EC

-

‘Urban Green Space Affects Citizens’ Happiness’

Study finds the relationship between green space, the economy, and happiness

A recent study revealed that as a city becomes more economically developed, its citizens’ happiness becomes more directly related to the area of urban green space.

A joint research project by Professor Meeyoung Cha of the School of Computing and her collaborators studied the relationship between green space and citizen happiness by analyzing big data from satellite images of 60 different countries.

Urban green space, including parks, gardens, and riversides not only provides aesthetic pleasure, but also positively affects our health by promoting physical activity and social interactions. Most of the previous research attempting to verify the correlation between urban green space and citizen happiness was based on few developed countries. Therefore, it was difficult to identify whether the positive effects of green space are global, or merely phenomena that depended on the economic state of the country. There have also been limitations in data collection, as it is difficult to visit each location or carry out investigations on a large scale based on aerial photographs.

The research team used data collected by Sentinel-2, a high-resolution satellite operated by the European Space Agency (ESA) to investigate 90 green spaces from 60 different countries around the world. The subjects of analysis were cities with the highest population densities (cities that contain at least 10% of the national population), and the images were obtained during the summer of each region for clarity. Images from the northern hemisphere were obtained between June and September of 2018, and those from the southern hemisphere were obtained between December of 2017 and February of 2018.

The areas of urban green space were then quantified and crossed with data from the World Happiness Report and GDP by country reported by the United Nations in 2018. Using these data, the relationships between green space, the economy, and citizen happiness were analyzed.

The results showed that in all cities, citizen happiness was positively correlated with the area of urban green space regardless of the country’s economic state. However, out of the 60 countries studied, the happiness index of the bottom 30 by GDP showed a stronger correlation with economic growth. In countries whose gross national income (GDP per capita) was higher than 38,000 USD, the area of green space acted as a more important factor affecting happiness than economic growth. Data from Seoul was analyzed to represent South Korea, and showed an increased happiness index with increased green areas compared to the past.

The authors point out their work has several policy-level implications. First, public green space should be made accessible to urban dwellers to enhance social support. If public safety in urban parks is not guaranteed, its positive role in social support and happiness may diminish. Also, the meaning of public safety may change; for example, ensuring biological safety will be a priority in keeping urban parks accessible during the COVID-19 pandemic.

Second, urban planning for public green space is needed for both developed and developing countries. As it is challenging or nearly impossible to secure land for green space after the area is developed, urban planning for parks and green space should be considered in developing economies where new cities and suburban areas are rapidly expanding.

Third, recent climate changes can present substantial difficulty in sustaining urban green space. Extreme events such as wildfires, floods, droughts, and cold waves could endanger urban forests while global warming could conversely accelerate tree growth in cities due to the urban heat island effect. Thus, more attention must be paid to predict climate changes and discovering their impact on the maintenance of urban green space.

“There has recently been an increase in the number of studies using big data from satellite images to solve social conundrums,” said Professor Cha. “The tool developed for this investigation can also be used to quantify the area of aquatic environments like lakes and the seaside, and it will now be possible to analyze the relationship between citizen happiness and aquatic environments in future studies,” she added.

Professor Woo Sung Jung from POSTECH and Professor Donghee Wohn from the New Jersey Institute of Technology also joined this research. It was reported in the online issue of EPJ Data Science on May 30.

-PublicationOh-Hyun Kwon, Inho Hong, Jeasurk Yang, Donghee Y. Wohn, Woo-Sung Jung, andMeeyoung Cha, 2021. Urban green space and happiness in developed countries. EPJ Data Science. DOI: https://doi.org/10.1140/epjds/s13688-021-00278-7

-ProfileProfessor Meeyoung ChaData Science Labhttps://ds.ibs.re.kr/

School of Computing

KAIST

2021.06.21 View 13086

‘Urban Green Space Affects Citizens’ Happiness’

Study finds the relationship between green space, the economy, and happiness

A recent study revealed that as a city becomes more economically developed, its citizens’ happiness becomes more directly related to the area of urban green space.

A joint research project by Professor Meeyoung Cha of the School of Computing and her collaborators studied the relationship between green space and citizen happiness by analyzing big data from satellite images of 60 different countries.

Urban green space, including parks, gardens, and riversides not only provides aesthetic pleasure, but also positively affects our health by promoting physical activity and social interactions. Most of the previous research attempting to verify the correlation between urban green space and citizen happiness was based on few developed countries. Therefore, it was difficult to identify whether the positive effects of green space are global, or merely phenomena that depended on the economic state of the country. There have also been limitations in data collection, as it is difficult to visit each location or carry out investigations on a large scale based on aerial photographs.

The research team used data collected by Sentinel-2, a high-resolution satellite operated by the European Space Agency (ESA) to investigate 90 green spaces from 60 different countries around the world. The subjects of analysis were cities with the highest population densities (cities that contain at least 10% of the national population), and the images were obtained during the summer of each region for clarity. Images from the northern hemisphere were obtained between June and September of 2018, and those from the southern hemisphere were obtained between December of 2017 and February of 2018.

The areas of urban green space were then quantified and crossed with data from the World Happiness Report and GDP by country reported by the United Nations in 2018. Using these data, the relationships between green space, the economy, and citizen happiness were analyzed.

The results showed that in all cities, citizen happiness was positively correlated with the area of urban green space regardless of the country’s economic state. However, out of the 60 countries studied, the happiness index of the bottom 30 by GDP showed a stronger correlation with economic growth. In countries whose gross national income (GDP per capita) was higher than 38,000 USD, the area of green space acted as a more important factor affecting happiness than economic growth. Data from Seoul was analyzed to represent South Korea, and showed an increased happiness index with increased green areas compared to the past.

The authors point out their work has several policy-level implications. First, public green space should be made accessible to urban dwellers to enhance social support. If public safety in urban parks is not guaranteed, its positive role in social support and happiness may diminish. Also, the meaning of public safety may change; for example, ensuring biological safety will be a priority in keeping urban parks accessible during the COVID-19 pandemic.

Second, urban planning for public green space is needed for both developed and developing countries. As it is challenging or nearly impossible to secure land for green space after the area is developed, urban planning for parks and green space should be considered in developing economies where new cities and suburban areas are rapidly expanding.

Third, recent climate changes can present substantial difficulty in sustaining urban green space. Extreme events such as wildfires, floods, droughts, and cold waves could endanger urban forests while global warming could conversely accelerate tree growth in cities due to the urban heat island effect. Thus, more attention must be paid to predict climate changes and discovering their impact on the maintenance of urban green space.

“There has recently been an increase in the number of studies using big data from satellite images to solve social conundrums,” said Professor Cha. “The tool developed for this investigation can also be used to quantify the area of aquatic environments like lakes and the seaside, and it will now be possible to analyze the relationship between citizen happiness and aquatic environments in future studies,” she added.

Professor Woo Sung Jung from POSTECH and Professor Donghee Wohn from the New Jersey Institute of Technology also joined this research. It was reported in the online issue of EPJ Data Science on May 30.

-PublicationOh-Hyun Kwon, Inho Hong, Jeasurk Yang, Donghee Y. Wohn, Woo-Sung Jung, andMeeyoung Cha, 2021. Urban green space and happiness in developed countries. EPJ Data Science. DOI: https://doi.org/10.1140/epjds/s13688-021-00278-7

-ProfileProfessor Meeyoung ChaData Science Labhttps://ds.ibs.re.kr/

School of Computing

KAIST

2021.06.21 View 13086 -

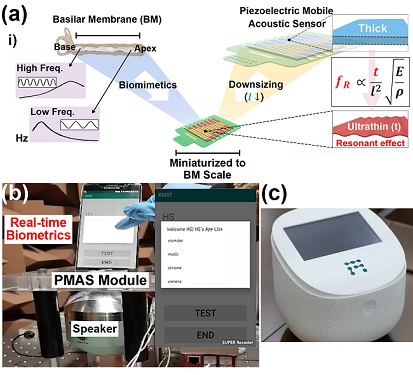

Biomimetic Resonant Acoustic Sensor Detecting Far-Distant Voices Accurately to Hit the Market

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering has developed a bioinspired flexible piezoelectric acoustic sensor with multi-resonant ultrathin piezoelectric membrane mimicking the basilar membrane of the human cochlea. The flexible acoustic sensor has been miniaturized for embedding into smartphones and the first commercial prototype is ready for accurate and far-distant voice detection.

In 2018, Professor Lee presented the first concept of a flexible piezoelectric acoustic sensor, inspired by the fact that humans can accurately detect far-distant voices using a multi-resonant trapezoidal membrane with 20,000 hair cells. However, previous acoustic sensors could not be integrated into commercial products like smartphones and AI speakers due to their large device size.

In this work, the research team fabricated a mobile-sized acoustic sensor by adopting ultrathin piezoelectric membranes with high sensitivity. Simulation studies proved that the ultrathin polymer underneath inorganic piezoelectric thin film can broaden the resonant bandwidth to cover the entire voice frequency range using seven channels. Based on this theory, the research team successfully demonstrated the miniaturized acoustic sensor mounted in commercial smartphones and AI speakers for machine learning-based biometric authentication and voice processing. (Please refer to the explanatory movie KAIST Flexible Piezoelectric Mobile Acoustic Sensor).

The resonant mobile acoustic sensor has superior sensitivity and multi-channel signals compared to conventional condenser microphones with a single channel, and it has shown highly accurate and far-distant speaker identification with a small amount of voice training data. The error rate of speaker identification was significantly reduced by 56% (with 150 training datasets) and 75% (with 2,800 training datasets) compared to that of a MEMS condenser device.

Professor Lee said, “Recently, Google has been targeting the ‘Wolverine Project’ on far-distant voice separation from multi-users for next-generation AI user interfaces. I expect that our multi-channel resonant acoustic sensor with abundant voice information is the best fit for this application. Currently, the mass production process is on the verge of completion, so we hope that this will be used in our daily lives very soon.”

Professor Lee also established a startup company called Fronics Inc., located both in Korea and U.S. (branch office) to commercialize this flexible acoustic sensor and is seeking collaborations with global AI companies.

These research results entitled “Biomimetic and Flexible Piezoelectric Mobile Acoustic Sensors with Multi-Resonant Ultrathin Structures for Machine Learning Biometrics” were published in Science Advances in 2021 (7, eabe5683).

-Publication

“Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics,” Science Advances (DOI: 10.1126/sciadv.abe5683)

-Profile

Professor Keon Jae Lee

Department of Materials Science and Engineering

Flexible and Nanobio Device Lab

http://fand.kaist.ac.kr/

KAIST

2021.06.14 View 10937

Biomimetic Resonant Acoustic Sensor Detecting Far-Distant Voices Accurately to Hit the Market

A KAIST research team led by Professor Keon Jae Lee from the Department of Materials Science and Engineering has developed a bioinspired flexible piezoelectric acoustic sensor with multi-resonant ultrathin piezoelectric membrane mimicking the basilar membrane of the human cochlea. The flexible acoustic sensor has been miniaturized for embedding into smartphones and the first commercial prototype is ready for accurate and far-distant voice detection.

In 2018, Professor Lee presented the first concept of a flexible piezoelectric acoustic sensor, inspired by the fact that humans can accurately detect far-distant voices using a multi-resonant trapezoidal membrane with 20,000 hair cells. However, previous acoustic sensors could not be integrated into commercial products like smartphones and AI speakers due to their large device size.

In this work, the research team fabricated a mobile-sized acoustic sensor by adopting ultrathin piezoelectric membranes with high sensitivity. Simulation studies proved that the ultrathin polymer underneath inorganic piezoelectric thin film can broaden the resonant bandwidth to cover the entire voice frequency range using seven channels. Based on this theory, the research team successfully demonstrated the miniaturized acoustic sensor mounted in commercial smartphones and AI speakers for machine learning-based biometric authentication and voice processing. (Please refer to the explanatory movie KAIST Flexible Piezoelectric Mobile Acoustic Sensor).

The resonant mobile acoustic sensor has superior sensitivity and multi-channel signals compared to conventional condenser microphones with a single channel, and it has shown highly accurate and far-distant speaker identification with a small amount of voice training data. The error rate of speaker identification was significantly reduced by 56% (with 150 training datasets) and 75% (with 2,800 training datasets) compared to that of a MEMS condenser device.

Professor Lee said, “Recently, Google has been targeting the ‘Wolverine Project’ on far-distant voice separation from multi-users for next-generation AI user interfaces. I expect that our multi-channel resonant acoustic sensor with abundant voice information is the best fit for this application. Currently, the mass production process is on the verge of completion, so we hope that this will be used in our daily lives very soon.”

Professor Lee also established a startup company called Fronics Inc., located both in Korea and U.S. (branch office) to commercialize this flexible acoustic sensor and is seeking collaborations with global AI companies.

These research results entitled “Biomimetic and Flexible Piezoelectric Mobile Acoustic Sensors with Multi-Resonant Ultrathin Structures for Machine Learning Biometrics” were published in Science Advances in 2021 (7, eabe5683).

-Publication

“Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics,” Science Advances (DOI: 10.1126/sciadv.abe5683)

-Profile

Professor Keon Jae Lee

Department of Materials Science and Engineering

Flexible and Nanobio Device Lab

http://fand.kaist.ac.kr/

KAIST

2021.06.14 View 10937 -

KAIST to join Deep Space Exploration Project

KAIST agreed to launch the Deep Space Exploration Research Consortium with two key leading aerospace research institutes, the Korea Aerospace Research Institute (KARI) and the Korea Astronomy and Space Science Institute (KASI) during a recent meeting at the KAIST campus. President Kwang Hyung Lee, KARI President Sang-Yool Lee, KASI President Young-Deuk Park, and Vice Minister of Science and ICT Hong-taek Yong attended the meeting to discuss medium- and long-term deep space exploration plans and collaborations.

The three entities have cooperated in scientific research for the last 30 years during which Korea has been developing its space exploration expertise. They signed the MoU for Cooperation for R&D and Industrialization on Deep Space Exploration’ last December. The research consortium will share and discuss research plans for space science research and exploration technology, and contribute to planning the nation’s deep space exploration.

At the meeting, KAIST reported its plans to return KITSAT-1 to Earth, Korea’s first satellite using local technology, and to explore the radiation belt (the Van Allen belt) around Earth. KAIST launched Korea’s first satellite KITSAT-1 in 1992. Meanwhile, KARI shared their plans to launch a lunar landing module using a Korean Space Launch Vehicle by 2030 and explained the current technologies and research related to a lunar landing and space exploration. Based on the payload technology it has been building on for the last 20 years, KASI emphasized the importance of research for deep space exploration in relation to the formation of the universe and the origin of mankind.

Vice Minister of Science and Technology Yong also stressed that “to enhance Korea’s capabilities for space research after launching our space launch vehicle, Nuri, in October, there must be continued efforts and preparation for higher level space research, including space exploration planning. The various experts’ opinions discussed in today’s meeting will be taken into consideration for governmental policies related to the ‘National Space Exploration Roadmap’ to be established in the latter half of this year.”

2021.06.07 View 9415

KAIST to join Deep Space Exploration Project

KAIST agreed to launch the Deep Space Exploration Research Consortium with two key leading aerospace research institutes, the Korea Aerospace Research Institute (KARI) and the Korea Astronomy and Space Science Institute (KASI) during a recent meeting at the KAIST campus. President Kwang Hyung Lee, KARI President Sang-Yool Lee, KASI President Young-Deuk Park, and Vice Minister of Science and ICT Hong-taek Yong attended the meeting to discuss medium- and long-term deep space exploration plans and collaborations.

The three entities have cooperated in scientific research for the last 30 years during which Korea has been developing its space exploration expertise. They signed the MoU for Cooperation for R&D and Industrialization on Deep Space Exploration’ last December. The research consortium will share and discuss research plans for space science research and exploration technology, and contribute to planning the nation’s deep space exploration.

At the meeting, KAIST reported its plans to return KITSAT-1 to Earth, Korea’s first satellite using local technology, and to explore the radiation belt (the Van Allen belt) around Earth. KAIST launched Korea’s first satellite KITSAT-1 in 1992. Meanwhile, KARI shared their plans to launch a lunar landing module using a Korean Space Launch Vehicle by 2030 and explained the current technologies and research related to a lunar landing and space exploration. Based on the payload technology it has been building on for the last 20 years, KASI emphasized the importance of research for deep space exploration in relation to the formation of the universe and the origin of mankind.

Vice Minister of Science and Technology Yong also stressed that “to enhance Korea’s capabilities for space research after launching our space launch vehicle, Nuri, in October, there must be continued efforts and preparation for higher level space research, including space exploration planning. The various experts’ opinions discussed in today’s meeting will be taken into consideration for governmental policies related to the ‘National Space Exploration Roadmap’ to be established in the latter half of this year.”

2021.06.07 View 9415 -

Observing Individual Atoms in 3D Nanomaterials and Their Surfaces

Atoms are the basic building blocks for all materials. To tailor functional properties, it is essential to accurately determine their atomic structures. KAIST researchers observed the 3D atomic structure of a nanoparticle at the atom level via neural network-assisted atomic electron tomography.

Using a platinum nanoparticle as a model system, a research team led by Professor Yongsoo Yang demonstrated that an atomicity-based deep learning approach can reliably identify the 3D surface atomic structure with a precision of 15 picometers (only about 1/3 of a hydrogen atom’s radius). The atomic displacement, strain, and facet analysis revealed that the surface atomic structure and strain are related to both the shape of the nanoparticle and the particle-substrate interface.

Combined with quantum mechanical calculations such as density functional theory, the ability to precisely identify surface atomic structure will serve as a powerful key for understanding catalytic performance and oxidation effect.

“We solved the problem of determining the 3D surface atomic structure of nanomaterials in a reliable manner. It has been difficult to accurately measure the surface atomic structures due to the ‘missing wedge problem’ in electron tomography, which arises from geometrical limitations, allowing only part of a full tomographic angular range to be measured. We resolved the problem using a deep learning-based approach,” explained Professor Yang.

The missing wedge problem results in elongation and ringing artifacts, negatively affecting the accuracy of the atomic structure determined from the tomogram, especially for identifying the surface structures. The missing wedge problem has been the main roadblock for the precise determination of the 3D surface atomic structures of nanomaterials.

The team used atomic electron tomography (AET), which is basically a very high-resolution CT scan for nanomaterials using transmission electron microscopes. AET allows individual atom level 3D atomic structural determination.

“The main idea behind this deep learning-based approach is atomicity—the fact that all matter is composed of atoms. This means that true atomic resolution electron tomogram should only contain sharp 3D atomic potentials convolved with the electron beam profile,” said Professor Yang.

“A deep neural network can be trained using simulated tomograms that suffer from missing wedges as inputs, and the ground truth 3D atomic volumes as targets. The trained deep learning network effectively augments the imperfect tomograms and removes the artifacts resulting from the missing wedge problem.”

The precision of 3D atomic structure can be enhanced by nearly 70% by applying the deep learning-based augmentation. The accuracy of surface atom identification was also significantly improved.

Structure-property relationships of functional nanomaterials, especially the ones that strongly depend on the surface structures, such as catalytic properties for fuel-cell applications, can now be revealed at one of the most fundamental scales: the atomic scale.

Professor Yang concluded, “We would like to fully map out the 3D atomic structure with higher precision and better elemental specificity. And not being limited to atomic structures, we aim to measure the physical, chemical, and functional properties of nanomaterials at the 3D atomic scale by further advancing electron tomography techniques.”

This research, reported at Nature Communications, was funded by the National Research Foundation of Korea and the KAIST Global Singularity Research M3I3 Project.

-Publication

Juhyeok Lee, Chaehwa Jeong & Yongsoo Yang

“Single-atom level determination of 3-dimensional surface atomic structure via neural network-assisted atomic electron tomography”

Nature Communications

-Profile

Professor Yongsoo Yang

Department of Physics

Multi-Dimensional Atomic Imaging Lab (MDAIL)

http://mdail.kaist.ac.kr

KAIST

2021.05.12 View 13539

Observing Individual Atoms in 3D Nanomaterials and Their Surfaces

Atoms are the basic building blocks for all materials. To tailor functional properties, it is essential to accurately determine their atomic structures. KAIST researchers observed the 3D atomic structure of a nanoparticle at the atom level via neural network-assisted atomic electron tomography.

Using a platinum nanoparticle as a model system, a research team led by Professor Yongsoo Yang demonstrated that an atomicity-based deep learning approach can reliably identify the 3D surface atomic structure with a precision of 15 picometers (only about 1/3 of a hydrogen atom’s radius). The atomic displacement, strain, and facet analysis revealed that the surface atomic structure and strain are related to both the shape of the nanoparticle and the particle-substrate interface.

Combined with quantum mechanical calculations such as density functional theory, the ability to precisely identify surface atomic structure will serve as a powerful key for understanding catalytic performance and oxidation effect.

“We solved the problem of determining the 3D surface atomic structure of nanomaterials in a reliable manner. It has been difficult to accurately measure the surface atomic structures due to the ‘missing wedge problem’ in electron tomography, which arises from geometrical limitations, allowing only part of a full tomographic angular range to be measured. We resolved the problem using a deep learning-based approach,” explained Professor Yang.

The missing wedge problem results in elongation and ringing artifacts, negatively affecting the accuracy of the atomic structure determined from the tomogram, especially for identifying the surface structures. The missing wedge problem has been the main roadblock for the precise determination of the 3D surface atomic structures of nanomaterials.

The team used atomic electron tomography (AET), which is basically a very high-resolution CT scan for nanomaterials using transmission electron microscopes. AET allows individual atom level 3D atomic structural determination.

“The main idea behind this deep learning-based approach is atomicity—the fact that all matter is composed of atoms. This means that true atomic resolution electron tomogram should only contain sharp 3D atomic potentials convolved with the electron beam profile,” said Professor Yang.

“A deep neural network can be trained using simulated tomograms that suffer from missing wedges as inputs, and the ground truth 3D atomic volumes as targets. The trained deep learning network effectively augments the imperfect tomograms and removes the artifacts resulting from the missing wedge problem.”

The precision of 3D atomic structure can be enhanced by nearly 70% by applying the deep learning-based augmentation. The accuracy of surface atom identification was also significantly improved.

Structure-property relationships of functional nanomaterials, especially the ones that strongly depend on the surface structures, such as catalytic properties for fuel-cell applications, can now be revealed at one of the most fundamental scales: the atomic scale.

Professor Yang concluded, “We would like to fully map out the 3D atomic structure with higher precision and better elemental specificity. And not being limited to atomic structures, we aim to measure the physical, chemical, and functional properties of nanomaterials at the 3D atomic scale by further advancing electron tomography techniques.”

This research, reported at Nature Communications, was funded by the National Research Foundation of Korea and the KAIST Global Singularity Research M3I3 Project.

-Publication

Juhyeok Lee, Chaehwa Jeong & Yongsoo Yang

“Single-atom level determination of 3-dimensional surface atomic structure via neural network-assisted atomic electron tomography”

Nature Communications

-Profile

Professor Yongsoo Yang

Department of Physics

Multi-Dimensional Atomic Imaging Lab (MDAIL)

http://mdail.kaist.ac.kr

KAIST

2021.05.12 View 13539 -

KAIST Teams Up with Yozma Group to Nurture Startups

KAIST has joined hands with Israeli venture capital investor Yozma Group to help campus-based startups grow and build success. The two signed a memorandum of understanding (MOU) on joint technology value creation initiatives at the signing ceremony that was held at KAIST’s main campus in Daejeon on April 8.

Under the MOU, Yozma Group will make investments and implement acceleration programs for startups established by KAIST professors, graduates, and students, as well as those invested in by the university.

Yozma Group already launched a $70 million fund to help grow companies in Korea and Israel. Yozma Group will use the fund as well as its global acceleration know-how and network of over 400 R&D centers across Israel to help promising KAIST startups enter overseas markets.

Moreover, Yozma Group also plans to discover and support KAIST startups that need technology from the Weizmann Institute of Science, Israel’s leading multidisciplinary basic research institution in natural and exact sciences.

KAIST is also in talks to locate Yozma Group’s branch office on the university’s campus to ensure seamless collaborations.

KAIST President Kwang Hyung Lee explained to Yozma Group’s Founder and Chairman Yigal Erlich and Head of Asia Pacific Won-Jae Lee at the MOU signing ceremony that “startup and technology commercialization are the crucial areas where KAIST will make innovations.”

“Cooperation with Yozma Group will help KAIST startups transform their ideas and technologies into real businesses and build a global presence,” he added.

Yozma Group started as Yozma Fund, created in conjunction with the Israeli government in 1993 to support the globalization of Israeli startups and to foster the growth of Israel’s venture capital industry. The Fund, which was privatized in 1998, has supported 97 Israeli tech ventures joining the Nasdaq, leading Israel to become a global innovation hub that has the third-most companies listed on the Nasdaq.

(END)

2021.04.20 View 8305

KAIST Teams Up with Yozma Group to Nurture Startups

KAIST has joined hands with Israeli venture capital investor Yozma Group to help campus-based startups grow and build success. The two signed a memorandum of understanding (MOU) on joint technology value creation initiatives at the signing ceremony that was held at KAIST’s main campus in Daejeon on April 8.

Under the MOU, Yozma Group will make investments and implement acceleration programs for startups established by KAIST professors, graduates, and students, as well as those invested in by the university.

Yozma Group already launched a $70 million fund to help grow companies in Korea and Israel. Yozma Group will use the fund as well as its global acceleration know-how and network of over 400 R&D centers across Israel to help promising KAIST startups enter overseas markets.

Moreover, Yozma Group also plans to discover and support KAIST startups that need technology from the Weizmann Institute of Science, Israel’s leading multidisciplinary basic research institution in natural and exact sciences.

KAIST is also in talks to locate Yozma Group’s branch office on the university’s campus to ensure seamless collaborations.

KAIST President Kwang Hyung Lee explained to Yozma Group’s Founder and Chairman Yigal Erlich and Head of Asia Pacific Won-Jae Lee at the MOU signing ceremony that “startup and technology commercialization are the crucial areas where KAIST will make innovations.”

“Cooperation with Yozma Group will help KAIST startups transform their ideas and technologies into real businesses and build a global presence,” he added.

Yozma Group started as Yozma Fund, created in conjunction with the Israeli government in 1993 to support the globalization of Israeli startups and to foster the growth of Israel’s venture capital industry. The Fund, which was privatized in 1998, has supported 97 Israeli tech ventures joining the Nasdaq, leading Israel to become a global innovation hub that has the third-most companies listed on the Nasdaq.

(END)

2021.04.20 View 8305 -

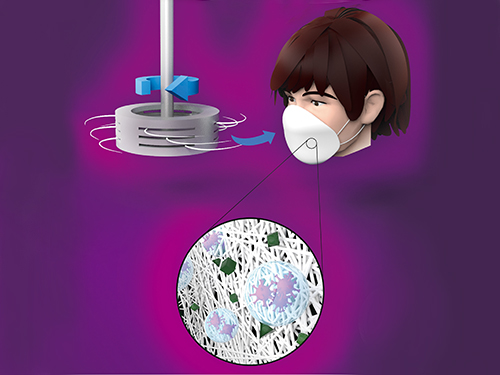

Centrifugal Multispun Nanofibers Put a New Spin on COVID-19 Masks

KAIST researchers have developed a novel nanofiber production technique called ‘centrifugal multispinning’ that will open the door for the safe and cost-effective mass production of high-performance polymer nanofibers. This new technique, which has shown up to a 300 times higher nanofiber production rate per hour than that of the conventional electrospinning method, has many potential applications including the development of face mask filters for coronavirus protection.

Nanofibers make good face mask filters because their mechanical interactions with aerosol particles give them a greater ability to capture more than 90% of harmful particles such as fine dust and virus-containing droplets.

The impact of the COVID-19 pandemic has further accelerated the growing demand in recent years for a better kind of face mask. A polymer nanofiber-based mask filter that can more effectively block harmful particles has also been in higher demand as the pandemic continues.

‘Electrospinning’ has been a common process used to prepare fine and uniform polymer nanofibers, but in terms of safety, cost-effectiveness, and mass production, it has several drawbacks. The electrospinning method requires a high-voltage electric field and electrically conductive target, and this hinders the safe and cost-effective mass production of polymer nanofibers.

In response to this shortcoming, ‘centrifugal spinning’ that utilizes centrifugal force instead of high voltage to produce polymer nanofibers has been suggested as a safer and more cost-effective alternative to the electrospinning. Easy scalability is another advantage, as this technology only requires a rotating spinneret and a collector.

However, since the existing centrifugal force-based spinning technology employs only a single rotating spinneret, productivity is limited and not much higher than that of some advanced electrospinning technologies such as ‘multi-nozzle electrospinning’ and ‘nozzleless electrospinning.’ This problem persists even when the size of the spinneret is increased.

Inspired by these limitations, a research team led by Professor Do Hyun Kim from the Department of Chemical and Biomolecular Engineering at KAIST developed a centrifugal multispinning spinneret with mass-producibility, by sectioning a rotating spinneret into three sub-disks. This study was published as a front cover article of ACS Macro Letters, Volume 10, Issue 3 in March 2021.

Using this new centrifugal multispinning spinneret with three sub-disks, the lead author of the paper PhD candidate Byeong Eun Kwak and his fellow researchers Hyo Jeong Yoo and Eungjun Lee demonstrated the gram-scale production of various polymer nanofibers with a maximum production rate of up to 25 grams per hour, which is approximately 300 times higher than that of the conventional electrospinning system. The production rate of up to 25 grams of polymer nanofibers per hour corresponds to the production rate of about 30 face mask filters per day in a lab-scale manufacturing system.

By integrating the mass-produced polymer nanofibers into the form of a mask filter, the researchers were able to fabricate face masks that have comparable filtration performance with the KF80 and KF94 face masks that are currently available in the Korean market. The KF80 and KF94 masks have been approved by the Ministry of Food and Drug Safety of Korea to filter out at least 80% and 94% of harmful particles respectively.

“When our system is scaled up from the lab scale to an industrial scale, the large-scale production of centrifugal multispun polymer nanofibers will be made possible, and the cost of polymer nanofiber-based face mask filters will also be lowered dramatically,” Kwak explained.

This work was supported by the KAIST-funded Global Singularity Research Program for 2020.

Publication:

Byeong Eun Kwak, Hyo Jeong Yoo, Eungjun Lee, and Do Hyun Kim. (2021) Large-Scale Centrifugal Multispinning Production of Polymer Micro- and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers. ACS Macro Letters, Volume No. 10, Issue No. 3, pp. 382-388. Available online at https://doi.org/10.1021/acsmacrolett.0c00829

Profile:

Do Hyun Kim, Sc.D.

Professor

dohyun.kim@kaist.edu

http://procal.kaist.ac.kr/

Process Analysis Laboratory

Department of Chemical and Biomolecular Engineering

https:/kaist.ac.kr/en/

Korea Advanced Institute of Science and Technology (KAIST)Daejeon 34141, Korea

(END)

2021.04.12 View 13836

Centrifugal Multispun Nanofibers Put a New Spin on COVID-19 Masks

KAIST researchers have developed a novel nanofiber production technique called ‘centrifugal multispinning’ that will open the door for the safe and cost-effective mass production of high-performance polymer nanofibers. This new technique, which has shown up to a 300 times higher nanofiber production rate per hour than that of the conventional electrospinning method, has many potential applications including the development of face mask filters for coronavirus protection.

Nanofibers make good face mask filters because their mechanical interactions with aerosol particles give them a greater ability to capture more than 90% of harmful particles such as fine dust and virus-containing droplets.

The impact of the COVID-19 pandemic has further accelerated the growing demand in recent years for a better kind of face mask. A polymer nanofiber-based mask filter that can more effectively block harmful particles has also been in higher demand as the pandemic continues.

‘Electrospinning’ has been a common process used to prepare fine and uniform polymer nanofibers, but in terms of safety, cost-effectiveness, and mass production, it has several drawbacks. The electrospinning method requires a high-voltage electric field and electrically conductive target, and this hinders the safe and cost-effective mass production of polymer nanofibers.

In response to this shortcoming, ‘centrifugal spinning’ that utilizes centrifugal force instead of high voltage to produce polymer nanofibers has been suggested as a safer and more cost-effective alternative to the electrospinning. Easy scalability is another advantage, as this technology only requires a rotating spinneret and a collector.

However, since the existing centrifugal force-based spinning technology employs only a single rotating spinneret, productivity is limited and not much higher than that of some advanced electrospinning technologies such as ‘multi-nozzle electrospinning’ and ‘nozzleless electrospinning.’ This problem persists even when the size of the spinneret is increased.

Inspired by these limitations, a research team led by Professor Do Hyun Kim from the Department of Chemical and Biomolecular Engineering at KAIST developed a centrifugal multispinning spinneret with mass-producibility, by sectioning a rotating spinneret into three sub-disks. This study was published as a front cover article of ACS Macro Letters, Volume 10, Issue 3 in March 2021.

Using this new centrifugal multispinning spinneret with three sub-disks, the lead author of the paper PhD candidate Byeong Eun Kwak and his fellow researchers Hyo Jeong Yoo and Eungjun Lee demonstrated the gram-scale production of various polymer nanofibers with a maximum production rate of up to 25 grams per hour, which is approximately 300 times higher than that of the conventional electrospinning system. The production rate of up to 25 grams of polymer nanofibers per hour corresponds to the production rate of about 30 face mask filters per day in a lab-scale manufacturing system.

By integrating the mass-produced polymer nanofibers into the form of a mask filter, the researchers were able to fabricate face masks that have comparable filtration performance with the KF80 and KF94 face masks that are currently available in the Korean market. The KF80 and KF94 masks have been approved by the Ministry of Food and Drug Safety of Korea to filter out at least 80% and 94% of harmful particles respectively.

“When our system is scaled up from the lab scale to an industrial scale, the large-scale production of centrifugal multispun polymer nanofibers will be made possible, and the cost of polymer nanofiber-based face mask filters will also be lowered dramatically,” Kwak explained.

This work was supported by the KAIST-funded Global Singularity Research Program for 2020.

Publication:

Byeong Eun Kwak, Hyo Jeong Yoo, Eungjun Lee, and Do Hyun Kim. (2021) Large-Scale Centrifugal Multispinning Production of Polymer Micro- and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers. ACS Macro Letters, Volume No. 10, Issue No. 3, pp. 382-388. Available online at https://doi.org/10.1021/acsmacrolett.0c00829

Profile:

Do Hyun Kim, Sc.D.

Professor

dohyun.kim@kaist.edu

http://procal.kaist.ac.kr/

Process Analysis Laboratory

Department of Chemical and Biomolecular Engineering

https:/kaist.ac.kr/en/

Korea Advanced Institute of Science and Technology (KAIST)Daejeon 34141, Korea

(END)

2021.04.12 View 13836 -

Streamlining the Process of Materials Discovery

The materials platform M3I3 reduces the time for materials discovery by reverse engineering future materials using multiscale/multimodal imaging and machine learning of the processing-structure-properties relationship

Developing new materials and novel processes has continued to change the world. The M3I3 Initiative at KAIST has led to new insights into advancing materials development by implementing breakthroughs in materials imaging that have created a paradigm shift in the discovery of materials. The Initiative features the multiscale modeling and imaging of structure and property relationships and materials hierarchies combined with the latest material-processing data.

The research team led by Professor Seungbum Hong analyzed the materials research projects reported by leading global institutes and research groups, and derived a quantitative model using machine learning with a scientific interpretation. This process embodies the research goal of the M3I3: Materials and Molecular Modeling, Imaging, Informatics and Integration.

The researchers discussed the role of multiscale materials and molecular imaging combined with machine learning and also presented a future outlook for developments and the major challenges of M3I3. By building this model, the research team envisions creating desired sets of properties for materials and obtaining the optimum processing recipes to synthesize them.

“The development of various microscopy and diffraction tools with the ability to map the structure, property, and performance of materials at multiscale levels and in real time enabled us to think that materials imaging could radically accelerate materials discovery and development,” says Professor Hong.

“We plan to build an M3I3 repository of searchable structural and property maps using FAIR (Findable, Accessible, Interoperable, and Reusable) principles to standardize best practices as well as streamline the training of early career researchers.”

One of the examples that shows the power of structure-property imaging at the nanoscale is the development of future materials for emerging nonvolatile memory devices. Specifically, the research team focused on microscopy using photons, electrons, and physical probes on the multiscale structural hierarchy, as well as structure-property relationships to enhance the performance of memory devices.

“M3I3 is an algorithm for performing the reverse engineering of future materials. Reverse engineering starts by analyzing the structure and composition of cutting-edge materials or products. Once the research team determines the performance of our targeted future materials, we need to know the candidate structures and compositions for producing the future materials.”

The research team has built a data-driven experimental design based on traditional NCM (nickel, cobalt, and manganese) cathode materials. With this, the research team expanded their future direction for achieving even higher discharge capacity, which can be realized via Li-rich cathodes.

However, one of the major challenges was the limitation of available data that describes the Li-rich cathode properties. To mitigate this problem, the researchers proposed two solutions: First, they should build a machine-learning-guided data generator for data augmentation. Second, they would use a machine-learning method based on ‘transfer learning.’ Since the NCM cathode database shares a common feature with a Li-rich cathode, one could consider repurposing the NCM trained model for assisting the Li-rich prediction. With the pretrained model and transfer learning, the team expects to achieve outstanding predictions for Li-rich cathodes even with the small data set.

With advances in experimental imaging and the availability of well-resolved information and big data, along with significant advances in high-performance computing and a worldwide thrust toward a general, collaborative, integrative, and on-demand research platform, there is a clear confluence in the required capabilities of advancing the M3I3 Initiative.

Professor Hong said, “Once we succeed in using the inverse “property−structure−processing” solver to develop cathode, anode, electrolyte, and membrane materials for high energy density Li-ion batteries, we will expand our scope of materials to battery/fuel cells, aerospace, automobiles, food, medicine, and cosmetic materials.”

The review was published in ACS Nano in March. This study was conducted through collaborations with Dr. Chi Hao Liow, Professor Jong Min Yuk, Professor Hye Ryung Byon, Professor Yongsoo Yang, Professor EunAe Cho, Professor Pyuck-Pa Choi, and Professor Hyuck Mo Lee at KAIST, Professor Joshua C. Agar at Lehigh University, Dr. Sergei V. Kalinin at Oak Ridge National Laboratory, Professor Peter W. Voorhees at Northwestern University, and Professor Peter Littlewood at the University of Chicago (Article title: Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics, and Integration).This work was supported by the KAIST Global Singularity Research Program for 2019 and 2020.

Publication:

“Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics and Integration,” S. Hong, C. H. Liow, J. M. Yuk, H. R. Byon, Y. Yang, E. Cho, J. Yeom, G. Park, H. Kang, S. Kim, Y. Shim, M. Na, C. Jeong, G. Hwang, H. Kim, H. Kim, S. Eom, S. Cho, H. Jun, Y. Lee, A. Baucour, K. Bang, M. Kim, S. Yun, J. Ryu, Y. Han, A. Jetybayeva, P.-P. Choi, J. C. Agar, S. V. Kalinin, P. W. Voorhees, P. Littlewood, and H. M. Lee, ACS Nano 15, 3, 3971–3995 (2021) https://doi.org/10.1021/acsnano.1c00211

Profile:

Seungbum Hong, PhD

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr

Department of Materials Science and Engineering

KAIST

(END)

2021.04.05 View 14957

Streamlining the Process of Materials Discovery

The materials platform M3I3 reduces the time for materials discovery by reverse engineering future materials using multiscale/multimodal imaging and machine learning of the processing-structure-properties relationship

Developing new materials and novel processes has continued to change the world. The M3I3 Initiative at KAIST has led to new insights into advancing materials development by implementing breakthroughs in materials imaging that have created a paradigm shift in the discovery of materials. The Initiative features the multiscale modeling and imaging of structure and property relationships and materials hierarchies combined with the latest material-processing data.

The research team led by Professor Seungbum Hong analyzed the materials research projects reported by leading global institutes and research groups, and derived a quantitative model using machine learning with a scientific interpretation. This process embodies the research goal of the M3I3: Materials and Molecular Modeling, Imaging, Informatics and Integration.

The researchers discussed the role of multiscale materials and molecular imaging combined with machine learning and also presented a future outlook for developments and the major challenges of M3I3. By building this model, the research team envisions creating desired sets of properties for materials and obtaining the optimum processing recipes to synthesize them.

“The development of various microscopy and diffraction tools with the ability to map the structure, property, and performance of materials at multiscale levels and in real time enabled us to think that materials imaging could radically accelerate materials discovery and development,” says Professor Hong.

“We plan to build an M3I3 repository of searchable structural and property maps using FAIR (Findable, Accessible, Interoperable, and Reusable) principles to standardize best practices as well as streamline the training of early career researchers.”

One of the examples that shows the power of structure-property imaging at the nanoscale is the development of future materials for emerging nonvolatile memory devices. Specifically, the research team focused on microscopy using photons, electrons, and physical probes on the multiscale structural hierarchy, as well as structure-property relationships to enhance the performance of memory devices.

“M3I3 is an algorithm for performing the reverse engineering of future materials. Reverse engineering starts by analyzing the structure and composition of cutting-edge materials or products. Once the research team determines the performance of our targeted future materials, we need to know the candidate structures and compositions for producing the future materials.”

The research team has built a data-driven experimental design based on traditional NCM (nickel, cobalt, and manganese) cathode materials. With this, the research team expanded their future direction for achieving even higher discharge capacity, which can be realized via Li-rich cathodes.

However, one of the major challenges was the limitation of available data that describes the Li-rich cathode properties. To mitigate this problem, the researchers proposed two solutions: First, they should build a machine-learning-guided data generator for data augmentation. Second, they would use a machine-learning method based on ‘transfer learning.’ Since the NCM cathode database shares a common feature with a Li-rich cathode, one could consider repurposing the NCM trained model for assisting the Li-rich prediction. With the pretrained model and transfer learning, the team expects to achieve outstanding predictions for Li-rich cathodes even with the small data set.

With advances in experimental imaging and the availability of well-resolved information and big data, along with significant advances in high-performance computing and a worldwide thrust toward a general, collaborative, integrative, and on-demand research platform, there is a clear confluence in the required capabilities of advancing the M3I3 Initiative.

Professor Hong said, “Once we succeed in using the inverse “property−structure−processing” solver to develop cathode, anode, electrolyte, and membrane materials for high energy density Li-ion batteries, we will expand our scope of materials to battery/fuel cells, aerospace, automobiles, food, medicine, and cosmetic materials.”

The review was published in ACS Nano in March. This study was conducted through collaborations with Dr. Chi Hao Liow, Professor Jong Min Yuk, Professor Hye Ryung Byon, Professor Yongsoo Yang, Professor EunAe Cho, Professor Pyuck-Pa Choi, and Professor Hyuck Mo Lee at KAIST, Professor Joshua C. Agar at Lehigh University, Dr. Sergei V. Kalinin at Oak Ridge National Laboratory, Professor Peter W. Voorhees at Northwestern University, and Professor Peter Littlewood at the University of Chicago (Article title: Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics, and Integration).This work was supported by the KAIST Global Singularity Research Program for 2019 and 2020.

Publication:

“Reducing Time to Discovery: Materials and Molecular Modeling, Imaging, Informatics and Integration,” S. Hong, C. H. Liow, J. M. Yuk, H. R. Byon, Y. Yang, E. Cho, J. Yeom, G. Park, H. Kang, S. Kim, Y. Shim, M. Na, C. Jeong, G. Hwang, H. Kim, H. Kim, S. Eom, S. Cho, H. Jun, Y. Lee, A. Baucour, K. Bang, M. Kim, S. Yun, J. Ryu, Y. Han, A. Jetybayeva, P.-P. Choi, J. C. Agar, S. V. Kalinin, P. W. Voorhees, P. Littlewood, and H. M. Lee, ACS Nano 15, 3, 3971–3995 (2021) https://doi.org/10.1021/acsnano.1c00211

Profile:

Seungbum Hong, PhD

Associate Professor

seungbum@kaist.ac.kr

http://mii.kaist.ac.kr

Department of Materials Science and Engineering

KAIST

(END)

2021.04.05 View 14957 -

Professor Jihee Kim Wins the Lucas Prize for Her Income Inequality Theory

Professor Jihee Kim from the School of Business and Technology Management at KAIST was announced as one of two winners of the 2021 Robert E. Lucas Jr. Prize. Professor Kim was recognized for having provided an empirical analysis on engines of income growth, sources of income inequality, and their rich interplay in her paper published in the Journal of Political Economy (JPE) in October 2018. The co-author of this study, Professor Charles I. Jones at Stanford University, was honored to be another awardee of this year’s Lucas Prize.

The Robert E. Lucas Jr. Prize, simply known as the Lucas Prize, is awarded biannually for the most interesting paper in the area of Dynamic Economics published in the leading economics journal JPE in the preceding two years. The prize was established in 2016 in celebration of the 1995 Nobel Prize in Economics Laureate Dr. Lucas’s seminal contributions to economics. The two former prizes were presented in 2019 and 2017 respectively.

Professor Kim and Professor Jones, in their award-winning paper titled 'A Schumpeterian Model of Top Income Inequality', observed that top income inequality was relatively low and stable between 1960 and 1980, but then rose sharply in some countries, including the United States and the United Kingdom.

The authors focused on entrepreneurial activities and the resulting income as the driving force of income inequality. They assumed that the forces that increased the efforts of fast-growing entrepreneurs to improve their products or increased productivity of their efforts could increase income inequality. On the other hand, the forces that enhanced creative destruction or that raised the rate at which high-growth entrepreneurs lost that status could decrease income inequality, according to the authors’ theory.

Professor Kim explained, “Various economic forces due to globalization, the advancement in AI and IT technologies, taxes, and policies related to innovation blocking may explain the varied patterns in income inequality.”

“Through follow-up research, I will continue developing economic theory models that can analyze the impact of changes such as income tax rates and salary negotiations on income inequality,” she added.

Professor Kim received her bachelor’s degree from the KAIST School of Computing in 2005 and pursued her graduates studies at Stanford University, acquiring a master’s degree in economics in 2011 and a doctoral degree in management science and engineering in 2013.

(END)

2021.03.26 View 8968

Professor Jihee Kim Wins the Lucas Prize for Her Income Inequality Theory

Professor Jihee Kim from the School of Business and Technology Management at KAIST was announced as one of two winners of the 2021 Robert E. Lucas Jr. Prize. Professor Kim was recognized for having provided an empirical analysis on engines of income growth, sources of income inequality, and their rich interplay in her paper published in the Journal of Political Economy (JPE) in October 2018. The co-author of this study, Professor Charles I. Jones at Stanford University, was honored to be another awardee of this year’s Lucas Prize.

The Robert E. Lucas Jr. Prize, simply known as the Lucas Prize, is awarded biannually for the most interesting paper in the area of Dynamic Economics published in the leading economics journal JPE in the preceding two years. The prize was established in 2016 in celebration of the 1995 Nobel Prize in Economics Laureate Dr. Lucas’s seminal contributions to economics. The two former prizes were presented in 2019 and 2017 respectively.

Professor Kim and Professor Jones, in their award-winning paper titled 'A Schumpeterian Model of Top Income Inequality', observed that top income inequality was relatively low and stable between 1960 and 1980, but then rose sharply in some countries, including the United States and the United Kingdom.

The authors focused on entrepreneurial activities and the resulting income as the driving force of income inequality. They assumed that the forces that increased the efforts of fast-growing entrepreneurs to improve their products or increased productivity of their efforts could increase income inequality. On the other hand, the forces that enhanced creative destruction or that raised the rate at which high-growth entrepreneurs lost that status could decrease income inequality, according to the authors’ theory.

Professor Kim explained, “Various economic forces due to globalization, the advancement in AI and IT technologies, taxes, and policies related to innovation blocking may explain the varied patterns in income inequality.”

“Through follow-up research, I will continue developing economic theory models that can analyze the impact of changes such as income tax rates and salary negotiations on income inequality,” she added.

Professor Kim received her bachelor’s degree from the KAIST School of Computing in 2005 and pursued her graduates studies at Stanford University, acquiring a master’s degree in economics in 2011 and a doctoral degree in management science and engineering in 2013.

(END)

2021.03.26 View 8968 -

Acoustic Graphene Plasmons Study Paves Way for Optoelectronic Applications

- The first images of mid-infrared optical waves compressed 1,000 times captured using a highly sensitive scattering-type scanning near-field optical microscope. -

KAIST researchers and their collaborators at home and abroad have successfully demonstrated a new methodology for direct near-field optical imaging of acoustic graphene plasmon fields. This strategy will provide a breakthrough for the practical applications of acoustic graphene plasmon platforms in next-generation, high-performance, graphene-based optoelectronic devices with enhanced light-matter interactions and lower propagation loss.

It was recently demonstrated that ‘graphene plasmons’ – collective oscillations of free electrons in graphene coupled to electromagnetic waves of light – can be used to trap and compress optical waves inside a very thin dielectric layer separating graphene from a metallic sheet. In such a configuration, graphene’s conduction electrons are “reflected” in the metal, so when the light waves “push” the electrons in graphene, their image charges in metal also start to oscillate. This new type of collective electronic oscillation mode is called ‘acoustic graphene plasmon (AGP)’.

The existence of AGP could previously be observed only via indirect methods such as far-field infrared spectroscopy and photocurrent mapping. This indirect observation was the price that researchers had to pay for the strong compression of optical waves inside nanometer-thin structures. It was believed that the intensity of electromagnetic fields outside the device was insufficient for direct near-field optical imaging of AGP.

Challenged by these limitations, three research groups combined their efforts to bring together a unique experimental technique using advanced nanofabrication methods. Their findings were published in Nature Communications on February 19.

A KAIST research team led by Professor Min Seok Jang from the School of Electrical Engineering used a highly sensitive scattering-type scanning near-field optical microscope (s-SNOM) to directly measure the optical fields of the AGP waves propagating in a nanometer-thin waveguide, visualizing thousand-fold compression of mid-infrared light for the first time.

Professor Jang and a post-doc researcher in his group, Sergey G. Menabde, successfully obtained direct images of AGP waves by taking advantage of their rapidly decaying yet always present electric field above graphene. They showed that AGPs are detectable even when most of their energy is flowing inside the dielectric below the graphene.

This became possible due to the ultra-smooth surfaces inside the nano-waveguides where plasmonic waves can propagate at longer distances. The AGP mode probed by the researchers was up to 2.3 times more confined and exhibited a 1.4 times higher figure of merit in terms of the normalized propagation length compared to the graphene surface plasmon under similar conditions.

These ultra-smooth nanostructures of the waveguides used in the experiment were created using a template-stripping method by Professor Sang-Hyun Oh and a post-doc researcher, In-Ho Lee, from the Department of Electrical and Computer Engineering at the University of Minnesota.

Professor Young Hee Lee and his researchers at the Center for Integrated Nanostructure Physics (CINAP) of the Institute of Basic Science (IBS) at Sungkyunkwan University synthesized the graphene with a monocrystalline structure, and this high-quality, large-area graphene enabled low-loss plasmonic propagation.

The chemical and physical properties of many important organic molecules can be detected and evaluated by their absorption signatures in the mid-infrared spectrum. However, conventional detection methods require a large number of molecules for successful detection, whereas the ultra-compressed AGP fields can provide strong light-matter interactions at the microscopic level, thus significantly improving the detection sensitivity down to a single molecule.

Furthermore, the study conducted by Professor Jang and the team demonstrated that the mid-infrared AGPs are inherently less sensitive to losses in graphene due to their fields being mostly confined within the dielectric. The research team’s reported results suggest that AGPs could become a promising platform for electrically tunable graphene-based optoelectronic devices that typically suffer from higher absorption rates in graphene such as metasurfaces, optical switches, photovoltaics, and other optoelectronic applications operating at infrared frequencies.

Professor Jang said, “Our research revealed that the ultra-compressed electromagnetic fields of acoustic graphene plasmons can be directly accessed through near-field optical microscopy methods. I hope this realization will motivate other researchers to apply AGPs to various problems where strong light-matter interactions and lower propagation loss are needed.”

This research was primarily funded by the Samsung Research Funding & Incubation Center of Samsung Electronics. The National Research Foundation of Korea (NRF), the U.S. National Science Foundation (NSF), Samsung Global Research Outreach (GRO) Program, and Institute for Basic Science of Korea (IBS) also supported the work.

Publication:

Menabde, S. G., et al. (2021) Real-space imaging of acoustic plasmons in large-area graphene grown by chemical vapor deposition. Nature Communications 12, Article No. 938. Available online at https://doi.org/10.1038/s41467-021-21193-5

Profile:

Min Seok Jang, MS, PhD

Associate Professorjang.minseok@kaist.ac.krhttp://jlab.kaist.ac.kr/

Min Seok Jang Research GroupSchool of Electrical Engineering

http://kaist.ac.kr/en/Korea Advanced Institute of Science and Technology (KAIST)Daejeon, Republic of Korea

(END)

2021.03.16 View 15814

Acoustic Graphene Plasmons Study Paves Way for Optoelectronic Applications

- The first images of mid-infrared optical waves compressed 1,000 times captured using a highly sensitive scattering-type scanning near-field optical microscope. -

KAIST researchers and their collaborators at home and abroad have successfully demonstrated a new methodology for direct near-field optical imaging of acoustic graphene plasmon fields. This strategy will provide a breakthrough for the practical applications of acoustic graphene plasmon platforms in next-generation, high-performance, graphene-based optoelectronic devices with enhanced light-matter interactions and lower propagation loss.

It was recently demonstrated that ‘graphene plasmons’ – collective oscillations of free electrons in graphene coupled to electromagnetic waves of light – can be used to trap and compress optical waves inside a very thin dielectric layer separating graphene from a metallic sheet. In such a configuration, graphene’s conduction electrons are “reflected” in the metal, so when the light waves “push” the electrons in graphene, their image charges in metal also start to oscillate. This new type of collective electronic oscillation mode is called ‘acoustic graphene plasmon (AGP)’.

The existence of AGP could previously be observed only via indirect methods such as far-field infrared spectroscopy and photocurrent mapping. This indirect observation was the price that researchers had to pay for the strong compression of optical waves inside nanometer-thin structures. It was believed that the intensity of electromagnetic fields outside the device was insufficient for direct near-field optical imaging of AGP.

Challenged by these limitations, three research groups combined their efforts to bring together a unique experimental technique using advanced nanofabrication methods. Their findings were published in Nature Communications on February 19.

A KAIST research team led by Professor Min Seok Jang from the School of Electrical Engineering used a highly sensitive scattering-type scanning near-field optical microscope (s-SNOM) to directly measure the optical fields of the AGP waves propagating in a nanometer-thin waveguide, visualizing thousand-fold compression of mid-infrared light for the first time.

Professor Jang and a post-doc researcher in his group, Sergey G. Menabde, successfully obtained direct images of AGP waves by taking advantage of their rapidly decaying yet always present electric field above graphene. They showed that AGPs are detectable even when most of their energy is flowing inside the dielectric below the graphene.

This became possible due to the ultra-smooth surfaces inside the nano-waveguides where plasmonic waves can propagate at longer distances. The AGP mode probed by the researchers was up to 2.3 times more confined and exhibited a 1.4 times higher figure of merit in terms of the normalized propagation length compared to the graphene surface plasmon under similar conditions.

These ultra-smooth nanostructures of the waveguides used in the experiment were created using a template-stripping method by Professor Sang-Hyun Oh and a post-doc researcher, In-Ho Lee, from the Department of Electrical and Computer Engineering at the University of Minnesota.

Professor Young Hee Lee and his researchers at the Center for Integrated Nanostructure Physics (CINAP) of the Institute of Basic Science (IBS) at Sungkyunkwan University synthesized the graphene with a monocrystalline structure, and this high-quality, large-area graphene enabled low-loss plasmonic propagation.

The chemical and physical properties of many important organic molecules can be detected and evaluated by their absorption signatures in the mid-infrared spectrum. However, conventional detection methods require a large number of molecules for successful detection, whereas the ultra-compressed AGP fields can provide strong light-matter interactions at the microscopic level, thus significantly improving the detection sensitivity down to a single molecule.

Furthermore, the study conducted by Professor Jang and the team demonstrated that the mid-infrared AGPs are inherently less sensitive to losses in graphene due to their fields being mostly confined within the dielectric. The research team’s reported results suggest that AGPs could become a promising platform for electrically tunable graphene-based optoelectronic devices that typically suffer from higher absorption rates in graphene such as metasurfaces, optical switches, photovoltaics, and other optoelectronic applications operating at infrared frequencies.

Professor Jang said, “Our research revealed that the ultra-compressed electromagnetic fields of acoustic graphene plasmons can be directly accessed through near-field optical microscopy methods. I hope this realization will motivate other researchers to apply AGPs to various problems where strong light-matter interactions and lower propagation loss are needed.”

This research was primarily funded by the Samsung Research Funding & Incubation Center of Samsung Electronics. The National Research Foundation of Korea (NRF), the U.S. National Science Foundation (NSF), Samsung Global Research Outreach (GRO) Program, and Institute for Basic Science of Korea (IBS) also supported the work.

Publication:

Menabde, S. G., et al. (2021) Real-space imaging of acoustic plasmons in large-area graphene grown by chemical vapor deposition. Nature Communications 12, Article No. 938. Available online at https://doi.org/10.1038/s41467-021-21193-5

Profile:

Min Seok Jang, MS, PhD

Associate Professorjang.minseok@kaist.ac.krhttp://jlab.kaist.ac.kr/

Min Seok Jang Research GroupSchool of Electrical Engineering

http://kaist.ac.kr/en/Korea Advanced Institute of Science and Technology (KAIST)Daejeon, Republic of Korea

(END)

2021.03.16 View 15814 -

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.

The issue also emphasized the need for KAIST to enhance global cooperation and the exchange of ideas in the years to come, especially during the post-COVID era intertwined with the Fourth Industrial Revolution (4IR). In this regard, the issue cited the first ‘KAIST Emerging Materials e-Symposium (EMS)’, which was held online for five days in September of last year with a global audience of over 10,000 participating live via Zoom and YouTube, as a successful example of what academic collaboration could look like in the post-COVID and 4IR eras.

In addition, the “Science & Technology New Deal Project for COVID-19 Response,” a project conducted by KAIST with support from the Ministry of Science and ICT (MSIT) of South Korea, was also introduced as another excellent case of KAIST’s collective intelligence and technological innovation. The issue highlighted some key achievements from this project for overcoming the pandemic-driven crisis, such as: reusable anti-virus filters, negative-pressure ambulances for integrated patient transport and hospitalization, and movable and expandable negative-pressure ward modules.

“We hold our expectations high for the outstanding achievements and progress KAIST will have made by its centennial,” said Professor Kim on the background of curating the 14 review articles contributed by KAIST faculty from the fields of Materials Science and Engineering (MSE), Chemical and Biomolecular Engineering (CBE), Nuclear and Quantum Engineering (NQE), Electrical Engineering (EE), and Chemistry (Chem).

Review articles discussing emerging materials and their properties covered photonic carbon dots (Professor Chan Beum Park, MSE), single-atom and ensemble catalysts (Professor Hyunjoo Lee, CBE), and metal/metal oxide electrocatalysts (Professor Sung-Yoon Chung, MSE).

Review articles discussing materials processing covered 2D layered materials synthesis based on interlayer engineering (Professor Kibum Kang, MSE), eco-friendly methods for solar cell production (Professor Bumjoon J. Kim, CBE), an ex-solution process for the synthesis of highly stable catalysts (Professor WooChul Jung, MSE), and 3D light-patterning synthesis of ordered nanostructures (Professor Seokwoo Jeon, MSE, and Professor Dongchan Jang, NQE).

Review articles discussing advanced analysis techniques covered operando materials analyses (Professor Jeong Yeong Park, Chem), graphene liquid cell transmission electron microscopy (Professor Jong Min Yuk, MSE), and multiscale modeling and visualization of materials systems (Professor Seungbum Hong, MSE).

Review articles discussing practical state-of-the-art devices covered chemiresistive hydrogen sensors (Professor Il-Doo Kim, MSE), patient-friendly diagnostics and implantable treatment devices (Professor Steve Park, MSE), triboelectric nanogenerators (Professor Yang-Kyu Choi, EE), and next-generation lithium-air batteries (Professor Hye Ryung Byon, Chem, and Professor Il-Doo Kim, MSE).

In addition to Professor Il-Doo Kim, post-doctoral researcher Dr. Jaewan Ahn from the KAIST Applied Science Research Institute, Dean of the College of Engineering at KAIST Professor Choongsik Bae, and ACS Nano Editor-in-Chief Professor Paul S. Weiss from the University of California, Los Angeles also contributed to the publication of this ACS Nano special virtual issue.

The issue can be viewed and downloaded from the ACS Nano website at https://doi.org/10.1021/acsnano.1c01101.

Image credit: KAIST

Image usage restrictions: News organizations may use or redistribute this image,with proper attribution, as part of news coverage of this paper only.

Publication:

Ahn, J., et al. (2021) Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues. ACS Nano 15(3): 1895-1907. Available online at https://doi.org/10.1021/acsnano.1c01101

Profile:

Il-Doo Kim, Ph.D

Chair Professor

idkim@kaist.ac.kr

http://advnano.kaist.ac.kr

Advanced Nanomaterials and Energy Lab.

Department of Materials Science and Engineering

Membrane Innovation Center for Anti-Virus and Air-Quality Control

https://kaist.ac.kr/

Korea Advanced Institute of Science and Technology (KAIST) Daejeon, Republic of Korea

(END)

2021.03.05 View 33687

ACS Nano Special Edition Highlights Innovations at KAIST

- The collective intelligence and technological innovation of KAIST was highlighted with case studies including the Post-COVID-19 New Deal R&D Initiative Project. -

KAIST’s innovative academic achievements and R&D efforts for addressing the world’s greatest challenges such as the COVID-19 pandemic were featured in ACS Nano as part of its special virtual issue commemorating the 50th anniversary of KAIST. The issue consisted of 14 review articles contributed by KAIST faculty from five departments, including two from Professor Il-Doo Kim from the Department of Materials Science and Engineering, who serves as an associate editor of the ACS Nano.

ACS Nano, the leading international journal in nanoscience and nanotechnology, published a special virtual issue last month, titled ‘Celebrating 50 Years of KAIST: Collective Intelligence and Innovation for Confronting Contemporary Issues.’

This special virtual issue introduced KAIST’s vision of becoming a ‘global value-creative leading university’ and its progress toward this vision over the last 50 years. The issue explained how KAIST has served as the main hub for advanced scientific research and technological innovation in South Korea since its establishment in 1971, and how its faculty and over 69,000 graduates played a key role in propelling the nation’s rapid industrialization and economic development.