AT

-

Professor Mikyoung Lim from Mathematical Sciences to Deliver Keynote at International Conference on Applied Inverse Problems

<Professor Mikyoung Lim from KAIST Department of Mathematical Sciences>

Professor Mikyoung Lim from KAIST Department of Mathematical Sciences gave a plenary talk on "Research on Inverse Problems based on Geometric Function Theory" at AIP 2025 (12th Applied Inverse Problems Conference). AIP is one of the leading international conferences in applied mathematics, organized biennially by the Inverse Problems International Association (IPIA). This year's conference was held from July 28 to August 1 in Rio de Janeiro, Brazil, and consisted of plenary talks, over 40 mini-symposia, and poster sessions. The IPIA began in 2007 and was re-established in 2022 as a non-profit international academic organization officially registered in Germany. At that time, Professor Lim served as an executive committee member for the re-establishment.

During the lecture, Professor Lim's research team introduced a new geometric solution and its applications to boundary value problems for electric/elastic equations, which they have been working on for the past 10 years. In particular, they presented a method for reconstructing partial differential equation boundary value problems into matrix equations and applying them to inverse problems using geometric function theory, a classical theory of complex analysis. A representative achievement was the formalization of the relationship between conformal mappings for simply connected domains in a plane and the measured values of solutions to equations of inhomogeneous conductors into a closed-form expression.

This research led to the plenary talk, as it was recognized for pioneering a new methodology for inverse problem research by connecting geometric function theory and layer potential theory.

2025.08.14 View 34

Professor Mikyoung Lim from Mathematical Sciences to Deliver Keynote at International Conference on Applied Inverse Problems

<Professor Mikyoung Lim from KAIST Department of Mathematical Sciences>

Professor Mikyoung Lim from KAIST Department of Mathematical Sciences gave a plenary talk on "Research on Inverse Problems based on Geometric Function Theory" at AIP 2025 (12th Applied Inverse Problems Conference). AIP is one of the leading international conferences in applied mathematics, organized biennially by the Inverse Problems International Association (IPIA). This year's conference was held from July 28 to August 1 in Rio de Janeiro, Brazil, and consisted of plenary talks, over 40 mini-symposia, and poster sessions. The IPIA began in 2007 and was re-established in 2022 as a non-profit international academic organization officially registered in Germany. At that time, Professor Lim served as an executive committee member for the re-establishment.

During the lecture, Professor Lim's research team introduced a new geometric solution and its applications to boundary value problems for electric/elastic equations, which they have been working on for the past 10 years. In particular, they presented a method for reconstructing partial differential equation boundary value problems into matrix equations and applying them to inverse problems using geometric function theory, a classical theory of complex analysis. A representative achievement was the formalization of the relationship between conformal mappings for simply connected domains in a plane and the measured values of solutions to equations of inhomogeneous conductors into a closed-form expression.

This research led to the plenary talk, as it was recognized for pioneering a new methodology for inverse problem research by connecting geometric function theory and layer potential theory.

2025.08.14 View 34 -

KAIST Takes the Lead in Developing Core Technologies for Generative AI National R&D Project

KAIST (President Kwang Hyung Lee) is leading the transition to AI Transformation (AX) by advancing research topics based on the practical technological demands of industries, fostering AI talent, and demonstrating research outcomes in industrial settings. In this context, KAIST announced on the 13th of August that it is at the forefront of strengthening the nation's AI technology competitiveness by developing core AI technologies via national R&D projects for generative AI led by the Ministry of Science and ICT.

In the 'Generative AI Leading Talent Cultivation Project,' KAIST was selected as a joint research institution for all three projects—two led by industry partners and one by a research institution—and will thus be tasked with the dual challenge of developing core generative AI technologies and cultivating practical, core talent through industry-academia collaborations.

Moreover, in the 'Development of a Proprietary AI Foundation Model' project, KAIST faculty members are participating as key researchers in four out of five consortia, establishing the university as a central hub for domestic generative AI research.

Each project in the Generative AI Leading Talent Cultivation Project will receive 6.7 billion won, while each consortium in the proprietary AI foundation model development project will receive a total of 200 billion won in government support, including GPU infrastructure.

As part of the 'Generative AI Leading Talent Cultivation Project,' which runs until the end of 2028, KAIST is collaborating with LG AI Research. Professor Noseong Park from the School of Computing will participate as the principal investigator for KAIST, conducting research in the field of physics-based generative AI (Physical AI). This project focuses on developing image and video generation technologies based on physical laws and developing a 'World Model.'

<(From Left) Professor Noseong Park, Professor Jae-gil Lee, Professor Jiyoung Whang, Professor Sung-Eui Yoon, Professor Hyunwoo Kim>

In particular, research being conducted by Professor Noseong Park's team and Professor Sung-Eui Yoon's team proposes a model structure designed to help AI learn the real-world rules of the physical world more precisely. This is considered a core technology for Physical AI.

Professors Noseong Park, Jae-gil Lee, Jiyoung Hwang, Sung-Eui Yoon, and Hyun-Woo Kim from the School of Computing, who have been globally recognized for their achievements in the AI field, are jointly participating in this project. This year, they have presented work at top AI conferences such as ICLR, ICRA, ICCV, and ICML, including: ▲ Research on physics-based Ollivier Ricci-flow (ICLR 2025, Prof. Noseong Park) ▲ Technology to improve the navigation efficiency of quadruped robots (ICRA 2025, Prof. Sung-Eui Yoon) ▲ A multimodal large language model for text-video retrieval (ICCV 2025, Prof. Hyun-Woo Kim) ▲ Structured representation learning for knowledge generation (ICML 2025, Prof. Jiyoung Whang).

In the collaboration with NC AI, Professor Tae-Kyun Kim from the School of Computing is participating as the principal investigator to develop multimodal AI agent technology. The research will explore technologies applicable to the entire gaming industry, such as 3D modeling, animation, avatar expression generation, and character AI. It is expected to contribute to training practical AI talents by giving them hands-on experience in the industrial field and making the game production pipeline more efficient.

As the principal investigator, Professor Tae-Kyun Kim, a renowned scholar in 3D computer vision and generative AI, is developing key technologies for creating immersive avatars in the virtual and gaming industries. He will apply a first-person full-body motion diffusion model, which he developed through a joint research project with Meta, to VR and AR environments.

<Professor Tae-Kyun Kim, Minhyeok Seong, and Tae-Hyun Oh from the School of Computing, and Professor Sung-Hee Lee, Woon-Tack Woo, Jun-Yong Noh, and Kyung-Tae Lim from the Graduate School of Culture Technology, Professor Ki-min Lee, Seungryong Kim from the Kim Jae-chul Graduate School of AI>

Professor Tae-Kyun Kim, Minhyeok Seong, and Tae-Hyun Oh from the School of Computing, and Professors Sung-Hee Lee, Woon-Tack Woo, Jun-Yong Noh, and Kyung-Tae Lim from the Graduate School of Culture Technology, are participating in the NC AI project. They have presented globally recognized work at CVPR 2025 and ICLR 2025, including: ▲ A first-person full-body motion diffusion model (CVPR 2025, Prof. Tae-Kyun Kim) ▲ Stochastic diffusion synchronization technology for image generation (ICLR 2025, Prof. Minhyeok Seong) ▲ The creation of a large-scale 3D facial mesh video dataset (ICLR 2025, Prof. Tae-Hyun Oh) ▲ Object-adaptive agent motion generation technology, InterFaceRays (Eurographics 2025, Prof. Sung-Hee Lee) ▲ 3D neural face editing technology (CVPR 2025, Prof. Jun-Yong Noh) ▲ Research on selective search augmentation for multilingual vision-language models (COLING 2025, Prof. Kyung-Tae Lim).

In the project led by the Korea Electronics Technology Institute (KETI), Professor Seungryong Kim from the Kim Jae-chul Graduate School of AI is participating in generative AI technology development. His team recently developed new technology for extracting robust point-tracking information from video data in collaboration with Adobe Research and Google DeepMind, proposing a key technology for clearly understanding and generating videos.

Each industry partner will open joint courses with KAIST and provide their generative AI foundation models for education and research. Selected outstanding students will be dispatched to these companies to conduct practical research, and KAIST faculty will also serve as adjunct professors at the in-house AI graduate school established by LG AI Research.

<Egocentric Whole-Body Motion Diffusion (CVPR 2025, Prof. Taekyun Kim's Lab), Stochastic Diffusion Synchronization for Image Generation (ICLR 2025, Prof. Minhyuk Sung's Lab), A Large-Scale 3D Face Mesh Video Dataset (ICLR 2025, Prof. Taehyun Oh's Lab), InterFaceRays: Object-Adaptive Agent Action Generation (Eurographics 2025, Prof. Sunghee Lee's Lab), 3D Neural Face Editing (CVPR 2025, Prof. Junyong Noh's Lab), and Selective Retrieval Augmentation for Multilingual Vision-Language Models (COLING 2025, Prof. Kyeong-tae Lim's Lab)>

Meanwhile, KAIST showed an unrivaled presence by participating in four consortia for the Ministry of Science and ICT's 'Proprietary AI Foundation Model Development' project.

In the NC AI Consortium, Professors Tae-Kyun Kim, Sung-Eui Yoon, Noseong Park, Jiyoung Hwang, and Minhyeok Seong from the School of Computing are participating, focusing on the development of multimodal foundation models (LMMs) and robot-based models. They are particularly concentrating on developing LMMs that learn common sense about space, physics, and time. They have formed a research team optimized for developing next-generation, multimodal AI models that can understand and interact with the physical world, equipped with an 'all-purpose AI brain' capable of simultaneously understanding and processing diverse information such as text, images, video, and sound.

In the Upstage Consortium, Professors Jae-gil Lee and Hyeon-eon Oh from the School of Computing, both renowned scholars in data AI and NLP (natural language processing), along with Professor Kyung-Tae Lim from the Graduate School of Culture Technology, an LLM expert, are responsible for developing vertical models for industries such as finance, law, and manufacturing. The KAIST researchers will concentrate on developing practical AI models that are directly applicable to industrial settings and tailored to each specific industry.

The Naver Consortium includes Professor Tae-Hyun Oh from the School of Computing, who has developed key technology for multimodal learning and compositional language-vision models, Professor Hyun-Woo Kim, who has proposed video reasoning and generation methods using language models, and faculty from the Kim Jae-chul Graduate School of AI and the Department of Electrical Engineering.

In the SKT Consortium, Professor Ki-min Lee from the Kim Jae-chul Graduate School of AI, who has achieved outstanding results in text-to-image generation, human preference modeling, and visual robotic manipulation technology development, is participating. This technology is expected to play a key role in developing personalized services and customized AI solutions for telecommunications companies.

This outcome is considered a successful culmination of KAIST's strategy for developing AI technology based on industry demand and centered on on-site demonstrations.

KAIST President Kwang Hyung Lee said, "For AI technology to go beyond academic achievements and be connected to and practical for industry, continuous government support, research, and education centered on industry-academia collaboration are essential. KAIST will continue to strive to solve problems in industrial settings and make a real contribution to enhancing the competitiveness of the AI ecosystem."

He added that while the project led by Professor Sung-Ju Hwang from the Kim Jae-chul Graduate School of AI, which had applied as a lead institution for the proprietary foundation model development project, was unfortunately not selected, it was a meaningful challenge that stood out for its original approach and bold attempts. President Lee further commented, "Regardless of whether it was selected or not, such attempts will accumulate and make the Korean AI ecosystem even richer."

2025.08.13 View 88

KAIST Takes the Lead in Developing Core Technologies for Generative AI National R&D Project

KAIST (President Kwang Hyung Lee) is leading the transition to AI Transformation (AX) by advancing research topics based on the practical technological demands of industries, fostering AI talent, and demonstrating research outcomes in industrial settings. In this context, KAIST announced on the 13th of August that it is at the forefront of strengthening the nation's AI technology competitiveness by developing core AI technologies via national R&D projects for generative AI led by the Ministry of Science and ICT.

In the 'Generative AI Leading Talent Cultivation Project,' KAIST was selected as a joint research institution for all three projects—two led by industry partners and one by a research institution—and will thus be tasked with the dual challenge of developing core generative AI technologies and cultivating practical, core talent through industry-academia collaborations.

Moreover, in the 'Development of a Proprietary AI Foundation Model' project, KAIST faculty members are participating as key researchers in four out of five consortia, establishing the university as a central hub for domestic generative AI research.

Each project in the Generative AI Leading Talent Cultivation Project will receive 6.7 billion won, while each consortium in the proprietary AI foundation model development project will receive a total of 200 billion won in government support, including GPU infrastructure.

As part of the 'Generative AI Leading Talent Cultivation Project,' which runs until the end of 2028, KAIST is collaborating with LG AI Research. Professor Noseong Park from the School of Computing will participate as the principal investigator for KAIST, conducting research in the field of physics-based generative AI (Physical AI). This project focuses on developing image and video generation technologies based on physical laws and developing a 'World Model.'

<(From Left) Professor Noseong Park, Professor Jae-gil Lee, Professor Jiyoung Whang, Professor Sung-Eui Yoon, Professor Hyunwoo Kim>

In particular, research being conducted by Professor Noseong Park's team and Professor Sung-Eui Yoon's team proposes a model structure designed to help AI learn the real-world rules of the physical world more precisely. This is considered a core technology for Physical AI.

Professors Noseong Park, Jae-gil Lee, Jiyoung Hwang, Sung-Eui Yoon, and Hyun-Woo Kim from the School of Computing, who have been globally recognized for their achievements in the AI field, are jointly participating in this project. This year, they have presented work at top AI conferences such as ICLR, ICRA, ICCV, and ICML, including: ▲ Research on physics-based Ollivier Ricci-flow (ICLR 2025, Prof. Noseong Park) ▲ Technology to improve the navigation efficiency of quadruped robots (ICRA 2025, Prof. Sung-Eui Yoon) ▲ A multimodal large language model for text-video retrieval (ICCV 2025, Prof. Hyun-Woo Kim) ▲ Structured representation learning for knowledge generation (ICML 2025, Prof. Jiyoung Whang).

In the collaboration with NC AI, Professor Tae-Kyun Kim from the School of Computing is participating as the principal investigator to develop multimodal AI agent technology. The research will explore technologies applicable to the entire gaming industry, such as 3D modeling, animation, avatar expression generation, and character AI. It is expected to contribute to training practical AI talents by giving them hands-on experience in the industrial field and making the game production pipeline more efficient.

As the principal investigator, Professor Tae-Kyun Kim, a renowned scholar in 3D computer vision and generative AI, is developing key technologies for creating immersive avatars in the virtual and gaming industries. He will apply a first-person full-body motion diffusion model, which he developed through a joint research project with Meta, to VR and AR environments.

<Professor Tae-Kyun Kim, Minhyeok Seong, and Tae-Hyun Oh from the School of Computing, and Professor Sung-Hee Lee, Woon-Tack Woo, Jun-Yong Noh, and Kyung-Tae Lim from the Graduate School of Culture Technology, Professor Ki-min Lee, Seungryong Kim from the Kim Jae-chul Graduate School of AI>

Professor Tae-Kyun Kim, Minhyeok Seong, and Tae-Hyun Oh from the School of Computing, and Professors Sung-Hee Lee, Woon-Tack Woo, Jun-Yong Noh, and Kyung-Tae Lim from the Graduate School of Culture Technology, are participating in the NC AI project. They have presented globally recognized work at CVPR 2025 and ICLR 2025, including: ▲ A first-person full-body motion diffusion model (CVPR 2025, Prof. Tae-Kyun Kim) ▲ Stochastic diffusion synchronization technology for image generation (ICLR 2025, Prof. Minhyeok Seong) ▲ The creation of a large-scale 3D facial mesh video dataset (ICLR 2025, Prof. Tae-Hyun Oh) ▲ Object-adaptive agent motion generation technology, InterFaceRays (Eurographics 2025, Prof. Sung-Hee Lee) ▲ 3D neural face editing technology (CVPR 2025, Prof. Jun-Yong Noh) ▲ Research on selective search augmentation for multilingual vision-language models (COLING 2025, Prof. Kyung-Tae Lim).

In the project led by the Korea Electronics Technology Institute (KETI), Professor Seungryong Kim from the Kim Jae-chul Graduate School of AI is participating in generative AI technology development. His team recently developed new technology for extracting robust point-tracking information from video data in collaboration with Adobe Research and Google DeepMind, proposing a key technology for clearly understanding and generating videos.

Each industry partner will open joint courses with KAIST and provide their generative AI foundation models for education and research. Selected outstanding students will be dispatched to these companies to conduct practical research, and KAIST faculty will also serve as adjunct professors at the in-house AI graduate school established by LG AI Research.

<Egocentric Whole-Body Motion Diffusion (CVPR 2025, Prof. Taekyun Kim's Lab), Stochastic Diffusion Synchronization for Image Generation (ICLR 2025, Prof. Minhyuk Sung's Lab), A Large-Scale 3D Face Mesh Video Dataset (ICLR 2025, Prof. Taehyun Oh's Lab), InterFaceRays: Object-Adaptive Agent Action Generation (Eurographics 2025, Prof. Sunghee Lee's Lab), 3D Neural Face Editing (CVPR 2025, Prof. Junyong Noh's Lab), and Selective Retrieval Augmentation for Multilingual Vision-Language Models (COLING 2025, Prof. Kyeong-tae Lim's Lab)>

Meanwhile, KAIST showed an unrivaled presence by participating in four consortia for the Ministry of Science and ICT's 'Proprietary AI Foundation Model Development' project.

In the NC AI Consortium, Professors Tae-Kyun Kim, Sung-Eui Yoon, Noseong Park, Jiyoung Hwang, and Minhyeok Seong from the School of Computing are participating, focusing on the development of multimodal foundation models (LMMs) and robot-based models. They are particularly concentrating on developing LMMs that learn common sense about space, physics, and time. They have formed a research team optimized for developing next-generation, multimodal AI models that can understand and interact with the physical world, equipped with an 'all-purpose AI brain' capable of simultaneously understanding and processing diverse information such as text, images, video, and sound.

In the Upstage Consortium, Professors Jae-gil Lee and Hyeon-eon Oh from the School of Computing, both renowned scholars in data AI and NLP (natural language processing), along with Professor Kyung-Tae Lim from the Graduate School of Culture Technology, an LLM expert, are responsible for developing vertical models for industries such as finance, law, and manufacturing. The KAIST researchers will concentrate on developing practical AI models that are directly applicable to industrial settings and tailored to each specific industry.

The Naver Consortium includes Professor Tae-Hyun Oh from the School of Computing, who has developed key technology for multimodal learning and compositional language-vision models, Professor Hyun-Woo Kim, who has proposed video reasoning and generation methods using language models, and faculty from the Kim Jae-chul Graduate School of AI and the Department of Electrical Engineering.

In the SKT Consortium, Professor Ki-min Lee from the Kim Jae-chul Graduate School of AI, who has achieved outstanding results in text-to-image generation, human preference modeling, and visual robotic manipulation technology development, is participating. This technology is expected to play a key role in developing personalized services and customized AI solutions for telecommunications companies.

This outcome is considered a successful culmination of KAIST's strategy for developing AI technology based on industry demand and centered on on-site demonstrations.

KAIST President Kwang Hyung Lee said, "For AI technology to go beyond academic achievements and be connected to and practical for industry, continuous government support, research, and education centered on industry-academia collaboration are essential. KAIST will continue to strive to solve problems in industrial settings and make a real contribution to enhancing the competitiveness of the AI ecosystem."

He added that while the project led by Professor Sung-Ju Hwang from the Kim Jae-chul Graduate School of AI, which had applied as a lead institution for the proprietary foundation model development project, was unfortunately not selected, it was a meaningful challenge that stood out for its original approach and bold attempts. President Lee further commented, "Regardless of whether it was selected or not, such attempts will accumulate and make the Korean AI ecosystem even richer."

2025.08.13 View 88 -

KAIST develops “FlexGNN,” a graph analysis AI 95 times faster with a single GPU

<(From Left) Donghyoung Han, CTO of GraphAI Co, Ph.D candidate Jeongmin Bae from KAIST, Professor Min-soo Kim from KAIST>

Alongside text-based large language models (LLMs) including ChatGPT, in industrial fields, GNN (Graph Neural Network)-based graph AI models that analyze unstructured data such as financial transactions, stocks, social media, and patient records in graph form are being actively used. However, there is a limitation in that full graph learning—training the entire graph at once—requires massive memory and GPU servers. A KAIST research team has succeeded in developing the world’s highest-performance software technology that can train large-scale GNN models at maximum speed using only a single GPU server.

KAIST (President Kwang Hyung Lee) announced on the 13th that the research team led by Professor Min-Soo Kim of the School of Computing has developed “FlexGNN,” a GNN system that, unlike existing methods using multiple GPU servers, can quickly train and infer large-scale full-graph AI models on a single GPU server. FlexGNN improves training speed by up to 95 times compared to existing technologies.

Recently, in various fields such as climate, finance, medicine, pharmaceuticals, manufacturing, and distribution, there has been a growing number of cases where data is converted into graph form, consisting of nodes and edges, for analysis and prediction.

While the full graph approach, which uses the entire graph for training, achieves higher accuracy, it has the drawback of frequently running out of memory due to the generation of massive intermediate data during training, as well as prolonged training times caused by data communication between multiple servers.

To overcome these problems, FlexGNN performs optimal AI model training on a single GPU server by utilizing SSDs (solid-state drives) and main memory instead of multiple GPU servers.

<Figure (a): This illustrates the typical execution flow of a conventional full-graph GNN training system. All intermediate data generated during training are retained in GPU memory, and computations are performed sequentially without data movement or memory optimization. Consequently, if the GPU memory capacity is exceeded, training becomes infeasible. Additionally, inter-GPU data exchange relies solely on a fixed method (X_rigid), limiting performance and scalability. Figure (b): This depicts an example of the execution flow based on the optimized training execution plan generated by FlexGNN. For each intermediate data, strategies such as retention, offloading, or recomputation are selectively applied. Depending on resource constraints and data size, an appropriate inter-GPU exchange method—either GPU-to-GPU (G2G) or GPU-to-Host (G2H)—is adaptively chosen by the exchange operator (X_adapt). Furthermore, offloading and reloading operations are scheduled to overlap as much as possible with computation, maximizing compute-data movement parallelism. The adaptive exchange operator and various data offloading and reloading operators (R, O) within the figure demonstrate FlexGNN's ability to flexibly control intermediate data management and inter-GPU exchange strategies based on the training execution plan.>

Particularly, through AI query optimization training—which optimizes the quality of database systems—the team developed a new training optimization technology that calculates model parameters, training data, and intermediate data between GPU, main memory, and SSD layers at the optimal timing and method.

As a result, FlexGNN flexibly generates optimal training execution plans according to available resources such as data size, model scale, and GPU memory, thereby achieving high resource efficiency and training speed.

Consequently, it became possible to train GNN models on data far exceeding main memory capacity, and training could be up to 95 times faster even on a single GPU server. In particular, the realization of full-graph AI, capable of more precise analysis than supercomputers in applications such as climate prediction, has become a reality.

Professor Min-Soo Kim of KAIST stated, “As full-graph GNN models are actively used to solve complex problems such as weather prediction and new material discovery, the importance of related technologies is increasing.” He added that “since FlexGNN has dramatically solved the longstanding problems of training scale and speed in graph AI models, we expect it to be widely used in various industries.”

In this research, Jeongmin Bae, a doctoral student in the School of Computing at KAIST, participated as the first author, Donghyoung Han, CTO of GraphAI Co. (founded by Professor Kim) participated as the second author, and Professor Kim served as the corresponding author.

The research results were presented on August 5 at ACM KDD, a world-renowned data mining conference. The FlexGNN technology is also planned to be applied to Grapheye’s graph database solution, GraphOn.

● Paper title: FlexGNN: A High-Performance, Large-Scale Full-Graph GNN System with Best-Effort Training Plan Optimization

● DOI: https://doi.org/10.1145/3711896.3736964

This research was supported by the IITP SW Star Lab and IITP-ITRC of the Ministry of Science and ICT, as well as the mid-level project program of the National Research Foundation of Korea.

2025.08.13 View 46

KAIST develops “FlexGNN,” a graph analysis AI 95 times faster with a single GPU

<(From Left) Donghyoung Han, CTO of GraphAI Co, Ph.D candidate Jeongmin Bae from KAIST, Professor Min-soo Kim from KAIST>

Alongside text-based large language models (LLMs) including ChatGPT, in industrial fields, GNN (Graph Neural Network)-based graph AI models that analyze unstructured data such as financial transactions, stocks, social media, and patient records in graph form are being actively used. However, there is a limitation in that full graph learning—training the entire graph at once—requires massive memory and GPU servers. A KAIST research team has succeeded in developing the world’s highest-performance software technology that can train large-scale GNN models at maximum speed using only a single GPU server.

KAIST (President Kwang Hyung Lee) announced on the 13th that the research team led by Professor Min-Soo Kim of the School of Computing has developed “FlexGNN,” a GNN system that, unlike existing methods using multiple GPU servers, can quickly train and infer large-scale full-graph AI models on a single GPU server. FlexGNN improves training speed by up to 95 times compared to existing technologies.

Recently, in various fields such as climate, finance, medicine, pharmaceuticals, manufacturing, and distribution, there has been a growing number of cases where data is converted into graph form, consisting of nodes and edges, for analysis and prediction.

While the full graph approach, which uses the entire graph for training, achieves higher accuracy, it has the drawback of frequently running out of memory due to the generation of massive intermediate data during training, as well as prolonged training times caused by data communication between multiple servers.

To overcome these problems, FlexGNN performs optimal AI model training on a single GPU server by utilizing SSDs (solid-state drives) and main memory instead of multiple GPU servers.

<Figure (a): This illustrates the typical execution flow of a conventional full-graph GNN training system. All intermediate data generated during training are retained in GPU memory, and computations are performed sequentially without data movement or memory optimization. Consequently, if the GPU memory capacity is exceeded, training becomes infeasible. Additionally, inter-GPU data exchange relies solely on a fixed method (X_rigid), limiting performance and scalability. Figure (b): This depicts an example of the execution flow based on the optimized training execution plan generated by FlexGNN. For each intermediate data, strategies such as retention, offloading, or recomputation are selectively applied. Depending on resource constraints and data size, an appropriate inter-GPU exchange method—either GPU-to-GPU (G2G) or GPU-to-Host (G2H)—is adaptively chosen by the exchange operator (X_adapt). Furthermore, offloading and reloading operations are scheduled to overlap as much as possible with computation, maximizing compute-data movement parallelism. The adaptive exchange operator and various data offloading and reloading operators (R, O) within the figure demonstrate FlexGNN's ability to flexibly control intermediate data management and inter-GPU exchange strategies based on the training execution plan.>

Particularly, through AI query optimization training—which optimizes the quality of database systems—the team developed a new training optimization technology that calculates model parameters, training data, and intermediate data between GPU, main memory, and SSD layers at the optimal timing and method.

As a result, FlexGNN flexibly generates optimal training execution plans according to available resources such as data size, model scale, and GPU memory, thereby achieving high resource efficiency and training speed.

Consequently, it became possible to train GNN models on data far exceeding main memory capacity, and training could be up to 95 times faster even on a single GPU server. In particular, the realization of full-graph AI, capable of more precise analysis than supercomputers in applications such as climate prediction, has become a reality.

Professor Min-Soo Kim of KAIST stated, “As full-graph GNN models are actively used to solve complex problems such as weather prediction and new material discovery, the importance of related technologies is increasing.” He added that “since FlexGNN has dramatically solved the longstanding problems of training scale and speed in graph AI models, we expect it to be widely used in various industries.”

In this research, Jeongmin Bae, a doctoral student in the School of Computing at KAIST, participated as the first author, Donghyoung Han, CTO of GraphAI Co. (founded by Professor Kim) participated as the second author, and Professor Kim served as the corresponding author.

The research results were presented on August 5 at ACM KDD, a world-renowned data mining conference. The FlexGNN technology is also planned to be applied to Grapheye’s graph database solution, GraphOn.

● Paper title: FlexGNN: A High-Performance, Large-Scale Full-Graph GNN System with Best-Effort Training Plan Optimization

● DOI: https://doi.org/10.1145/3711896.3736964

This research was supported by the IITP SW Star Lab and IITP-ITRC of the Ministry of Science and ICT, as well as the mid-level project program of the National Research Foundation of Korea.

2025.08.13 View 46 -

KAIST Develops AI That Automatically Designs Optimal Drug Candidates for Cancer-Targeting Mutations

< (From left) Ph.D candidate Wonho Zhung, Ph.D cadidate Joongwon Lee , Prof. Woo Young Kim , Ph.D candidate Jisu Seo >

Traditional drug development methods involve identifying a target protin (e.g., a cancer cell receptor) that causes disease, and then searching through countless molecular candidates (potential drugs) that could bind to that protein and block its function. This process is costly, time-consuming, and has a low success rate. KAIST researchers have developed an AI model that, using only information about the target protein, can design optimal drug candidates without any prior molecular data—opening up new possibilities for drug discovery.

KAIST (President Kwang Hyung Lee) announced on the 10th that a research team led by Professor Woo Youn Kim in the Department of Chemistry has developed an AI model named BInD (Bond and Interaction-generating Diffusion model), which can design and optimize drug candidate molecules tailored to a protein’s structure alone—without needing prior information about binding molecules. The model also predicts the binding mechanism (non-covalent interactions) between the drug and the target protein.

The core innovation of this technology lies in its “simultaneous design” approach. Previous AI models either focused on generating molecules or separately evaluating whether the generated molecule could bind to the target protein. In contrast, this new model considers the binding mechanism between the molecule and the protein during the generation process, enabling comprehensive design in one step. Since it pre-accounts for critical factors in protein-ligand binding, it has a much higher likelihood of generating effective and stable molecules. The generation process visually demonstrates how types and positions of atoms, covalent bonds, and interactions are created simultaneously to fit the protein’s binding site.

<Figure 1. Schematic of the diffusion model developed by the research team, which generates molecular structures and non-covalent interactions based on protein structures. Starting from a noise distribution, the model gradually removes noise (via reverse diffusion) to restore the atom positions, types, covalent bond types, and interaction types, thereby generating molecules. Interacting patterns are extracted from prior knowledge of known binding molecules or proteins, and through an inpainting technique, these patterns are kept fixed during the reverse diffusion process to guide the molecular generation.>

Moreover, this model is designed to meet multiple essential drug design criteria simultaneously—such as target binding affinity, drug-like properties, and structural stability. Traditional models often optimized for only one or two goals at the expense of others, but this new model balances various objectives, significantly enhancing its practical applicability.

The research team explained that the AI operates based on a “diffusion model”—a generative approach where a structure becomes increasingly refined from a random state. This is the same type of model used in AlphaFold 3, the 2024 Nobel Chemistry Prize-winning tool for protein-ligand structure generation, which has already demonstrated high efficiency.

Unlike AlphaFold 3, which provides spatial coordinates for atom positions, this study introduced a knowledge-based guide grounded in actual chemical laws—such as bond lengths and protein-ligand distances—enabling more chemically realistic structure generation.

<Figure 2. (Left) Target protein and the original bound molecule; (Right) Examples of molecules designed using the model developed in this study. The values for protein binding affinity (Vina), drug-likeness (QED), and synthetic accessibility (SA) are shown at the bottom.>

Additionally, the team applied an optimization strategy where outstanding binding patterns from prior results are reused. This allowed the model to generate even better drug candidates without additional training. Notably, the AI successfully produced molecules that selectively bind to the mutated residues of EGFR, a cancer-related target protein.

This study is also meaningful because it advances beyond the team’s previous research, which required prior input about the molecular conditions for the interaction pattern of protein binding.

Professor Woo Youn Kim commented that “the newly developed AI can learn and understand the key features required for strong binding to a target protein, and design optimal drug candidate molecules—even without any prior input. This could significantly shift the paradigm of drug development.” He added, “Since this technology generates molecular structures based on principles of chemical interactions, it is expected to enable faster and more reliable drug development.”

Joongwon Lee and Wonho Zhung, PhD students in the Department of Chemistry, participated as co-first authors of this study. The research results were published in the international journal Advanced Science (IF = 14.1) on July 11.

● Paper Title: BInD: Bond and Interaction-Generating Diffusion Model for Multi-Objective Structure-Based Drug Design

● DOI: 10.1002/advs.202502702

This research was supported by the National Research Foundation of Korea and the Ministry of Health and Welfare.

2025.08.12 View 202

KAIST Develops AI That Automatically Designs Optimal Drug Candidates for Cancer-Targeting Mutations

< (From left) Ph.D candidate Wonho Zhung, Ph.D cadidate Joongwon Lee , Prof. Woo Young Kim , Ph.D candidate Jisu Seo >

Traditional drug development methods involve identifying a target protin (e.g., a cancer cell receptor) that causes disease, and then searching through countless molecular candidates (potential drugs) that could bind to that protein and block its function. This process is costly, time-consuming, and has a low success rate. KAIST researchers have developed an AI model that, using only information about the target protein, can design optimal drug candidates without any prior molecular data—opening up new possibilities for drug discovery.

KAIST (President Kwang Hyung Lee) announced on the 10th that a research team led by Professor Woo Youn Kim in the Department of Chemistry has developed an AI model named BInD (Bond and Interaction-generating Diffusion model), which can design and optimize drug candidate molecules tailored to a protein’s structure alone—without needing prior information about binding molecules. The model also predicts the binding mechanism (non-covalent interactions) between the drug and the target protein.

The core innovation of this technology lies in its “simultaneous design” approach. Previous AI models either focused on generating molecules or separately evaluating whether the generated molecule could bind to the target protein. In contrast, this new model considers the binding mechanism between the molecule and the protein during the generation process, enabling comprehensive design in one step. Since it pre-accounts for critical factors in protein-ligand binding, it has a much higher likelihood of generating effective and stable molecules. The generation process visually demonstrates how types and positions of atoms, covalent bonds, and interactions are created simultaneously to fit the protein’s binding site.

<Figure 1. Schematic of the diffusion model developed by the research team, which generates molecular structures and non-covalent interactions based on protein structures. Starting from a noise distribution, the model gradually removes noise (via reverse diffusion) to restore the atom positions, types, covalent bond types, and interaction types, thereby generating molecules. Interacting patterns are extracted from prior knowledge of known binding molecules or proteins, and through an inpainting technique, these patterns are kept fixed during the reverse diffusion process to guide the molecular generation.>

Moreover, this model is designed to meet multiple essential drug design criteria simultaneously—such as target binding affinity, drug-like properties, and structural stability. Traditional models often optimized for only one or two goals at the expense of others, but this new model balances various objectives, significantly enhancing its practical applicability.

The research team explained that the AI operates based on a “diffusion model”—a generative approach where a structure becomes increasingly refined from a random state. This is the same type of model used in AlphaFold 3, the 2024 Nobel Chemistry Prize-winning tool for protein-ligand structure generation, which has already demonstrated high efficiency.

Unlike AlphaFold 3, which provides spatial coordinates for atom positions, this study introduced a knowledge-based guide grounded in actual chemical laws—such as bond lengths and protein-ligand distances—enabling more chemically realistic structure generation.

<Figure 2. (Left) Target protein and the original bound molecule; (Right) Examples of molecules designed using the model developed in this study. The values for protein binding affinity (Vina), drug-likeness (QED), and synthetic accessibility (SA) are shown at the bottom.>

Additionally, the team applied an optimization strategy where outstanding binding patterns from prior results are reused. This allowed the model to generate even better drug candidates without additional training. Notably, the AI successfully produced molecules that selectively bind to the mutated residues of EGFR, a cancer-related target protein.

This study is also meaningful because it advances beyond the team’s previous research, which required prior input about the molecular conditions for the interaction pattern of protein binding.

Professor Woo Youn Kim commented that “the newly developed AI can learn and understand the key features required for strong binding to a target protein, and design optimal drug candidate molecules—even without any prior input. This could significantly shift the paradigm of drug development.” He added, “Since this technology generates molecular structures based on principles of chemical interactions, it is expected to enable faster and more reliable drug development.”

Joongwon Lee and Wonho Zhung, PhD students in the Department of Chemistry, participated as co-first authors of this study. The research results were published in the international journal Advanced Science (IF = 14.1) on July 11.

● Paper Title: BInD: Bond and Interaction-Generating Diffusion Model for Multi-Objective Structure-Based Drug Design

● DOI: 10.1002/advs.202502702

This research was supported by the National Research Foundation of Korea and the Ministry of Health and Welfare.

2025.08.12 View 202 -

KAIST Develops Bioelectrosynthesis Platform for Switch-Like Precision Control of Cell Signaling

<(From left)Professor Jimin Park, Ph.D candidate Myeongeun Lee, Ph.D cadidate Jaewoong Lee,Professor Jihan Kim>

Cells use various signaling molecules to regulate the nervous, immune, and vascular systems. Among these, nitric oxide (NO) and ammonia (NH₃) play important roles, but their chemical instability and gaseous nature make them difficult to generate or control externally. A KAIST research team has developed a platform that generates specific signaling molecules in situ from a single precursor under an applied electrical signal, enabling switch-like, precise spatiotemporal control of cellular responses. This approach could provide a foundation for future medical technologies such as electroceuticals, electrogenetics, and personalized cell therapies.

KAIST (President Kwang Hyung Lee) announced on August 11 that a research team led by Professor Jimin Park from the Department of Chemical and Biomolecular Engineering, in collaboration with Professor Jihan Kim's group, has developed a 'Bioelectrosynthesis Platform' capable of producing either nitric oxide or ammonia on demand using only an electrical signal. The platform allows control over the timing, spatial range, and duration of cell responses.

Inspired by enzymes involved in nitrite reduction, the researchers implemented an electrochemical strategy that selectively produces nitric oxide or ammonia from a single precursor, nitrite (NO₂⁻). By changing the catalyst, the team generated ammonia or nitric oxide from nitrite using a copper-molybdenum-sulfur catalyst (Cu2MoS4) and an iron-incorporated catalyst (FeCuMS4), respectively.

Through electrochemical measurements and computer simulations, the team revealed that Fe sites in the FeCuMoS4 catalyst bind nitric oxide intermediates more strongly, shifting product selectivity toward nitric oxide. Under the same electrical conditions, the Fe-containing catalyst preferentially produces nitric oxide, whereas the Cu2MoS4 catalyst favors ammonia production.

<Figure 1. Schematic diagram of a bio-electrosynthesis platform that synthesizes a desired signaling substance with an electrical signal (left) and the results of precise cell control using it (right)>

The research team demonstrated biological functionality by using the platform to activate ion channels in human cells. Specifically, electrochemically produced nitric oxide activated TRPV1 channels (responsive to heat and chemical stimuli), while electrochemically produced ammonia induced intracellular alkalinization and activated OTOP1 proton channels. By tuning the applied voltage and electrolysis duration, the team modulated the onset time, spatial extent, and termination of cellular responses, which effectively turned cellular signaling on and off like a switch.

<Figure 2. Experimental results showing the change in the production ratio of nitric oxide and ammonia signaling substances according to the type of catalyst (left) and computational simulation results showing the strong bond between iron and nitric oxide (right)>

Professor Jimin Park said, "This work is significant because it enables precise cellular control by selectively producing signaling molecules with electricity. We believe it has strong potential for applications in electroceutical technologies targeting the nervous system or metabolic disorders."

Myeongeun Lee and Jaewoong Lee, Ph.D. students in the Department of Chemical and Biomolecular Engineering at KAIST, served as the co-first authors. Professor Jihan Kim is a co-author. The paper was published online in 'Angewandte Chemie International Edition' on July 8, 2025 (DOI: 10.1002/ange.202508192).

Reference: https://doi.org/10.1002/ange.202508192

Authors: Myeongeun Lee†, Jaewoong Lee†, Yongha Kim, Changho Lee, Sang Yeon Oh, Prof. Jihan Kim, Prof. Jimin Park*

†These authors contributed equally. *Corresponding author.

2025.08.12 View 118

KAIST Develops Bioelectrosynthesis Platform for Switch-Like Precision Control of Cell Signaling

<(From left)Professor Jimin Park, Ph.D candidate Myeongeun Lee, Ph.D cadidate Jaewoong Lee,Professor Jihan Kim>

Cells use various signaling molecules to regulate the nervous, immune, and vascular systems. Among these, nitric oxide (NO) and ammonia (NH₃) play important roles, but their chemical instability and gaseous nature make them difficult to generate or control externally. A KAIST research team has developed a platform that generates specific signaling molecules in situ from a single precursor under an applied electrical signal, enabling switch-like, precise spatiotemporal control of cellular responses. This approach could provide a foundation for future medical technologies such as electroceuticals, electrogenetics, and personalized cell therapies.

KAIST (President Kwang Hyung Lee) announced on August 11 that a research team led by Professor Jimin Park from the Department of Chemical and Biomolecular Engineering, in collaboration with Professor Jihan Kim's group, has developed a 'Bioelectrosynthesis Platform' capable of producing either nitric oxide or ammonia on demand using only an electrical signal. The platform allows control over the timing, spatial range, and duration of cell responses.

Inspired by enzymes involved in nitrite reduction, the researchers implemented an electrochemical strategy that selectively produces nitric oxide or ammonia from a single precursor, nitrite (NO₂⁻). By changing the catalyst, the team generated ammonia or nitric oxide from nitrite using a copper-molybdenum-sulfur catalyst (Cu2MoS4) and an iron-incorporated catalyst (FeCuMS4), respectively.

Through electrochemical measurements and computer simulations, the team revealed that Fe sites in the FeCuMoS4 catalyst bind nitric oxide intermediates more strongly, shifting product selectivity toward nitric oxide. Under the same electrical conditions, the Fe-containing catalyst preferentially produces nitric oxide, whereas the Cu2MoS4 catalyst favors ammonia production.

<Figure 1. Schematic diagram of a bio-electrosynthesis platform that synthesizes a desired signaling substance with an electrical signal (left) and the results of precise cell control using it (right)>

The research team demonstrated biological functionality by using the platform to activate ion channels in human cells. Specifically, electrochemically produced nitric oxide activated TRPV1 channels (responsive to heat and chemical stimuli), while electrochemically produced ammonia induced intracellular alkalinization and activated OTOP1 proton channels. By tuning the applied voltage and electrolysis duration, the team modulated the onset time, spatial extent, and termination of cellular responses, which effectively turned cellular signaling on and off like a switch.

<Figure 2. Experimental results showing the change in the production ratio of nitric oxide and ammonia signaling substances according to the type of catalyst (left) and computational simulation results showing the strong bond between iron and nitric oxide (right)>

Professor Jimin Park said, "This work is significant because it enables precise cellular control by selectively producing signaling molecules with electricity. We believe it has strong potential for applications in electroceutical technologies targeting the nervous system or metabolic disorders."

Myeongeun Lee and Jaewoong Lee, Ph.D. students in the Department of Chemical and Biomolecular Engineering at KAIST, served as the co-first authors. Professor Jihan Kim is a co-author. The paper was published online in 'Angewandte Chemie International Edition' on July 8, 2025 (DOI: 10.1002/ange.202508192).

Reference: https://doi.org/10.1002/ange.202508192

Authors: Myeongeun Lee†, Jaewoong Lee†, Yongha Kim, Changho Lee, Sang Yeon Oh, Prof. Jihan Kim, Prof. Jimin Park*

†These authors contributed equally. *Corresponding author.

2025.08.12 View 118 -

2025 APEC Youth STEM Science Exchange Program Successfully Completed

<Photo1. Group photo at the end of the program>

KAIST (President Kwang Hyung Lee) announced on the 11thof August that it successfully hosted the 'APEC Youth STEM Conference KAIST Academic Program,' a global science exchange program for 28 youth researchers from 10 countries and over 30 experts who participated in the '2025 APEC Youth STEM* Collaborative Research and Competition.' The event was held at the main campus in Daejeon on Saturday, August 9.

STEM (Science, Technology, Engineering, Math) refers to the fields of science and engineering.

The competition was hosted by the Ministry of Science and ICT and organized by the APEC Science Gifted Mentoring Center. It took place from Wednesday, August 6, to Saturday, August 9, 2025, at KAIST in Daejeon and the Korea Science Academy of KAIST in Busan. The KAIST program was organized by the APEC Science Gifted Mentoring Center and supported by the KAIST Institute for the Gifted and Talented in Science Education.

Participants had the opportunity to experience Korea's cutting-edge research infrastructure firsthand, broaden their horizons in science and technology, and collaborate and exchange ideas with future science talents from the APEC region.

As the 2025 APEC chair, Korea is promoting various international collaborations to discover and nurture the next generation of talent in the STEM fields. The KAIST academic exchange program was particularly meaningful as it was designed with the international goal of revitalizing science gifted exchanges and expanding the basis for cooperation among APEC member countries. It moved beyond the traditional online-centric research collaboration model to focus on hands-on, on-site, and convergence research experiences.

The global science exchange program at KAIST introduced participants to KAIST's world-class educational and research environment and provided various academic content to allow them to experience real-world examples of convergence technology-based research.

<Photo2. Program Activities>

First, the KAIST Admissions Office participated, introducing KAIST's admissions system and its educational and research environment to outstanding international students, providing an opportunity to attract global talent. Following this, Dr. Tae-kyun Kwon of the Music and Audio Computing Lab at the Graduate School of Culture Technology presented a convergence art project based on musical artificial intelligence data, including a research demonstration in an anechoic chamber.

<Photo3. Participation in a music AI research demonstration>

Furthermore, a Climate Talk Concert program was organized under the leadership of the Graduate School of Green Growth and Sustainability, in connection with the theme of the APEC Youth STEM Collaborative Research: 'Youth-led STEM Solutions: Enhancing Climate Resilience.'

The program was planned and hosted by Dean Jiyong Eom. It provided a platform for young people to explore creative and practical STEM-based solutions to the climate crisis and seek opportunities for international cooperation.

<Photo4. Participation in Music AI Research Demonstration >

The program was a meaningful time for APEC youth researchers, offering practical support for their research through special lectures and Q&A sessions on:

Interdisciplinary Research and Education in the Era of Climate Crisis (Dean Jiyong Eom)

Energy Transition Technology in the Carbon Neutral Era (Professor Jeongrak Son)

Policies for Energy System Change (Professor Jihyo Kim)

Carbon Neutral Bio-technology (Professor Gyeongrok Choi)

After the afternoon talk concert, Lee Jing Jing, a student from Brunei, shared her thoughts, saying, "The lectures by the four professors were very meaningful and insightful. I was able to think about energy transition plans to solve climate change from various perspectives."

Si-jong Kwak, Director of the KAIST Global Institute for Talented Education, stated, "I hope that young people from all over the world will directly experience KAIST's research areas and environment, expand their interest in KAIST, and continue to grow as outstanding talents in the fields of science and engineering."

KAIST President Kwang Hyung Lee said, "KAIST will be at the center of science and technology-based international cooperation and will spare no effort to support future talents in developing creative and practical problem-solving skills. I hope this event served as an opportunity for young people to understand the value of global cooperation and grow into future science leaders."

2025.08.11 View 171

2025 APEC Youth STEM Science Exchange Program Successfully Completed

<Photo1. Group photo at the end of the program>

KAIST (President Kwang Hyung Lee) announced on the 11thof August that it successfully hosted the 'APEC Youth STEM Conference KAIST Academic Program,' a global science exchange program for 28 youth researchers from 10 countries and over 30 experts who participated in the '2025 APEC Youth STEM* Collaborative Research and Competition.' The event was held at the main campus in Daejeon on Saturday, August 9.

STEM (Science, Technology, Engineering, Math) refers to the fields of science and engineering.

The competition was hosted by the Ministry of Science and ICT and organized by the APEC Science Gifted Mentoring Center. It took place from Wednesday, August 6, to Saturday, August 9, 2025, at KAIST in Daejeon and the Korea Science Academy of KAIST in Busan. The KAIST program was organized by the APEC Science Gifted Mentoring Center and supported by the KAIST Institute for the Gifted and Talented in Science Education.

Participants had the opportunity to experience Korea's cutting-edge research infrastructure firsthand, broaden their horizons in science and technology, and collaborate and exchange ideas with future science talents from the APEC region.

As the 2025 APEC chair, Korea is promoting various international collaborations to discover and nurture the next generation of talent in the STEM fields. The KAIST academic exchange program was particularly meaningful as it was designed with the international goal of revitalizing science gifted exchanges and expanding the basis for cooperation among APEC member countries. It moved beyond the traditional online-centric research collaboration model to focus on hands-on, on-site, and convergence research experiences.

The global science exchange program at KAIST introduced participants to KAIST's world-class educational and research environment and provided various academic content to allow them to experience real-world examples of convergence technology-based research.

<Photo2. Program Activities>

First, the KAIST Admissions Office participated, introducing KAIST's admissions system and its educational and research environment to outstanding international students, providing an opportunity to attract global talent. Following this, Dr. Tae-kyun Kwon of the Music and Audio Computing Lab at the Graduate School of Culture Technology presented a convergence art project based on musical artificial intelligence data, including a research demonstration in an anechoic chamber.

<Photo3. Participation in a music AI research demonstration>

Furthermore, a Climate Talk Concert program was organized under the leadership of the Graduate School of Green Growth and Sustainability, in connection with the theme of the APEC Youth STEM Collaborative Research: 'Youth-led STEM Solutions: Enhancing Climate Resilience.'

The program was planned and hosted by Dean Jiyong Eom. It provided a platform for young people to explore creative and practical STEM-based solutions to the climate crisis and seek opportunities for international cooperation.

<Photo4. Participation in Music AI Research Demonstration >

The program was a meaningful time for APEC youth researchers, offering practical support for their research through special lectures and Q&A sessions on:

Interdisciplinary Research and Education in the Era of Climate Crisis (Dean Jiyong Eom)

Energy Transition Technology in the Carbon Neutral Era (Professor Jeongrak Son)

Policies for Energy System Change (Professor Jihyo Kim)

Carbon Neutral Bio-technology (Professor Gyeongrok Choi)

After the afternoon talk concert, Lee Jing Jing, a student from Brunei, shared her thoughts, saying, "The lectures by the four professors were very meaningful and insightful. I was able to think about energy transition plans to solve climate change from various perspectives."

Si-jong Kwak, Director of the KAIST Global Institute for Talented Education, stated, "I hope that young people from all over the world will directly experience KAIST's research areas and environment, expand their interest in KAIST, and continue to grow as outstanding talents in the fields of science and engineering."

KAIST President Kwang Hyung Lee said, "KAIST will be at the center of science and technology-based international cooperation and will spare no effort to support future talents in developing creative and practical problem-solving skills. I hope this event served as an opportunity for young people to understand the value of global cooperation and grow into future science leaders."

2025.08.11 View 171 -

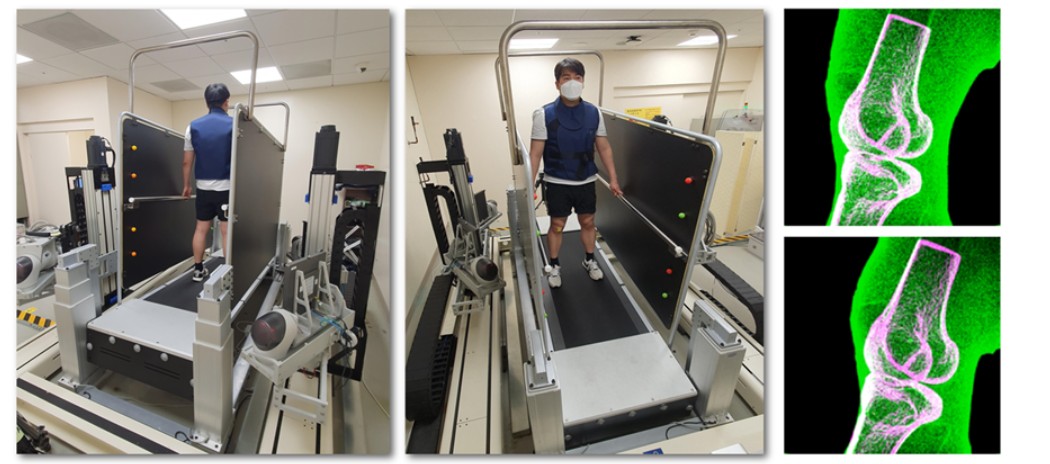

Prof. Seungbum Koo’s Team Receives Clinical Biomechanics Award at the 30th International Society of Biomechanics Conference

<(From Left) Ph.D candidate Jeongseok Oh from KAIST, Dr. Seungwoo Yoon from KAIST, Prof.Joon-Ho Wang from Samsung Medical Center, Prof.Seungbum Koo from KAIST>

Professor Seungbum Koo’s research team received the Clinical Biomechanics Award at the 30th International Society of Biomechanics (ISB) Conference, held in July 2025 in Stockholm, Sweden. The Plenary Lecture was delivered by first author and Ph.D. candidate Jeongseok Oh. This research was conducted in collaboration with Professor Joon-Ho Wang’s team at Samsung Medical Center.

Residual Translational and Rotational Kinematics After Combined ACL and Anterolateral Ligament Reconstruction During Walking

Jeongseok Oh, Seungwoo Yoon, Joon-Ho Wang, Seungbum Koo

The study analyzed gait-related knee joint motion using high-speed biplane X-ray imaging and three-dimensional kinematic reconstruction in 10 healthy individuals and 10 patients who underwent ACL reconstruction with ALL augmentation. The patient group showed excessive anterior translation and internal rotation, suggesting incomplete restoration of normal joint kinematics post-surgery. These findings provide mechanistic insight into the early onset of knee osteoarthritis often reported in this population.'

The ISB conference, held biennially for over 60 years, is the largest international biomechanics meeting. This year, it hosted 1,600 researchers from 46 countries and featured over 1,400 presentations. The Clinical Biomechanics Award is given to one outstanding study selected from five top-rated abstracts invited for full manuscript review. The winning paper is published in Clinical Biomechanics, and the award includes a monetary prize and a Plenary Lecture opportunity.

From 2019 to 2023, Koo and Wang’s teams developed a system with support from the Samsung Future Technology Development Program to track knee motion in real time during treadmill walking, using high-speed biplane X-rays and custom three-dimensional reconstruction software. This system, along with proprietary software that precisely reconstructs the three-dimensional motion of joints, was approved for clinical trials by the Ministry of Food and Drug Safety and installed at Samsung Medical Center. It is being used to quantitatively analyze abnormal joint motion patterns in patients with knee ligament injuries and those who have undergone knee surgery.

Additionally, Jeongseok Oh was named one of five finalists for the David Winter Young Investigator Award, presenting his work during the award session. This award recognizes promising young researchers in biomechanics worldwide.

2025.08.10 View 164

Prof. Seungbum Koo’s Team Receives Clinical Biomechanics Award at the 30th International Society of Biomechanics Conference

<(From Left) Ph.D candidate Jeongseok Oh from KAIST, Dr. Seungwoo Yoon from KAIST, Prof.Joon-Ho Wang from Samsung Medical Center, Prof.Seungbum Koo from KAIST>

Professor Seungbum Koo’s research team received the Clinical Biomechanics Award at the 30th International Society of Biomechanics (ISB) Conference, held in July 2025 in Stockholm, Sweden. The Plenary Lecture was delivered by first author and Ph.D. candidate Jeongseok Oh. This research was conducted in collaboration with Professor Joon-Ho Wang’s team at Samsung Medical Center.

Residual Translational and Rotational Kinematics After Combined ACL and Anterolateral Ligament Reconstruction During Walking

Jeongseok Oh, Seungwoo Yoon, Joon-Ho Wang, Seungbum Koo

The study analyzed gait-related knee joint motion using high-speed biplane X-ray imaging and three-dimensional kinematic reconstruction in 10 healthy individuals and 10 patients who underwent ACL reconstruction with ALL augmentation. The patient group showed excessive anterior translation and internal rotation, suggesting incomplete restoration of normal joint kinematics post-surgery. These findings provide mechanistic insight into the early onset of knee osteoarthritis often reported in this population.'

The ISB conference, held biennially for over 60 years, is the largest international biomechanics meeting. This year, it hosted 1,600 researchers from 46 countries and featured over 1,400 presentations. The Clinical Biomechanics Award is given to one outstanding study selected from five top-rated abstracts invited for full manuscript review. The winning paper is published in Clinical Biomechanics, and the award includes a monetary prize and a Plenary Lecture opportunity.

From 2019 to 2023, Koo and Wang’s teams developed a system with support from the Samsung Future Technology Development Program to track knee motion in real time during treadmill walking, using high-speed biplane X-rays and custom three-dimensional reconstruction software. This system, along with proprietary software that precisely reconstructs the three-dimensional motion of joints, was approved for clinical trials by the Ministry of Food and Drug Safety and installed at Samsung Medical Center. It is being used to quantitatively analyze abnormal joint motion patterns in patients with knee ligament injuries and those who have undergone knee surgery.

Additionally, Jeongseok Oh was named one of five finalists for the David Winter Young Investigator Award, presenting his work during the award session. This award recognizes promising young researchers in biomechanics worldwide.

2025.08.10 View 164 -

Key Figures in the Establishment of KAIST, Specially Invited to the Presidential Office’s National Appointment Ceremony

KAIST announced on August 6 that Professor Emeritus Jung-Woong Ra from the Department of Electrical Engineering and Won-ki Kwon, former Vice Minister of the Ministry of Science and Technology, who played pivotal roles in the establishment of KAIST, were selected as special guests for the 'National Appointment Ceremony' hosted by the Presidential Office on August 15th.

The Presidential Office selected special invitees across eight categories for the ceremony. These include individuals born in 1945 (referred to as 'Liberation Babies'), those involved in the founding of KAIST in 1971, independence activists and national patriots, overseas workers in Germany and the Middle East, AI industry professionals, residents from regions facing depopulation, leading figures in K-culture, military personnel, firefighters, police officers, families of fallen public servants and victims of social disasters, as well as promising talents in economics, science, culture, and the arts.

Considering the historical significance of its establishment and its symbolic meaning for the development of national science and technology, KAIST Professor Emeritus Jung-Woong Ra, who was a key figure in the establishment of the Department of Electrical Engineering after being appointed as a professor in 1971, and former Vice Minister Kwon Won-ki, who was the first practical leader of the establishment project. Both were officially included on the special invitation list.

Briefing from the Presidential Office regarding the 'National Appointment Ceremony' (2025.07.28) https://www.president.go.kr/newsroom/briefing/grehGMuP

2025.08.06 View 227

Key Figures in the Establishment of KAIST, Specially Invited to the Presidential Office’s National Appointment Ceremony

KAIST announced on August 6 that Professor Emeritus Jung-Woong Ra from the Department of Electrical Engineering and Won-ki Kwon, former Vice Minister of the Ministry of Science and Technology, who played pivotal roles in the establishment of KAIST, were selected as special guests for the 'National Appointment Ceremony' hosted by the Presidential Office on August 15th.

The Presidential Office selected special invitees across eight categories for the ceremony. These include individuals born in 1945 (referred to as 'Liberation Babies'), those involved in the founding of KAIST in 1971, independence activists and national patriots, overseas workers in Germany and the Middle East, AI industry professionals, residents from regions facing depopulation, leading figures in K-culture, military personnel, firefighters, police officers, families of fallen public servants and victims of social disasters, as well as promising talents in economics, science, culture, and the arts.

Considering the historical significance of its establishment and its symbolic meaning for the development of national science and technology, KAIST Professor Emeritus Jung-Woong Ra, who was a key figure in the establishment of the Department of Electrical Engineering after being appointed as a professor in 1971, and former Vice Minister Kwon Won-ki, who was the first practical leader of the establishment project. Both were officially included on the special invitation list.

Briefing from the Presidential Office regarding the 'National Appointment Ceremony' (2025.07.28) https://www.president.go.kr/newsroom/briefing/grehGMuP

2025.08.06 View 227 -

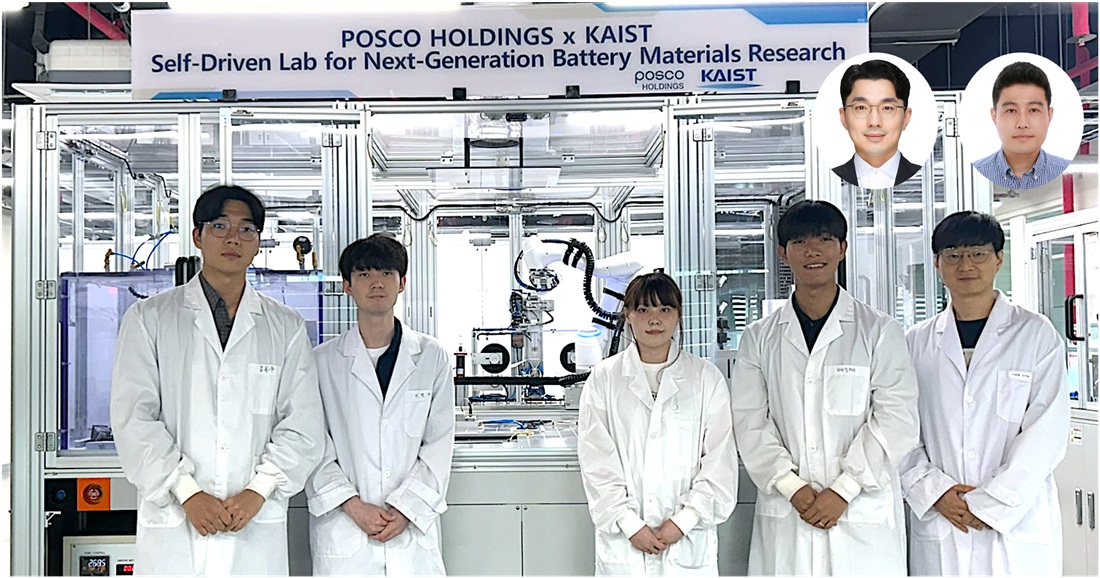

Material Innovation Realized with Robotic Arms and AI, Without Human Researchers

<(From Left) M.S candidate Dongwoo Kim from KAIST, Ph.D candidate Hyun-Gi Lee from KAIST, Intern Yeham Kang from KAIST, M.S candidate Seongjae Bae from KAIST, Professor Dong-Hwa Seo from KAIST, (From top right, from left) Senior Researcher Inchul Park from POSCO Holdings, Senior Researcher Jung Woo Park, senior researcher from POSCO Holdings>

A joint research team from industry and academia in Korea has successfully developed an autonomous lab that uses AI and automation to create new cathode materials for secondary batteries. This system operates without human intervention, drastically reducing researcher labor and cutting the material discovery period by 93%.

* Autonomous Lab: A platform that autonomously designs, conducts, and analyzes experiments to find the optimal material.

KAIST (President Kwang Hyung Lee) announced on the 3rd of August that the research team led by Professor Dong-Hwa Seo of the Department of Materials Science and Engineering, in collaboration with the team of LIB Materials Research Center in Energy Materials R&D Laboratories at POSCO Holdings' POSCO N.EX.T Hub (Director Ki Soo Kim), built the lab to explore cathode materials using AI and automation technology.

Developing secondary battery cathode materials is a labor-intensive and time-consuming process for skilled researchers. It involves extensive exploration of various compositions and experimental variables through weighing, transporting, mixing, sintering*, and analyzing samples.

* Sintering: A process in which powder particles are heated to form a single solid mass through thermal activation.

The research team's autonomous lab combines an automated system with an AI model. The system handles all experimental steps—weighing, mixing, pelletizing, sintering, and analysis—without human interference. The AI model then interprets the data, learns from it, and selects the best candidates for the next experiment.

<Figure 1. Outline of the Anode Material Autonomous Exploration Laboratory>

To increase efficiency, the team designed the automation system with separate modules for each process, which are managed by a central robotic arm. This modular approach reduces the system's reliance on the robotic arm.

The team also significantly improved the synthesis speed by using a new high-speed sintering method, which is 50 times faster than the conventional low-speed method. This allows the autonomous lab to acquire 12 times more material data compared to traditional, researcher-led experiments.

<Figure 2. Synthesis of Cathode Material Using a High-Speed Sintering Device>

The vast amount of data collected is automatically interpreted by the AI model to extract information such as synthesized phases and impurity ratios. This data is systematically stored to create a high-quality database, which then serves as training data for an optimization AI model. This creates a closed-loop experimental system that recommends the next cathode composition and synthesis conditions for the automated system.

* Closed-loop experimental system: A system that independently performs all experimental processes without researcher intervention.

Operating this intelligent automation system 24 hours a day can secure more than 12 times the experimental data and shorten material discovery time by 93%. For a project requiring 500 experiments, the system can complete the work in about 6 days, whereas a traditional researcher-led approach would take 84 days.

During development, POSCO Holdings team managed the overall project planning, reviewed the platform design, and co-developed the partial module design and AI-based experimental model. The KAIST team, led by Professor Dong-hwa Seo, was responsible for the actual system implementation and operation, including platform design, module fabrication, algorithm creation, and system verification and improvement.

Professor Dong-Hwa Seo of KAIST stated that this system is a solution to the decrease in research personnel due to the low birth rate in Korea. He expects it will enhance global competitiveness by accelerating secondary battery material development through the acquisition of high-quality data.

<Figure 3. Exterior View (Side) of the Cathode Material Autonomous Exploration Laboratory>

POSCO N.EX.T Hub plans to apply an upgraded version of this autonomous lab to its own research facilities after 2026 to dramatically speed up next-generation secondary battery material development. They are planning further developments to enhance the system's stability and scalability, and hope this industry-academia collaboration will serve as a model for using innovative technology in real-world R&D.

<Figure 4. Exterior View (Front) of the Cathode Material Autonomous Exploration Laboratory>

The research was spearheaded by Ph.D. student Hyun-Gi Lee, along with master's students Seongjae Bae and Dongwoo Kim from Professor Dong-Hwa Seo’s lab at KAIST. Senior researchers Jung Woo Park and Inchul Park from LIB Materials Research Center of POSCO N.EX.T Hub's Energy Materials R&D Laboratories (Director Jeongjin Hong) also participated.

2025.08.06 View 302

Material Innovation Realized with Robotic Arms and AI, Without Human Researchers

<(From Left) M.S candidate Dongwoo Kim from KAIST, Ph.D candidate Hyun-Gi Lee from KAIST, Intern Yeham Kang from KAIST, M.S candidate Seongjae Bae from KAIST, Professor Dong-Hwa Seo from KAIST, (From top right, from left) Senior Researcher Inchul Park from POSCO Holdings, Senior Researcher Jung Woo Park, senior researcher from POSCO Holdings>

A joint research team from industry and academia in Korea has successfully developed an autonomous lab that uses AI and automation to create new cathode materials for secondary batteries. This system operates without human intervention, drastically reducing researcher labor and cutting the material discovery period by 93%.

* Autonomous Lab: A platform that autonomously designs, conducts, and analyzes experiments to find the optimal material.

KAIST (President Kwang Hyung Lee) announced on the 3rd of August that the research team led by Professor Dong-Hwa Seo of the Department of Materials Science and Engineering, in collaboration with the team of LIB Materials Research Center in Energy Materials R&D Laboratories at POSCO Holdings' POSCO N.EX.T Hub (Director Ki Soo Kim), built the lab to explore cathode materials using AI and automation technology.

Developing secondary battery cathode materials is a labor-intensive and time-consuming process for skilled researchers. It involves extensive exploration of various compositions and experimental variables through weighing, transporting, mixing, sintering*, and analyzing samples.

* Sintering: A process in which powder particles are heated to form a single solid mass through thermal activation.

The research team's autonomous lab combines an automated system with an AI model. The system handles all experimental steps—weighing, mixing, pelletizing, sintering, and analysis—without human interference. The AI model then interprets the data, learns from it, and selects the best candidates for the next experiment.

<Figure 1. Outline of the Anode Material Autonomous Exploration Laboratory>

To increase efficiency, the team designed the automation system with separate modules for each process, which are managed by a central robotic arm. This modular approach reduces the system's reliance on the robotic arm.