Electrical+Engineering

-

The 2015 Intelligent SoC Robot War Finals

The final round of the 2015 Intelligent SoC (System on Chip) Robot War took place from October 29, 2015 to November 1, 2015 at Kintex in Ilsan, Korea.

A “SoC robot” refers to an intelligent robot capable of autonomous object recognition and decision making by employing advanced semiconductor and information technology.

First hosted in 2002, the Intelligent SoC Robot War cultivates top talents in the field of semiconductors and seeks to revitalize Korea’s information technology (IT) and semiconductor industries.

The event consists of two competitions: HURO and the Tae Kwon Do Robot.

In the HURO competition, participating robots sequentially complete eight assignments without outside controls. Whichever robot finishes the highest number of tasks and spends the shortest amount of time for the completion of assignments wins the competition.

At the HURO competition, a SoC robot overcomes obstacles.

The Tae Kwon Do Robot competition includes Korea’s traditional martial arts into robotics. Here, the winner is selected by sparring between a pair of competitors. The camera attached to the robot’s head recognizes the position of the opponent and the distance between them. From that, the robot takes actions such as punching or kicking.

Two robots are vying for the title of the Tae Kwon Do Robot.

This year, 570 people from 104 teams from all over the nation applied, and after preliminaries, 26 teams entered the finals.

The winners of the HURO and Tae Kwon Do Robot competitions receive awards from the president and prime minister of Korea, respectively.

The Chairman of the Intelligent SoC Robot War, Professor Hoi-Jun Yoo of Electrical Engineering Department at KAIST, said,

“Korea’s strength in semiconductors and information technology can serve as a great potential to advance the development of intelligent robots. We hope that our experiences in this competition will allow Korea to excel in this field.”

2015.11.01 View 10281

The 2015 Intelligent SoC Robot War Finals

The final round of the 2015 Intelligent SoC (System on Chip) Robot War took place from October 29, 2015 to November 1, 2015 at Kintex in Ilsan, Korea.

A “SoC robot” refers to an intelligent robot capable of autonomous object recognition and decision making by employing advanced semiconductor and information technology.

First hosted in 2002, the Intelligent SoC Robot War cultivates top talents in the field of semiconductors and seeks to revitalize Korea’s information technology (IT) and semiconductor industries.

The event consists of two competitions: HURO and the Tae Kwon Do Robot.

In the HURO competition, participating robots sequentially complete eight assignments without outside controls. Whichever robot finishes the highest number of tasks and spends the shortest amount of time for the completion of assignments wins the competition.

At the HURO competition, a SoC robot overcomes obstacles.

The Tae Kwon Do Robot competition includes Korea’s traditional martial arts into robotics. Here, the winner is selected by sparring between a pair of competitors. The camera attached to the robot’s head recognizes the position of the opponent and the distance between them. From that, the robot takes actions such as punching or kicking.

Two robots are vying for the title of the Tae Kwon Do Robot.

This year, 570 people from 104 teams from all over the nation applied, and after preliminaries, 26 teams entered the finals.

The winners of the HURO and Tae Kwon Do Robot competitions receive awards from the president and prime minister of Korea, respectively.

The Chairman of the Intelligent SoC Robot War, Professor Hoi-Jun Yoo of Electrical Engineering Department at KAIST, said,

“Korea’s strength in semiconductors and information technology can serve as a great potential to advance the development of intelligent robots. We hope that our experiences in this competition will allow Korea to excel in this field.”

2015.11.01 View 10281 -

KAIST and Chongqing University of Technology in China Open an International Program

With the help of KAIST, Chongqing University of Technology (CQUT) in China established an electrical engineering and computer science program and admitted their first 66 freshmen this fall semester.

The joint program was created to foster skilled engineers in the fields of electrical engineering and computer science, which are necessary for the development of the Korean and Chinese Industrial Complex located in Chongqing City.

KAIST has provided CQUT with a majority of the program’s curricula currently offered to its students in Daejeon, Korea.

Under the jointly administered program, KAIST takes on education and research while CQUT is responsible for student selection and administration.

KAIST has dispatched eight professors to teach the related fields in English, and 17 CQUT professors will teach the rest of the curricula.

In August 2014, KAIST and CQUT singed a cooperation agreement for education and research exchange and created the CQUT-KAIST Education Cooperation Center, which is headed by Professor Young-Nam Han of the Electrical Engineering Department at KAIST.

The two universities will expand their collaboration to include graduate programs by 2016.

In the picture below, President Steve Kang of KAIST (right) shakes hands with President Shi Xiaohui of Chongqing University of Technology (left).

2015.09.17 View 12948

KAIST and Chongqing University of Technology in China Open an International Program

With the help of KAIST, Chongqing University of Technology (CQUT) in China established an electrical engineering and computer science program and admitted their first 66 freshmen this fall semester.

The joint program was created to foster skilled engineers in the fields of electrical engineering and computer science, which are necessary for the development of the Korean and Chinese Industrial Complex located in Chongqing City.

KAIST has provided CQUT with a majority of the program’s curricula currently offered to its students in Daejeon, Korea.

Under the jointly administered program, KAIST takes on education and research while CQUT is responsible for student selection and administration.

KAIST has dispatched eight professors to teach the related fields in English, and 17 CQUT professors will teach the rest of the curricula.

In August 2014, KAIST and CQUT singed a cooperation agreement for education and research exchange and created the CQUT-KAIST Education Cooperation Center, which is headed by Professor Young-Nam Han of the Electrical Engineering Department at KAIST.

The two universities will expand their collaboration to include graduate programs by 2016.

In the picture below, President Steve Kang of KAIST (right) shakes hands with President Shi Xiaohui of Chongqing University of Technology (left).

2015.09.17 View 12948 -

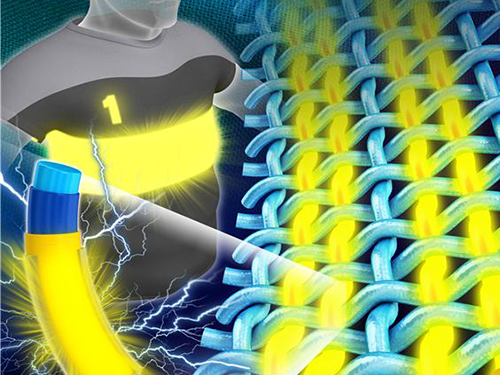

KAIST Develops Fiber-Like Light-Emitting Diodes for Wearable Displays

Professor Kyung-Cheol Choi and his research team from the School of Electrical Engineering at KAIST have developed fiber-like light-emitting diodes (LEDs), which can be applied in wearable displays. The research findings were published online in the July 14th issue of Advanced Electronic Materials.

Traditional wearable displays were manufactured on a hard substrate, which was later attached to the surface of clothes. This technique had limited applications for wearable displays because they were inflexible and ignored the characteristics of fabric.

To solve this problem, the research team discarded the notion of creating light-emitting diode displays on a plane. Instead, they focused on fibers, a component of fabrics, and developed a fiber-like LED that shared the characteristics of both fabrics and displays.

The essence of this technology, the dip-coating process, is to immerse and extract a three dimensional (3-D) rod (a polyethylene terephthalate fiber) from a solution, which functions like thread. Then, the regular levels of organic materials are formed as layers on the thread.

The dip-coating process allows the layers of organic materials to be easily created on the fibers with a 3-D cylindrical structure, which had been difficult in existing processes such as heat-coating process. By controlling of the withdrawal rate of the fiber, the coating's thickness can also be adjusted to the hundreds of thousandths of a nanometer.

The researchers said that this technology would accelerate the commercialization of fiber-based wearable displays because it offers low-cost mass production using roll-to-roll processing, a technology applied to create electronic devices on a roll of flexible plastics or metal foils.

Professor Choi said, “Our research will become a core technology in developing light emitting diodes on fibers, which are fundamental elements of fabrics. We hope we can lower the barrier of wearable displays entering the market.”

The lead author of the published paper, Seon-Il Kwon, added, “This technology will eventually allow the production of wearable displays to be as easy as making clothes.”

Picture 1: The Next Generation Wearable Display Using Fiber-Based Light-Emitting Diodes

Picture 2: Dip-Coating Process to Create Fiber-Based Light-Emitting Diodes

Picture 3: Fiber-Based Light-Emitting Diodes

2015.08.11 View 14019

KAIST Develops Fiber-Like Light-Emitting Diodes for Wearable Displays

Professor Kyung-Cheol Choi and his research team from the School of Electrical Engineering at KAIST have developed fiber-like light-emitting diodes (LEDs), which can be applied in wearable displays. The research findings were published online in the July 14th issue of Advanced Electronic Materials.

Traditional wearable displays were manufactured on a hard substrate, which was later attached to the surface of clothes. This technique had limited applications for wearable displays because they were inflexible and ignored the characteristics of fabric.

To solve this problem, the research team discarded the notion of creating light-emitting diode displays on a plane. Instead, they focused on fibers, a component of fabrics, and developed a fiber-like LED that shared the characteristics of both fabrics and displays.

The essence of this technology, the dip-coating process, is to immerse and extract a three dimensional (3-D) rod (a polyethylene terephthalate fiber) from a solution, which functions like thread. Then, the regular levels of organic materials are formed as layers on the thread.

The dip-coating process allows the layers of organic materials to be easily created on the fibers with a 3-D cylindrical structure, which had been difficult in existing processes such as heat-coating process. By controlling of the withdrawal rate of the fiber, the coating's thickness can also be adjusted to the hundreds of thousandths of a nanometer.

The researchers said that this technology would accelerate the commercialization of fiber-based wearable displays because it offers low-cost mass production using roll-to-roll processing, a technology applied to create electronic devices on a roll of flexible plastics or metal foils.

Professor Choi said, “Our research will become a core technology in developing light emitting diodes on fibers, which are fundamental elements of fabrics. We hope we can lower the barrier of wearable displays entering the market.”

The lead author of the published paper, Seon-Il Kwon, added, “This technology will eventually allow the production of wearable displays to be as easy as making clothes.”

Picture 1: The Next Generation Wearable Display Using Fiber-Based Light-Emitting Diodes

Picture 2: Dip-Coating Process to Create Fiber-Based Light-Emitting Diodes

Picture 3: Fiber-Based Light-Emitting Diodes

2015.08.11 View 14019 -

KAIST Operates a Summer School with Imperial College London

KAIST and Imperial College London jointly hosted a summer school on the KAIST campus on July 14-17, 2015. Twenty-five students from both universities, 11 from KAIST and 14 from Imperial College, participated in the summer program.

KAIST and Imperial College agreed to hold academic and research exchange programs in 2013; this year’s summer school represented the first effort.

Participants were divided into a few cohorts of four or five students. They conducted a series of activities to implement joint research projects involving team building, networking, joint study, discussions, and presentations.

Among the projects the summer school ran, Professor Hoi-Jun Yoo of the Electrical Engineering Department at KAIST was invited to teach students about the mobile healthcare system, Dr. M, that he had developed.

Sung-Hyon Myaeng, Associate Vice President of the International Affairs Office, KAIST, said, “This summer school is yet another example of KAIST’s ongoing efforts to make the campus more global and to interact actively with members of the international community.”

2015.07.29 View 9427

KAIST Operates a Summer School with Imperial College London

KAIST and Imperial College London jointly hosted a summer school on the KAIST campus on July 14-17, 2015. Twenty-five students from both universities, 11 from KAIST and 14 from Imperial College, participated in the summer program.

KAIST and Imperial College agreed to hold academic and research exchange programs in 2013; this year’s summer school represented the first effort.

Participants were divided into a few cohorts of four or five students. They conducted a series of activities to implement joint research projects involving team building, networking, joint study, discussions, and presentations.

Among the projects the summer school ran, Professor Hoi-Jun Yoo of the Electrical Engineering Department at KAIST was invited to teach students about the mobile healthcare system, Dr. M, that he had developed.

Sung-Hyon Myaeng, Associate Vice President of the International Affairs Office, KAIST, said, “This summer school is yet another example of KAIST’s ongoing efforts to make the campus more global and to interact actively with members of the international community.”

2015.07.29 View 9427 -

World Renowned Wireless Technology Experts Gathered in KAIST

KAIST hosted the 2015 IEEE WoW from June 5 to 6, 2015

Wireless power transfer technologies, such as wireless electric vehicles, trains and batteries, are increasingly in use. A conference, The 2015 IEEE WoW (Workshop on Wireless Power), was held in KI Building for two days starting June 5, 2015 to exchange ideas on the new trends and issues of the world wireless power technology.

The wireless power conference hosted by Institute of Electrical and Electronics Engineers (IEEE), IEEE WoW, was sponsored by its societies, PELS, IAS, IES, VTS, MAG, and PES.

This year’s conference took place in Korea for the first time and was titled “IEEE PELS Workshop on Emerging Technologies: Wireless Power.” The event was attended by around 200 experts in wireless power from 15 countries to discuss the international standards and current trends.

Keynote speakers were President Don Tan of IEEE; Professor Grant Covic of the University of Auckland; Andrew Daga, the CEO at Momentum Dynamics Corporation; Professor Ron Hui of the City University of Hong Kong; and Jung Goo Cho, the CEO of Green Power Technologies.

The forum included plenary speaking sessions on “The Futures of EV and Power Electronics,” “Development of IPT at the University of Auckland,” “Interoperable Solution for Wireless EV Charging,” “Development of IPT for Factory Automation,” “Commercialization of High Power WPT,” and “WPT: From Directional Power to Omni-directional Power.”

Notably, KAIST Professor Dong-Ho Cho, responsible for KAIST’s On-Line Electric Vehicle (OLEV) development, spoke on “The Development of Shaped Magnetic Field Systems for EVs and Trains” to introduce the KAIST OLEV bus and OLEV trains developed in cooperation with Korea Railroad Research Institute.

The Dialog Sessions on “The Futures of Wireless Electric Vehicles” were led by John M. Miller of JNJ Miller and “Road Charged EV and WPT Regulation and Standard for EV in Japan” by Yoichi Hori of University of Tokyo.

The General Chair of this year’s IEEE WoW, KAIST Professor Chun T. Rim said, “This forum serves a great assistance to the industry using wireless power technology in areas such as smartphones, home appliances, Internet of Things, and wearable devices.”

2015.05.29 View 11122

World Renowned Wireless Technology Experts Gathered in KAIST

KAIST hosted the 2015 IEEE WoW from June 5 to 6, 2015

Wireless power transfer technologies, such as wireless electric vehicles, trains and batteries, are increasingly in use. A conference, The 2015 IEEE WoW (Workshop on Wireless Power), was held in KI Building for two days starting June 5, 2015 to exchange ideas on the new trends and issues of the world wireless power technology.

The wireless power conference hosted by Institute of Electrical and Electronics Engineers (IEEE), IEEE WoW, was sponsored by its societies, PELS, IAS, IES, VTS, MAG, and PES.

This year’s conference took place in Korea for the first time and was titled “IEEE PELS Workshop on Emerging Technologies: Wireless Power.” The event was attended by around 200 experts in wireless power from 15 countries to discuss the international standards and current trends.

Keynote speakers were President Don Tan of IEEE; Professor Grant Covic of the University of Auckland; Andrew Daga, the CEO at Momentum Dynamics Corporation; Professor Ron Hui of the City University of Hong Kong; and Jung Goo Cho, the CEO of Green Power Technologies.

The forum included plenary speaking sessions on “The Futures of EV and Power Electronics,” “Development of IPT at the University of Auckland,” “Interoperable Solution for Wireless EV Charging,” “Development of IPT for Factory Automation,” “Commercialization of High Power WPT,” and “WPT: From Directional Power to Omni-directional Power.”

Notably, KAIST Professor Dong-Ho Cho, responsible for KAIST’s On-Line Electric Vehicle (OLEV) development, spoke on “The Development of Shaped Magnetic Field Systems for EVs and Trains” to introduce the KAIST OLEV bus and OLEV trains developed in cooperation with Korea Railroad Research Institute.

The Dialog Sessions on “The Futures of Wireless Electric Vehicles” were led by John M. Miller of JNJ Miller and “Road Charged EV and WPT Regulation and Standard for EV in Japan” by Yoichi Hori of University of Tokyo.

The General Chair of this year’s IEEE WoW, KAIST Professor Chun T. Rim said, “This forum serves a great assistance to the industry using wireless power technology in areas such as smartphones, home appliances, Internet of Things, and wearable devices.”

2015.05.29 View 11122 -

KAIST Introduces New UI for K-Glass 2

A newly developed user interface, the “i-Mouse,” in the K-Glass 2 tracks the user’s gaze and connects the device to the Internet through blinking eyes such as winks. This low-power interface provides smart glasses with an excellent user experience, with a long-lasting battery and augmented reality.

Smart glasses are wearable computers that will likely lead to the growth of the Internet of Things. Currently available smart glasses, however, reveal a set of problems for commercialization, such as short battery life and low energy efficiency. In addition, glasses that use voice commands have raised the issue of privacy concerns.

A research team led by Professor Hoi-Jun Yoo of the Electrical Engineering Department at the Korea Advanced Institute of Science and Technology (KAIST) has recently developed an upgraded model of the K-Glass (http://www.eurekalert.org/pub_releases/2014-02/tkai-kdl021714.php) called “K-Glass 2.”

K-Glass 2 detects users’ eye movements to point the cursor to recognize computer icons or objects in the Internet, and uses winks for commands. The researchers call this interface the “i-Mouse,” which removes the need to use hands or voice to control a mouse or touchpad. Like its predecessor, K-Glass 2 also employs augmented reality, displaying in real time the relevant, complementary information in the form of text, 3D graphics, images, and audio over the target objects selected by users.

The research results were presented, and K-Glass 2’s successful operation was demonstrated on-site to the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Solid-State Circuits Conference (ISSCC) held on February 23-25, 2015 in San Francisco. The title of the paper was “A 2.71nJ/Pixel 3D-Stacked Gaze-Activated Object Recognition System for Low-power Mobile HMD Applications” (http://ieeexplore.ieee.org/Xplore/home.jsp).

The i-Mouse is a new user interface for smart glasses in which the gaze-image sensor (GIS) and object recognition processor (ORP) are stacked vertically to form a small chip. When three infrared LEDs (light-emitting diodes) built into the K-Glass 2 are projected into the user’s eyes, GIS recognizes their focal point and estimates the possible locations of the gaze as the user glances over the display screen. Then the electro-oculography sensor embedded on the nose pads reads the user’s eyelid movements, for example, winks, to click the selection. It is worth noting that the ORP is wired to perform only within the selected region of interest (ROI) by users. This results in a significant saving of battery life. Compared to the previous ORP chips, this chip uses 3.4 times less power, consuming on average 75 milliwatts (mW), thereby helping K-Glass 2 to run for almost 24 hours on a single charge.

Professor Yoo said, “The smart glass industry will surely grow as we see the Internet of Things becomes commonplace in the future. In order to expedite the commercial use of smart glasses, improving the user interface (UI) and the user experience (UX) are just as important as the development of compact-size, low-power wearable platforms with high energy efficiency. We have demonstrated such advancement through our K-Glass 2. Using the i-Mouse, K-Glass 2 can provide complicated augmented reality with low power through eye clicking.”

Professor Yoo and his doctoral student, Injoon Hong, conducted this research under the sponsorship of the Brain-mimicking Artificial Intelligence Many-core Processor project by the Ministry of Science, ICT and Future Planning in the Republic of Korea.

Youtube Link:

https://www.youtube.com/watchv=JaYtYK9E7p0&list=PLXmuftxI6pTW2jdIf69teY7QDXdI3Ougr

Picture 1: K-Glass 2

K-Glass 2 can detect eye movements and click computer icons via users’ winking.

Picture 2: Object Recognition Processor Chip

This picture shows a gaze-activated object-recognition system.

Picture 3: Augmented Reality Integrated into K-Glass 2

Users receive additional visual information overlaid on the objects they select.

2015.03.13 View 17628

KAIST Introduces New UI for K-Glass 2

A newly developed user interface, the “i-Mouse,” in the K-Glass 2 tracks the user’s gaze and connects the device to the Internet through blinking eyes such as winks. This low-power interface provides smart glasses with an excellent user experience, with a long-lasting battery and augmented reality.

Smart glasses are wearable computers that will likely lead to the growth of the Internet of Things. Currently available smart glasses, however, reveal a set of problems for commercialization, such as short battery life and low energy efficiency. In addition, glasses that use voice commands have raised the issue of privacy concerns.

A research team led by Professor Hoi-Jun Yoo of the Electrical Engineering Department at the Korea Advanced Institute of Science and Technology (KAIST) has recently developed an upgraded model of the K-Glass (http://www.eurekalert.org/pub_releases/2014-02/tkai-kdl021714.php) called “K-Glass 2.”

K-Glass 2 detects users’ eye movements to point the cursor to recognize computer icons or objects in the Internet, and uses winks for commands. The researchers call this interface the “i-Mouse,” which removes the need to use hands or voice to control a mouse or touchpad. Like its predecessor, K-Glass 2 also employs augmented reality, displaying in real time the relevant, complementary information in the form of text, 3D graphics, images, and audio over the target objects selected by users.

The research results were presented, and K-Glass 2’s successful operation was demonstrated on-site to the 2015 Institute of Electrical and Electronics Engineers (IEEE) International Solid-State Circuits Conference (ISSCC) held on February 23-25, 2015 in San Francisco. The title of the paper was “A 2.71nJ/Pixel 3D-Stacked Gaze-Activated Object Recognition System for Low-power Mobile HMD Applications” (http://ieeexplore.ieee.org/Xplore/home.jsp).

The i-Mouse is a new user interface for smart glasses in which the gaze-image sensor (GIS) and object recognition processor (ORP) are stacked vertically to form a small chip. When three infrared LEDs (light-emitting diodes) built into the K-Glass 2 are projected into the user’s eyes, GIS recognizes their focal point and estimates the possible locations of the gaze as the user glances over the display screen. Then the electro-oculography sensor embedded on the nose pads reads the user’s eyelid movements, for example, winks, to click the selection. It is worth noting that the ORP is wired to perform only within the selected region of interest (ROI) by users. This results in a significant saving of battery life. Compared to the previous ORP chips, this chip uses 3.4 times less power, consuming on average 75 milliwatts (mW), thereby helping K-Glass 2 to run for almost 24 hours on a single charge.

Professor Yoo said, “The smart glass industry will surely grow as we see the Internet of Things becomes commonplace in the future. In order to expedite the commercial use of smart glasses, improving the user interface (UI) and the user experience (UX) are just as important as the development of compact-size, low-power wearable platforms with high energy efficiency. We have demonstrated such advancement through our K-Glass 2. Using the i-Mouse, K-Glass 2 can provide complicated augmented reality with low power through eye clicking.”

Professor Yoo and his doctoral student, Injoon Hong, conducted this research under the sponsorship of the Brain-mimicking Artificial Intelligence Many-core Processor project by the Ministry of Science, ICT and Future Planning in the Republic of Korea.

Youtube Link:

https://www.youtube.com/watchv=JaYtYK9E7p0&list=PLXmuftxI6pTW2jdIf69teY7QDXdI3Ougr

Picture 1: K-Glass 2

K-Glass 2 can detect eye movements and click computer icons via users’ winking.

Picture 2: Object Recognition Processor Chip

This picture shows a gaze-activated object-recognition system.

Picture 3: Augmented Reality Integrated into K-Glass 2

Users receive additional visual information overlaid on the objects they select.

2015.03.13 View 17628 -

News Article: Flexible, High-performance Nonvolatile Memory Developed with SONOS Technology

Professor Yang-Kyu Choi of KAIST’s Department of Electrical Engineering and his team presented a research paper entitled “Flexible High-performance Nonvolatile Memory by Transferring GAA Silicon Nanowire SONOS onto a Plastic Substrate” at the conference of the International Electron Devices Meeting that took place on December 15-17, 2014 in San Francisco.

The Electronic Engineering Journal (http://www.eejournal.com/) recently posted an article on the paper:

Electronic Engineering Journal, February 2, 2015

“A Flat-Earth Memory”

Another Way to Make the Brittle Flexible

http://www.techfocusmedia.net/archives/articles/20150202-flexiblegaa/?printView=true

2015.02.03 View 8685

News Article: Flexible, High-performance Nonvolatile Memory Developed with SONOS Technology

Professor Yang-Kyu Choi of KAIST’s Department of Electrical Engineering and his team presented a research paper entitled “Flexible High-performance Nonvolatile Memory by Transferring GAA Silicon Nanowire SONOS onto a Plastic Substrate” at the conference of the International Electron Devices Meeting that took place on December 15-17, 2014 in San Francisco.

The Electronic Engineering Journal (http://www.eejournal.com/) recently posted an article on the paper:

Electronic Engineering Journal, February 2, 2015

“A Flat-Earth Memory”

Another Way to Make the Brittle Flexible

http://www.techfocusmedia.net/archives/articles/20150202-flexiblegaa/?printView=true

2015.02.03 View 8685 -

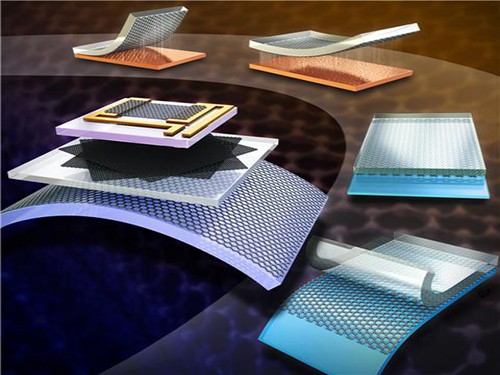

KAIST Develops a Method to Transfer Graphene by Stamping

Professor Sung-Yool Choi’s research team from KAIST's Department of Electrical Engineering has developed a technique that can produce a single-layer graphene from a metal etching. Through this, transferring a graphene layer onto a circuit board can be done as easily as stamping a seal on paper.

The research findings were published in the January 14th issue of Small as the lead article.

This technology will allow different types of wafer transfer methods such as transfer onto a surface of a device or a curved surface, and large surface transfer onto a 4 inch wafer. It will be applied in the field of wearable smart gadgets through commercialization of graphene electronic devices.

The traditional method used to transfer graphene onto a circuit board is a wet transfer. However, it has some drawbacks as the graphene layer can be damaged or contaminated during the transfer process from residue from the metal etching. This may affect the electrical properties of the transferred graphene.

After a graphene growth substrate formed on a catalytic metal substrate is pretreated in an aqueous poly vinyl alcohol (PVA) solution, a PVA film forms on the pretreated substrate. The substrate and the graphene layers bond strongly. The graphene is lifted from the growth substrate by means of an elastomeric stamp.

The delaminated graphene layer is isolated state from the elastomeric stamp and thus can be freely transferred onto a circuit board. As the catalytic metal substrate can be reused and does not contain harmful chemical substances, such transfer method is very eco-friendly.

Professor Choi said, “As the new graphene transfer method has a wide range of applications and allows a large surface transfer, it will contribute to the commercialization of graphene electronic devices.” He added that “because this technique has a high degree of freedom in transfer process, it has a variety of usages for graphene and 2 dimensional nano-devices.”

This research was sponsored by the Ministry of Science, ICT and Future Planning, the Republic of Korea.

Figure 1. Cover photo of the journal Small which illustrates the research findings

Figure 2. Above view of Graphene layer transferred through the new method

Figure 3. Large surface transfer of Graphene

2015.01.23 View 12616

KAIST Develops a Method to Transfer Graphene by Stamping

Professor Sung-Yool Choi’s research team from KAIST's Department of Electrical Engineering has developed a technique that can produce a single-layer graphene from a metal etching. Through this, transferring a graphene layer onto a circuit board can be done as easily as stamping a seal on paper.

The research findings were published in the January 14th issue of Small as the lead article.

This technology will allow different types of wafer transfer methods such as transfer onto a surface of a device or a curved surface, and large surface transfer onto a 4 inch wafer. It will be applied in the field of wearable smart gadgets through commercialization of graphene electronic devices.

The traditional method used to transfer graphene onto a circuit board is a wet transfer. However, it has some drawbacks as the graphene layer can be damaged or contaminated during the transfer process from residue from the metal etching. This may affect the electrical properties of the transferred graphene.

After a graphene growth substrate formed on a catalytic metal substrate is pretreated in an aqueous poly vinyl alcohol (PVA) solution, a PVA film forms on the pretreated substrate. The substrate and the graphene layers bond strongly. The graphene is lifted from the growth substrate by means of an elastomeric stamp.

The delaminated graphene layer is isolated state from the elastomeric stamp and thus can be freely transferred onto a circuit board. As the catalytic metal substrate can be reused and does not contain harmful chemical substances, such transfer method is very eco-friendly.

Professor Choi said, “As the new graphene transfer method has a wide range of applications and allows a large surface transfer, it will contribute to the commercialization of graphene electronic devices.” He added that “because this technique has a high degree of freedom in transfer process, it has a variety of usages for graphene and 2 dimensional nano-devices.”

This research was sponsored by the Ministry of Science, ICT and Future Planning, the Republic of Korea.

Figure 1. Cover photo of the journal Small which illustrates the research findings

Figure 2. Above view of Graphene layer transferred through the new method

Figure 3. Large surface transfer of Graphene

2015.01.23 View 12616 -

The 2014 Wearable Computer Competition Takes Place at KAIST

“This is a smart wig for patients who are reluctant to go outdoors because their hair is falling out from cancer treatment.”

A graduate student from Sungkyunkwan University, Jee-Hoon Lee enthusiastically explains his project at the KAIST KI Building where the 2014 Wearable Computer Competition was held. He said, “The sensor embedded inside the wig monitors the heart rate and the body temperature, and during an emergency, the device warns the patient about the situation. The product emphasizes two aspects; it notifies the patient in emergency situations, and it encourages patients to perform outdoor activities by enhancing their looks.”

The the tenth anniversary meeting of the 2014 Wearable Computer Competition took place at the KAIST campus on November 13-14, 2014.

A wearable computer is a mobile device designed to be put on the body or clothes so that a user can comfortably use it while walking. Recently, these devices that are able to support versatile internet-based services through smartphones are receiving a great deal of attention.

Wearable devices have been employed in two categorizes: health checks and information-entertainment. In this year’s competition, six healthcare products and nine information-entertainment products were exhibited.

Among these products, participants favored a smart helmet for motorcycle drivers. The driver can see through a rear camera with a navigation screen of the smartphone and text messages through the screen installed in the front glass of the helmet. Another product included a uniform that can control presentation slides by means of motion detection and voice recognition technology. Yet another popular device offered an insole to guide travelers to their destination with the help of motion sensors.

The chairman of the competition, Professor Hoi-Jun Yoo from the Department of Electrical Engineering at KAIST said, “Wearable devices such as smart watches, glasses, and clothes are gaining interest these days. Through this event, people will have a chance to look at the creativity of our students through the display of their wearable devices. In turn, these devices will advance computer technology.”

The third annual wearable computer workshop on convergence technology of wearable computers followed the competition. In the workshop, experts from leading information technology companies such as Samsung Electronics, LG Electronics, and KT Corporation addressed the convergence technology of wearable computers and trends in the field.

2014.11.19 View 11975

The 2014 Wearable Computer Competition Takes Place at KAIST

“This is a smart wig for patients who are reluctant to go outdoors because their hair is falling out from cancer treatment.”

A graduate student from Sungkyunkwan University, Jee-Hoon Lee enthusiastically explains his project at the KAIST KI Building where the 2014 Wearable Computer Competition was held. He said, “The sensor embedded inside the wig monitors the heart rate and the body temperature, and during an emergency, the device warns the patient about the situation. The product emphasizes two aspects; it notifies the patient in emergency situations, and it encourages patients to perform outdoor activities by enhancing their looks.”

The the tenth anniversary meeting of the 2014 Wearable Computer Competition took place at the KAIST campus on November 13-14, 2014.

A wearable computer is a mobile device designed to be put on the body or clothes so that a user can comfortably use it while walking. Recently, these devices that are able to support versatile internet-based services through smartphones are receiving a great deal of attention.

Wearable devices have been employed in two categorizes: health checks and information-entertainment. In this year’s competition, six healthcare products and nine information-entertainment products were exhibited.

Among these products, participants favored a smart helmet for motorcycle drivers. The driver can see through a rear camera with a navigation screen of the smartphone and text messages through the screen installed in the front glass of the helmet. Another product included a uniform that can control presentation slides by means of motion detection and voice recognition technology. Yet another popular device offered an insole to guide travelers to their destination with the help of motion sensors.

The chairman of the competition, Professor Hoi-Jun Yoo from the Department of Electrical Engineering at KAIST said, “Wearable devices such as smart watches, glasses, and clothes are gaining interest these days. Through this event, people will have a chance to look at the creativity of our students through the display of their wearable devices. In turn, these devices will advance computer technology.”

The third annual wearable computer workshop on convergence technology of wearable computers followed the competition. In the workshop, experts from leading information technology companies such as Samsung Electronics, LG Electronics, and KT Corporation addressed the convergence technology of wearable computers and trends in the field.

2014.11.19 View 11975 -

The 2014 SoC Robot Competition Took Place

Professor Hoi-Jun Yoo of the Department of Electrical Engineering at KAIST and his research team hosted a competition for miniature robots with artificial intelligence at KINTEX in Ilsan, Korea, on October 23-26, 2014.

The competition, called the 2014 SoC Robot War, showed the latest developments of semiconductor and robot technology through the robots’ presentations of the Korean martial art, Taekwondo, and hurdles race. SoC is a system on ship, an integrated circuit that holds all components of a computer or other electronic systems in a single chip. SoC robots are equipped with an artificial intelligence system, and therefore, can recognize things on their own or respond automatically to environmental changes. SoC robots are developed with the integration of semiconductor technology and robotics engineering.

Marking the thirteenth competition this year since its inception, the Robot War featured two competitions between HURO and Taekwon Robots. Under the HURO competition, participating robots were required to run a hurdle race, pass through barricades, and cross a bridge. The winning team received an award from the president of the Republic of Korea. Robots participating in the Taekwon Robot competition performed some of the main movements of Taekwondo such as front and side kicks and fist techniques. The winning team received an award from the prime minster of the Republic of Korea.

A total of 105 teams with 530 students and researchers from different universities across the country participated in preliminaries, and 30 teams qualified for the final competition.

2014.10.27 View 9872

The 2014 SoC Robot Competition Took Place

Professor Hoi-Jun Yoo of the Department of Electrical Engineering at KAIST and his research team hosted a competition for miniature robots with artificial intelligence at KINTEX in Ilsan, Korea, on October 23-26, 2014.

The competition, called the 2014 SoC Robot War, showed the latest developments of semiconductor and robot technology through the robots’ presentations of the Korean martial art, Taekwondo, and hurdles race. SoC is a system on ship, an integrated circuit that holds all components of a computer or other electronic systems in a single chip. SoC robots are equipped with an artificial intelligence system, and therefore, can recognize things on their own or respond automatically to environmental changes. SoC robots are developed with the integration of semiconductor technology and robotics engineering.

Marking the thirteenth competition this year since its inception, the Robot War featured two competitions between HURO and Taekwon Robots. Under the HURO competition, participating robots were required to run a hurdle race, pass through barricades, and cross a bridge. The winning team received an award from the president of the Republic of Korea. Robots participating in the Taekwon Robot competition performed some of the main movements of Taekwondo such as front and side kicks and fist techniques. The winning team received an award from the prime minster of the Republic of Korea.

A total of 105 teams with 530 students and researchers from different universities across the country participated in preliminaries, and 30 teams qualified for the final competition.

2014.10.27 View 9872 -

Workshop on Wearable Healthcare Takes Place on July 15, 2014

A workshop on wearable healthcare was held at KAIST campus on July 15, 2014.

In recent years, wearable healthcare has received much attention as an emerging technology that will have a great impact on our society.

At the workshop, participants from academia and industry reviewed the Korean healthcare industry and discussed issues related to the development of a wearable healthcare industry in Korea, while capitalizing on the nation’s strength in information and communications.

Professor Hoi-Jun Yoo of Electrical Engineering at KAIST, the chairman of the organizing committee of the workshop, presented a keynote speech entitled “The Current State and Future of Wearable Healthcare,” arguing that the wearable healthcare industry developed through the Internet of things and big data would become the next-generation growth engine for Korea.

Other key presentations were “Smart Glasses and Micro Display Semiconductor Technology” by Bo-Eun Kim, Chief Executive Officer of Raon-Tech, Inc., “Wearable Device: A Comprehensive Approach” by Min-Kyu Je, a professor of Daegu Gyeongbuk Institute of Science and Technology, and “Microwave Imaging System for Breast Cancer Detection” by Seung-Joon Lee, a professor of Ewha Woman’s University.

Professor Yoo said, “We hope that the workshop will provide good momentum for participants to evaluate the Korean healthcare industry in the context of the Internet of things, information and communications technology, and medical technology as well as offering practical solutions to nurture the indigenous wearable healthcare industry in Korea.”

2014.07.15 View 9709

Workshop on Wearable Healthcare Takes Place on July 15, 2014

A workshop on wearable healthcare was held at KAIST campus on July 15, 2014.

In recent years, wearable healthcare has received much attention as an emerging technology that will have a great impact on our society.

At the workshop, participants from academia and industry reviewed the Korean healthcare industry and discussed issues related to the development of a wearable healthcare industry in Korea, while capitalizing on the nation’s strength in information and communications.

Professor Hoi-Jun Yoo of Electrical Engineering at KAIST, the chairman of the organizing committee of the workshop, presented a keynote speech entitled “The Current State and Future of Wearable Healthcare,” arguing that the wearable healthcare industry developed through the Internet of things and big data would become the next-generation growth engine for Korea.

Other key presentations were “Smart Glasses and Micro Display Semiconductor Technology” by Bo-Eun Kim, Chief Executive Officer of Raon-Tech, Inc., “Wearable Device: A Comprehensive Approach” by Min-Kyu Je, a professor of Daegu Gyeongbuk Institute of Science and Technology, and “Microwave Imaging System for Breast Cancer Detection” by Seung-Joon Lee, a professor of Ewha Woman’s University.

Professor Yoo said, “We hope that the workshop will provide good momentum for participants to evaluate the Korean healthcare industry in the context of the Internet of things, information and communications technology, and medical technology as well as offering practical solutions to nurture the indigenous wearable healthcare industry in Korea.”

2014.07.15 View 9709 -

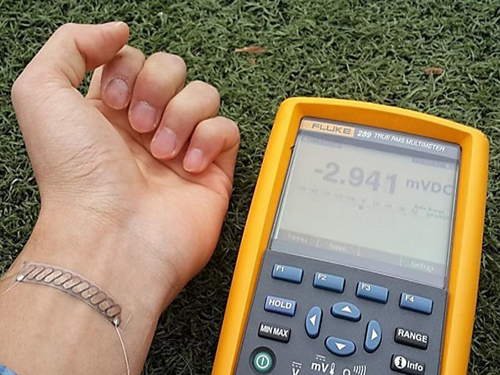

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 21849

Thermoelectric generator on glass fabric for wearable electronic devices

Wearable computers or devices have been hailed as the next generation of mobile electronic gadgets, from smart watches to smart glasses to smart pacemakers. For electronics to be worn by a user, they must be light, flexible, and equipped with a power source, which could be a portable, long-lasting battery or no battery at all but a generator. How to supply power in a stable and reliable manner is one of the most critical issues to commercialize wearable devices.

A team of KAIST researchers headed by Byung Jin Cho, a professor of electrical engineering, proposed a solution to this problem by developing a glass fabric-based thermoelectric (TE) generator that is extremely light and flexible and produces electricity from the heat of the human body. In fact, it is so flexible that the allowable bending radius of the generator is as low as 20 mm. There are no changes in performance even if the generator bends upward and downward for up to 120 cycles.

To date, two types of TE generators have been developed based either on organic or inorganic materials. The organic-based TE generators use polymers that are highly flexible and compatible with human skin, ideal for wearable electronics. The polymers, however, have a low power output. Inorganic-based TE generators produce a high electrical energy, but they are heavy, rigid, and bulky.

Professor Cho came up with a new concept and design technique to build a flexible TE generator that minimizes thermal energy loss but maximizes power output. His team synthesized liquid-like pastes of n-type (Bi2Te3) and p-type (Sb2Te3) TE materials and printed them onto a glass fabric by applying a screen printing technique. The pastes permeated through the meshes of the fabric and formed films of TE materials in a range of thickness of several hundreds of microns. As a result, hundreds of TE material dots (in combination of n and p types) were printed and well arranged on a specific area of the glass fabric.

Professor Cho explained that his TE generator has a self-sustaining structure, eliminating thick external substrates (usually made of ceramic or alumina) that hold inorganic TE materials. These substrates have taken away a great portion of thermal energy, a serious setback which causes low output power.

He also commented,

"For our case, the glass fabric itself serves as the upper and lower substrates of a TE generator, keeping the inorganic TE materials in between. This is quite a revolutionary approach to design a generator. In so doing, we were able to significantly reduce the weight of our generator (~0.13g/cm2), which is an essential element for wearable electronics."

When using KAIST's TE generator (with a size of 10 cm x 10 cm) for a wearable wristband device, it will produce around 40 mW electric power based on the temperature difference of 31 °F between human skin and the surrounding air.

Professor Cho further described about the merits of the new generator:

"Our technology presents an easy and simple way of fabricating an extremely flexible, light, and high-performance TE generator. We expect that this technology will find further applications in scale-up systems such as automobiles, factories, aircrafts, and vessels where we see abundant thermal energy being wasted."

This research result was published online in the March 14th issue of Energy & Environmental Science and was entitled "Wearable Thermoelectric Generator Fabricated on Glass Fabric."

Youtube Link: http://www.youtube.com/watch?v=BlN9lvEzCuw&feature=youtu.be

[Picture Captions]

Caption 1: The picture shows a high-performance wearable thermoelectric generator that is extremely flexible and light.

Caption 2: A thermoelectric generator developed as a wristband. The generator can be easily curved along with the shape of human body.

Caption 3: KAIST’s thermoelectric generator can be bent as many as 120 times, but it still shows the same high performance.

2014.04.21 View 21849