Jaewook+Myung

-

Unlocking New Potential for Natural Gas–Based Bioplastic Production

<(From Left)Jaewook Myung from KAIST, Sunho Park from KAIST, Dr. Chungheon Shin from Stanford University, Prof. Craig S. Criddle from Stanford University >

KAIST announced that a research team led by Professor Jaewook Myung from the Department of Civil and Environmental Engineering, in collaboration with Stanford University, has identified how ethane (C2H6)—a major constituent of natural gas—affects the core metabolic pathways of the obligate methanotroph Methylosinus trichosporium OB3b.

Methane (CH4), a greenhouse gas with roughly 25 times the global warming potential of carbon dioxide, is rarely emitted alone into the environment. It is typically released in mixtures with other gases. In the case of natural gas, ethane can comprise up to 15% of the total composition.

Methanotrophs are aerobic bacteria that can utilize methane as their sole source of carbon and energy. Obligate methanotrophs, in particular, strictly utilize only C1 compounds such as methane or methanol. Until now, little was known about how these organisms respond to C2 compounds like ethane, which they cannot use for growth.

<Figure 1. Conceptual overview of obligate methanotroph metabolism and PHB biosynthesis under mixed-substrate conditions of methane and ethane>

This study reveals that although ethane cannot serve as a growth substrate, its presence significantly affects key metabolic functions in M. trichosporium OB3b—including methane oxidation, cell proliferation, and the intracellular synthesis of polyhydroxybutyrate (PHB), a biodegradable polymer.

Under varying methane and oxygen conditions, the team observed that ethane addition consistently resulted in three metabolic effects: reduced cell growth, lower methane consumption, and increased PHB accumulation. These effects intensified with rising ethane concentrations. Notably, ethane oxidation occurred only when methane was present, confirming that it is co-oxidized via particulate methane monooxygenase (pMMO), the key enzyme responsible for methane oxidation.

<Figure2. Effects of increasing ethane concentrations on methane and ethane consumption, cell growth, and PHB production in Methylosinus trichosporium OB3b>

Further analysis showed that acetate, an intermediate formed during ethane oxidation, played a pivotal role in this response. Higher acetate levels inhibited growth but enhanced PHB production, suggesting that ethane-derived acetate drives contrasting carbon assimilation patterns depending on nutrient conditions—nutrient-balanced growth phase and nutrient-imbalanced PHB accumulation phas.

In addition, when external reducing power was supplemented (via methanol or formate), ethane consumption was enhanced significantly, while methane oxidation remained largely unaffected. This finding suggests that ethane, despite not supporting growth, actively competes for intracellular resources such as reducing equivalents. It offers new insights into substrate prioritization and resource allocation in methanotrophs under mixed-substrate conditions.

Interestingly, while methane uptake declined in the presence of ethane, the expression of pmoA, the gene encoding pMMO, remained unchanged. This suggests that ethane’s impact occurs beyond the transcriptional level—likely via post-transcriptional or enzymatic regulation.

<Figure 3. Mechanistic analysis of ethane-induced metabolic changes in obligate methanotrophs: acetate-driven carbon assimilation change (blue box), intracellular reducing power depletion (red box), and pmoA expression quantitative analysis (green box)>

“This is the first study to systematically investigate how obligate methanotrophs respond to complex gas mixtures involving ethane,” said Professor Jaewook Myung. “Our findings show that even non-growth substrates can meaningfully influence microbial metabolism and biopolymer synthesis, opening new possibilities for methane-based biotechnologies and bioplastic production.”

The study was supported by the National Research Foundation of Korea, the Ministry of Land, Infrastructure and Transport, and the Ministry of Oceans and Fisheries. The results were published in Applied and Environmental Microbiology, a journal of the American Society for Microbiology.

2025.08.07 View 122

Unlocking New Potential for Natural Gas–Based Bioplastic Production

<(From Left)Jaewook Myung from KAIST, Sunho Park from KAIST, Dr. Chungheon Shin from Stanford University, Prof. Craig S. Criddle from Stanford University >

KAIST announced that a research team led by Professor Jaewook Myung from the Department of Civil and Environmental Engineering, in collaboration with Stanford University, has identified how ethane (C2H6)—a major constituent of natural gas—affects the core metabolic pathways of the obligate methanotroph Methylosinus trichosporium OB3b.

Methane (CH4), a greenhouse gas with roughly 25 times the global warming potential of carbon dioxide, is rarely emitted alone into the environment. It is typically released in mixtures with other gases. In the case of natural gas, ethane can comprise up to 15% of the total composition.

Methanotrophs are aerobic bacteria that can utilize methane as their sole source of carbon and energy. Obligate methanotrophs, in particular, strictly utilize only C1 compounds such as methane or methanol. Until now, little was known about how these organisms respond to C2 compounds like ethane, which they cannot use for growth.

<Figure 1. Conceptual overview of obligate methanotroph metabolism and PHB biosynthesis under mixed-substrate conditions of methane and ethane>

This study reveals that although ethane cannot serve as a growth substrate, its presence significantly affects key metabolic functions in M. trichosporium OB3b—including methane oxidation, cell proliferation, and the intracellular synthesis of polyhydroxybutyrate (PHB), a biodegradable polymer.

Under varying methane and oxygen conditions, the team observed that ethane addition consistently resulted in three metabolic effects: reduced cell growth, lower methane consumption, and increased PHB accumulation. These effects intensified with rising ethane concentrations. Notably, ethane oxidation occurred only when methane was present, confirming that it is co-oxidized via particulate methane monooxygenase (pMMO), the key enzyme responsible for methane oxidation.

<Figure2. Effects of increasing ethane concentrations on methane and ethane consumption, cell growth, and PHB production in Methylosinus trichosporium OB3b>

Further analysis showed that acetate, an intermediate formed during ethane oxidation, played a pivotal role in this response. Higher acetate levels inhibited growth but enhanced PHB production, suggesting that ethane-derived acetate drives contrasting carbon assimilation patterns depending on nutrient conditions—nutrient-balanced growth phase and nutrient-imbalanced PHB accumulation phas.

In addition, when external reducing power was supplemented (via methanol or formate), ethane consumption was enhanced significantly, while methane oxidation remained largely unaffected. This finding suggests that ethane, despite not supporting growth, actively competes for intracellular resources such as reducing equivalents. It offers new insights into substrate prioritization and resource allocation in methanotrophs under mixed-substrate conditions.

Interestingly, while methane uptake declined in the presence of ethane, the expression of pmoA, the gene encoding pMMO, remained unchanged. This suggests that ethane’s impact occurs beyond the transcriptional level—likely via post-transcriptional or enzymatic regulation.

<Figure 3. Mechanistic analysis of ethane-induced metabolic changes in obligate methanotrophs: acetate-driven carbon assimilation change (blue box), intracellular reducing power depletion (red box), and pmoA expression quantitative analysis (green box)>

“This is the first study to systematically investigate how obligate methanotrophs respond to complex gas mixtures involving ethane,” said Professor Jaewook Myung. “Our findings show that even non-growth substrates can meaningfully influence microbial metabolism and biopolymer synthesis, opening new possibilities for methane-based biotechnologies and bioplastic production.”

The study was supported by the National Research Foundation of Korea, the Ministry of Land, Infrastructure and Transport, and the Ministry of Oceans and Fisheries. The results were published in Applied and Environmental Microbiology, a journal of the American Society for Microbiology.

2025.08.07 View 122 -

Novel High-performance and Sustainable Paper Coating Material created by KAIST-Yonsei University Research Team to reduce microplastic pollution

What if there is a biodegradable packaging material with high performance without leaving microplastics?

Plastic pollution presents a global challenge that must be solved. In particular, packaging accounts for 30-50% of the total plastic consumption. While paper packaging is eco-friendly, it lacks crucial functionalities like moisture resistance and strength. Traditional coating materials exacerbate plastic pollution, prompting the need for sustainable alternatives.

Polyethylene (PE) and ethylene vinyl alcohol (EVOH) are typically used as coating materials to improve the low barrier properties of paper packaging, but these substances do not decompose and worsen microplastic pollution when disposed of in the natural environment. In response to this problem, packaging materials made from bio-based substances and biodegradable plastics have been developed, but in most cases, as the packaging performance improves, the biodegradability diminishes rapidly.

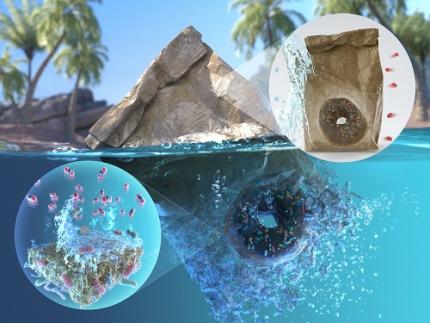

KAIST announced that a joint research team led by Professor Jaewook Myung of the Department of Civil and Environmental Engineering, Professor Hanseul Yang of the Department of Life Sciences, and Professor Jongcheol Seo of the Department of Packaging and Logistics <Figure 4. Back cover art of Green Chemistry journal of the latest volume, describing the boric acid cross-linked poly(vinyl alcohol) coated paper featuring marine biodegradability, biocompatibility, high barrier properties, and robustness developed through this study.>

at Yonsei University tackled the challenge of balancing packaging performance and sustainability. They successfully developed a sustainable, marine biodegradable, high-performance paper coating material.

* Biodegradable plastic: A plastic that can be decomposed by microorganisms in natural environments such as soil and ocean or artificial conditions such as industrial composting and anaerobic digestion by microorganisms.

*Microplastics: Tiny pieces of plastic less than 5 mm, produced during the decomposition of bulk plastic materials. Microplastics can persist in the sea for more than decades, causing severe marine pollution.

The team utilized boric acid-crosslinked poly(vinyl alcohol) (PVA), a biodegradable plastic, to coat the paper, thereby enhancing its biodegradability, barrier properties, and strength. The resulting coated paper exhibited superior performance compared to conventional plastics, with excellent barrier properties and physical strength, even in humid conditions.

<Figure 1. (a) Chemical structure of boric acid-crosslinked poly(vinyl alcohol) coating on paper, (b-c) Oxygen and water vapor barrier properties, (d-f) Tensile strength in dry and moist conditions. OTR: Oxygen transmission rate, WVTR: Water vapor transmission rate.>

The team also conducted an in-depth examination of biodegradation and biocompatibility to systematically evaluate the sustainability of the newly developed coated paper. Biodegradation was assessed by simulating the marine environment, known for its challenging biodegradability conditions. The team employed a respiratory system-based bioreactor to measure the degree of carbon mineralization into carbon dioxide. After 111 days of biodegradation, it was found that the coated papers achieved 59-82% biodegradation depending on the coating component. The phenomenon in which marine bacteria are decomposing the coating material was captured through a scanning electron microscope. In addition, in vitro biocompatibility was confirmed through human embryonic kidney and mouse embryonic fibroblast cells, as well as high in-vivo biocompatibility of the coated paper was verified through mouse experiments.

Through this study, the joint research team proposed a coating strategy that can improve packaging performance while upholding sustainability to address the drawbacks of paper packaging. The boric acid-crosslinked PVA-coated paper eliminates the need for artificial composting conditions or sewage treatment facilities. Being biodegradable in natural environments and characterized by low toxicity, this newly coated paper does not exacerbate environmental pollution when accidentally discarded. Thus, it presents a sustainable substitute for plastic packaging materials.

<Figure 2. (a) Normal paper and boric acid-crosslinked poly(vinyl alcohol) coated paper, (b) Biodegradation of the coated paper by marine bacteria, (c) Result of cytotoxicity test using human embryonic kidney and mouse embryonic fibroblast cells. (d) Vital organs after one-month exposure of the coated papers to mice.>

Professor Jaewook Myung at KAIST, who led the sustainability study of coated paper, said, "The development of a marine biodegradable high-performance paper coating is the result of combining the innovative technologies of three leading research teams in each field." He said, “We will continue to develop sustainable materials with excellent performance.” Meanwhile, Professor Jongchul Seo of Yonsei University, who led the research on the development of high-performance paper coating, mentioned, “Through this research, we have developed a sustainable paper packaging technology that can replace non-degradable plastic packaging, and we expect the research outcome will be applied in industry,”.

<Figure 3. End-of-life scenario of papers coated by BA-crosslinked PVA in the marine environment. The coated papers potentially be disintegrated by marine microorganisms and ocean waves and tides. The depolymerization of PVA coating and paper is then mediated by extracellular depolymerases such as oxidases and cellulases, after which the small subunits (oligomers and monomers) are assimilated by microbial cells. The carbon components in the coated papers are ultimately mineralized into CO2, posing no harm in the ocean.>

The work was published in Green Chemistry and Food Chemistry journals. This study was conducted with the support of the Korea Research Foundation and the Korea Institute for Agriculture, Food and Rural Affairs Technology Planning and Evaluation, etc.

*Title of paper published in Green Chemistry: Boric acid-crosslinked poly(vinyl alcohol): biodegradable, biocompatible, robust, and high-barrier paper coating

※ Selected as the article for the back cover of the journal .

- Authors: Shinhyeong Choe, Seulki You, Kitae Park, Youngju Kim, Jehee Park, Yongjun Cho, Jongchul Seo, Hanseul Yang, and Jaewook Myung)

- Date: April 17, 2024

- DOI: 10.1039/D4GC00618F

*Title of paper published in Food Chemistry: Effect of epichlorohydrin treatment on the coating process and performance of high-barrier paper packaging

- Authors: Kitae Park, Shinhyeong Choe, Kambiz Sadeghi, Pradeep Kumar Panda, Jaewook Myung, Dowan Kim, and Jongchul Seo

- Date: February 19, 2024

- DOI: 10.1016/j.foodchem.2024.138772

<Figure 4. Back cover art of Green Chemistry journal of the latest volume, describing the boric acid cross-linked poly(vinyl alcohol) coated paper featuring marine biodegradability, biocompatibility, high barrier properties, and robustness developed through this study.>

2024.05.22 View 9627

Novel High-performance and Sustainable Paper Coating Material created by KAIST-Yonsei University Research Team to reduce microplastic pollution

What if there is a biodegradable packaging material with high performance without leaving microplastics?

Plastic pollution presents a global challenge that must be solved. In particular, packaging accounts for 30-50% of the total plastic consumption. While paper packaging is eco-friendly, it lacks crucial functionalities like moisture resistance and strength. Traditional coating materials exacerbate plastic pollution, prompting the need for sustainable alternatives.

Polyethylene (PE) and ethylene vinyl alcohol (EVOH) are typically used as coating materials to improve the low barrier properties of paper packaging, but these substances do not decompose and worsen microplastic pollution when disposed of in the natural environment. In response to this problem, packaging materials made from bio-based substances and biodegradable plastics have been developed, but in most cases, as the packaging performance improves, the biodegradability diminishes rapidly.

KAIST announced that a joint research team led by Professor Jaewook Myung of the Department of Civil and Environmental Engineering, Professor Hanseul Yang of the Department of Life Sciences, and Professor Jongcheol Seo of the Department of Packaging and Logistics <Figure 4. Back cover art of Green Chemistry journal of the latest volume, describing the boric acid cross-linked poly(vinyl alcohol) coated paper featuring marine biodegradability, biocompatibility, high barrier properties, and robustness developed through this study.>

at Yonsei University tackled the challenge of balancing packaging performance and sustainability. They successfully developed a sustainable, marine biodegradable, high-performance paper coating material.

* Biodegradable plastic: A plastic that can be decomposed by microorganisms in natural environments such as soil and ocean or artificial conditions such as industrial composting and anaerobic digestion by microorganisms.

*Microplastics: Tiny pieces of plastic less than 5 mm, produced during the decomposition of bulk plastic materials. Microplastics can persist in the sea for more than decades, causing severe marine pollution.

The team utilized boric acid-crosslinked poly(vinyl alcohol) (PVA), a biodegradable plastic, to coat the paper, thereby enhancing its biodegradability, barrier properties, and strength. The resulting coated paper exhibited superior performance compared to conventional plastics, with excellent barrier properties and physical strength, even in humid conditions.

<Figure 1. (a) Chemical structure of boric acid-crosslinked poly(vinyl alcohol) coating on paper, (b-c) Oxygen and water vapor barrier properties, (d-f) Tensile strength in dry and moist conditions. OTR: Oxygen transmission rate, WVTR: Water vapor transmission rate.>

The team also conducted an in-depth examination of biodegradation and biocompatibility to systematically evaluate the sustainability of the newly developed coated paper. Biodegradation was assessed by simulating the marine environment, known for its challenging biodegradability conditions. The team employed a respiratory system-based bioreactor to measure the degree of carbon mineralization into carbon dioxide. After 111 days of biodegradation, it was found that the coated papers achieved 59-82% biodegradation depending on the coating component. The phenomenon in which marine bacteria are decomposing the coating material was captured through a scanning electron microscope. In addition, in vitro biocompatibility was confirmed through human embryonic kidney and mouse embryonic fibroblast cells, as well as high in-vivo biocompatibility of the coated paper was verified through mouse experiments.

Through this study, the joint research team proposed a coating strategy that can improve packaging performance while upholding sustainability to address the drawbacks of paper packaging. The boric acid-crosslinked PVA-coated paper eliminates the need for artificial composting conditions or sewage treatment facilities. Being biodegradable in natural environments and characterized by low toxicity, this newly coated paper does not exacerbate environmental pollution when accidentally discarded. Thus, it presents a sustainable substitute for plastic packaging materials.

<Figure 2. (a) Normal paper and boric acid-crosslinked poly(vinyl alcohol) coated paper, (b) Biodegradation of the coated paper by marine bacteria, (c) Result of cytotoxicity test using human embryonic kidney and mouse embryonic fibroblast cells. (d) Vital organs after one-month exposure of the coated papers to mice.>

Professor Jaewook Myung at KAIST, who led the sustainability study of coated paper, said, "The development of a marine biodegradable high-performance paper coating is the result of combining the innovative technologies of three leading research teams in each field." He said, “We will continue to develop sustainable materials with excellent performance.” Meanwhile, Professor Jongchul Seo of Yonsei University, who led the research on the development of high-performance paper coating, mentioned, “Through this research, we have developed a sustainable paper packaging technology that can replace non-degradable plastic packaging, and we expect the research outcome will be applied in industry,”.

<Figure 3. End-of-life scenario of papers coated by BA-crosslinked PVA in the marine environment. The coated papers potentially be disintegrated by marine microorganisms and ocean waves and tides. The depolymerization of PVA coating and paper is then mediated by extracellular depolymerases such as oxidases and cellulases, after which the small subunits (oligomers and monomers) are assimilated by microbial cells. The carbon components in the coated papers are ultimately mineralized into CO2, posing no harm in the ocean.>

The work was published in Green Chemistry and Food Chemistry journals. This study was conducted with the support of the Korea Research Foundation and the Korea Institute for Agriculture, Food and Rural Affairs Technology Planning and Evaluation, etc.

*Title of paper published in Green Chemistry: Boric acid-crosslinked poly(vinyl alcohol): biodegradable, biocompatible, robust, and high-barrier paper coating

※ Selected as the article for the back cover of the journal .

- Authors: Shinhyeong Choe, Seulki You, Kitae Park, Youngju Kim, Jehee Park, Yongjun Cho, Jongchul Seo, Hanseul Yang, and Jaewook Myung)

- Date: April 17, 2024

- DOI: 10.1039/D4GC00618F

*Title of paper published in Food Chemistry: Effect of epichlorohydrin treatment on the coating process and performance of high-barrier paper packaging

- Authors: Kitae Park, Shinhyeong Choe, Kambiz Sadeghi, Pradeep Kumar Panda, Jaewook Myung, Dowan Kim, and Jongchul Seo

- Date: February 19, 2024

- DOI: 10.1016/j.foodchem.2024.138772

<Figure 4. Back cover art of Green Chemistry journal of the latest volume, describing the boric acid cross-linked poly(vinyl alcohol) coated paper featuring marine biodegradability, biocompatibility, high barrier properties, and robustness developed through this study.>

2024.05.22 View 9627