CO

-

Robotic Herding of a Flock of Birds Using Drones

A joint team from KAIST, Caltech, and Imperial College London, presents a drone with a new algorithm to shepherd birds safely away from airports

Researchers made a new algorithm for enabling a single robotic unmanned aerial vehicle to herd a flock of birds away from a designated airspace. This novel approach allows a single autonomous quadrotor drone to herd an entire flock of birds away without breaking their formation.

Professor David Hyunchul Shim at KAIST in collaboration with Professor Soon-Jo Chung of Caltech and Professor Aditya Paranjape of Imperial College London investigated the problem of diverting a flock of birds away from a prescribed area, such as an airport, using a robotic UVA. A novel boundary control strategy called the m-waypoint algorithm was introduced for enabling a single pursuer UAV to safely herd the flock without fragmenting it.

The team developed the herding algorithm on the basis of macroscopic properties of the flocking model and the response of the flock. They tested their robotic autonomous drone by successfully shepherding an entire flock of birds out of a designated airspace near KAIST’s campus in Daejeon, South Korea. This study is published in IEEE Transactions on Robotics.

“It is quite interesting, and even awe-inspiring, to monitor how birds react to threats and collectively behave against threatening objects through the flock. We made careful observations of flock dynamics and interactions between flocks and the pursuer. This allowed us to create a new herding algorithm for ideal flight paths for incoming drones to move the flock away from a protected airspace,” said Professor Shim, who leads the Unmanned Systems Research Group at KAIST.

Bird strikes can threaten the safety of airplanes and their passengers. Korean civil aircraft suffered more than 1,000 bird strikes between 2011 and 2016. In the US, 142,000 bird strikes destroyed 62 civilian airplanes, injured 279 people, and killed 25 between 1990 and 2013. In the UK in 2016, there were 1,835 confirmed bird strikes, about eight for every 10,000 flights. Bird and other wildlife collisions with aircraft cause well over 1.2 billion USD in damages to the aviation industry worldwide annually. In the worst case, Canadian geese knocked out both engines of a US Airway jet in January 2009. The flight had to make an emergency landing on the Hudson River.

Airports and researchers have continued to reduce the risk of bird strikes through a variety of methods. They scare birds away using predators such as falcons or loud noises from small cannons or guns. Some airports try to prevent birds from coming by ridding the surrounding areas of crops that birds eat and hide in.

However, birds are smart. “I was amazed with the birds’ capability to interact with flying objects. We thought that only birds of prey have a strong sense of maneuvering with the prey. But our observation of hundreds of migratory birds such as egrets and loons led us to reach the hypothesis that they all have similar levels of maneuvering with the flying objects. It will be very interesting to collaborate with ornithologists to study further with birds’ behaviors with aerial objects,” said Professor Shim. “Airports are trying to transform into smart airports. This algorithm will help improve safety for the aviation industry. In addition, this will also help control avian influenza that plagues farms nationwide every year,” he stressed.

For this study, two drones were deployed. One drone performed various types of maneuvers around the flocks as a pursuer of herding drone, while a surveillance drone hovered at a high altitude with a camera pointing down for recording the trajectories of the pursuer drone and the birds.

During the experiments on egrets, the birds made frequent visits to a hunting area nearby and a large number of egrets were found to return to their nests at sunset. During the time, the team attempted to fly the herding drone in various directions with respect to the flock.

The drone approached the flock from the side. When the birds noticed the drone, they diverted from their original paths and flew at a 45˚ angle to their right. When the birds noticed the drone while it was still far away, they adjusted their paths horizontally and made smaller changes in the vertical direction. In the second round of the experiment on loons, the drone flew almost parallel to the flight path of a flock of birds, starting from an initial position located just off the nominal flight path. The birds had a nominal flight speed that was considerably higher than that of the drone so the interaction took place over a relatively short period of time.

Professor Shim said, “I think we just completed the first step of the research. For the next step, more systems will be developed and integrated for bird detection, ranging, and automatic deployment of drones.” “Professor Chung at Caltech is a KAIST graduate. And his first student was Professor Paranjape who now teaches at Imperial. It is pretty interesting that this research was made by a KAIST faculty member, an alumnus, and his student on three different continents,” he said.

(Figure A. Case 1: drone approaches the herd with sufficient distance to induce horizontal deviation)

(Figure B. Case 2: drone approaches the herd abruptly to cause vertical deviation)

2018.08.23 View 9885

Robotic Herding of a Flock of Birds Using Drones

A joint team from KAIST, Caltech, and Imperial College London, presents a drone with a new algorithm to shepherd birds safely away from airports

Researchers made a new algorithm for enabling a single robotic unmanned aerial vehicle to herd a flock of birds away from a designated airspace. This novel approach allows a single autonomous quadrotor drone to herd an entire flock of birds away without breaking their formation.

Professor David Hyunchul Shim at KAIST in collaboration with Professor Soon-Jo Chung of Caltech and Professor Aditya Paranjape of Imperial College London investigated the problem of diverting a flock of birds away from a prescribed area, such as an airport, using a robotic UVA. A novel boundary control strategy called the m-waypoint algorithm was introduced for enabling a single pursuer UAV to safely herd the flock without fragmenting it.

The team developed the herding algorithm on the basis of macroscopic properties of the flocking model and the response of the flock. They tested their robotic autonomous drone by successfully shepherding an entire flock of birds out of a designated airspace near KAIST’s campus in Daejeon, South Korea. This study is published in IEEE Transactions on Robotics.

“It is quite interesting, and even awe-inspiring, to monitor how birds react to threats and collectively behave against threatening objects through the flock. We made careful observations of flock dynamics and interactions between flocks and the pursuer. This allowed us to create a new herding algorithm for ideal flight paths for incoming drones to move the flock away from a protected airspace,” said Professor Shim, who leads the Unmanned Systems Research Group at KAIST.

Bird strikes can threaten the safety of airplanes and their passengers. Korean civil aircraft suffered more than 1,000 bird strikes between 2011 and 2016. In the US, 142,000 bird strikes destroyed 62 civilian airplanes, injured 279 people, and killed 25 between 1990 and 2013. In the UK in 2016, there were 1,835 confirmed bird strikes, about eight for every 10,000 flights. Bird and other wildlife collisions with aircraft cause well over 1.2 billion USD in damages to the aviation industry worldwide annually. In the worst case, Canadian geese knocked out both engines of a US Airway jet in January 2009. The flight had to make an emergency landing on the Hudson River.

Airports and researchers have continued to reduce the risk of bird strikes through a variety of methods. They scare birds away using predators such as falcons or loud noises from small cannons or guns. Some airports try to prevent birds from coming by ridding the surrounding areas of crops that birds eat and hide in.

However, birds are smart. “I was amazed with the birds’ capability to interact with flying objects. We thought that only birds of prey have a strong sense of maneuvering with the prey. But our observation of hundreds of migratory birds such as egrets and loons led us to reach the hypothesis that they all have similar levels of maneuvering with the flying objects. It will be very interesting to collaborate with ornithologists to study further with birds’ behaviors with aerial objects,” said Professor Shim. “Airports are trying to transform into smart airports. This algorithm will help improve safety for the aviation industry. In addition, this will also help control avian influenza that plagues farms nationwide every year,” he stressed.

For this study, two drones were deployed. One drone performed various types of maneuvers around the flocks as a pursuer of herding drone, while a surveillance drone hovered at a high altitude with a camera pointing down for recording the trajectories of the pursuer drone and the birds.

During the experiments on egrets, the birds made frequent visits to a hunting area nearby and a large number of egrets were found to return to their nests at sunset. During the time, the team attempted to fly the herding drone in various directions with respect to the flock.

The drone approached the flock from the side. When the birds noticed the drone, they diverted from their original paths and flew at a 45˚ angle to their right. When the birds noticed the drone while it was still far away, they adjusted their paths horizontally and made smaller changes in the vertical direction. In the second round of the experiment on loons, the drone flew almost parallel to the flight path of a flock of birds, starting from an initial position located just off the nominal flight path. The birds had a nominal flight speed that was considerably higher than that of the drone so the interaction took place over a relatively short period of time.

Professor Shim said, “I think we just completed the first step of the research. For the next step, more systems will be developed and integrated for bird detection, ranging, and automatic deployment of drones.” “Professor Chung at Caltech is a KAIST graduate. And his first student was Professor Paranjape who now teaches at Imperial. It is pretty interesting that this research was made by a KAIST faculty member, an alumnus, and his student on three different continents,” he said.

(Figure A. Case 1: drone approaches the herd with sufficient distance to induce horizontal deviation)

(Figure B. Case 2: drone approaches the herd abruptly to cause vertical deviation)

2018.08.23 View 9885 -

'K-FLEX' Makes a Splash as a Flexible Endoscopic Surgical Robot

( Robot arms perform an incision during an ex-vivo test on a porcine gallbladder.)

K-FLEX, a flexible endoscopic surgical robot developed by the KAIST Future Medical Robotics Research Center, opens a new chapter for minimally invasive robot-assisted surgery with its precision control of 3.7 mm diameter robotic arms. The two arms, placing at the end of flexible endoscopes, highlight impeccable precision control and robust mini-joint design technologies. While cruising through the complicated inner body pliably, it carries out procedures on the spot with its robotic arms.

The research team under Professor Dong-Soo Kwon recently tested the device in-vivo, conducting a complicated endoscopic procedure dissecting a porcine gallbladder in collaboration with Professor Dae-Kyung Son of the National Cancer Center. The arms successfully manipulated the tissue safely.

During the test, K-FLEX, inserted through an incision in the navel, snaked through the narrow passages of the complicated inner organs. When reaching the desired spot, one of the robot arms pushed aside and held up the nearby tissue to secure proper vision and space for the procedure. Meanwhile, a cautery needle mounted at the tip of the other hand removed the lesion tissue on the gallbladder. The tiny camera installed at the front of the robot arms relayed the internal conditions. The full procedure was able to be monitored from the master console.

The two arms are placed onto 4.2 mm internal channels of an endoscope which is 17 mm in diameter. The arms can be deployable forward and backward and are extendable up to 7 cm for performing procedures.

K-FLEX is made of domestically produced components, except for the endoscopic module. It will expand new medical robotics research while offering novel therapeutic capabilities for endoscopes.

Flexible endoscopes are very promising for surgical applications because they can treat areas thought to be difficult to reach, such as the posterior side of an organ. Current rigid-type laparoscopic tools could not reach a lesion if it occurs in such serpentine and complicated areas. However, this flexible endoscopic surgery robot will bypass obstacles to reach the troubled area.

The ability to seamlessly integrate effective actuation into millimeter-scale deployable mechanisms fits well with minimally invasive surgical procedures. This flexible endoscopic surgery robot, only half the size of current laparoscopic surgical robots, is deployable into natural orifices such as the mouth, anus, and vagina without requiring external incisions. Laparoscopic devices and robots require at least three to four external incisions to insert the devices; however, the applicability of internal incisions reduces the possibility of complications arousing from excessive bleeding and bacterial infections.

Despite these advantages, it has remained challenging to manipulate the robotic arms of flexible endoscopes with integrated grabbing force, flexibility, and multiple degrees of freedom for clinical environments.

The team focused on smaller but smarter devices. Dr. Min-Ho Hwang, a principal researcher of K-FLEX, said that developing tiny robots that are able to generate the necessary forces without compromising safety was the challenge. They created a robust but smaller-joint technology that can exert a relatively greater force even into millimeter scale.

Professor Kwon said, “K-FLEX is the first flexible endoscopic surgery robot in Korea. We already confirmed the clinical adaptation through ex vivo tests and will see complete commercialization in two to three years.” The team believes K-FLEX will be very effective for surgery on incipient cancer cells in the stomach, colon, and thyroid.

Professor Kwon and his eight researchers recently established a tech start-up called EasyEndo Surgical Inc. with these core technologies. In June, K-FLEX won the ‘Best Application Award’ and the ‘Overall Winner’ at the Surgical Robot Challenge 2018 held at Imperial College London. The Korea Research Foundation funded the research on K-FLEX.

(The team conducts a procedure using K-FLEX, flexible endoscopic surgical robot.)

2018.08.17 View 8952

'K-FLEX' Makes a Splash as a Flexible Endoscopic Surgical Robot

( Robot arms perform an incision during an ex-vivo test on a porcine gallbladder.)

K-FLEX, a flexible endoscopic surgical robot developed by the KAIST Future Medical Robotics Research Center, opens a new chapter for minimally invasive robot-assisted surgery with its precision control of 3.7 mm diameter robotic arms. The two arms, placing at the end of flexible endoscopes, highlight impeccable precision control and robust mini-joint design technologies. While cruising through the complicated inner body pliably, it carries out procedures on the spot with its robotic arms.

The research team under Professor Dong-Soo Kwon recently tested the device in-vivo, conducting a complicated endoscopic procedure dissecting a porcine gallbladder in collaboration with Professor Dae-Kyung Son of the National Cancer Center. The arms successfully manipulated the tissue safely.

During the test, K-FLEX, inserted through an incision in the navel, snaked through the narrow passages of the complicated inner organs. When reaching the desired spot, one of the robot arms pushed aside and held up the nearby tissue to secure proper vision and space for the procedure. Meanwhile, a cautery needle mounted at the tip of the other hand removed the lesion tissue on the gallbladder. The tiny camera installed at the front of the robot arms relayed the internal conditions. The full procedure was able to be monitored from the master console.

The two arms are placed onto 4.2 mm internal channels of an endoscope which is 17 mm in diameter. The arms can be deployable forward and backward and are extendable up to 7 cm for performing procedures.

K-FLEX is made of domestically produced components, except for the endoscopic module. It will expand new medical robotics research while offering novel therapeutic capabilities for endoscopes.

Flexible endoscopes are very promising for surgical applications because they can treat areas thought to be difficult to reach, such as the posterior side of an organ. Current rigid-type laparoscopic tools could not reach a lesion if it occurs in such serpentine and complicated areas. However, this flexible endoscopic surgery robot will bypass obstacles to reach the troubled area.

The ability to seamlessly integrate effective actuation into millimeter-scale deployable mechanisms fits well with minimally invasive surgical procedures. This flexible endoscopic surgery robot, only half the size of current laparoscopic surgical robots, is deployable into natural orifices such as the mouth, anus, and vagina without requiring external incisions. Laparoscopic devices and robots require at least three to four external incisions to insert the devices; however, the applicability of internal incisions reduces the possibility of complications arousing from excessive bleeding and bacterial infections.

Despite these advantages, it has remained challenging to manipulate the robotic arms of flexible endoscopes with integrated grabbing force, flexibility, and multiple degrees of freedom for clinical environments.

The team focused on smaller but smarter devices. Dr. Min-Ho Hwang, a principal researcher of K-FLEX, said that developing tiny robots that are able to generate the necessary forces without compromising safety was the challenge. They created a robust but smaller-joint technology that can exert a relatively greater force even into millimeter scale.

Professor Kwon said, “K-FLEX is the first flexible endoscopic surgery robot in Korea. We already confirmed the clinical adaptation through ex vivo tests and will see complete commercialization in two to three years.” The team believes K-FLEX will be very effective for surgery on incipient cancer cells in the stomach, colon, and thyroid.

Professor Kwon and his eight researchers recently established a tech start-up called EasyEndo Surgical Inc. with these core technologies. In June, K-FLEX won the ‘Best Application Award’ and the ‘Overall Winner’ at the Surgical Robot Challenge 2018 held at Imperial College London. The Korea Research Foundation funded the research on K-FLEX.

(The team conducts a procedure using K-FLEX, flexible endoscopic surgical robot.)

2018.08.17 View 8952 -

Participation in the 2018 Bio-Digital City Workshop in Paris

(A student make a presentatiion during the Bio-Digital City Workshop in Paris last month.)

KAIST students explored ideas for developing future cities during the 2018 Bio-Digital City Workshop held in Paris last month.

This international workshop hosted by Cité des Sciences et de l'Industrie was held under the theme “Biomimicry, Digital City and Big Data.” During the workshop from July 10 to July 20, students teamed up with French counterparts to develop innovative urban design ideas. Cité des Sciences et de l'Industrie is the largest science museum in Europe and is operated by Universcience, a specialized institute of science and technology in France.

Professor Seongju Chang from the Department of Civil and Environmental Engineering and Professor Jihyun Lee of the Graduate School of Culture Technology Students led the students group.

Participants presented their ideas and findings on new urban solutions that combine biomimetic systems and digital technology. Each student group analyzed a special natural ecosystem such as sand dunes, jellyfish communities, or mangrove forests and conducted research to extract algorithms for constructing sustainable urban building complexes based on the results. The extracted algorithm was used to conceive a sustainable building complex forming a part of the urban environment by applying it to the actual Parisian city segment given as the virtual site for the workshop.

Students from diverse background in both countries participated in this convergence workshop. KAIST students included Ph.D. candidate Hyung Min Cho, undergraduates Min-Woo Jeong, Seung-Hwan Cha, and Sang-Jun Park from the Department of Civil and Environmental Engineering, undergraduate Kyeong-Keun Seo from the Department of Materials Science and Engineering, JiWhan Jeong (Master’s course) from the Department of Industrial and Systems Engineering, Ph.D. candidate Bo-Yoon Zang from the Graduate School of Culture Technology. They teamed up with French students from diverse backgrounds, including Design/Science, Visual Design, Geography, Computer Science and Humanities and Social Science.

This workshop will serve as another opportunity to expand academic and human exchange efforts in the domain of smart and sustainable cities with Europe in the future as the first international cooperation activity of KAIST and the Paris La Villette Science Museum.

Professor Seong-Ju Chang who led the research group said, "We will continue to establish a cooperative relationship between KAIST and the European scientific community. This workshop is a good opportunity to demonstrate the competence of KAIST students and their scientific and technological excellence on the international stage.”

2018.08.01 View 11143

Participation in the 2018 Bio-Digital City Workshop in Paris

(A student make a presentatiion during the Bio-Digital City Workshop in Paris last month.)

KAIST students explored ideas for developing future cities during the 2018 Bio-Digital City Workshop held in Paris last month.

This international workshop hosted by Cité des Sciences et de l'Industrie was held under the theme “Biomimicry, Digital City and Big Data.” During the workshop from July 10 to July 20, students teamed up with French counterparts to develop innovative urban design ideas. Cité des Sciences et de l'Industrie is the largest science museum in Europe and is operated by Universcience, a specialized institute of science and technology in France.

Professor Seongju Chang from the Department of Civil and Environmental Engineering and Professor Jihyun Lee of the Graduate School of Culture Technology Students led the students group.

Participants presented their ideas and findings on new urban solutions that combine biomimetic systems and digital technology. Each student group analyzed a special natural ecosystem such as sand dunes, jellyfish communities, or mangrove forests and conducted research to extract algorithms for constructing sustainable urban building complexes based on the results. The extracted algorithm was used to conceive a sustainable building complex forming a part of the urban environment by applying it to the actual Parisian city segment given as the virtual site for the workshop.

Students from diverse background in both countries participated in this convergence workshop. KAIST students included Ph.D. candidate Hyung Min Cho, undergraduates Min-Woo Jeong, Seung-Hwan Cha, and Sang-Jun Park from the Department of Civil and Environmental Engineering, undergraduate Kyeong-Keun Seo from the Department of Materials Science and Engineering, JiWhan Jeong (Master’s course) from the Department of Industrial and Systems Engineering, Ph.D. candidate Bo-Yoon Zang from the Graduate School of Culture Technology. They teamed up with French students from diverse backgrounds, including Design/Science, Visual Design, Geography, Computer Science and Humanities and Social Science.

This workshop will serve as another opportunity to expand academic and human exchange efforts in the domain of smart and sustainable cities with Europe in the future as the first international cooperation activity of KAIST and the Paris La Villette Science Museum.

Professor Seong-Ju Chang who led the research group said, "We will continue to establish a cooperative relationship between KAIST and the European scientific community. This workshop is a good opportunity to demonstrate the competence of KAIST students and their scientific and technological excellence on the international stage.”

2018.08.01 View 11143 -

It's Time to 3D Sketch with Air Scaffolding

People often use their hands when describing an object, while pens are great tools for describing objects in detail. Taking this idea, a KAIST team introduced a new 3D sketching workflow, combining the strengths of hand and pen input. This technique will ease the way for ideation in three dimensions, leading to efficient product design in terms of time and cost.

For a designer's drawing to become a product in reality, one has to transform a designer's 2D drawing into a 3D shape; however, it is difficult to infer accurate 3D shapes that match the original intention from an inaccurate 2D drawing made by hand. When creating a 3D shape from a planar 2D drawing, unobtainable information is required. On the other hand, loss of depth information occurs when a 3D shape is expressed as a 2D drawing using perspective drawing techniques.

To fill in these “missing links” during the conversion, "3D sketching" techniques have been actively studied. Their main purpose is to help designers naturally provide missing 3D shape information in a 2D drawing. For example, if a designer draws two symmetric curves from a single point of view or draws the same curves from different points of view, the geometric clues that are left in this process are collected and mathematically interpreted to define the proper 3D curve. As a result, designers can use 3D sketching to directly draw a 3D shape as if using pen and paper.

Among 3D sketching tools, sketching with hand motions, in VR environments in particular, has drawn attention because it is easy and quick. But the biggest limitation is that they cannot articulate the design solely using rough hand motions, hence they are difficult to be applied to product designs. Moreover, users may feel tired after raising their hands in the air during the entire drawing process.

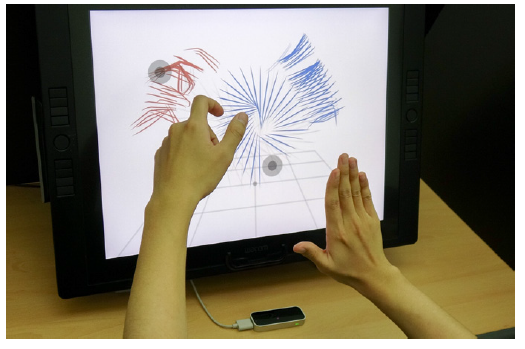

Using hand motions but to elaborate designs, Professor Seok-Hyung Bae and his team from the Department of Industrial Design integrated hand motions and pen-based sketching, allocating roles according to their strengths. This new technique is called Agile 3D Sketching with Air Scaffolding. Designers use their hand motions in the air to create rough 3D shapes which will be used as scaffolds, and then they can add details with pen-based 3D sketching on a tablet (Figure 1).

Figure 1. In the agile 3D sketching workflow with air scaffolding, the user (a) makes unconstrained hand movements in the air to quickly generate rough shapes to be used as scaffolds, (b) uses the scaffolds as references and draws finer details with them, (c) produces a high-fidelity 3D concept sketch of a steering wheel in an iterative and progressive manner.

The team came up with an algorithm to identify descriptive hand motions from transitory hand motions and extract only the intended shapes from unconstrained hand motions, based on air scaffolds from the identified motions.

Through user tests, the team identified that this technique is easy to learn and use, and demonstrates good applicability. Most importantly, the users can reduce time, yet enhance the accuracy of defining the proportion and scale of products.

Eventually, this tool will be able to be applied to various fields including the automobile industry, home appliances, animations and the movie making industry, and robotics. It also can be linked to smart production technology, such as 3D printing, to make manufacturing process faster and more flexible.

PhD candidate Yongkwan Kim, who led the research project, said, “I believe the system will enhance product quality and work efficiency because designers can express their 3D ideas quickly yet accurately without using complex 3D CAD modeling software. I will make it into a product that every designer wants to use in various fields.”

“There have been many attempts to encourage creative activities in various fields by using advanced computer technology. Based on in-depth understanding of designers, we will take the lead in innovating the design process by applying cutting-edge technology,” Professor Bae added.

Professor Bae and his team from the Department of Industrial Design has been delving into developing better 3D sketching tools. They started with a 3D curve sketching system for professional designers called ILoveSketch and moved on to SketchingWithHands for designing a handheld product with first-person hand postures captured by a hand-tracking sensor. They then took their project to the next level and introduced Agile 3D Sketching with Air Scaffolding, a new 3D sketching workflow combining hand motion and pen drawing which was chosen as one of the CHI (Conference on Human Factors in Computing Systems) 2018 Best Papers by the Association for Computing Machinery.

- Click the link to watch video clip of SketchingWithHands

2018.07.25 View 9829

It's Time to 3D Sketch with Air Scaffolding

People often use their hands when describing an object, while pens are great tools for describing objects in detail. Taking this idea, a KAIST team introduced a new 3D sketching workflow, combining the strengths of hand and pen input. This technique will ease the way for ideation in three dimensions, leading to efficient product design in terms of time and cost.

For a designer's drawing to become a product in reality, one has to transform a designer's 2D drawing into a 3D shape; however, it is difficult to infer accurate 3D shapes that match the original intention from an inaccurate 2D drawing made by hand. When creating a 3D shape from a planar 2D drawing, unobtainable information is required. On the other hand, loss of depth information occurs when a 3D shape is expressed as a 2D drawing using perspective drawing techniques.

To fill in these “missing links” during the conversion, "3D sketching" techniques have been actively studied. Their main purpose is to help designers naturally provide missing 3D shape information in a 2D drawing. For example, if a designer draws two symmetric curves from a single point of view or draws the same curves from different points of view, the geometric clues that are left in this process are collected and mathematically interpreted to define the proper 3D curve. As a result, designers can use 3D sketching to directly draw a 3D shape as if using pen and paper.

Among 3D sketching tools, sketching with hand motions, in VR environments in particular, has drawn attention because it is easy and quick. But the biggest limitation is that they cannot articulate the design solely using rough hand motions, hence they are difficult to be applied to product designs. Moreover, users may feel tired after raising their hands in the air during the entire drawing process.

Using hand motions but to elaborate designs, Professor Seok-Hyung Bae and his team from the Department of Industrial Design integrated hand motions and pen-based sketching, allocating roles according to their strengths. This new technique is called Agile 3D Sketching with Air Scaffolding. Designers use their hand motions in the air to create rough 3D shapes which will be used as scaffolds, and then they can add details with pen-based 3D sketching on a tablet (Figure 1).

Figure 1. In the agile 3D sketching workflow with air scaffolding, the user (a) makes unconstrained hand movements in the air to quickly generate rough shapes to be used as scaffolds, (b) uses the scaffolds as references and draws finer details with them, (c) produces a high-fidelity 3D concept sketch of a steering wheel in an iterative and progressive manner.

The team came up with an algorithm to identify descriptive hand motions from transitory hand motions and extract only the intended shapes from unconstrained hand motions, based on air scaffolds from the identified motions.

Through user tests, the team identified that this technique is easy to learn and use, and demonstrates good applicability. Most importantly, the users can reduce time, yet enhance the accuracy of defining the proportion and scale of products.

Eventually, this tool will be able to be applied to various fields including the automobile industry, home appliances, animations and the movie making industry, and robotics. It also can be linked to smart production technology, such as 3D printing, to make manufacturing process faster and more flexible.

PhD candidate Yongkwan Kim, who led the research project, said, “I believe the system will enhance product quality and work efficiency because designers can express their 3D ideas quickly yet accurately without using complex 3D CAD modeling software. I will make it into a product that every designer wants to use in various fields.”

“There have been many attempts to encourage creative activities in various fields by using advanced computer technology. Based on in-depth understanding of designers, we will take the lead in innovating the design process by applying cutting-edge technology,” Professor Bae added.

Professor Bae and his team from the Department of Industrial Design has been delving into developing better 3D sketching tools. They started with a 3D curve sketching system for professional designers called ILoveSketch and moved on to SketchingWithHands for designing a handheld product with first-person hand postures captured by a hand-tracking sensor. They then took their project to the next level and introduced Agile 3D Sketching with Air Scaffolding, a new 3D sketching workflow combining hand motion and pen drawing which was chosen as one of the CHI (Conference on Human Factors in Computing Systems) 2018 Best Papers by the Association for Computing Machinery.

- Click the link to watch video clip of SketchingWithHands

2018.07.25 View 9829 -

Distinguished Professor Lee Receives 2018 George Washington Carver Award

(Distinguished Professor Lee)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering will become the 11th recipient of the George Washington Carver Award. The award ceremony will be held during the 2018 Biotechnology Innovation Organization (BIO) World Congress on Industrial Biotechnology from July 16 through 19 at the Pennsylvania Convention Center in Philadelphia.

The annual Carver award recognizes an individual who has made a significant contribution to building the bio-based economy by applying industrial biotechnology to create environmentally sustainable products. It serves as a lasting memorial to the original vision of George Washington Carver who, over a century ago, pioneered bio-based products, materials, and energy derived from renewable agricultural feedstock. Previous recipients include the founder and CEO of POET Jeff Broin, the CEO of DuPont Ellen Kullman, and Professor Gregory Stephanopoulos at MIT.

Professor Lee is a pioneering scholar of systems metabolic engineering, leveraging technology to develop microbial bioprocesses for the sustainable and environment-friendly production of chemicals, fuels, and materials from non-food renewable biomass. He also serves as the dean of the multi-and interdisciplinary research center hub, KAIST Institute.Through his work, Professor Lee has garnered countless achievements, including being one of only 13 people in the world elected as a foreign member of both the National Academy of Sciences USA and the National Academy of Engineering USA.

He has actively promoted the importance of industrial biotechnology through engagement with the public, policymakers, and decision makers around the world. He currently serves as the co-chairman of the Global Future Council on Biotechnology for the World Economic Forum and served as the Chairman of the Emerging Technologies Council and Biotechnology Council for the World Economic Forum.

Upon the award announcement, Dr. Brent Erickson, executive vice president of BIO’s Industrial & Environmental Section lauded Professor Lee’s achievement, saying “Dr. Lee has advanced the bio-based economy by developing innovative products and processes that are sustainable and environmentally friendly. In doing so, he has become a leader in advocating on the importance of industrial biotechnology. His contributions to the advancement of the industry are a continuation of the legacy left behind by George Washington Carver.”

Professor Lee thanked his research team who has worked together for the past few decades, adding, “Industrial biotechnology is becoming increasingly important to help achieve the UN’s Sustainable Development Goals. We should continue to work together to advance the field and establish a solid foundation for the sustainable future.”

The George Washington Carver Award is sponsored by the Iowa Biotechnology Association. Joe Hrdlicka, executive director of the Iowa Biotechnology Association, said, “Dr. Sang Yup Lee’s significant contributions to the advancement of industrial biotechnology make him the perfect recipient for the George Washington Carver Award. Having published more than 575 peer-reviewed papers, contributed to 82 books, and holding 636 patents, the culmination of Dr. Lee’s work has led to the establishment of sustainable systems for bio-based production of chemicals, fuels, and materials, thus reducing environmental impact and improving quality of life for all.”

2018.07.12 View 11997

Distinguished Professor Lee Receives 2018 George Washington Carver Award

(Distinguished Professor Lee)

Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering will become the 11th recipient of the George Washington Carver Award. The award ceremony will be held during the 2018 Biotechnology Innovation Organization (BIO) World Congress on Industrial Biotechnology from July 16 through 19 at the Pennsylvania Convention Center in Philadelphia.

The annual Carver award recognizes an individual who has made a significant contribution to building the bio-based economy by applying industrial biotechnology to create environmentally sustainable products. It serves as a lasting memorial to the original vision of George Washington Carver who, over a century ago, pioneered bio-based products, materials, and energy derived from renewable agricultural feedstock. Previous recipients include the founder and CEO of POET Jeff Broin, the CEO of DuPont Ellen Kullman, and Professor Gregory Stephanopoulos at MIT.

Professor Lee is a pioneering scholar of systems metabolic engineering, leveraging technology to develop microbial bioprocesses for the sustainable and environment-friendly production of chemicals, fuels, and materials from non-food renewable biomass. He also serves as the dean of the multi-and interdisciplinary research center hub, KAIST Institute.Through his work, Professor Lee has garnered countless achievements, including being one of only 13 people in the world elected as a foreign member of both the National Academy of Sciences USA and the National Academy of Engineering USA.

He has actively promoted the importance of industrial biotechnology through engagement with the public, policymakers, and decision makers around the world. He currently serves as the co-chairman of the Global Future Council on Biotechnology for the World Economic Forum and served as the Chairman of the Emerging Technologies Council and Biotechnology Council for the World Economic Forum.

Upon the award announcement, Dr. Brent Erickson, executive vice president of BIO’s Industrial & Environmental Section lauded Professor Lee’s achievement, saying “Dr. Lee has advanced the bio-based economy by developing innovative products and processes that are sustainable and environmentally friendly. In doing so, he has become a leader in advocating on the importance of industrial biotechnology. His contributions to the advancement of the industry are a continuation of the legacy left behind by George Washington Carver.”

Professor Lee thanked his research team who has worked together for the past few decades, adding, “Industrial biotechnology is becoming increasingly important to help achieve the UN’s Sustainable Development Goals. We should continue to work together to advance the field and establish a solid foundation for the sustainable future.”

The George Washington Carver Award is sponsored by the Iowa Biotechnology Association. Joe Hrdlicka, executive director of the Iowa Biotechnology Association, said, “Dr. Sang Yup Lee’s significant contributions to the advancement of industrial biotechnology make him the perfect recipient for the George Washington Carver Award. Having published more than 575 peer-reviewed papers, contributed to 82 books, and holding 636 patents, the culmination of Dr. Lee’s work has led to the establishment of sustainable systems for bio-based production of chemicals, fuels, and materials, thus reducing environmental impact and improving quality of life for all.”

2018.07.12 View 11997 -

Professor Suh Chosen for IT Young Engineer Award

(The ceremony photo of Professor Changho Suh)

Professor Changho Suh from the School of Electrical Engineering received the IT Young Engineer Award on June 28. This award is hosted by the Institute of Electrical and Electronics Engineers (IEEE) and the Institute of Electrical and Information Engineers (IEIE) and funded by the Haedong Science Foundation.

The IT Young Engineer Award is given to researchers under the age of 40 in Korea. The selection criteria include the researches’ technical practicability, their social and environmental contributions, and their creativity.

Professor Suh has shown outstanding academic performance in the field of telecommunications, distributed storage, and artificial intelligence and he has also contributed to technological commercialization. He published 23 papers in SCI journals and ten papers at top-level international conferences including the Conference on Neural Information Processing Systems and the International Conference on Machine Learning. His papers were cited more than 4,100 times. He has also achieved 30 international patent registrations.

Currently, he is developing an autonomous driving system using an AI-tutor and deep learning technology.

Professor Suh said, “It is my great honor to receive the IT Young Engineer Award. I strive to continue guiding students and carrying out research in order to make a contribution to the fields of IT and AI.”

2018.07.04 View 9841

Professor Suh Chosen for IT Young Engineer Award

(The ceremony photo of Professor Changho Suh)

Professor Changho Suh from the School of Electrical Engineering received the IT Young Engineer Award on June 28. This award is hosted by the Institute of Electrical and Electronics Engineers (IEEE) and the Institute of Electrical and Information Engineers (IEIE) and funded by the Haedong Science Foundation.

The IT Young Engineer Award is given to researchers under the age of 40 in Korea. The selection criteria include the researches’ technical practicability, their social and environmental contributions, and their creativity.

Professor Suh has shown outstanding academic performance in the field of telecommunications, distributed storage, and artificial intelligence and he has also contributed to technological commercialization. He published 23 papers in SCI journals and ten papers at top-level international conferences including the Conference on Neural Information Processing Systems and the International Conference on Machine Learning. His papers were cited more than 4,100 times. He has also achieved 30 international patent registrations.

Currently, he is developing an autonomous driving system using an AI-tutor and deep learning technology.

Professor Suh said, “It is my great honor to receive the IT Young Engineer Award. I strive to continue guiding students and carrying out research in order to make a contribution to the fields of IT and AI.”

2018.07.04 View 9841 -

KAIST Team Reaching Out with Appropriate Technology

(The gold prize winning team of KATT)

The KAIST Appropriate Technology Team (KATT) consisting of international students at KAIST won the gold and silver prizes at ‘The 10th Creative Design Competition for the Other 90 Percent.’

More than 218 students from 50 teams nationwide participated in the competition hosted by the Ministry of Science and ICT last month.

The competition was created to discover appropriate technology and sustainable design items to enhance the quality of life for those with no or few accessible technologies.

A team led by Juan Luis Gonzalez Bello, graduate student from the School of Electrical Engineering received the gold prize for presenting a prosthetic arm. Their artificial arm was highly recognized for its affordability and good manageability. The team said that it cost less than 10 US dollars to construct from materials available in underprivileged regions and was easy to assemble.

Sophomore Hutomo Calvin from the Department of Materials Science & Engineering also worked on the prosthetic arm project with freshmen Bella Godiva, Stephanie Tan, and Koptieuov Yearbola.

Alexandra Tran, senior from the School of Electrical Engineering led the silver prize winning team. Her team developed a portable weather monitor, ‘Breathe Easy’. She worked with Alisher Tortay, senior from the School of Computing, Ashar Alam, senior from the Department of Mechanical Engineering, Bereket Eshete, junior from the School of Computing, and Marthens Hakzimana, sophomore from the Department of Mechanical Engineering.

This weather monitor is a low-cost but efficient air quality monitor. The team said it just cost less than seven US dollars to construct the monitor.KAIST students have now won the gold prize for two consecutive years.

2018.06.19 View 11327

KAIST Team Reaching Out with Appropriate Technology

(The gold prize winning team of KATT)

The KAIST Appropriate Technology Team (KATT) consisting of international students at KAIST won the gold and silver prizes at ‘The 10th Creative Design Competition for the Other 90 Percent.’

More than 218 students from 50 teams nationwide participated in the competition hosted by the Ministry of Science and ICT last month.

The competition was created to discover appropriate technology and sustainable design items to enhance the quality of life for those with no or few accessible technologies.

A team led by Juan Luis Gonzalez Bello, graduate student from the School of Electrical Engineering received the gold prize for presenting a prosthetic arm. Their artificial arm was highly recognized for its affordability and good manageability. The team said that it cost less than 10 US dollars to construct from materials available in underprivileged regions and was easy to assemble.

Sophomore Hutomo Calvin from the Department of Materials Science & Engineering also worked on the prosthetic arm project with freshmen Bella Godiva, Stephanie Tan, and Koptieuov Yearbola.

Alexandra Tran, senior from the School of Electrical Engineering led the silver prize winning team. Her team developed a portable weather monitor, ‘Breathe Easy’. She worked with Alisher Tortay, senior from the School of Computing, Ashar Alam, senior from the Department of Mechanical Engineering, Bereket Eshete, junior from the School of Computing, and Marthens Hakzimana, sophomore from the Department of Mechanical Engineering.

This weather monitor is a low-cost but efficient air quality monitor. The team said it just cost less than seven US dollars to construct the monitor.KAIST students have now won the gold prize for two consecutive years.

2018.06.19 View 11327 -

Czech Technology Mission with KAIST

Members of the Czech research community visited KAIST to discuss medium to long-term cooperation with KAIST. This visit was hosted by the Fourth Industrial Revolution Intelligence Center (FIRIC).

The community is comprised of people from Czech enterprises and academic institutes that are leading core technologies for the Fourth Industrial Revolution in the fields of AI, robotics, and biotechnology. They had a chance to meet KAIST professors and visit research labs.

Professor Il-Doo Kim from the Department of Materials Science and Engineering, Professor Seongsu Kim from the Department of Mechanical Engineering, and Professor Hyun Uk Kim from the Department of Chemical and Biomolecular Engineering attended the meeting, which took place in the Mechatronics, Systems, and Control Lab under the Vice President for Planning and Budget Soo Hyun Kim and Professor Kyung Soo Kim from the Department of Mechanical Engineering.

Professor Petr Novák from the Technical University of Ostrava said, “It was a meaningful meeting to help understand research trends on industrial robots in Korea.” Professor So Young Kim from FIRIC said, “The Czech research community is strong in basic research where KAIST has outstanding source technology. I hope this visit will open up a path for medium to long-term cooperation on sharing research and technology know-how between the Czech research community and KAIST.”

2018.06.07 View 6964

Czech Technology Mission with KAIST

Members of the Czech research community visited KAIST to discuss medium to long-term cooperation with KAIST. This visit was hosted by the Fourth Industrial Revolution Intelligence Center (FIRIC).

The community is comprised of people from Czech enterprises and academic institutes that are leading core technologies for the Fourth Industrial Revolution in the fields of AI, robotics, and biotechnology. They had a chance to meet KAIST professors and visit research labs.

Professor Il-Doo Kim from the Department of Materials Science and Engineering, Professor Seongsu Kim from the Department of Mechanical Engineering, and Professor Hyun Uk Kim from the Department of Chemical and Biomolecular Engineering attended the meeting, which took place in the Mechatronics, Systems, and Control Lab under the Vice President for Planning and Budget Soo Hyun Kim and Professor Kyung Soo Kim from the Department of Mechanical Engineering.

Professor Petr Novák from the Technical University of Ostrava said, “It was a meaningful meeting to help understand research trends on industrial robots in Korea.” Professor So Young Kim from FIRIC said, “The Czech research community is strong in basic research where KAIST has outstanding source technology. I hope this visit will open up a path for medium to long-term cooperation on sharing research and technology know-how between the Czech research community and KAIST.”

2018.06.07 View 6964 -

The Center for Anthropocene Studies (CAS) Opens

KAIST will start Anthropocene research, a convergence field of study, to address issues related to the commencement of human activities that have had scientific, industrial, and economic impacts on the Earth’s ecosystem. The National Research Foundation (NRF) of Korea endorsed the KAIST Center for Anthropocene Studies as its Convergence Research Center project.

Anthropocene refers to a new geological age in which various polluting materials that humans have made during the post-industrial revolution era have made a significant impact on the Earth and the lives of humankind. The studies expand the diverse socio-economic and environmental sectors for responding to climate change, natural disasters, ecological destruction, the polarization of the inequality and wealth, and many others.

The KAIST research group at the center, in collaboration with the Graduate School of Science and Technology Policy, the Graduate School of Culture Technology, the School of Humanities & Social Sciences, the Department of Industrial Design, the School of Electrical Engineering, the Satellite Technology Research Center (SaRTec), and the KAIST Initiative for Disaster Studies will conduct multidisciplinary research to address intriguing challenges with complex but creative approaches incorporating the fields of engineering, socioeconomics, and art.

The group will investigate topics such as▲ surface and marine changes to the Earth by applying satellite data ▲disaster prediction and governance system building through AI modeling ▲sustainable housing, transportation, and lifestyles ▲ engineering and artistic approaches for envisioning a new future for humankind and the Earth.

Professor Buhm Soon Park, who is in charge of the center, said, “This pioneering research work will inspire the re-creation of a new paradigm of convergence studies in science, engineering, humanities, and social science. We will contribute to making the world better by designing new technologies and social policies.

2018.06.05 View 12188

The Center for Anthropocene Studies (CAS) Opens

KAIST will start Anthropocene research, a convergence field of study, to address issues related to the commencement of human activities that have had scientific, industrial, and economic impacts on the Earth’s ecosystem. The National Research Foundation (NRF) of Korea endorsed the KAIST Center for Anthropocene Studies as its Convergence Research Center project.

Anthropocene refers to a new geological age in which various polluting materials that humans have made during the post-industrial revolution era have made a significant impact on the Earth and the lives of humankind. The studies expand the diverse socio-economic and environmental sectors for responding to climate change, natural disasters, ecological destruction, the polarization of the inequality and wealth, and many others.

The KAIST research group at the center, in collaboration with the Graduate School of Science and Technology Policy, the Graduate School of Culture Technology, the School of Humanities & Social Sciences, the Department of Industrial Design, the School of Electrical Engineering, the Satellite Technology Research Center (SaRTec), and the KAIST Initiative for Disaster Studies will conduct multidisciplinary research to address intriguing challenges with complex but creative approaches incorporating the fields of engineering, socioeconomics, and art.

The group will investigate topics such as▲ surface and marine changes to the Earth by applying satellite data ▲disaster prediction and governance system building through AI modeling ▲sustainable housing, transportation, and lifestyles ▲ engineering and artistic approaches for envisioning a new future for humankind and the Earth.

Professor Buhm Soon Park, who is in charge of the center, said, “This pioneering research work will inspire the re-creation of a new paradigm of convergence studies in science, engineering, humanities, and social science. We will contribute to making the world better by designing new technologies and social policies.

2018.06.05 View 12188 -

Professor YongKeun Park Wins the 2018 Fumio Okano Award

(Professor Park)

Professor YongKeun Park from the Department of Physics won the 2018 Fumio Okano Award in recognition of his contributions to 3D display technology development during the annual conference of the International Society for Optics and Photonics (SPIE) held last month in Orlando, Florida in the US.

The Fumio Okano Best 3D Paper Prize is presented annually in memory of Dr. Fumio Okano, a pioneer and innovator of 3D displays who passed away in 2013, for his contributions to the field of 3D TVs and displays. The award is sponsored by NHK-ES.

Professor Park and his team are developing novel technology for measuring and visualizing 3D images by applying random light scattering. He has published numerous papers on 3D holographic camera technology and 3000x enhanced performance of 3D holographic displays in renowned international journals such as Nature Photonics, Nature Communications, and Science Advances. His technology has drawn international attention from renowned media outlets including Newsweek and Forbes.

He has established two startups to commercialize his technology. Tomocube specializes in 3D imaging microscopes using holotomographic technology and the company exports their products to several countries including the US and Japan. The.Wave.Talk is exploring technology for examining pre-existing bacteria anywhere and anytime.

Professor Park’s innovations have already been recognized in and out of KAIST. In February, he was selected as the KAISTian of the Year for his outstanding research, commercialization, and startups. He was also decorated with the National Science Award in April by the Ministry of Science and ICT and the Hong Jin-Ki Innovation Award later in May by the Yumin Cultural Foundation.

Professor Park said, “3D holography is emerging as a significant technology with growing potential and positive impacts on our daily lives. However, the current technology lags far behind the levels displayed in SF movies. We will do our utmost to reach this level with more commercialization."

2018.05.31 View 11042

Professor YongKeun Park Wins the 2018 Fumio Okano Award

(Professor Park)

Professor YongKeun Park from the Department of Physics won the 2018 Fumio Okano Award in recognition of his contributions to 3D display technology development during the annual conference of the International Society for Optics and Photonics (SPIE) held last month in Orlando, Florida in the US.

The Fumio Okano Best 3D Paper Prize is presented annually in memory of Dr. Fumio Okano, a pioneer and innovator of 3D displays who passed away in 2013, for his contributions to the field of 3D TVs and displays. The award is sponsored by NHK-ES.

Professor Park and his team are developing novel technology for measuring and visualizing 3D images by applying random light scattering. He has published numerous papers on 3D holographic camera technology and 3000x enhanced performance of 3D holographic displays in renowned international journals such as Nature Photonics, Nature Communications, and Science Advances. His technology has drawn international attention from renowned media outlets including Newsweek and Forbes.

He has established two startups to commercialize his technology. Tomocube specializes in 3D imaging microscopes using holotomographic technology and the company exports their products to several countries including the US and Japan. The.Wave.Talk is exploring technology for examining pre-existing bacteria anywhere and anytime.

Professor Park’s innovations have already been recognized in and out of KAIST. In February, he was selected as the KAISTian of the Year for his outstanding research, commercialization, and startups. He was also decorated with the National Science Award in April by the Ministry of Science and ICT and the Hong Jin-Ki Innovation Award later in May by the Yumin Cultural Foundation.

Professor Park said, “3D holography is emerging as a significant technology with growing potential and positive impacts on our daily lives. However, the current technology lags far behind the levels displayed in SF movies. We will do our utmost to reach this level with more commercialization."

2018.05.31 View 11042 -

Fast-Charging Lithium-Oxygen Batteries

(Professor Hye Ryung Byon)

KAIST researchers have paved the way for fast-charging lithium-oxygen batteries.

Professor Hye Ryung Byon from the Department of Chemistry and Professor Yousung Jung from the Graduate School of EEWS led a joint research team to develop lithium-oxygen batteries exhibiting 80% round-trip efficiency even at high charging rates, solving the problem of existing lithium-oxygen batteries which generally showed drastically lower efficiencies when the charge current rate was increased.

This study exploits the size and shape lithium peroxide, a discharge product, which is known to cause the very problems mentioned above. In doing so, the researchers have lowered the overpotential, which is the difference between the thermodynamic reversible potential and the measured potential, and simultaneously improved battery efficiency. Of particular interest is the fact that these high-performance lithium-oxygen batteries can be realized without costly catalysts.

One remarkable property of lithium-oxygen batteries is that they can accommodate three to five times the energy density of lithium-ion batteries commonly used today. Therefore, lithium-oxygen batteries would render longer driving distance to electric vehicles or drones, which operate on the continued use of electrical power.

However, their weakness lies in that, during charge, the lithium peroxide remains undecomposed at low overpotential, resulting in eventually compromising the battery’s overall performance. This is due to the poor ionic and electrical conductivity of lithium peroxide.

To tackle this issue, the researchers could form one-dimensional amorphous lithium peroxide nanostructures through the use of a mesoporous carbon electrode, CMK-3. When compared against non-mesoporous electrodes, CMK-3 showed exceptionally lower overpotential, thereby enhancing the round-trip efficiency of lithium-oxygen batteries.

The amorphous lithium peroxide produced along the electrode has a small volume and a large surface area contacting electrolyte solution, which is presumably endowed with high conductivity to speed up the charging of the lithium-oxygen batteries.

This research underpins the feasibility of overcoming the fundamental limitations of lithium-oxygen batteries even without the addition of expensive catalytic materials, but rather by the re-configuration of the size and shape of the lithium peroxide.

The findings of this research were published in Nature Communications on February 14.

Figure 1. Transmission electron microscopy (TEM) images

Figure 2. Galvanostatic rate capability

Figure 3. Density functional calculation and Bader charge analysis

2018.05.30 View 10025

Fast-Charging Lithium-Oxygen Batteries

(Professor Hye Ryung Byon)

KAIST researchers have paved the way for fast-charging lithium-oxygen batteries.

Professor Hye Ryung Byon from the Department of Chemistry and Professor Yousung Jung from the Graduate School of EEWS led a joint research team to develop lithium-oxygen batteries exhibiting 80% round-trip efficiency even at high charging rates, solving the problem of existing lithium-oxygen batteries which generally showed drastically lower efficiencies when the charge current rate was increased.

This study exploits the size and shape lithium peroxide, a discharge product, which is known to cause the very problems mentioned above. In doing so, the researchers have lowered the overpotential, which is the difference between the thermodynamic reversible potential and the measured potential, and simultaneously improved battery efficiency. Of particular interest is the fact that these high-performance lithium-oxygen batteries can be realized without costly catalysts.

One remarkable property of lithium-oxygen batteries is that they can accommodate three to five times the energy density of lithium-ion batteries commonly used today. Therefore, lithium-oxygen batteries would render longer driving distance to electric vehicles or drones, which operate on the continued use of electrical power.

However, their weakness lies in that, during charge, the lithium peroxide remains undecomposed at low overpotential, resulting in eventually compromising the battery’s overall performance. This is due to the poor ionic and electrical conductivity of lithium peroxide.

To tackle this issue, the researchers could form one-dimensional amorphous lithium peroxide nanostructures through the use of a mesoporous carbon electrode, CMK-3. When compared against non-mesoporous electrodes, CMK-3 showed exceptionally lower overpotential, thereby enhancing the round-trip efficiency of lithium-oxygen batteries.

The amorphous lithium peroxide produced along the electrode has a small volume and a large surface area contacting electrolyte solution, which is presumably endowed with high conductivity to speed up the charging of the lithium-oxygen batteries.

This research underpins the feasibility of overcoming the fundamental limitations of lithium-oxygen batteries even without the addition of expensive catalytic materials, but rather by the re-configuration of the size and shape of the lithium peroxide.

The findings of this research were published in Nature Communications on February 14.

Figure 1. Transmission electron microscopy (TEM) images

Figure 2. Galvanostatic rate capability

Figure 3. Density functional calculation and Bader charge analysis

2018.05.30 View 10025 -

2018 KAIST Research Day Honors Outstanding Research Achievements

(KAIST President Sung-Chul Shin and Professor Jong-Hwan Kim) Professor Jong-Hwan Kim from the School of Electrical Engineering was recognized at the 2018 KAIST Research Day as the Research Grand Prize Awardee. The ten most distinguished research achievements of the past year were also recognized.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator was the highest over the past five years. The indicator combines the number of research contracts, IPR and royalty income.

During the May 25th ceremony, Professor Hyochoong Bang from the Department of Aerospace Engineering and Professor In so Kweon from the School of Electrical Engineering also won the Best Research Award prize.

This year, the Research Innovation Award went to Professor Dong Soo Han from the School of Computing. The Research Innovation Award combines scores in the categories of foreign patent registrations, contracts of technological transfer, and income from technology fees, technology consultations, and startups.

The Convergence Research Award was given to Professor Junmo Kim from the School of Electrical Engineering and Professor Hyun Myung from the Department of Civil & Environmental Engineering. The Convergence Research Award recognizes the most outstanding research team that created innovative research results over a one-year period.

President Sung-Chul Shin said, “KAIST has selected the ten most outstanding research achievements of 2017 conducted by our faculty and researchers. All of them demonstrated exceptional creativity, which opens new research paths in each field though their novelty, innovation, and impact.”

KAIST hosts Research Day every year to introduce major research performances at KAIST and share knowledge about the research and development.

During Research Day, KAIST also announced the ten most distinguished research achievements contributed by KAIST professors during the previous year. They are listed below.

▲ High-Speed Motion Core Technology for Magnetic Memory by Professor Kab-Jin Kim from the Department of Physics

▲ A Double Well Potential System by Professor Jaeyoung Byeon from the Department of Mathematical Sciences

▲ Cheap and Efficient Dehydrogenation of Alkanes by Professor Mu-Hyun Baik from the Department of Chemistry

▲ A Dynamic LPS Transfer Mechanism for Innate Immune Activation by Professor Ho Min Kim from the Graduate School of Medical Science and Engineering

▲ A Memristive Functional Device and Circuit on Fabric for Fibertronics by Professor Yang-Kyu Choi and Professor Sung-Yool Choi from the School of Electrical Engineering

▲ A Hippocampal Morphology Study Based on a Progressive Template Deformable Model by Professor Jinah Park from the School of Computing

▲ The Development of a 6-DOF Dynamic Response Measurement System for Civil Infrastructure Monitoring by Professor Hoon Sohn from the Department of Civil and Environmental Engineering

▲ Cooperative Tumour Cell Membrane Targeted Phototherapy by Professor Ji-Ho Park from the Department of Bio and Brain Engineering

▲ HUMICOTTA: A 3D-Printed Terracotta Humidifier by Professor Sangmin Bae from the Department of Industrial Design

▲ Ultrathin, Cross-Linked Ionic Polymer Thin Films by Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering

2018.05.28 View 11467

2018 KAIST Research Day Honors Outstanding Research Achievements

(KAIST President Sung-Chul Shin and Professor Jong-Hwan Kim) Professor Jong-Hwan Kim from the School of Electrical Engineering was recognized at the 2018 KAIST Research Day as the Research Grand Prize Awardee. The ten most distinguished research achievements of the past year were also recognized.

The Research Grand Prize recognizes the professor whose comprehensive research performance evaluation indicator was the highest over the past five years. The indicator combines the number of research contracts, IPR and royalty income.

During the May 25th ceremony, Professor Hyochoong Bang from the Department of Aerospace Engineering and Professor In so Kweon from the School of Electrical Engineering also won the Best Research Award prize.

This year, the Research Innovation Award went to Professor Dong Soo Han from the School of Computing. The Research Innovation Award combines scores in the categories of foreign patent registrations, contracts of technological transfer, and income from technology fees, technology consultations, and startups.

The Convergence Research Award was given to Professor Junmo Kim from the School of Electrical Engineering and Professor Hyun Myung from the Department of Civil & Environmental Engineering. The Convergence Research Award recognizes the most outstanding research team that created innovative research results over a one-year period.

President Sung-Chul Shin said, “KAIST has selected the ten most outstanding research achievements of 2017 conducted by our faculty and researchers. All of them demonstrated exceptional creativity, which opens new research paths in each field though their novelty, innovation, and impact.”

KAIST hosts Research Day every year to introduce major research performances at KAIST and share knowledge about the research and development.

During Research Day, KAIST also announced the ten most distinguished research achievements contributed by KAIST professors during the previous year. They are listed below.

▲ High-Speed Motion Core Technology for Magnetic Memory by Professor Kab-Jin Kim from the Department of Physics

▲ A Double Well Potential System by Professor Jaeyoung Byeon from the Department of Mathematical Sciences

▲ Cheap and Efficient Dehydrogenation of Alkanes by Professor Mu-Hyun Baik from the Department of Chemistry

▲ A Dynamic LPS Transfer Mechanism for Innate Immune Activation by Professor Ho Min Kim from the Graduate School of Medical Science and Engineering

▲ A Memristive Functional Device and Circuit on Fabric for Fibertronics by Professor Yang-Kyu Choi and Professor Sung-Yool Choi from the School of Electrical Engineering

▲ A Hippocampal Morphology Study Based on a Progressive Template Deformable Model by Professor Jinah Park from the School of Computing

▲ The Development of a 6-DOF Dynamic Response Measurement System for Civil Infrastructure Monitoring by Professor Hoon Sohn from the Department of Civil and Environmental Engineering

▲ Cooperative Tumour Cell Membrane Targeted Phototherapy by Professor Ji-Ho Park from the Department of Bio and Brain Engineering

▲ HUMICOTTA: A 3D-Printed Terracotta Humidifier by Professor Sangmin Bae from the Department of Industrial Design

▲ Ultrathin, Cross-Linked Ionic Polymer Thin Films by Professor Sung Gap Im from the Department of Chemical and Biomolecular Engineering

2018.05.28 View 11467