Atom

-

A Parallel MRI Method Accelerating Imaging Time Proposed

KAIST researchers proposed new technology that reduces MRI (magnetic resonance imaging) acquisition time to less than a sixth of the conventional method. They made a reconstruction method using machine learning of multilayer perception (MLP) algorithm to accelerate imaging time.

High-quality image can be reconstructed from subsampled data using the proposed method. This method can be further applied to various k-space subsampling patterns in a phase encoding direction, and its processing can be performed in real time.

The research, led by Professor Hyun Wook Park from the Department of Electrical Engineering, was described in Medical Physics as the cover paper last December. Ph.D. candidate Kinam Kwon is the first author.

MRI is an imaging technique that allows various contrasts of soft tissues without using radioactivity. Since MRI could image not only anatomical structures, but also functional and physiological features, it is widely used in medical diagnoses. However, one of the major shortcomings of MRI is its long imaging time. It induces patients’ discomfort, which is closely related to voluntary and involuntary motions, thereby deteriorating the quality of the MR images. In addition, lengthy imaging times limit the system’s throughput, which results in the long waiting times of patients as well as the increased medical expenses.

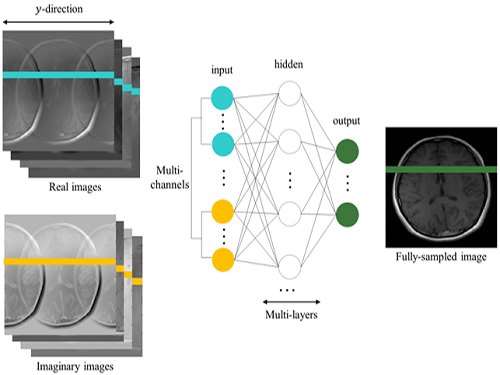

To reconstruct MR images from subsampled data, the team applied the MLP to reduce aliasing artifacts generated by subsampling in k-space. The MLP is learned from training data to map aliased input images into desired alias-free images. The input of the MLP is all voxels in the aliased lines of multichannel real and imaginary images from the subsampled k-space data, and the desired output is all voxels in the corresponding alias-free line of the root-sum-of-squares of multichannel images from fully sampled k-space data. Aliasing artifacts in an image reconstructed from subsampled data were reduced by line-by-line processing of the learned MLP architecture.

Reconstructed images from the proposed method are better than those from compared methods in terms of normalized root-mean-square error. The proposed method can be applied to image reconstruction for any k-space subsampling patterns in a phase encoding direction. Moreover, to further reduce the reconstruction time, it is easily implemented by parallel processing.

To address the aliasing artifact phenomenon, the team employed a parallel imaging technique using several receiver coils of various sensitivities and a compressed sensing technique using sparsity of signals.

Existing methods are heavily affected by sub-sampling patterns, but the team’s technique is applicable for various sub-sampling patterns, resulting in superior reconstructed images compared to existing methods, as well as allowing real-time reconstruction.

Professor Park said, "MRIs have become essential equipment in clinical diagnosis. However, the time consumption and the cost led to many inconveniences." He continued, "This method using machine learning could greatly improve the patients’ satisfaction with medical service." This research was funded by the Ministry of Science and ICT.

(Firgure 1. Cover of Medical Physics for December 2017)

(Figure 2. Concept map for the suggested network)

(Figure 3. Concept map for conventional MRI image acquisition and accelerated image acquisiton)

2018.01.16 View 7178

A Parallel MRI Method Accelerating Imaging Time Proposed

KAIST researchers proposed new technology that reduces MRI (magnetic resonance imaging) acquisition time to less than a sixth of the conventional method. They made a reconstruction method using machine learning of multilayer perception (MLP) algorithm to accelerate imaging time.

High-quality image can be reconstructed from subsampled data using the proposed method. This method can be further applied to various k-space subsampling patterns in a phase encoding direction, and its processing can be performed in real time.

The research, led by Professor Hyun Wook Park from the Department of Electrical Engineering, was described in Medical Physics as the cover paper last December. Ph.D. candidate Kinam Kwon is the first author.

MRI is an imaging technique that allows various contrasts of soft tissues without using radioactivity. Since MRI could image not only anatomical structures, but also functional and physiological features, it is widely used in medical diagnoses. However, one of the major shortcomings of MRI is its long imaging time. It induces patients’ discomfort, which is closely related to voluntary and involuntary motions, thereby deteriorating the quality of the MR images. In addition, lengthy imaging times limit the system’s throughput, which results in the long waiting times of patients as well as the increased medical expenses.

To reconstruct MR images from subsampled data, the team applied the MLP to reduce aliasing artifacts generated by subsampling in k-space. The MLP is learned from training data to map aliased input images into desired alias-free images. The input of the MLP is all voxels in the aliased lines of multichannel real and imaginary images from the subsampled k-space data, and the desired output is all voxels in the corresponding alias-free line of the root-sum-of-squares of multichannel images from fully sampled k-space data. Aliasing artifacts in an image reconstructed from subsampled data were reduced by line-by-line processing of the learned MLP architecture.

Reconstructed images from the proposed method are better than those from compared methods in terms of normalized root-mean-square error. The proposed method can be applied to image reconstruction for any k-space subsampling patterns in a phase encoding direction. Moreover, to further reduce the reconstruction time, it is easily implemented by parallel processing.

To address the aliasing artifact phenomenon, the team employed a parallel imaging technique using several receiver coils of various sensitivities and a compressed sensing technique using sparsity of signals.

Existing methods are heavily affected by sub-sampling patterns, but the team’s technique is applicable for various sub-sampling patterns, resulting in superior reconstructed images compared to existing methods, as well as allowing real-time reconstruction.

Professor Park said, "MRIs have become essential equipment in clinical diagnosis. However, the time consumption and the cost led to many inconveniences." He continued, "This method using machine learning could greatly improve the patients’ satisfaction with medical service." This research was funded by the Ministry of Science and ICT.

(Firgure 1. Cover of Medical Physics for December 2017)

(Figure 2. Concept map for the suggested network)

(Figure 3. Concept map for conventional MRI image acquisition and accelerated image acquisiton)

2018.01.16 View 7178 -

New Arylation Inducing Reaction Developed

(Professor Chang(left) and Professor Baik)

KAIST researchers have identified a reaction mechanism that selectively introduces aryl groups at the desired position of a molecule at room temperature. A team, co-led by Professor Sukbok Chang and Mu-Hyun Baik of the Department of Chemistry, used an iridium catalyst for the reaction. The team also proved that the reaction proceeds by an unusual mechanism by employing computer simulations that were substantiated with targeted experimental probes.

Hydrocarbon is an omnipresent material in nature. But its low reactivity makes it difficult to process to value-added products at the room temperature. Thus, designing catalysts that can accelerate the reaction remains an important challenge in chemistry.

In particular, since most chemicals used in medicine, pharmacy, or material chemistry contain aryl groups, an effective reaction to selectively introduce the aryl group has been an area of intensive research in organic chemistry.

In order to introduce an aryl group into stable carbon-hydrogen (C-H) bond, activation of the C-H bond with a halogen atom or organic metal is required prior to the introduction of the aryl group, or C-H functionalization directly on C-H bond is needed. Direct functionalization is more effective and economical, but most reactions require harsh reaction conditions such as high temperature or excess additives. And adding the aryl fragment selectively to only one among the many possible sites in the molecule is difficult. The new catalyst developed by these KAIST researchers is highly selective.

This work is the latest example of a successful teamwork between experimental and theoretical research groups: Computer simulations revealed that traditional approaches to arylation required high energies because the intermediates produced during the reaction are too low in energy. Based on this insight, the researchers thought of changing the character of the intermediate by oxidizing it, which was predicted to be a great way of increasing the reactivity of the catalyst. Subsequent experimental work showed that this design strategy is highly effective resulting in unprecedented chemical transformations.

Professor Chang said, “We have been able to carry out location-selective arylation at room temperature, as well as identifying a new reaction pathway, different from the conventionally suggested mechanism.” He continued, “This research is significant for identifying the reaction pathway and developing a novel selective reaction method that does not require high temperature or additives based on the mechanistic understanding. This work is a triumph of rational design, rather than fortuitous discovery.” The research findings were published online in Nature Chemistry on December 11, 2017.

(Figure 1: X-ray crystal structure transmetallation intermediate)

(Figure 2: Correlation between oxidation state of intermediate and energy barrier required for reductive elimination of intermediate as calculated using density function from computational chemistry )

(Figure 3: Arylation mechanism using iridium catalyst as suggested by the research team)

2018.01.11 View 6616

New Arylation Inducing Reaction Developed

(Professor Chang(left) and Professor Baik)

KAIST researchers have identified a reaction mechanism that selectively introduces aryl groups at the desired position of a molecule at room temperature. A team, co-led by Professor Sukbok Chang and Mu-Hyun Baik of the Department of Chemistry, used an iridium catalyst for the reaction. The team also proved that the reaction proceeds by an unusual mechanism by employing computer simulations that were substantiated with targeted experimental probes.

Hydrocarbon is an omnipresent material in nature. But its low reactivity makes it difficult to process to value-added products at the room temperature. Thus, designing catalysts that can accelerate the reaction remains an important challenge in chemistry.

In particular, since most chemicals used in medicine, pharmacy, or material chemistry contain aryl groups, an effective reaction to selectively introduce the aryl group has been an area of intensive research in organic chemistry.

In order to introduce an aryl group into stable carbon-hydrogen (C-H) bond, activation of the C-H bond with a halogen atom or organic metal is required prior to the introduction of the aryl group, or C-H functionalization directly on C-H bond is needed. Direct functionalization is more effective and economical, but most reactions require harsh reaction conditions such as high temperature or excess additives. And adding the aryl fragment selectively to only one among the many possible sites in the molecule is difficult. The new catalyst developed by these KAIST researchers is highly selective.

This work is the latest example of a successful teamwork between experimental and theoretical research groups: Computer simulations revealed that traditional approaches to arylation required high energies because the intermediates produced during the reaction are too low in energy. Based on this insight, the researchers thought of changing the character of the intermediate by oxidizing it, which was predicted to be a great way of increasing the reactivity of the catalyst. Subsequent experimental work showed that this design strategy is highly effective resulting in unprecedented chemical transformations.

Professor Chang said, “We have been able to carry out location-selective arylation at room temperature, as well as identifying a new reaction pathway, different from the conventionally suggested mechanism.” He continued, “This research is significant for identifying the reaction pathway and developing a novel selective reaction method that does not require high temperature or additives based on the mechanistic understanding. This work is a triumph of rational design, rather than fortuitous discovery.” The research findings were published online in Nature Chemistry on December 11, 2017.

(Figure 1: X-ray crystal structure transmetallation intermediate)

(Figure 2: Correlation between oxidation state of intermediate and energy barrier required for reductive elimination of intermediate as calculated using density function from computational chemistry )

(Figure 3: Arylation mechanism using iridium catalyst as suggested by the research team)

2018.01.11 View 6616 -

Controlling Superconductivity Using Spin Currents

(Professor Jhinhwan Lee and Dr. Seokhwan Choi)

A KAIST research team led by Professor Jhinhwan Lee of the Department of Physics has discovered a method to flip between superconducting and non-superconducting states within an iron-based superconductor using a type of electron microscopy. The team applied spin-polarized and non-polarized currents to locally change the magnetic order in the sample.

The team identified a basic physical principle required to develop transistors that control superconductivity and to implement novel magnetic memory at the atomic level. This study is the first report of a direct real-space observation of this type of control. In addition, this is the first direct atomic-scale demonstration of the correlation between magnetism and superconductivity.

The team controlled and observed the magnetic and electronic properties with a spin-polarized scanning tunneling microscope (SPSTM), a device that passes an atomically-sharp metal tip over the surface of a sample. The team introduced new ways to perform SPSTM using an antiferromagnetic chromium tip. An antiferromagnet is a material in which the magnetic fields of its atoms are ordered in an alternating up-down pattern such that it has a minimal stray magnetic field that can inadvertently kill the local superconductivity of the sample when used as an SPSTM tip.

To study the connection between the C4 magnetic order and the suppression of superconductivity, the team performed high-resolution SPSTM scans of the C4 state with chromium tips and compared them with simulations. The results led them to suggest that the low-energy spin fluctuations in the C4 state cannot mediate pairing between electrons in the typical FeAs band structure. This is critical because this paring of electrons, defying their natural urge to repel each other, leads to superconductivity.

Professor Lee said, “Our findings may be extended to future studies where magnetism and superconductivity are manipulated using spin-polarized and unpolarized currents, leading to novel antiferromagnetic memory devices and transistors controlling superconductivity.”

This study was published in Physical Review Letters (PRL) on November 27 as the Editor’s Suggestion. It was also featured in Viewpoint in Physics, in which the top 3% of PRL papers are presented with a commentary. It was also featured on Phys.org, which is a science news website led by the US national research institutes. Furthermore, the equipment designed and manufactured by Professor Lee’s team and used for the research was selected for the cover of Review of Scientific Instruments (RSI) in the October 2017 issue.

Professor Lee said, “When designing the experiment, we attempted to implement some decisive features. For instance, we included a spin control function using an antiferromagnetic probe, wide range variable temperature functions that were thought to be impossible in high-magnetic field structures, and multiple sample storage functions at low temperatures for systematic spin control experiments, rather than using simpler scanning probe microscopes with well-known principles or commercial microscopes. As a result, we were able to conduct systematic experiments on controlling magnetism and superconductivity, which competing groups would take years to replicate.”

He continued, “There were some minor difficulties in the basic science research environment such as the lack of a shared helium liquefier on campus and insufficient university-scale appreciation for large scale physics that inevitably takes time. We will do our best to lead the advancement of cutting-edge science through research projects expanding on this achievement in physical knowledge to practical devices and various technological innovations in measurements.” This research was funded by National Research Foundation of Korea.

Figure 1. Research concept illustration

The spin-polarized chromium (Cr) tip being scanned over the pristine superconducting area of the C2 magnetic order, represented in the background with electron pairs shown as coupled red spheres. The spin current through the tip induces the C4 magnetic order (yellow and blue plaquettes) with suppressed superconductivity in the sample because its spin fluctuations cannot mediate electron pairing, represented as decoupled red spheres in the plaquette area.

2018.01.05 View 6702

Controlling Superconductivity Using Spin Currents

(Professor Jhinhwan Lee and Dr. Seokhwan Choi)

A KAIST research team led by Professor Jhinhwan Lee of the Department of Physics has discovered a method to flip between superconducting and non-superconducting states within an iron-based superconductor using a type of electron microscopy. The team applied spin-polarized and non-polarized currents to locally change the magnetic order in the sample.

The team identified a basic physical principle required to develop transistors that control superconductivity and to implement novel magnetic memory at the atomic level. This study is the first report of a direct real-space observation of this type of control. In addition, this is the first direct atomic-scale demonstration of the correlation between magnetism and superconductivity.

The team controlled and observed the magnetic and electronic properties with a spin-polarized scanning tunneling microscope (SPSTM), a device that passes an atomically-sharp metal tip over the surface of a sample. The team introduced new ways to perform SPSTM using an antiferromagnetic chromium tip. An antiferromagnet is a material in which the magnetic fields of its atoms are ordered in an alternating up-down pattern such that it has a minimal stray magnetic field that can inadvertently kill the local superconductivity of the sample when used as an SPSTM tip.

To study the connection between the C4 magnetic order and the suppression of superconductivity, the team performed high-resolution SPSTM scans of the C4 state with chromium tips and compared them with simulations. The results led them to suggest that the low-energy spin fluctuations in the C4 state cannot mediate pairing between electrons in the typical FeAs band structure. This is critical because this paring of electrons, defying their natural urge to repel each other, leads to superconductivity.

Professor Lee said, “Our findings may be extended to future studies where magnetism and superconductivity are manipulated using spin-polarized and unpolarized currents, leading to novel antiferromagnetic memory devices and transistors controlling superconductivity.”

This study was published in Physical Review Letters (PRL) on November 27 as the Editor’s Suggestion. It was also featured in Viewpoint in Physics, in which the top 3% of PRL papers are presented with a commentary. It was also featured on Phys.org, which is a science news website led by the US national research institutes. Furthermore, the equipment designed and manufactured by Professor Lee’s team and used for the research was selected for the cover of Review of Scientific Instruments (RSI) in the October 2017 issue.

Professor Lee said, “When designing the experiment, we attempted to implement some decisive features. For instance, we included a spin control function using an antiferromagnetic probe, wide range variable temperature functions that were thought to be impossible in high-magnetic field structures, and multiple sample storage functions at low temperatures for systematic spin control experiments, rather than using simpler scanning probe microscopes with well-known principles or commercial microscopes. As a result, we were able to conduct systematic experiments on controlling magnetism and superconductivity, which competing groups would take years to replicate.”

He continued, “There were some minor difficulties in the basic science research environment such as the lack of a shared helium liquefier on campus and insufficient university-scale appreciation for large scale physics that inevitably takes time. We will do our best to lead the advancement of cutting-edge science through research projects expanding on this achievement in physical knowledge to practical devices and various technological innovations in measurements.” This research was funded by National Research Foundation of Korea.

Figure 1. Research concept illustration

The spin-polarized chromium (Cr) tip being scanned over the pristine superconducting area of the C2 magnetic order, represented in the background with electron pairs shown as coupled red spheres. The spin current through the tip induces the C4 magnetic order (yellow and blue plaquettes) with suppressed superconductivity in the sample because its spin fluctuations cannot mediate electron pairing, represented as decoupled red spheres in the plaquette area.

2018.01.05 View 6702 -

Ultra-Low Power Flexible Memory Using 2D Materials

(Professor Choi and Ph.D. candidate Jang)

KAIST research team led by Professor Sung-Yool Choi at School of Electrical Engineering and Professor Sung Gap Im at the Department of Chemical and Biomolecular Engineering developed high-density, ultra-low power, non-volatile, flexible memory technology using 2D materials. The team used ultrathin molybdenum disulfide (MoS2) with atomic-scale thickness as the channel material and high-performance polymeric insulator film as the tunneling dielectric material. This research was published on the cover of Advanced Functional Materials on November 17. KAIST graduate Myung Hun Woo, a researcher at Samsung Electronics and Ph.D. candidate Byung Chul Jang are first authors.

The surge of new technologies such as Internet of Things (IoT), Artificial Intelligence (AI), and cloud server led to the paradigm shift from processor-centric computing to memory-centric computing in the industry, as well as the increase in demand of wearable devices. This led to an increased need for high-density, ultra-low power, non-volatile flexible memory. In particular, ultrathin MoS2 as semiconductor material has been recently regarded as post-silicon material. This is due to its ultrathin thickness of atomic-scale which suppresses short channel effect observed in conventional silicon material, leading to advantages in high- density and low-power consumption. Further, this thickness allows the material to be flexible, and thus the material is applicable to wearable devices.

However, due to the dangling-bond free surface of MoS2 semiconductor material, it is difficult to deposit the thin insulator film to be uniform and stable over a large area via the conventional atomic layer deposition process. Further, the currently used solution process makes it difficult to deposit uniformly low dielectric constant (k) polymeric insulator film with sub-10 nm thickness on a large area, thus indicating that the memory device utilizing the conventional solution-processed polymer insulator film cannot be operated at low-operating voltage and is not compatible with photolithography.

The research team tried to overcome the hurdles and develop high-density, ultra-low power, non-volatile flexible memory by employing a low-temperature, solvent-free, and all-dry vapor phase technique named initiated chemical vapor deposition (iCVD) process. Using iCVD process, tunneling polymeric insulator film with 10 nm thickness was deposited uniformly on MoS2 semiconductor material without being restricted by the dangling bond-free surface of MoS2. The team observed that the newly developed MoS2-based non-volatile memory can be operated at low-voltage (around 10V), in contrast to the conventional MoS2-based non-volatile memory that requires over 20V.

Professor Choi said, “As the basis for the Fourth Industrial revolution technologies including AI and IoT, semiconductor device technology needs to have characteristics of low-power and flexibility, in clear contrast to conventional memory devices.” He continued, “This new technology is significant in developing source technology in terms of materials, processes, and devices to contribute to achieve these characteristics.”

This research was supported by the Global Frontier Center for Advanced Soft Electronics and the Creative Materials Discovery Program by funded the National Research Foundation of Korea of Ministry of Science and ICT.

( Figure 1. Cover of Advanced Functional Materials)

(Figure 2. Concept map for the developed non-volatile memory material and high-resolution transmission electron microscopy image for material cross-section )

2018.01.02 View 10969

Ultra-Low Power Flexible Memory Using 2D Materials

(Professor Choi and Ph.D. candidate Jang)

KAIST research team led by Professor Sung-Yool Choi at School of Electrical Engineering and Professor Sung Gap Im at the Department of Chemical and Biomolecular Engineering developed high-density, ultra-low power, non-volatile, flexible memory technology using 2D materials. The team used ultrathin molybdenum disulfide (MoS2) with atomic-scale thickness as the channel material and high-performance polymeric insulator film as the tunneling dielectric material. This research was published on the cover of Advanced Functional Materials on November 17. KAIST graduate Myung Hun Woo, a researcher at Samsung Electronics and Ph.D. candidate Byung Chul Jang are first authors.

The surge of new technologies such as Internet of Things (IoT), Artificial Intelligence (AI), and cloud server led to the paradigm shift from processor-centric computing to memory-centric computing in the industry, as well as the increase in demand of wearable devices. This led to an increased need for high-density, ultra-low power, non-volatile flexible memory. In particular, ultrathin MoS2 as semiconductor material has been recently regarded as post-silicon material. This is due to its ultrathin thickness of atomic-scale which suppresses short channel effect observed in conventional silicon material, leading to advantages in high- density and low-power consumption. Further, this thickness allows the material to be flexible, and thus the material is applicable to wearable devices.

However, due to the dangling-bond free surface of MoS2 semiconductor material, it is difficult to deposit the thin insulator film to be uniform and stable over a large area via the conventional atomic layer deposition process. Further, the currently used solution process makes it difficult to deposit uniformly low dielectric constant (k) polymeric insulator film with sub-10 nm thickness on a large area, thus indicating that the memory device utilizing the conventional solution-processed polymer insulator film cannot be operated at low-operating voltage and is not compatible with photolithography.

The research team tried to overcome the hurdles and develop high-density, ultra-low power, non-volatile flexible memory by employing a low-temperature, solvent-free, and all-dry vapor phase technique named initiated chemical vapor deposition (iCVD) process. Using iCVD process, tunneling polymeric insulator film with 10 nm thickness was deposited uniformly on MoS2 semiconductor material without being restricted by the dangling bond-free surface of MoS2. The team observed that the newly developed MoS2-based non-volatile memory can be operated at low-voltage (around 10V), in contrast to the conventional MoS2-based non-volatile memory that requires over 20V.

Professor Choi said, “As the basis for the Fourth Industrial revolution technologies including AI and IoT, semiconductor device technology needs to have characteristics of low-power and flexibility, in clear contrast to conventional memory devices.” He continued, “This new technology is significant in developing source technology in terms of materials, processes, and devices to contribute to achieve these characteristics.”

This research was supported by the Global Frontier Center for Advanced Soft Electronics and the Creative Materials Discovery Program by funded the National Research Foundation of Korea of Ministry of Science and ICT.

( Figure 1. Cover of Advanced Functional Materials)

(Figure 2. Concept map for the developed non-volatile memory material and high-resolution transmission electron microscopy image for material cross-section )

2018.01.02 View 10969 -

Non-Adiabatic Reaction Mechanism Identified at Conical Intersection

(Professor Kim(center) and Ph.D. candidates Kyung Chul Woo (left) and Kang Do Hyung)

Research team led by Professor Sang Kyu Kim at KAIST Department of Chemistry observed two distinct reaction pathways that occur at conical intersection where two different adiabatic potential energy surfaces cross at the same nuclear configuration.

Professor Kim previously identified the existence and molecular structure of conical intersection in 2010. In this following study, the team accurately measured reaction rates of two totally different reaction pathways activated only at conical intersection where the seminal Born-Oppenheimer approximation breaks down.

This study led by Kyung Chul Woo (1st author) and Do Hyung Kang, both Ph.D. candidates at KAIST, was published in Journal of the American Chemical Society in November 7th, 2017.

Chemical reaction induced by light occurs in excited electronic states where the reaction outcome is often destined by coupling among different electronic states mediated by nuclear motions during chemical reaction. Such a coupling is most critical and important at the conical intersection as nonadiabtic surface-hopping is most probable at situation where the Born-Oppenheimer approximation fails.

Professor Kim used spectroscopic methods in 2010 to experimentally observe conical intersection of polyatomic molecule. And yet, it was not possible to disentangle complex dynamic processes with frequency-domain study only.

The research team used pico-second time-resolution kinetic energy resolved mass spectrometry to identify two possible distinct reaction pathways in both energy and time domains.,.

The research team demonstrated that the reactive flux prepared at the conical intersection is bifurcated into adiabatic or non-adiabatic reaction pathways. These two pathways are quite distinct in terms of reaction rates, energy releases, and product branching ratios.

This is the first study to capture the moment of bifurcation dynamics at the conical intersection for complex polyatomic molecular system. The study could contribute to conceptual improvement in understanding complicated nonadiabatic dynamics in general.

Professor Kim said, “Basic science research is essential in understanding and wisely using the nature. New technological advances cannot be made without the advancement in basic science.” He continued, “I hope this study could lead to growth in many young academic talents in basic sciences.”

(Figure 1. Reaction graph starting from reaction intersection that divides into adiabatic reaction pathway (red) and non-adiabatic pathway (blue))

2017.12.19 View 7245

Non-Adiabatic Reaction Mechanism Identified at Conical Intersection

(Professor Kim(center) and Ph.D. candidates Kyung Chul Woo (left) and Kang Do Hyung)

Research team led by Professor Sang Kyu Kim at KAIST Department of Chemistry observed two distinct reaction pathways that occur at conical intersection where two different adiabatic potential energy surfaces cross at the same nuclear configuration.

Professor Kim previously identified the existence and molecular structure of conical intersection in 2010. In this following study, the team accurately measured reaction rates of two totally different reaction pathways activated only at conical intersection where the seminal Born-Oppenheimer approximation breaks down.

This study led by Kyung Chul Woo (1st author) and Do Hyung Kang, both Ph.D. candidates at KAIST, was published in Journal of the American Chemical Society in November 7th, 2017.

Chemical reaction induced by light occurs in excited electronic states where the reaction outcome is often destined by coupling among different electronic states mediated by nuclear motions during chemical reaction. Such a coupling is most critical and important at the conical intersection as nonadiabtic surface-hopping is most probable at situation where the Born-Oppenheimer approximation fails.

Professor Kim used spectroscopic methods in 2010 to experimentally observe conical intersection of polyatomic molecule. And yet, it was not possible to disentangle complex dynamic processes with frequency-domain study only.

The research team used pico-second time-resolution kinetic energy resolved mass spectrometry to identify two possible distinct reaction pathways in both energy and time domains.,.

The research team demonstrated that the reactive flux prepared at the conical intersection is bifurcated into adiabatic or non-adiabatic reaction pathways. These two pathways are quite distinct in terms of reaction rates, energy releases, and product branching ratios.

This is the first study to capture the moment of bifurcation dynamics at the conical intersection for complex polyatomic molecular system. The study could contribute to conceptual improvement in understanding complicated nonadiabatic dynamics in general.

Professor Kim said, “Basic science research is essential in understanding and wisely using the nature. New technological advances cannot be made without the advancement in basic science.” He continued, “I hope this study could lead to growth in many young academic talents in basic sciences.”

(Figure 1. Reaction graph starting from reaction intersection that divides into adiabatic reaction pathway (red) and non-adiabatic pathway (blue))

2017.12.19 View 7245 -

New Quantum Mechanical States Observed

(Professor Han (far right) and his research team)

A KAIST research team observed a new quantum mechanical magnetic state ‘Jeff = 3/2.’ This first observation of ‘Jeff=3/2’ could be the foundation for future research on superconductivity and quantum magnetism.

In quantum mechanics, total angular momentum is defined as the sum of spin and orbital angular momenta and is denoted with the ‘J.’ The newly identified magnetic moment can be described as a kind of angular momentum that occurs when specific conditions are met and has been denoted ‘Jeff’ with the meaning ‘effective angular momentum’ in the field. Jeff=3/2 has been a topic of discussion but was yet to be observed.

The research was co-led by Professor Myung Joon Han of the Department of Physics at Chung-Ang University in Korea, RIKEN in Japan, and the Argonne National Laboratory in the US. This research was published in Nature Communications on October 14, 2017.

In academia, spin-orbital coupling was known to lead to a unique quantum state and has been an active area of recent research. In contrast to magnetic moment by electron spin and orbital, the effective magnetic moment Jeff, formed from the coupling of the two, shows a unique ground state and interaction patterns, which could lead to new phenomena and properties.

Most studies in the last decade focused on ‘Jeff=1/2’, but there has not been any observation of ‘Jeff=3/2’, which led to slow progress. In 2014, the research team led by Prof. Han theoretically predicted the possibility of the ‘Jeff=3/2’ state in a certain type of materials based on molecular orbital, instead of atomic orbital. In the current study, the team applied the Selection Rule of quantum mechanics for the ‘Jeff=3/2’ state, which differs to the general spin moment, in order to experimentally detect this moment.

When electrons near the atomic nucleus are excited by X-rays, the excited electrons can be absorbed or re-emitted through interactions with other electrons. Here, the Selection Rule is applied to electrons. According to quantum mechanics, this rule is very unique in the ‘Jeff=3/2’ state and ‘Jeff=3/2’ is predicted to be distinguishable from general spin states. The prediction that was made using this idea was verified through the experiment using electrons extracted from tantalum at two different energy levels. In this material, the unique quantum mechanical interference by the ‘Jeff=3/2’ moment can be taken as direct evidence for its existence.

The new quantum state is very unique from any of the previously known magnetic states and this study could be the starting point for future research on the ‘Jeff=3/2’ moment. Further, this finding could contribute to future research on various properties of the magnetic states and its interactions.

(Figure 1: Crystal structure, MO levels, and RIXS process in GaTa4Se8.)

(Figure 2: Cluster model calculations of the L3 and L2 RIXS spectra)

2017.12.14 View 6526

New Quantum Mechanical States Observed

(Professor Han (far right) and his research team)

A KAIST research team observed a new quantum mechanical magnetic state ‘Jeff = 3/2.’ This first observation of ‘Jeff=3/2’ could be the foundation for future research on superconductivity and quantum magnetism.

In quantum mechanics, total angular momentum is defined as the sum of spin and orbital angular momenta and is denoted with the ‘J.’ The newly identified magnetic moment can be described as a kind of angular momentum that occurs when specific conditions are met and has been denoted ‘Jeff’ with the meaning ‘effective angular momentum’ in the field. Jeff=3/2 has been a topic of discussion but was yet to be observed.

The research was co-led by Professor Myung Joon Han of the Department of Physics at Chung-Ang University in Korea, RIKEN in Japan, and the Argonne National Laboratory in the US. This research was published in Nature Communications on October 14, 2017.

In academia, spin-orbital coupling was known to lead to a unique quantum state and has been an active area of recent research. In contrast to magnetic moment by electron spin and orbital, the effective magnetic moment Jeff, formed from the coupling of the two, shows a unique ground state and interaction patterns, which could lead to new phenomena and properties.

Most studies in the last decade focused on ‘Jeff=1/2’, but there has not been any observation of ‘Jeff=3/2’, which led to slow progress. In 2014, the research team led by Prof. Han theoretically predicted the possibility of the ‘Jeff=3/2’ state in a certain type of materials based on molecular orbital, instead of atomic orbital. In the current study, the team applied the Selection Rule of quantum mechanics for the ‘Jeff=3/2’ state, which differs to the general spin moment, in order to experimentally detect this moment.

When electrons near the atomic nucleus are excited by X-rays, the excited electrons can be absorbed or re-emitted through interactions with other electrons. Here, the Selection Rule is applied to electrons. According to quantum mechanics, this rule is very unique in the ‘Jeff=3/2’ state and ‘Jeff=3/2’ is predicted to be distinguishable from general spin states. The prediction that was made using this idea was verified through the experiment using electrons extracted from tantalum at two different energy levels. In this material, the unique quantum mechanical interference by the ‘Jeff=3/2’ moment can be taken as direct evidence for its existence.

The new quantum state is very unique from any of the previously known magnetic states and this study could be the starting point for future research on the ‘Jeff=3/2’ moment. Further, this finding could contribute to future research on various properties of the magnetic states and its interactions.

(Figure 1: Crystal structure, MO levels, and RIXS process in GaTa4Se8.)

(Figure 2: Cluster model calculations of the L3 and L2 RIXS spectra)

2017.12.14 View 6526 -

Dr. Steven Chu Talks on Sustainable Energy Policy at KAIST

Nobel Laureate in physics and former US Energy Secretary Steven Chu called for concerted efforts to develop a more sustainable energy policy and portfolio at a lecture held at KAIST and a forum in Seoul on November 23.

A policy with an energy mix including nuclear power and renewable energy could be ideal for retaining a stable energy supply given Korea’s very limited geographical conditions, Chu said during the Future Energy Forum in Seoul. He also held a lecture at KAIST’s Daejeon campus on “Climate Change, the Importance of Science and Policy in Achieving a Sustainable Future.”

He said that unlike the United States, Korea and Japan have geographical limitations for generating enough renewable energy. "Wind speeds of more than 10 meters per second would allow wind power generation, but, South Korea's southernmost wind speed in Jeju is less than 8 meters per second, and the amount of sunshine is lower than in the Middle East. It is ideal to combine renewable energy with nuclear power plants," he said.

Chu also stressed the role of science in achieving a sustainable future, citing many cases in foreign countries. For instance, Germany once decided to do away with nuclear power. However, their initial plan does not directly raise energy efficiency and the proportion of fossil fuels has led to an increase in the environmental issue of fine particular matter as well as carbon dioxide emission increases.

He said that in the long term, renewable energy will emerge as major alternative resources, stressing the role of science in achieving a sustainable future. Without this alternative, we will eventually burn more fossil fuels and pollute the air.

Chu also said that nuclear waste and safe plant operation will be a big concern, but it is technologically viable since Korea has already proven its prowess in nuclear power plant building and safety technology.

Chu added, "Research in chemical energy storage through novel electrochemistry may lead to solutions, but for the next half century we will need additional energy-on-demand and carbon-free sources of energy from proven technologies."

"While science, innovation and technology will no doubt lead to better solutions, sound government policies are needed to advance the transition to carbon-free energy needed to achieve a more sustainable world," he said.

After serving as the US Secretary of Energy for four years from 2009 to 2013, Professor Chu returned to Stanford University, and currently holds a position of the William R. Kenan, Jr. Professor of Physics as well as Professor in the Department of Molecular and Cellular Physiology.

Professor Chu is known for his research at Bell Labs and Stanford University regarding the cooling and trapping of atoms with laser light, for which he won the Nobel Prize in Physics in 1997.

2017.11.24 View 5886

Dr. Steven Chu Talks on Sustainable Energy Policy at KAIST

Nobel Laureate in physics and former US Energy Secretary Steven Chu called for concerted efforts to develop a more sustainable energy policy and portfolio at a lecture held at KAIST and a forum in Seoul on November 23.

A policy with an energy mix including nuclear power and renewable energy could be ideal for retaining a stable energy supply given Korea’s very limited geographical conditions, Chu said during the Future Energy Forum in Seoul. He also held a lecture at KAIST’s Daejeon campus on “Climate Change, the Importance of Science and Policy in Achieving a Sustainable Future.”

He said that unlike the United States, Korea and Japan have geographical limitations for generating enough renewable energy. "Wind speeds of more than 10 meters per second would allow wind power generation, but, South Korea's southernmost wind speed in Jeju is less than 8 meters per second, and the amount of sunshine is lower than in the Middle East. It is ideal to combine renewable energy with nuclear power plants," he said.

Chu also stressed the role of science in achieving a sustainable future, citing many cases in foreign countries. For instance, Germany once decided to do away with nuclear power. However, their initial plan does not directly raise energy efficiency and the proportion of fossil fuels has led to an increase in the environmental issue of fine particular matter as well as carbon dioxide emission increases.

He said that in the long term, renewable energy will emerge as major alternative resources, stressing the role of science in achieving a sustainable future. Without this alternative, we will eventually burn more fossil fuels and pollute the air.

Chu also said that nuclear waste and safe plant operation will be a big concern, but it is technologically viable since Korea has already proven its prowess in nuclear power plant building and safety technology.

Chu added, "Research in chemical energy storage through novel electrochemistry may lead to solutions, but for the next half century we will need additional energy-on-demand and carbon-free sources of energy from proven technologies."

"While science, innovation and technology will no doubt lead to better solutions, sound government policies are needed to advance the transition to carbon-free energy needed to achieve a more sustainable world," he said.

After serving as the US Secretary of Energy for four years from 2009 to 2013, Professor Chu returned to Stanford University, and currently holds a position of the William R. Kenan, Jr. Professor of Physics as well as Professor in the Department of Molecular and Cellular Physiology.

Professor Chu is known for his research at Bell Labs and Stanford University regarding the cooling and trapping of atoms with laser light, for which he won the Nobel Prize in Physics in 1997.

2017.11.24 View 5886 -

Platinum Single Atom Catalysts for 'Direct Formic Acid Fuel Cells'

(Professor Hyunjoo Lee (left) and Ph.D. candidate Jiwhan Kim)

A research team co-led by Professor Hyunjoo Lee at the Department of Chemical and Biomolecular Engineering at KAIST and Professor Jeong Woo Han from the University of Seoul synthesized highly stable high-Pt-content single atom catalysts for direct formic acid fuel cells. The amount of platinum can be reduced to 1/10 of that of conventional platinum nanoparticle catalysts.

Platinum (Pt) catalysts have been used in various catalytic reactions due to their high activity and stability. However, because Pt is rare and expensive, it is important to reduce the amount of Pt used. Pt single atom catalysts can reduce the size of the Pt particles to the size of an atom. Thus, the cost of Pt catalysts can be minimized because all of the Pt atoms can participate in the catalytic reactions. Additionally, single atom catalysts have no ensemble site in which two or more atoms are attached, and thus, the reaction selectivity is different from that of nanoparticle catalysts.

Despite these advantages, single atom catalysts are easily aggregated and less stable due to their low coordination number and high surface free energy. It is difficult to develop a single atom catalyst with high content and high stability, and thus, its application in practical devices is limited.

Direct formic acid fuel cells can be an energy source for next-generation portable devices because liquid formic acid as a fuel is safer and easier to store and transport than high-pressure hydrogen gas.

To improve the stability of Pt single atom catalysts, Professor Lee’s group developed a Pt-Sn single atom alloy structure on an antimony-doped tin oxide (ATO) support. This structure has been proven by computational calculations which show that Pt single atoms substitute antimony sites in the antimony-tin alloy structure and are thermodynamically stable. This catalyst has been shown to have a higher activity up to 50 times per weight of Pt than that of the commercial catalyst, Pt/C, in the oxidation of formic acid, and the stability of the catalyst was also remarkably high.

Professor Lee’s group also used a single atomic catalyst in a 'direct formic acid fuel cell’ consisting of membranes and electrodes. It is the first attempt to apply a single atomic catalyst to a full cell. In this case, an output similar to that of the commercial catalyst could be obtained by using 1/10 of the platinum compared to the commercial Pt/C catalyst.

Ph.D. candidate Jiwhan Kim from KAIST was the first author of the research. This research was published online on September 11 in Advanced Energy Materials.

This research was carried out with the support of the Samsung Electronics Future Technology Development Center.

(Figure 1. Concept photograph for Pt single atom catalysts.)

(Figure 2. Pt single atom catalysts by HAADF-STEM analysis (bright white circles))

2017.10.31 View 8377

Platinum Single Atom Catalysts for 'Direct Formic Acid Fuel Cells'

(Professor Hyunjoo Lee (left) and Ph.D. candidate Jiwhan Kim)

A research team co-led by Professor Hyunjoo Lee at the Department of Chemical and Biomolecular Engineering at KAIST and Professor Jeong Woo Han from the University of Seoul synthesized highly stable high-Pt-content single atom catalysts for direct formic acid fuel cells. The amount of platinum can be reduced to 1/10 of that of conventional platinum nanoparticle catalysts.

Platinum (Pt) catalysts have been used in various catalytic reactions due to their high activity and stability. However, because Pt is rare and expensive, it is important to reduce the amount of Pt used. Pt single atom catalysts can reduce the size of the Pt particles to the size of an atom. Thus, the cost of Pt catalysts can be minimized because all of the Pt atoms can participate in the catalytic reactions. Additionally, single atom catalysts have no ensemble site in which two or more atoms are attached, and thus, the reaction selectivity is different from that of nanoparticle catalysts.

Despite these advantages, single atom catalysts are easily aggregated and less stable due to their low coordination number and high surface free energy. It is difficult to develop a single atom catalyst with high content and high stability, and thus, its application in practical devices is limited.

Direct formic acid fuel cells can be an energy source for next-generation portable devices because liquid formic acid as a fuel is safer and easier to store and transport than high-pressure hydrogen gas.

To improve the stability of Pt single atom catalysts, Professor Lee’s group developed a Pt-Sn single atom alloy structure on an antimony-doped tin oxide (ATO) support. This structure has been proven by computational calculations which show that Pt single atoms substitute antimony sites in the antimony-tin alloy structure and are thermodynamically stable. This catalyst has been shown to have a higher activity up to 50 times per weight of Pt than that of the commercial catalyst, Pt/C, in the oxidation of formic acid, and the stability of the catalyst was also remarkably high.

Professor Lee’s group also used a single atomic catalyst in a 'direct formic acid fuel cell’ consisting of membranes and electrodes. It is the first attempt to apply a single atomic catalyst to a full cell. In this case, an output similar to that of the commercial catalyst could be obtained by using 1/10 of the platinum compared to the commercial Pt/C catalyst.

Ph.D. candidate Jiwhan Kim from KAIST was the first author of the research. This research was published online on September 11 in Advanced Energy Materials.

This research was carried out with the support of the Samsung Electronics Future Technology Development Center.

(Figure 1. Concept photograph for Pt single atom catalysts.)

(Figure 2. Pt single atom catalysts by HAADF-STEM analysis (bright white circles))

2017.10.31 View 8377 -

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 30331

Humicotta Wins the Silver Prize at the 2017 IDEA

The 3D-printed ceramic humidifier made by the research team led by Professor Sang-Min Bae won the silver prize at the 2017 International Design Excellence Awards (IDEA). Professor Bae’s ID+IM team was also listed as winners of three more appropriate technology designs at the IDEA. The awards, sponsored by the Industrial Designers Society of America, are one of the three prestigious design awards including the Red Dot Design Award and the iF Design Award in Germany.

The silver prize winner in the category of home and bath, Humicotta is an energy-efficient, bacteria free, and easy to clean humidifier. It includes a base module and filter. The base is a cylindrical pedestal with a built-in fan on which the filter is placed. The filter is a 3D-printed honeycomb structure made of diatomite. When water is added, the honeycomb structure and porous terracotta maximize natural humidification. It also offers an open platform service that customizes the filters or provides files that users can use their own 3D printer.

Professor Bae’s team has worked on philanthropy design using appropriate technology as their main topic for years. Their designs have been recognized at prestigious global design awards events, winning more than 50 prizes with innovative designs made for addressing various global and social problems.

The Light Funnel is a novel type of lighting device designed for off-grid areas of Africa. It helps to maximize the natural light effect in the daytime without any drastic home renovations. It consists of a transparent acrylic sphere and a reflective pathway. After filling the acrylic sphere with water and placing it on a rooftop, sunlight passes into the house through the water inside the sphere. It provides a lighted environment nine times brighter than without it. Also, once installed, it can be used almost permanently.

The Maasai Smart Cane is made using wood sticks purchased through fair trade with the Maasai tribe. GPS is installed into the grip of the birch-tree cane, so that cane users can send a signal when in an emergency situation. All of the proceeds of this product go to the tribe.

S.Cone is a first aid kit made in collaboration with Samsung Fire and Marine Insurance. The traffic cone-shaped kit is designed to help users handle an emergency situation intact and safe. The S.Cone has unique versions for fires, car accidents, and marine accidents. For example, the S.Cone for fires is equipped with a small fire extinguisher, smoke mask, and fire blanket. The cap of the S.Cone also functions as an IoT station connecting the fire and gas detector with smart phones.

Professor Bae said of his team’s winning design products, “By making the data public, any person can design their own humidifier if they have access to a 3D-printer. We want it to be a very accessible product for the public. The Light Funnel and Maasai Smart Cane are designed for economically-marginalized populations and the elderly. We will continue to make the best designed products serving the marginalized 90% of the population around the world.”

2017.09.14 View 30331 -

Innovative Nanosensor for Disease Diagnosis

(Figure 1. Sensing Device)

(Figure 2. Protein templating route)

Breath pattern recognition is a futuristic diagnostic platform. Simple characterizing target gas concentrations of human exhaled breath will lead to diagnose of the disease as well as physical condition.

A research group under Prof. Il-Doo Kim in the Department of Materials Science has developed diagnostic sensors using protein-encapsulated nanocatalysts, which can diagnose certain diseases by analyzing human exhaled breath. This technology enables early monitoring of various diseases through pattern recognition of biomarker gases related to diseases in human exhalation.

The protein-templated catalyst synthesis route is very simple and versatile for producing not only a single component of catalytic nanoparticles, but also diverse heterogeneous intermetallic catalysts with sizes less than 3 nm. The research team has developed ever more sensitive and selective chemiresistive sensors that can potentially diagnose specific diseases by analyzing exhaled breath gases.

The results of this study, which were contributed by Dr. Sang-Joon Kim and Dr. Seon-Jin Choi as first authors were selected as the cover-featured article in the July issue of 'Accounts of Chemical Research,' an international journal of the American Chemical Society.

In human breath, diverse components are found including water vapor, hydrogen, acetone, toluene, ammonia, hydrogen sulfide, and carbon monoxide, which are more excessively exhaled from patients. Some of these components are closely related to diseases such as asthma, lung cancer, type 1 diabetes mellitus, and halitosis.

Breath analysis for disease diagnosis started from capturing exhaled breaths in a Tedlar bag and subsequently the captured breath gases were injected into a miniaturized sensor system, similar to an alcohol detector. It is possible to analyze exhaled breath very rapidly with a simple analyzing process. The breath analysis can detect trace changes in exhaled breath components, which contribute to early diagnosis of diseases.

However, technological advances are needed to accurately analyze gases in the breath, which occur at very low levels, from 1 ppb to 1 ppm. In particular, it has been a critical challenge for chemiresistive type chemical sensors to selectively detect specific biomarkers in thousands of interfering gases including humid vapor.

Conventionally, noble metallic catalysts such as platinum and palladium have been functionalized onto metal oxide sensing layers. However, the gas sensitivity was not enough to detect ppb-levels of biomarker species in exhaled breath.

To overcome the current limitations, the research team utilized nanoscale protein (apoferritin) in animals as sacrificial templates. The protein templates possess hollow nanocages at the core site and various alloy catalytic nanoparticles can be encapsulated inside the protein nanocages.

The protein nanocages are advantageous because a nearly unlimited number of material compositions in the periodic table can be assembled for the synthesis of heterogeneous catalytic nanoparticles. In addition, intermetallic nanocatalysts with a controlled atomic ratio of two different elements can be achieved using the protein nanocages, which is an innovative strategy for finding new types of catalysts. For example, highly efficient platinum-based catalysts can be synthesized, such as platinum-palladium (PtPd), platinum-nickel (PtNi), platinum-ruthenium (PtRu), and platinum-yttrium (PtY).

The research team developed outstanding sensing layers consisting of metal oxide nanofibers functionalized by the heterogeneous catalysts with large and highly-porous surface areas, which are especially optimized for selective detection of specific biomarkers. The biomarker sensing performance was improved approximately 3~4-fold as compared to the conventional single component of platinum and palladium catalysts-loaded nanofiber sensors. In particular, 100-fold resistance transitions toward acetone (1 ppm) and hydrogen sulfide (1 ppm) were observed in exhaled breath sensors using the heterogeneous nanocatalysts, which is the best performance ever reported in literature.

The research team developed a disease diagnosis platform that recognizes individual breathing patterns by using a multiple sensor array system with diverse sensing layers and heterogeneous catalysts, so that the people can easily identify health abnormalities. Using a 16-sensor array system, physical conditions can be continuously monitored by analyzing concentration changes of biomarkers in exhaled breath gases.

Prof. Kim said, “New types of heterogeneous nanocatalysts were synthesized using protein templates with sizes around 2 nm and functionalized on various metal oxide nanofiber sensing layers. The established sensing libraries can detect biomarker species with high sensitivity and selectivity.” He added, “the new and innovative breath gas analysis platform will be very helpful for reducing medical expenditures and continuous monitoring of physical conditions”

Patents related to this technology were licensed to two companies in March and June this year.

2017.07.19 View 11982

Innovative Nanosensor for Disease Diagnosis

(Figure 1. Sensing Device)

(Figure 2. Protein templating route)

Breath pattern recognition is a futuristic diagnostic platform. Simple characterizing target gas concentrations of human exhaled breath will lead to diagnose of the disease as well as physical condition.

A research group under Prof. Il-Doo Kim in the Department of Materials Science has developed diagnostic sensors using protein-encapsulated nanocatalysts, which can diagnose certain diseases by analyzing human exhaled breath. This technology enables early monitoring of various diseases through pattern recognition of biomarker gases related to diseases in human exhalation.

The protein-templated catalyst synthesis route is very simple and versatile for producing not only a single component of catalytic nanoparticles, but also diverse heterogeneous intermetallic catalysts with sizes less than 3 nm. The research team has developed ever more sensitive and selective chemiresistive sensors that can potentially diagnose specific diseases by analyzing exhaled breath gases.

The results of this study, which were contributed by Dr. Sang-Joon Kim and Dr. Seon-Jin Choi as first authors were selected as the cover-featured article in the July issue of 'Accounts of Chemical Research,' an international journal of the American Chemical Society.

In human breath, diverse components are found including water vapor, hydrogen, acetone, toluene, ammonia, hydrogen sulfide, and carbon monoxide, which are more excessively exhaled from patients. Some of these components are closely related to diseases such as asthma, lung cancer, type 1 diabetes mellitus, and halitosis.

Breath analysis for disease diagnosis started from capturing exhaled breaths in a Tedlar bag and subsequently the captured breath gases were injected into a miniaturized sensor system, similar to an alcohol detector. It is possible to analyze exhaled breath very rapidly with a simple analyzing process. The breath analysis can detect trace changes in exhaled breath components, which contribute to early diagnosis of diseases.

However, technological advances are needed to accurately analyze gases in the breath, which occur at very low levels, from 1 ppb to 1 ppm. In particular, it has been a critical challenge for chemiresistive type chemical sensors to selectively detect specific biomarkers in thousands of interfering gases including humid vapor.

Conventionally, noble metallic catalysts such as platinum and palladium have been functionalized onto metal oxide sensing layers. However, the gas sensitivity was not enough to detect ppb-levels of biomarker species in exhaled breath.

To overcome the current limitations, the research team utilized nanoscale protein (apoferritin) in animals as sacrificial templates. The protein templates possess hollow nanocages at the core site and various alloy catalytic nanoparticles can be encapsulated inside the protein nanocages.

The protein nanocages are advantageous because a nearly unlimited number of material compositions in the periodic table can be assembled for the synthesis of heterogeneous catalytic nanoparticles. In addition, intermetallic nanocatalysts with a controlled atomic ratio of two different elements can be achieved using the protein nanocages, which is an innovative strategy for finding new types of catalysts. For example, highly efficient platinum-based catalysts can be synthesized, such as platinum-palladium (PtPd), platinum-nickel (PtNi), platinum-ruthenium (PtRu), and platinum-yttrium (PtY).

The research team developed outstanding sensing layers consisting of metal oxide nanofibers functionalized by the heterogeneous catalysts with large and highly-porous surface areas, which are especially optimized for selective detection of specific biomarkers. The biomarker sensing performance was improved approximately 3~4-fold as compared to the conventional single component of platinum and palladium catalysts-loaded nanofiber sensors. In particular, 100-fold resistance transitions toward acetone (1 ppm) and hydrogen sulfide (1 ppm) were observed in exhaled breath sensors using the heterogeneous nanocatalysts, which is the best performance ever reported in literature.

The research team developed a disease diagnosis platform that recognizes individual breathing patterns by using a multiple sensor array system with diverse sensing layers and heterogeneous catalysts, so that the people can easily identify health abnormalities. Using a 16-sensor array system, physical conditions can be continuously monitored by analyzing concentration changes of biomarkers in exhaled breath gases.

Prof. Kim said, “New types of heterogeneous nanocatalysts were synthesized using protein templates with sizes around 2 nm and functionalized on various metal oxide nanofiber sensing layers. The established sensing libraries can detect biomarker species with high sensitivity and selectivity.” He added, “the new and innovative breath gas analysis platform will be very helpful for reducing medical expenditures and continuous monitoring of physical conditions”

Patents related to this technology were licensed to two companies in March and June this year.

2017.07.19 View 11982 -

Professor Poong Hyun Seong Selected as Fellow of the ANS

Professor Poong Hyun Seong of the Department of Nuclear and Quantum Engineering was selected as a fellow of the American Nuclear Society.

The selection was announced at their annual meeting held in San Francisco on June 12, in recognition of Professor Seong's contributions to the field of nuclear instrumentation, control andhuman factors engineering.

Founded in 1954, the American Nuclear Society selects scholars who have made outstanding achievements and contributions to the development of the nuclear engineering field each year.

Professor Seong's researches in the field of nuclear instrumentation, control and human factors engineering have contributed to the safe operation of nuclear power plants, to the development of systems to maintain nuclear power plants safely in the event of emergency and to the enhancement of effective response capabilities of nuclear power plant operators. His researches significantly contributed to the safety improvement of nuclear power plants and have been recognized worldwide.

Professor Seong said, "Korea has emerged as a nuclear powerhouse. I think not only my academic career but our national reputation in the field of nuclear research has been well recognized by our global peers.” Professor Seong has served as president of the Korean Nuclear Society, editor in chief of Nuclear Engineering and Technology, and as a commissioner of the Korean Nuclear Safety Commission. He is currently working as a commissioner of the Korean Atomic Energy Commission.

2017.06.29 View 9716

Professor Poong Hyun Seong Selected as Fellow of the ANS

Professor Poong Hyun Seong of the Department of Nuclear and Quantum Engineering was selected as a fellow of the American Nuclear Society.

The selection was announced at their annual meeting held in San Francisco on June 12, in recognition of Professor Seong's contributions to the field of nuclear instrumentation, control andhuman factors engineering.

Founded in 1954, the American Nuclear Society selects scholars who have made outstanding achievements and contributions to the development of the nuclear engineering field each year.

Professor Seong's researches in the field of nuclear instrumentation, control and human factors engineering have contributed to the safe operation of nuclear power plants, to the development of systems to maintain nuclear power plants safely in the event of emergency and to the enhancement of effective response capabilities of nuclear power plant operators. His researches significantly contributed to the safety improvement of nuclear power plants and have been recognized worldwide.

Professor Seong said, "Korea has emerged as a nuclear powerhouse. I think not only my academic career but our national reputation in the field of nuclear research has been well recognized by our global peers.” Professor Seong has served as president of the Korean Nuclear Society, editor in chief of Nuclear Engineering and Technology, and as a commissioner of the Korean Nuclear Safety Commission. He is currently working as a commissioner of the Korean Atomic Energy Commission.

2017.06.29 View 9716 -

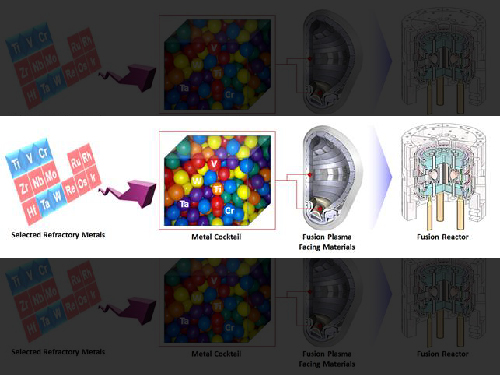

Extreme Materials for Fusion with Metal Cocktail

The research team under Professor Ryu Ho-jin of the Department of Nuclear and Quantum Engineering has developed a new material for facing fusion plasma environments using metal powder mixing technology. This technology is expected to extend the range of materials that can be designed for use in extreme environments such as in fusion power generators.

The durability of the tokamak vessel, which holds high-temperature plasma, is very important to create fusion power reactors, which are expected to be a future energy source. Currently, high-melting-point metals, such as tungsten, are considered plasma-facing materials to protect the tokamak vessel. However, high-energy thermal shocks, plasma ions, and neutrons are fatal to the plasma-facing material during high temperature fusion plasma operation. Therefore, it is necessary to develop new high-performance materials.

The ITER project, in which seven countries including the United States, the EU, and Korea participate jointly, is constructing a nuclear fusion experimental reactor in France with the goal of achieving the first plasma in 2025 and deuterium-tritium fusion operation in 2035. In Korea, the KSTAR tokamak at the National Fusion Research Institute has succeeded in maintaining high-performance plasma for 70 seconds.

Researchers in Europe, the United States, and China, who are leading the research on fusion plasma-facing materials, are studying the improvement of physical properties by adding a small amount of metal elements to tungsten. However, Professor Ryu’s team reported that by mixing various metals’ powders, including tungsten, they have succeeded in producing a new material that has twice the hardness and strength of tungsten. The difference in the atomic sizes of the well-mixed elements in the alloy is very significant because it makes it difficult to deform the alloy.

The team will continue its research to find alloying compositions that optimize mechanical properties as well as thermal conductivity, plasma interactions, neutron irradiation embrittlement, tritium absorption, and high-temperature oxidation properties.

Professor Ryu said, "Fusion plasma-facing materials are exposed to extreme environments and no metal is capable of withstanding thermal shock, plasma, and neutron damage simultaneously. As a result of this research, attempts to develop complex metallic materials for nuclear fusion and nuclear power are expected to become more active around the world. "

Ph.D. candidate Owais Ahmed Waseem is the first author of this project. The research is supported by the Ministry of Science, ICT and Future Planning, the Korea Research Foundation's Fusion Basic Research project, and the Engineering Research Center. The results were published in 'Scientific Report' on May 16.

Figure 1. Tungsten-based high strengh alloy sample

Figure 2. Fusion plasma facing material development by powder processing of refractory elements

2017.05.26 View 11084

Extreme Materials for Fusion with Metal Cocktail

The research team under Professor Ryu Ho-jin of the Department of Nuclear and Quantum Engineering has developed a new material for facing fusion plasma environments using metal powder mixing technology. This technology is expected to extend the range of materials that can be designed for use in extreme environments such as in fusion power generators.

The durability of the tokamak vessel, which holds high-temperature plasma, is very important to create fusion power reactors, which are expected to be a future energy source. Currently, high-melting-point metals, such as tungsten, are considered plasma-facing materials to protect the tokamak vessel. However, high-energy thermal shocks, plasma ions, and neutrons are fatal to the plasma-facing material during high temperature fusion plasma operation. Therefore, it is necessary to develop new high-performance materials.

The ITER project, in which seven countries including the United States, the EU, and Korea participate jointly, is constructing a nuclear fusion experimental reactor in France with the goal of achieving the first plasma in 2025 and deuterium-tritium fusion operation in 2035. In Korea, the KSTAR tokamak at the National Fusion Research Institute has succeeded in maintaining high-performance plasma for 70 seconds.

Researchers in Europe, the United States, and China, who are leading the research on fusion plasma-facing materials, are studying the improvement of physical properties by adding a small amount of metal elements to tungsten. However, Professor Ryu’s team reported that by mixing various metals’ powders, including tungsten, they have succeeded in producing a new material that has twice the hardness and strength of tungsten. The difference in the atomic sizes of the well-mixed elements in the alloy is very significant because it makes it difficult to deform the alloy.

The team will continue its research to find alloying compositions that optimize mechanical properties as well as thermal conductivity, plasma interactions, neutron irradiation embrittlement, tritium absorption, and high-temperature oxidation properties.

Professor Ryu said, "Fusion plasma-facing materials are exposed to extreme environments and no metal is capable of withstanding thermal shock, plasma, and neutron damage simultaneously. As a result of this research, attempts to develop complex metallic materials for nuclear fusion and nuclear power are expected to become more active around the world. "