio-compatibility because the siloxane matrix prevents the toxicity of Pb in perovskite nanoparticle.

By using this technology, the instability of perovskite materials, which is the biggest challenge for practical applications, is greatly improved through simple encapsulation method.

“Perovskite nanoparticle is the only photoluminescent material that can meet the next generation display color standard. Nevertheless, there has been reluctant to commercialize it due to its moisture vulnerability. The newly developed siloxane encapsulation technology will trigger more research on perovskite nanoparticles as color conversion materials and will accelerate early commercialization,” Professor Bae said.

This work was supported by the Wearable Platform Materials Technology Center (WMC) of the Engineering Research Center (ERC) Project, and the Leadership Research Program funded by the National Research Foundation of Korea.

-Publication:

Junho Jang, Young-Hoon Kim, Sunjoon Park, Dongsuk Yoo, Hyunjin Cho, Jinhyeong Jang, Han Beom Jeong, Hyunhwan Lee, Jong Min Yuk, Chan Beum Park, Duk Young Jeon, Yong-Hyun Kim, Byeong-Soo Bae, and Tae-Woo Lee. “Extremely Stable Luminescent Crosslinked Perovskite Nanoparticles under Harsh Environments over 1.5 Years” Advanced Materials, 2020, 2005255. https://doi.org/10.1002/adma.202005255.

Link to download the full-text paper:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202005255

-Profile: Prof. Byeong-Soo Bae (Corresponding author)

bsbae@kaist.ac.kr

Lab. of Optical Materials & Coating

Department of Materials Science and Engineering

Korea Advanced Institute of Science and Technology (KAIST)

2020.12.29 View 14606 -

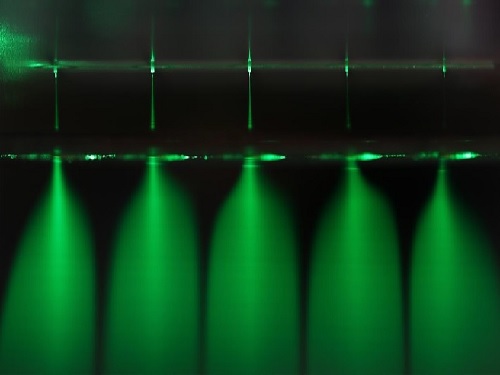

Electrosprayed Micro Droplets Help Kill Bacteria and Viruses

With COVID-19 raging around the globe, researchers are doubling down on methods for developing diverse antimicrobial technologies that could be effective in killing a virus, but harmless to humans and the environment.

A recent study by a KAIST research team will be one of the responses to such efforts. Professor Seung Seob Lee and Dr. Ji-hun Jeong from the Department of Mechanical Engineering developed a harmless air sterilization prototype featuring electrosprayed water from a polymer micro-nozzle array. This study is one of the projects being supported by the KAIST New Deal R&D Initiative in response to COVID-19. Their study was reported in Polymer.

The electrosprayed microdroplets encapsulate reactive oxygen species such as hydroxyl radicals, superoxides that are known to have an antimicrobial function. The encapsulation prolongs the life of reactive oxygen species, which enable the droplets to perform their antimicrobial function effectively. Prior research has already proven the antimicrobial and encapsulation effects of electrosprayed droplets.

Despite its potential for antimicrobial applications, electrosprayed water generally operates under an electrical discharge condition, which can generate ozone. The inhalation of ozone is known to cause damage to the respiratory system of humans. Another technical barrier for electrospraying is the low flow rate problem. Since electrospraying exhibits the dependence of droplet size on the flow rate, there is a limit for the amount of water microdroplets a single nozzle can produce.

With this in mind, the research team developed a dielectric polymer micro-nozzle array to perform the multiplexed electrospraying of water without electrical discharge. The polymer micro-nozzle array was fabricated using the MEMS (Micro Electro-Mechanical System) process. According to the research team, the nozzle can carry five to 19 micro-nozzles depending on the required application.

The high aspect ratio of the micro-nozzle and an in-plane extractor were proposed to concentrate the electric field at the tip of the micro-nozzle, which prevents the electrical discharge caused by the high surface tension of water. A micro-pillar array with a hydrophobic coating around the micro-nozzle was also proposed to prevent the wetting of the micro-nozzle array.

The polymer micro-nozzle array performed in steady cone jet mode without electrical discharge as confirmed by high-speed imaging and nanosecond pulsed imaging. The water microdroplets were measured to be in the range of six to 10 μm and displayed an antimicrobial effect on Escherichia coli and Staphylococcus aureus.

Professor Lee said, “We believe that this research can be applied to air conditioning products in areas that require antimicrobial and humidifying functions.”

Publication:

Jeong, J. H., et al. (2020) Polymer micro-atomizer for water electrospray in the cone jet mode. Polymer. Vol. No. 194, 122405. Available online at https://doi.org/10.1016/j.polymer.2020.122405

Profile: Seung Seob Lee, Ph.D.

sslee97@kaist.ac.kr

http://mmst.kaist.ac.kr/

Professor

Department of Mechanical Engineering (ME)

Korea Advanced Institute of Science and Technology (KAIST)

https://www.kaist.ac.kr

Daejeon 34141, Korea

Profile: Ji-hun Jeong, Ph.D.

jiuni6022@kaist.ac.kr

Postdoctoral researcher