CT

-

Ultra Elastic Electrode Material Developed

KAIST research team succeeded in developing the next generation flexible and elastic electrode material crucial in the development of flexible displays, wearable computers, and etc.

Professor Jeon Seok Woo’s team of the department of Materials Science and Engineering succeeded in the development of a super elastic material.

The result of the experiment was introduced as the research highlight in Nature Communications and is especially significant as the main driving force behind the achievement were domestic researchers.

Professor Jeons team developed a structured three dimensional nano-porous structure over a 1inch by 1inch area that is 10micrometers in thickness. The structure is fabricated using world’s largest area three dimensional nano patterning technique.

The nano-porous structure was injected with elastomeric material and was subsequently removed to yield an inverse three dimensional elastic nano material. The pores were infiltrated with liquid conductive material which yielded a super elastic flexible electrode.

The fabricated electrode showed amazing elasticity levels and was able to light LED lamps in a 200% stretched state without decrease in electrical conductivity.

Conventional methods included folding and expanding a material like an accordion or creating a mesh-like structure by making holes in the material. However these methods yielded materials with limited elasticity and even 100% stretching resulted in the drastic decrease in electrical conductivity.

Professor Jeon expects the domestically developed technology to obtain the upper hand in the market and make great contributions in both science and society.

2012.07.26 View 9788

Ultra Elastic Electrode Material Developed

KAIST research team succeeded in developing the next generation flexible and elastic electrode material crucial in the development of flexible displays, wearable computers, and etc.

Professor Jeon Seok Woo’s team of the department of Materials Science and Engineering succeeded in the development of a super elastic material.

The result of the experiment was introduced as the research highlight in Nature Communications and is especially significant as the main driving force behind the achievement were domestic researchers.

Professor Jeons team developed a structured three dimensional nano-porous structure over a 1inch by 1inch area that is 10micrometers in thickness. The structure is fabricated using world’s largest area three dimensional nano patterning technique.

The nano-porous structure was injected with elastomeric material and was subsequently removed to yield an inverse three dimensional elastic nano material. The pores were infiltrated with liquid conductive material which yielded a super elastic flexible electrode.

The fabricated electrode showed amazing elasticity levels and was able to light LED lamps in a 200% stretched state without decrease in electrical conductivity.

Conventional methods included folding and expanding a material like an accordion or creating a mesh-like structure by making holes in the material. However these methods yielded materials with limited elasticity and even 100% stretching resulted in the drastic decrease in electrical conductivity.

Professor Jeon expects the domestically developed technology to obtain the upper hand in the market and make great contributions in both science and society.

2012.07.26 View 9788 -

Commercialization of Carbon Capture and Storage Technology Speeds up

KAIST research team successfully developed the ideal method for carbon dioxide transportation, which is crucial in the capturing and underground storage of carbon dioxide technology.

Professor Jang Dae Joon of the department of Ocean Systems Engineering developed a carbon dioxide transportation that minimizes evaporative gases.

The new technology is the final piece of the three part carbon capture storage which involves capture, transportation, and storage of carbon dioxide. The completion of the three part technology will allow for commercialization in the near future.

Carbon Capture and Storage technology is regarded as the technology that will reduce carbon dioxide levels. It captures the carbon dioxide emitted from power plants and factories and storing them permanently in empty oil fields underground.

If the post Kyoto Protocol was to be implemented from 2013, Korea will not be able to shirk from the need to reduce carbon emissions. Therefore the Korean government set out to reduce 32 million tons of carbon dioxide (10% of predicted carbon reduction) until 2030. In response to the government’s efforts to reduce carbon dioxide emissions, Korean research teams like KAIST have responded.

Professor Jang’s team succeeded in developing the core technology for underground storage in the 2009 ‘Carbon dioxide Transport and Injection Terminal Project’. And as the final piece of the puzzle the team developed an optimization solution that addressed the evaporating gases emitted from carbon dioxide during transportation.

Professor Jang’s team focused on the required low temperature and high pressure conditions in liquid carbon dioxide transport.

The problem lies in the temperature gradient which can cause the transport canister to explode.

The solution developed by the team is to evaporate carbon dioxide in a pressurized contained which is then re-liquidated.

External variables like price of oil, carbon taxation, etc. have been considered and the process was optimized accordingly.

The result of Professor Jang’s team’s solution to Carbon Capture and Storage was stored in the online edition of International Journal of Greenhouse Gas Control.

2012.07.26 View 9872

Commercialization of Carbon Capture and Storage Technology Speeds up

KAIST research team successfully developed the ideal method for carbon dioxide transportation, which is crucial in the capturing and underground storage of carbon dioxide technology.

Professor Jang Dae Joon of the department of Ocean Systems Engineering developed a carbon dioxide transportation that minimizes evaporative gases.

The new technology is the final piece of the three part carbon capture storage which involves capture, transportation, and storage of carbon dioxide. The completion of the three part technology will allow for commercialization in the near future.

Carbon Capture and Storage technology is regarded as the technology that will reduce carbon dioxide levels. It captures the carbon dioxide emitted from power plants and factories and storing them permanently in empty oil fields underground.

If the post Kyoto Protocol was to be implemented from 2013, Korea will not be able to shirk from the need to reduce carbon emissions. Therefore the Korean government set out to reduce 32 million tons of carbon dioxide (10% of predicted carbon reduction) until 2030. In response to the government’s efforts to reduce carbon dioxide emissions, Korean research teams like KAIST have responded.

Professor Jang’s team succeeded in developing the core technology for underground storage in the 2009 ‘Carbon dioxide Transport and Injection Terminal Project’. And as the final piece of the puzzle the team developed an optimization solution that addressed the evaporating gases emitted from carbon dioxide during transportation.

Professor Jang’s team focused on the required low temperature and high pressure conditions in liquid carbon dioxide transport.

The problem lies in the temperature gradient which can cause the transport canister to explode.

The solution developed by the team is to evaporate carbon dioxide in a pressurized contained which is then re-liquidated.

External variables like price of oil, carbon taxation, etc. have been considered and the process was optimized accordingly.

The result of Professor Jang’s team’s solution to Carbon Capture and Storage was stored in the online edition of International Journal of Greenhouse Gas Control.

2012.07.26 View 9872 -

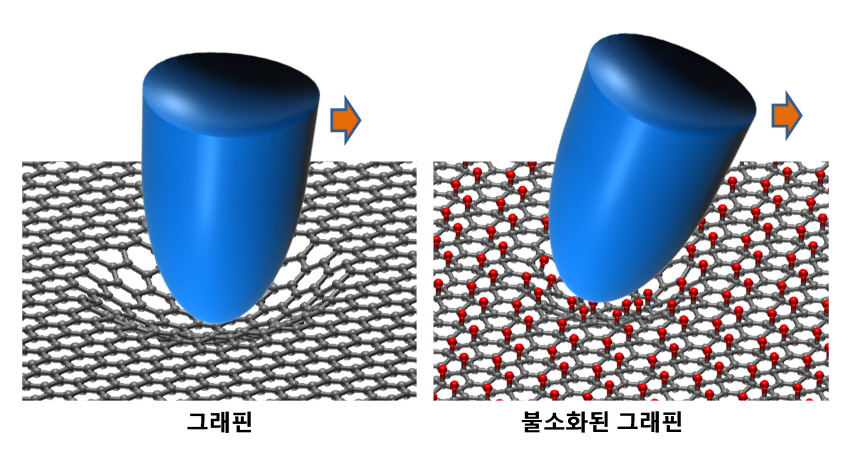

KAIST researchers verify and control the mechanical properties of graphene

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 16568

KAIST researchers verify and control the mechanical properties of graphene

KAIST researchers have successfully verified and controlled the mechanical properties of graphene, a next-generation material. Professor Park Jung Yong from the EEWS Graduate School and Professor Kim Yong Hyun from the Graduate School of Nanoscience and Technology have succeeded in fluorinating a single atomic-layered graphene sample and controlling its frictional and adhesive properties. This is the first time the frictional properties of graphene have been examined at the atomic level, and the technology is expected to be applied to nano-sized robots and microscopic joints.

Graphene is often dubbed “the dream material” because of its ability to conduct high amounts of electricity even when bent, making it the next-generation substitute for silicon semiconductors, paving the way for flexible display and wearable computer technologies. Graphene also has high potential applications in mechanical engineering because of its great material strength, but its mechanical properties remained elusive until now.

Professor Park’s research team successfully produced individual graphene samples with fluorine-deficiency at the atomic level by placing the samples in Fluoro-xenon (XeF2) gas and applying heat. The surface of the graphene was scanned using a micro probe and a high vacuum atomic microscope to measure its dynamic properties.

The research team found that the fluorinated graphene sample had 6 times more friction and 0.7 times more adhesiveness than the original graphene. Electrical measurements confirmed the fluorination process, and the analysis of the findings helped setup the theory of frictional changes in graphene.

Professor Park stated that “graphene can be used for the lubrication of joints in nano-sized devices” and that this research has numerous applications such as the coating of graphene-based microdynamic devices.

This research was published in the online June edition of Nano Letters and was supported by the Ministry of Science, Technology, and Education and the National Research Foundation as part of the World Class University (WCU) program.

2012.07.24 View 16568 -

New wireless charging device developed

The On-line Electric Vehicle (OLEV) developed by KAIST has made a step towards commercialization with the development of a more economic wireless charging device.

Professor Chun-Taek Rim from the Department of Nuclear and Quantum Engineering at KAIST has developed a new I-shaped wireless charging device that differs from the pre-existing rail-type electricity feeder. This device can be modularly produced and requires relatively less construction, significantly reducing the cost of implementation.

The KAIST OLEV is a new concept electric car that has a special electricity collecting device underneath it. The car’s battery is charged by magnetic fields produced from electric lines buried 15cm underneath the road. The vehicle was first tested in 2009, making it the first wireless electric car in the world. OLEV can be charged during stoppage time between traffic lights and receives real-time power when running. OLEV is currently in operation at the KAIST Munji Campus in Daejeon and is also being exhibited at the Yeosu Expo and Seoul Grand Park.

The device itself has a charging capacity of 15kW, and the electricity is supplied through an electricity feeder with a width of 80cm with a space interval of 20cm. Despite being hailed as a technological breakthrough and revolutionary concept, KAIST OLEV has been criticized for problems in commercialization, due to the difficulties in installing wires beneath existing roads, which costs a considerable amount of money.

The new I-shaped wireless charging device reduces the width of the electricity feeder by 10cm, a mere one-eighth of the size of the previous version, and greatly increases the charging power to 25kW. Furthermore, the left and right permissible space of automobiles has increased to 24cm and the magnetic field complies with the international design guidelines, making the OLEV safe for the human body.

The reduction of the width has made the mass production of modules possible, making the installation of KAIST OLEV more economical and marketable. Professor Rim emphasized that compared with the existing rail-type electricity feeder, the new technology will need only one-tenth of the construction time and 80% of the cost, significantly improving OLEV’s constructability and workability.

The research was published in the IEEE Transactions on Power Electronics last December, and Professor Rim was invited to talk at the Conference on Electric Roads & Vehicles, which was held in February in the United States, about the new technology.

2012.07.06 View 12149

New wireless charging device developed

The On-line Electric Vehicle (OLEV) developed by KAIST has made a step towards commercialization with the development of a more economic wireless charging device.

Professor Chun-Taek Rim from the Department of Nuclear and Quantum Engineering at KAIST has developed a new I-shaped wireless charging device that differs from the pre-existing rail-type electricity feeder. This device can be modularly produced and requires relatively less construction, significantly reducing the cost of implementation.

The KAIST OLEV is a new concept electric car that has a special electricity collecting device underneath it. The car’s battery is charged by magnetic fields produced from electric lines buried 15cm underneath the road. The vehicle was first tested in 2009, making it the first wireless electric car in the world. OLEV can be charged during stoppage time between traffic lights and receives real-time power when running. OLEV is currently in operation at the KAIST Munji Campus in Daejeon and is also being exhibited at the Yeosu Expo and Seoul Grand Park.

The device itself has a charging capacity of 15kW, and the electricity is supplied through an electricity feeder with a width of 80cm with a space interval of 20cm. Despite being hailed as a technological breakthrough and revolutionary concept, KAIST OLEV has been criticized for problems in commercialization, due to the difficulties in installing wires beneath existing roads, which costs a considerable amount of money.

The new I-shaped wireless charging device reduces the width of the electricity feeder by 10cm, a mere one-eighth of the size of the previous version, and greatly increases the charging power to 25kW. Furthermore, the left and right permissible space of automobiles has increased to 24cm and the magnetic field complies with the international design guidelines, making the OLEV safe for the human body.

The reduction of the width has made the mass production of modules possible, making the installation of KAIST OLEV more economical and marketable. Professor Rim emphasized that compared with the existing rail-type electricity feeder, the new technology will need only one-tenth of the construction time and 80% of the cost, significantly improving OLEV’s constructability and workability.

The research was published in the IEEE Transactions on Power Electronics last December, and Professor Rim was invited to talk at the Conference on Electric Roads & Vehicles, which was held in February in the United States, about the new technology.

2012.07.06 View 12149 -

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 14076

Flexible Nanogenerator Technology

KAIST research team successfully developed the foundation technology that will enable to fabrication of low cost, large area nanogenerator.

Professor Lee Gun Jae’s team (Department of Materials Science and Engineering) published a dissertation on a nanogenerator using nanocomplexes as the cover dissertation of the June edition of Advanced Materials.

The developed technology is receiving rave reviews for having overcome the complex and size limitations of the nanogenerator fabrication process.

A nanogenerator is an electricity generator that uses materials in the nanoscale and uses piezoelectricity that creates electricity with the application of physical force.

The generation technology using piezoelectricity was appointed as one of top 10 promising technologies by MIT in 2009 and was included in the 45 innovative technologies that will shake the world by Popular Science Magazine in 2010.

The only nanogenerator thus far was the ZnO model suggested by Georgia Tech’s Professor Zhong Lin Wang in 2005.

Professor Lee’s team used ceramic thin film material BaTiO3 which has 15~20 times greater piezoelectric capacity than ZnO and thus improved the overall performance of the device. The use of a nanocomplex allows large scale production and the simplification of the fabrication process itself.

The team created a mixture of PDMS (polydimethylsiloxane) with BaTiO3 and either of CNT (Carbon Nanotube) or RGO (Reduced Graphene Oxide) which has high electrical conductivity and applied this mixture to create a large scale nanogenerator.

2012.06.18 View 14076 -

President Nam Pyo Suh receives Honorary Doctorate from Bilkent University, Turkey

President of KAIST Nam Pyo Suh received an Honorary Doctorate from Turkey’s Bilkent University on June 13th, 2012.

Bilkent University revealed that it is President Suh’s invention of a plastic manufacture process used all over the world and the combination of academic achievements like the creation of the axiomatic design theory that merits the Honorary Doctorate.

After the presentation ceremony, President Suh gave a lecture to professors and students at Bilkent University on the "University of the Future: Changing Education Paradigm."

Bilkent University is located in Ankara, the capital of Turkey and was established in 1984, which is largely regarded as Turkey’s best private university. It ranked 32 out of 50 universities in Times Higher Educations’ 100 Under 50 List of World’s Best New Universities.

2012.06.18 View 9288

President Nam Pyo Suh receives Honorary Doctorate from Bilkent University, Turkey

President of KAIST Nam Pyo Suh received an Honorary Doctorate from Turkey’s Bilkent University on June 13th, 2012.

Bilkent University revealed that it is President Suh’s invention of a plastic manufacture process used all over the world and the combination of academic achievements like the creation of the axiomatic design theory that merits the Honorary Doctorate.

After the presentation ceremony, President Suh gave a lecture to professors and students at Bilkent University on the "University of the Future: Changing Education Paradigm."

Bilkent University is located in Ankara, the capital of Turkey and was established in 1984, which is largely regarded as Turkey’s best private university. It ranked 32 out of 50 universities in Times Higher Educations’ 100 Under 50 List of World’s Best New Universities.

2012.06.18 View 9288 -

High Capacity Molecular Storage Technology Developed by KAIST Professor Omar M. Yaghi

KAIST research team has succeeded in developing the technology that allows high capacity protein storage.

Professor Omar M. Yaghi (Graduate School of EEWS) and his research team succeeded in developing the core technology that enables the storage of various types of proteins by developing a metal organic structure. The result of their research was published in the May edition of Science magazine.

The newly developed technology can store various types and sizes of proteins. This property is expected to pave way to: 1) development of high capacity, high integration drugs 2) development of virus separation compounds 3) selective removal of protein causing negative reactions in the body 4) permanent preservation of rare polymeric proteins, among other expectations.

In addition it becomes possible to selectively remove and preserve all the body’s cells including stem cells which will aid the development of cures for incurable diseases and increase life expectancy and medical technology in general.

Conventional metal-organic structure used 7 Angstrom large small single molecules and therefore could not be used in the storage of large molecules or proteins. Its usability was proven only as potential high capacity gas storage structure. In addition the internal structure of the metal organic structure is cross linked which made it even more difficult to store large proteins within the structure.

Professor Yaghi’s team used molecular structure over 5nm in length in the development of the metal-organic structure to solve the problem associated with size of structure. The ordered structure of the structure’s pore was observed for the first time using Transmission Electron Microscope.

The new structure enables the ordered storage of large proteins and was able to store vitamin and proteins like myoglobin at high capacity for the first time in the world.

2012.05.30 View 9214

High Capacity Molecular Storage Technology Developed by KAIST Professor Omar M. Yaghi

KAIST research team has succeeded in developing the technology that allows high capacity protein storage.

Professor Omar M. Yaghi (Graduate School of EEWS) and his research team succeeded in developing the core technology that enables the storage of various types of proteins by developing a metal organic structure. The result of their research was published in the May edition of Science magazine.

The newly developed technology can store various types and sizes of proteins. This property is expected to pave way to: 1) development of high capacity, high integration drugs 2) development of virus separation compounds 3) selective removal of protein causing negative reactions in the body 4) permanent preservation of rare polymeric proteins, among other expectations.

In addition it becomes possible to selectively remove and preserve all the body’s cells including stem cells which will aid the development of cures for incurable diseases and increase life expectancy and medical technology in general.

Conventional metal-organic structure used 7 Angstrom large small single molecules and therefore could not be used in the storage of large molecules or proteins. Its usability was proven only as potential high capacity gas storage structure. In addition the internal structure of the metal organic structure is cross linked which made it even more difficult to store large proteins within the structure.

Professor Yaghi’s team used molecular structure over 5nm in length in the development of the metal-organic structure to solve the problem associated with size of structure. The ordered structure of the structure’s pore was observed for the first time using Transmission Electron Microscope.

The new structure enables the ordered storage of large proteins and was able to store vitamin and proteins like myoglobin at high capacity for the first time in the world.

2012.05.30 View 9214 -

Korea's First MOU between a University Education Volunteer Work Group and Local Government

- 200 Adolescents from Yuseong-gu to Receive Education Community Services

Midam Scholarship committee which is composed of KAIST"s students and graduates, will draw up a contract that states that it will work together with the Yuseong-gu municipality for the development of the district education services on the 14th at the Yuseong-gu office.

Both sides will together ▲mentor the local students, ▲cooperate to run and develop creative programs, ▲exchange work for the development of the KAIST Midam Scholarship Committee, ▲conduct various other projects.

From now, the Midam Scholarship Committee will teach about 200 students in Yuseong-gu. The drawing of this contract has much meaning in that it is the first of its kind.

The Midam Scholarship Committee was founded on 2009 by students in KAIST to teach math, english, and science to students from families with low income levels.

This committee has made educational pacts with middle and high schools located in Daejeong such as Chungnam High School and Beobdong High School, and has not only taught these students but also has given scholarships to the selected students.

On one hand, the Midam Scholarship Committee has also supported 10 students in KAIST who were in need with 300000won each on the 6th. This fund was raised through the donations of alumni and mentoring projects.

The Midam Scholarship Committee has been recognized for its positive impacts on the society and has received an award from the Yuseong-gu municipality office.

2012.05.10 View 9197

Korea's First MOU between a University Education Volunteer Work Group and Local Government

- 200 Adolescents from Yuseong-gu to Receive Education Community Services

Midam Scholarship committee which is composed of KAIST"s students and graduates, will draw up a contract that states that it will work together with the Yuseong-gu municipality for the development of the district education services on the 14th at the Yuseong-gu office.

Both sides will together ▲mentor the local students, ▲cooperate to run and develop creative programs, ▲exchange work for the development of the KAIST Midam Scholarship Committee, ▲conduct various other projects.

From now, the Midam Scholarship Committee will teach about 200 students in Yuseong-gu. The drawing of this contract has much meaning in that it is the first of its kind.

The Midam Scholarship Committee was founded on 2009 by students in KAIST to teach math, english, and science to students from families with low income levels.

This committee has made educational pacts with middle and high schools located in Daejeong such as Chungnam High School and Beobdong High School, and has not only taught these students but also has given scholarships to the selected students.

On one hand, the Midam Scholarship Committee has also supported 10 students in KAIST who were in need with 300000won each on the 6th. This fund was raised through the donations of alumni and mentoring projects.

The Midam Scholarship Committee has been recognized for its positive impacts on the society and has received an award from the Yuseong-gu municipality office.

2012.05.10 View 9197 -

Professor Kyung Wook Baek Wins the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium

Prof. Kyung Wook Baek from KAIST"s material science department has won the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium.

The title of this thesis was "Recent Advances in Anisotropic Conductive Adhesives Technology : Materials and Processes". Prof Baek had the honor of having his thesis be appointed the best thesis of the symposium.

This thesis includes his 15 years of research on ACAs which are a key element of display and semiconductor packaging technology.

Prof. Baek"s research results has been recognized as incredibly innovative in the field of ACAs and ultrasonic connection devices. This thesis has been recognized as setting the foundation for commercialization by professionals from all over the world at the symposium.

Prof. Baek has announced two innovative technologies on ACAs at the symposium.

One is a technology that merges the nanofiber technology with the ATAs. This technology was highly applauded for overcoming the problem of electric connection in micro-pitch display semiconductors, and successfully applying this to electronic packaging materials.

Currently, commercialization process based on the patent is ongoing. It is expected that we will be able to take hold of the entire market once the commercialization succeeds.

The other technology was to improve the liability and overcome the limits of the current flow in ACAs through the use of solder molecules. This is also undergoing commercialization process for use in mobile electronic devices.

Together with this, Prof.Baek has reported an innovative case where the original heat compression process was replaced with a new ultrasonic process. This discovery is deemed to be extremely great due to its implications in replacing all heat compression systems. This too will soon be commercialized

Prof.Baek has played a crucial role in the development of electronic packaging material and processing technology. He has written the largest number of theses in this area, and has proven himself to be the world"s best through winning this award.

2012.05.10 View 10525

Professor Kyung Wook Baek Wins the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium

Prof. Kyung Wook Baek from KAIST"s material science department has won the Best Thesis Award at the 2012 Pan-Pacific Microelectronic Symposium.

The title of this thesis was "Recent Advances in Anisotropic Conductive Adhesives Technology : Materials and Processes". Prof Baek had the honor of having his thesis be appointed the best thesis of the symposium.

This thesis includes his 15 years of research on ACAs which are a key element of display and semiconductor packaging technology.

Prof. Baek"s research results has been recognized as incredibly innovative in the field of ACAs and ultrasonic connection devices. This thesis has been recognized as setting the foundation for commercialization by professionals from all over the world at the symposium.

Prof. Baek has announced two innovative technologies on ACAs at the symposium.

One is a technology that merges the nanofiber technology with the ATAs. This technology was highly applauded for overcoming the problem of electric connection in micro-pitch display semiconductors, and successfully applying this to electronic packaging materials.

Currently, commercialization process based on the patent is ongoing. It is expected that we will be able to take hold of the entire market once the commercialization succeeds.

The other technology was to improve the liability and overcome the limits of the current flow in ACAs through the use of solder molecules. This is also undergoing commercialization process for use in mobile electronic devices.

Together with this, Prof.Baek has reported an innovative case where the original heat compression process was replaced with a new ultrasonic process. This discovery is deemed to be extremely great due to its implications in replacing all heat compression systems. This too will soon be commercialized

Prof.Baek has played a crucial role in the development of electronic packaging material and processing technology. He has written the largest number of theses in this area, and has proven himself to be the world"s best through winning this award.

2012.05.10 View 10525 -

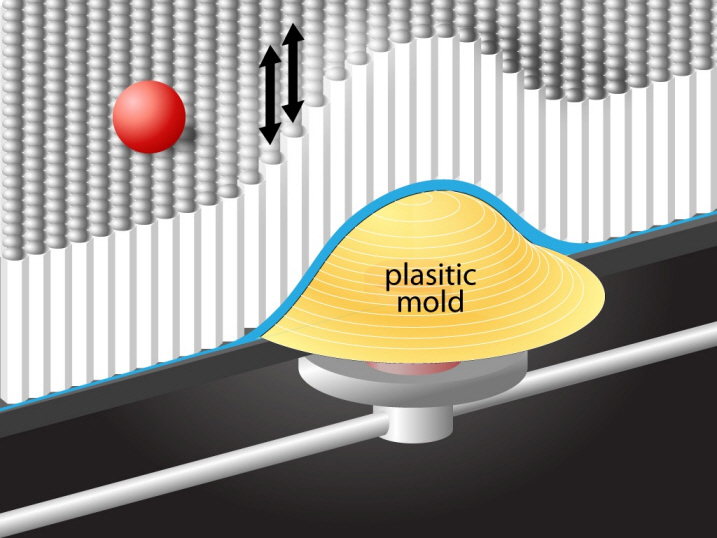

New concept 'mole game' robot developed

A new game robot concept developed by KAIST researchers came in first place at a world-renowned virtual reality exhibition, despite being the first ever entry by a Korean team.

Professor Lee Woohun’s team from the Department of Industrial Design at KAIST won the first-place award of ‘Gran Prix du Jury’ at the famous virtual reality exhibition, Laval Virtual 2012, which was held between March 28th and April 1st, with the mole game robot, ‘MoleBot’.

MoleBot can be enjoyed in a completely physical environment unlike other virtual reality games and allows interaction between the virtual world and reality. Such imaginative interaction attracted numerous spectators during the exhibition.

The MoleBot table consists of approximately 15,000 small cubes, and as the object inside the table moves, the cubes slide as if a mole is inside. By using a joystick, users can enjoy physical interaction with the table and a wide range of games.

The MoleBot can also be operated with hand gestures using ‘Kinect’, a motion sensing input device developed by Microsoft, making it possible to enjoy games as if playing with a pet.

Professor Lee’s team came up with the project from a simple idea: ‘What if moles lived inside the table?’

The team first created a table that would hold and allow the movement of the cubes, and then placed a plastic mold underneath it with a layer of spandex in between to lessen the friction, allowing smooth and lifelike movement.

The mold contains magnets that allow the accurate delivery of mechanical movement. After two years of continued additional research, MoleBot was released to the world.

In the acceptance speech, Professor Lee said, ‘It is rare for a design team to win first place in an engineering exhibition’ and that ‘to achieve such a feat, the MoleBot’s technological creativity and artistic completeness became one’.

Professor Lee also said that ‘this concept of creating an interactive world on a table could potentially become a new game interface’ and that he would research on applying this MoleBot technology to different fields such as human-computer interaction, architecture, interior, and clothing.

Laval Virtual is a world-renowned exhibition that displays cutting edge technologies in the field of virtual reality. This year was the 14th exhibit, and over 10,000 people participated in it. The exhibition gives out 12 awards, one per field, and Professor Lee’s team won the highest award.

2012.05.07 View 11749

New concept 'mole game' robot developed

A new game robot concept developed by KAIST researchers came in first place at a world-renowned virtual reality exhibition, despite being the first ever entry by a Korean team.

Professor Lee Woohun’s team from the Department of Industrial Design at KAIST won the first-place award of ‘Gran Prix du Jury’ at the famous virtual reality exhibition, Laval Virtual 2012, which was held between March 28th and April 1st, with the mole game robot, ‘MoleBot’.

MoleBot can be enjoyed in a completely physical environment unlike other virtual reality games and allows interaction between the virtual world and reality. Such imaginative interaction attracted numerous spectators during the exhibition.

The MoleBot table consists of approximately 15,000 small cubes, and as the object inside the table moves, the cubes slide as if a mole is inside. By using a joystick, users can enjoy physical interaction with the table and a wide range of games.

The MoleBot can also be operated with hand gestures using ‘Kinect’, a motion sensing input device developed by Microsoft, making it possible to enjoy games as if playing with a pet.

Professor Lee’s team came up with the project from a simple idea: ‘What if moles lived inside the table?’

The team first created a table that would hold and allow the movement of the cubes, and then placed a plastic mold underneath it with a layer of spandex in between to lessen the friction, allowing smooth and lifelike movement.

The mold contains magnets that allow the accurate delivery of mechanical movement. After two years of continued additional research, MoleBot was released to the world.

In the acceptance speech, Professor Lee said, ‘It is rare for a design team to win first place in an engineering exhibition’ and that ‘to achieve such a feat, the MoleBot’s technological creativity and artistic completeness became one’.

Professor Lee also said that ‘this concept of creating an interactive world on a table could potentially become a new game interface’ and that he would research on applying this MoleBot technology to different fields such as human-computer interaction, architecture, interior, and clothing.

Laval Virtual is a world-renowned exhibition that displays cutting edge technologies in the field of virtual reality. This year was the 14th exhibit, and over 10,000 people participated in it. The exhibition gives out 12 awards, one per field, and Professor Lee’s team won the highest award.

2012.05.07 View 11749 -

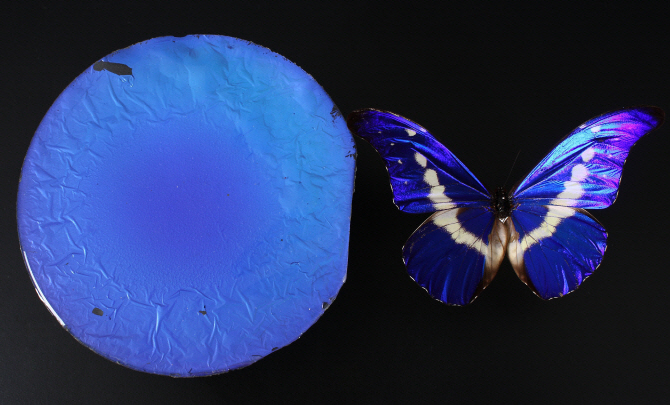

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 15391

Biomimetic reflective display technology developed

Professor Shin Jung Hoon

The bright colors of a rainbow or a peacock are produced by the reflection and interference of light in transparent periodic structures, producing what is called a structural color. These colors are very bright and change according to the viewing angle. On the other hand, the wings of a morpho-butterfly also have structural colors but are predominantly blue over a wide range of angles. This is because the unique structure of the morpho-butterfly’s wings contains both order and chaos.

Professor Shin Jung Hoon’s team from the Department of Physics and the Graduate School of Nanoscience and Technology at KAIST produced a display that mimics the structure of the morpho-butterfly’s wings using glass beads.

This research successfully produced a reflective display (one that reflects external light to project images), which could be used to make very bright displays with low energy consumption. This technology can also be used to make anti-counterfeit bills, as well as coating materials for mobile phones and wallets.

The structure of the morpho-butterfly’s wings seems to be in periodic order at the 1-micrometer level, but contains disorder at the 100-nanometer level. So far, no one had succeeded in reproducing a structure with both order and disorder at the nanometer level.

Professor Shin’s team randomly aligned differently sized glass beads of a few hundred nanometers to create chaos and placed a thin periodic film on top of it using the semiconductor deposition method, thereby creating the morpho-butterfly-like structure over a large area.

This new development produced better color and brightness than the morpho-butterfly wing and even exhibited less color change according to angle. The team sealed the film in thin plastic, which helped to maintain the superior properties whilst making it more firm and paper-like.

Professor Shin emphasized that the results were an exemplary success in the field of biomimetics and that structural colors could have other applications in sensors and fashion, for example.

The results were first introduced on May 3rd in Nature as one of the Research Highlights and will be published in the online version of the material science magazine, Advanced Materials.

This research was jointly conducted by Professor Shin Jung Hoon (Department of Physics / Graduate School of Nanoscience and Technology at KAIST), Professor Park NamKyoo (Department of Electrical and Computer Engineering at Seoul National University), and Samsung Advanced Institute of Technology. The funding was provided by the National Research Foundation of Korea and the Ministry of Education, Science and Technology as part of the World Class University (WCU) project.

Figure 2. The biomimetic film can express many different colors

Figure 3. The biomimetic diplay and a morpho-butterfly

2012.05.07 View 15391 -

10 Technolgies to Change the World in 2012: The Future Technology Global Agenda Council

The Future Technology Global Agenda Council which is under the World Economy Forum and which KAIST’s biochemical engineering department’s Prof. Sang Yeob Lee is the head of, chose the 10 new technologies that will change the world in year 2012.

The ten technologies include: IT, synthetic biology and metabolic engineering, Green Revolution 2.0, material construction nanotechnology, systematic biology and the simulation technology of biological systems, the technology to use CO2 as a natural resource, wireless power transmission technology, high density energy power system, personalized medical/nutritional/disease preventing system, and new education technology.

The technologies were chosen on the basis of the opinions various science, industry, and government specialists and is deemed to have high potential to change the world in the near future.

The Future Technology Global Agenda Council will choose ten new technologies yearly starting this year in order to solve the problems the world now faces.

The informatics systems that was ranked 1st place, sifts only the data necessary for decision making out of the overflowing amount of data. Much interest has been spurred at the Davos forum.

The synthetic biology and metabolic engineering chosen is expected to play an important role in creating new medicines and producing chemical substances and materials from reusable resources.

Biomass has also been chosen as one of the top ten most important technologies as it was seen to be necessary to lead the second Green Revolution in order to stably provide food for the increasing population and to create bio refineries.

Nanomaterials structured at the molecular level are expected to help us solve problems regarding energy, food, and resources.

Systematic biology and computer modeling is gaining importance in availing humans to construct efficient remedies, materials, and processes while causing minimum effects on the environment, resource reserves, and other people.

The technology to convert CO2, which is considered a problem all over the world, into a useful resource is also gaining the spotlight

Together with such technologies, wireless power transmission technology, high density energy power system, personalized medical/nutritional/disease preventing system, and new education technology are also considered the top ten technologies to change the world.

Prof. Lee said, “Many new discoveries are being made due to the accelerating rate of technological advancements. Many of the technologies that the council has found are sustainable and important for the construction of our future.”

2012.04.04 View 12013

10 Technolgies to Change the World in 2012: The Future Technology Global Agenda Council

The Future Technology Global Agenda Council which is under the World Economy Forum and which KAIST’s biochemical engineering department’s Prof. Sang Yeob Lee is the head of, chose the 10 new technologies that will change the world in year 2012.

The ten technologies include: IT, synthetic biology and metabolic engineering, Green Revolution 2.0, material construction nanotechnology, systematic biology and the simulation technology of biological systems, the technology to use CO2 as a natural resource, wireless power transmission technology, high density energy power system, personalized medical/nutritional/disease preventing system, and new education technology.

The technologies were chosen on the basis of the opinions various science, industry, and government specialists and is deemed to have high potential to change the world in the near future.

The Future Technology Global Agenda Council will choose ten new technologies yearly starting this year in order to solve the problems the world now faces.

The informatics systems that was ranked 1st place, sifts only the data necessary for decision making out of the overflowing amount of data. Much interest has been spurred at the Davos forum.

The synthetic biology and metabolic engineering chosen is expected to play an important role in creating new medicines and producing chemical substances and materials from reusable resources.

Biomass has also been chosen as one of the top ten most important technologies as it was seen to be necessary to lead the second Green Revolution in order to stably provide food for the increasing population and to create bio refineries.

Nanomaterials structured at the molecular level are expected to help us solve problems regarding energy, food, and resources.

Systematic biology and computer modeling is gaining importance in availing humans to construct efficient remedies, materials, and processes while causing minimum effects on the environment, resource reserves, and other people.

The technology to convert CO2, which is considered a problem all over the world, into a useful resource is also gaining the spotlight

Together with such technologies, wireless power transmission technology, high density energy power system, personalized medical/nutritional/disease preventing system, and new education technology are also considered the top ten technologies to change the world.

Prof. Lee said, “Many new discoveries are being made due to the accelerating rate of technological advancements. Many of the technologies that the council has found are sustainable and important for the construction of our future.”

2012.04.04 View 12013