AR

-

Professor Jong Chul Ye Appointed as Distinguished Lecturer of IEEE EMBS

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was appointed as a distinguished lecturer by the International Association of Electrical and Electronic Engineers (IEEE) Engineering in Medicine and Biology Society (EMBS). Professor Ye was invited to deliver a lecture on his leading research on artificial intelligence (AI) technology in medical video restoration. He will serve a term of two years beginning in 2020.

IEEE EMBS's distinguished lecturer program is designed to educate researchers around the world on the latest trends and technology in biomedical engineering. Sponsored by IEEE, its members can attend lectures on the distinguished professor's research subject.

Professor Ye said, "We are at a time where the importance of AI in medical imaging is increasing.” He added, “I am proud to be appointed as a distinguished lecturer of the IEEE EMBS in recognition of my contributions to this field.”

(END)

2020.02.27 View 14174

Professor Jong Chul Ye Appointed as Distinguished Lecturer of IEEE EMBS

Professor Jong Chul Ye from the Department of Bio and Brain Engineering was appointed as a distinguished lecturer by the International Association of Electrical and Electronic Engineers (IEEE) Engineering in Medicine and Biology Society (EMBS). Professor Ye was invited to deliver a lecture on his leading research on artificial intelligence (AI) technology in medical video restoration. He will serve a term of two years beginning in 2020.

IEEE EMBS's distinguished lecturer program is designed to educate researchers around the world on the latest trends and technology in biomedical engineering. Sponsored by IEEE, its members can attend lectures on the distinguished professor's research subject.

Professor Ye said, "We are at a time where the importance of AI in medical imaging is increasing.” He added, “I am proud to be appointed as a distinguished lecturer of the IEEE EMBS in recognition of my contributions to this field.”

(END)

2020.02.27 View 14174 -

Jeju Inspired Packaging by ID+IM Design Lab Wins 2020 iF Design Award

A water bottle designed by researchers from the ID+IM Design Laboratory led by Professor Sangmin Bae from the Department of Industrial Design won the packaging section of the 2020 iF Design Award.

The iF Design Award, hosted by the Hannover Exhibition Center in Germany, is one of the three major international design competitions. It receives more than 7,000 submissions from participants representing 60 countries.

The Jeju Yong-Am-Soo (which means ‘volcanic mineral water’ in English) bottle design was a product of an academic-industrial cooperation project carried out by Professor Bae’s team and a Korean confectionery company, Orion Corporation, to create a design for a premium mineral water bottle.

The motif of the awarded design was the beautiful nature of Jeju Island in Korea. The columnar joints and the horizon of Jeju Island were each represented by horizontal and vertical lines, completing a simple yet sensuous design.

The mystical volcanic Mount Halla printed on the transparent front-label of the bottle represents the daytime of Jeju Island, while the rear-label design, which is reflected through the transparent front-label, symbolizes the nighttime of Jeju Island. By putting the Orion constellation, a symbol of tourist’s guide, right above the Orion Corporation’s brand logo, Professor Bae’s team ambiently promotes the company’s identity.

Although the design uses a significantly smaller amount of materials than traditional water bottles, it can withstand about four times the pressure and weight. The efficient structure therefore shows excellence in both aesthetic and functional areas.

Professor Bae said, “I am happy with the fact that the result of this academic-industrial cooperation project became mass-produced through commercialization and was recognized by an international design award.” He continued, “Even though it was difficult for my team to come up with the design that fits both manufacturing and the distribution processes, we worked hard to achieve the structural and functional aspects, while also expressing beauty through its appearance.”

(END)

2020.02.20 View 8144

Jeju Inspired Packaging by ID+IM Design Lab Wins 2020 iF Design Award

A water bottle designed by researchers from the ID+IM Design Laboratory led by Professor Sangmin Bae from the Department of Industrial Design won the packaging section of the 2020 iF Design Award.

The iF Design Award, hosted by the Hannover Exhibition Center in Germany, is one of the three major international design competitions. It receives more than 7,000 submissions from participants representing 60 countries.

The Jeju Yong-Am-Soo (which means ‘volcanic mineral water’ in English) bottle design was a product of an academic-industrial cooperation project carried out by Professor Bae’s team and a Korean confectionery company, Orion Corporation, to create a design for a premium mineral water bottle.

The motif of the awarded design was the beautiful nature of Jeju Island in Korea. The columnar joints and the horizon of Jeju Island were each represented by horizontal and vertical lines, completing a simple yet sensuous design.

The mystical volcanic Mount Halla printed on the transparent front-label of the bottle represents the daytime of Jeju Island, while the rear-label design, which is reflected through the transparent front-label, symbolizes the nighttime of Jeju Island. By putting the Orion constellation, a symbol of tourist’s guide, right above the Orion Corporation’s brand logo, Professor Bae’s team ambiently promotes the company’s identity.

Although the design uses a significantly smaller amount of materials than traditional water bottles, it can withstand about four times the pressure and weight. The efficient structure therefore shows excellence in both aesthetic and functional areas.

Professor Bae said, “I am happy with the fact that the result of this academic-industrial cooperation project became mass-produced through commercialization and was recognized by an international design award.” He continued, “Even though it was difficult for my team to come up with the design that fits both manufacturing and the distribution processes, we worked hard to achieve the structural and functional aspects, while also expressing beauty through its appearance.”

(END)

2020.02.20 View 8144 -

New Graphene-Based Metasurface Capable of Independent Amplitude and Phase Control of Light

Researchers described a new strategy of designing metamolecules that incorporates two independently controllable subwavelength meta-atoms. This two-parametric control of the metamolecule secures the complete control of both amplitude and the phase of light.

A KAIST research team in collaboration with the University of Wisconsin-Madison theoretically suggested a graphene-based active metasurface capable of independent amplitude and phase control of mid-infrared light. This research gives a new insight into modulating the mid-infrared wavefront with high resolution by solving the problem of the independent control of light amplitude and phase, which has remained a long-standing challenge.

Light modulation technology is essential for developing future optical devices such as holography, high-resolution imaging, and optical communication systems. Liquid crystals and a microelectromechanical system (MEMS) have previously been utilized to modulate light. However, both methods suffer from significantly limited driving speeds and unit pixel sizes larger than the diffraction limit, which consequently prevent their integration into photonic systems.

The metasurface platform is considered a strong candidate for the next generation of light modulation technology. Metasurfaces have optical properties that natural materials cannot have, and can overcome the limitations of conventional optical systems, such as forming a high-resolution image beyond the diffraction limit. In particular, the active metasurface is regarded as a technology with a wide range of applications due to its tunable optical characteristics with an electrical signal.

However, the previous active metasurfaces suffered from the inevitable correlation between light amplitude control and phase control. This problem is caused by the modulation mechanism of conventional metasurfaces. Conventional metasurfaces have been designed such that a metaatom only has one resonance condition, but a single resonant design inherently lacks the degrees of freedom to independently control the amplitude and phase of light.

The research team made a metaunit by combining two independently controllable metaatoms, dramatically improving the modulation range of active metasurfaces. The proposed metasurface can control the amplitude and phase of the mid-infrared light independently with a resolution beyond the diffraction limit, thus allowing complete control of the optical wavefront.

The research team theoretically confirmed the performance of the proposed active metasurface and the possibility of wavefront shaping using this design method. Furthermore, they developed an analytical method that can approximate the optical properties of metasurfaces without complex electromagnetic simulations. This analytical platform proposes a more intuitive and comprehensively applicable metasurface design guideline.

The proposed technology is expected to enable accurate wavefront shaping with a much higher spatial resolution than existing wavefront shaping technologies, which will be applied to active optical systems such as mid-infrared holography, high-speed beam steering devices that can be applied for LiDAR, and variable focus infrared lenses.

Professor Min Seok Jang commented, "This study showed the independent control amplitude and phase of light, which has been a long-standing quest in light modulator technology. The development of optical devices using complex wavefront control is expected to become more active in the future."

MS candidate Sangjun Han and Dr. Seyoon Kim of the University of Wisconsin-Madison are the co-first authors of the research, which was published and selected as the front cover of the January 28 edition of ACS Nano titled “Complete complex amplitude modulation with electronically tunable graphene plasmonic metamolecules.”

This research was funded by the Samsung Research Funding & Incubation Center for Future Technology.

Publication:

Han et al. (2020) Complete Complex Amplitude Modulation with Electronically Tunable Graphene Plasmonic Metamolecules. ACS Nano, Vol. 14, Issue 1, pp. 1166-1175. Available online at https://doi.org/10.1021/acsnano.9b09277

Profile: Prof. Min Seok Jang, MS, PhD

jang.minseok@kaist.ac.kr

http://jlab.kaist.ac.kr/

Associate Professor

Jang Research Group

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Sangjun Han

sangjun.han@kaist.ac.kr

MS Candidate

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.20 View 11221

New Graphene-Based Metasurface Capable of Independent Amplitude and Phase Control of Light

Researchers described a new strategy of designing metamolecules that incorporates two independently controllable subwavelength meta-atoms. This two-parametric control of the metamolecule secures the complete control of both amplitude and the phase of light.

A KAIST research team in collaboration with the University of Wisconsin-Madison theoretically suggested a graphene-based active metasurface capable of independent amplitude and phase control of mid-infrared light. This research gives a new insight into modulating the mid-infrared wavefront with high resolution by solving the problem of the independent control of light amplitude and phase, which has remained a long-standing challenge.

Light modulation technology is essential for developing future optical devices such as holography, high-resolution imaging, and optical communication systems. Liquid crystals and a microelectromechanical system (MEMS) have previously been utilized to modulate light. However, both methods suffer from significantly limited driving speeds and unit pixel sizes larger than the diffraction limit, which consequently prevent their integration into photonic systems.

The metasurface platform is considered a strong candidate for the next generation of light modulation technology. Metasurfaces have optical properties that natural materials cannot have, and can overcome the limitations of conventional optical systems, such as forming a high-resolution image beyond the diffraction limit. In particular, the active metasurface is regarded as a technology with a wide range of applications due to its tunable optical characteristics with an electrical signal.

However, the previous active metasurfaces suffered from the inevitable correlation between light amplitude control and phase control. This problem is caused by the modulation mechanism of conventional metasurfaces. Conventional metasurfaces have been designed such that a metaatom only has one resonance condition, but a single resonant design inherently lacks the degrees of freedom to independently control the amplitude and phase of light.

The research team made a metaunit by combining two independently controllable metaatoms, dramatically improving the modulation range of active metasurfaces. The proposed metasurface can control the amplitude and phase of the mid-infrared light independently with a resolution beyond the diffraction limit, thus allowing complete control of the optical wavefront.

The research team theoretically confirmed the performance of the proposed active metasurface and the possibility of wavefront shaping using this design method. Furthermore, they developed an analytical method that can approximate the optical properties of metasurfaces without complex electromagnetic simulations. This analytical platform proposes a more intuitive and comprehensively applicable metasurface design guideline.

The proposed technology is expected to enable accurate wavefront shaping with a much higher spatial resolution than existing wavefront shaping technologies, which will be applied to active optical systems such as mid-infrared holography, high-speed beam steering devices that can be applied for LiDAR, and variable focus infrared lenses.

Professor Min Seok Jang commented, "This study showed the independent control amplitude and phase of light, which has been a long-standing quest in light modulator technology. The development of optical devices using complex wavefront control is expected to become more active in the future."

MS candidate Sangjun Han and Dr. Seyoon Kim of the University of Wisconsin-Madison are the co-first authors of the research, which was published and selected as the front cover of the January 28 edition of ACS Nano titled “Complete complex amplitude modulation with electronically tunable graphene plasmonic metamolecules.”

This research was funded by the Samsung Research Funding & Incubation Center for Future Technology.

Publication:

Han et al. (2020) Complete Complex Amplitude Modulation with Electronically Tunable Graphene Plasmonic Metamolecules. ACS Nano, Vol. 14, Issue 1, pp. 1166-1175. Available online at https://doi.org/10.1021/acsnano.9b09277

Profile: Prof. Min Seok Jang, MS, PhD

jang.minseok@kaist.ac.kr

http://jlab.kaist.ac.kr/

Associate Professor

Jang Research Group

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Sangjun Han

sangjun.han@kaist.ac.kr

MS Candidate

School of Electrical Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.20 View 11221 -

What Fuels a “Domino Effect” in Cancer Drug Resistance?

KAIST researchers have identified mechanisms that relay prior acquired resistance to the first-line chemotherapy to the second-line targeted therapy, fueling a “domino effect” in cancer drug resistance. Their study featured in the February 7 edition of Science Advances suggests a new strategy for improving the second-line setting of cancer treatment for patients who showed resistance to anti-cancer drugs.

Resistance to cancer drugs is often managed in the clinic by chemotherapy and targeted therapy. Unlike chemotherapy that works by repressing fast-proliferating cells, targeted therapy blocks a single oncogenic pathway to halt tumor growth. In many cases, targeted therapy is engaged as a maintenance therapy or employed in the second-line after front-line chemotherapy.

A team of researchers led by Professor Yoosik Kim from the Department of Chemical and Biomolecular Engineering and the KAIST Institute for Health Science and Technology (KIHST) has discovered an unexpected resistance signature that occurs between chemotherapy and targeted therapy. The team further identified a set of integrated mechanisms that promotes this kind of sequential therapy resistance.

“There have been multiple clinical accounts reflecting that targeted therapies tend to be least successful in patients who have exhausted all standard treatments,” said the first author of the paper Mark Borris D. Aldonza. He continued, “These accounts ignited our hypothesis that failed responses to some chemotherapies might speed up the evolution of resistance to other drugs, particularly those with specific targets.”

Aldonza and his colleagues extracted large amounts of drug-resistance information from the open-source database the Genomics of Drug Sensitivity in Cancer (GDSC), which contains thousands of drug response data entries from various human cancer cell lines. Their big data analysis revealed that cancer cell lines resistant to chemotherapies classified as anti-mitotic drugs (AMDs), toxins that inhibit overacting cell division, are also resistant to a class of targeted therapies called epidermal growth factor receptor-tyrosine kinase inhibitors (EGFR-TKIs).

In all of the cancer types analyzed, more than 84 percent of those resistant to AMDs, representatively ‘paclitaxel’, were also resistant to at least nine EGFR-TKIs. In lung, pancreatic, and breast cancers where paclitaxel is often used as a first-line, standard-of-care regimen, greater than 92 percent showed resistance to EGFR-TKIs. Professor Kim said, “It is surprising to see that such collateral resistance can occur specifically between two chemically different classes of drugs.”

To figure out how failed responses to paclitaxel leads to resistance to EGFR-TKIs, the team validated co-resistance signatures that they found in the database by generating and analyzing a subset of slow-doubling, paclitaxel-resistant cancer models called ‘persisters’.

The results demonstrated that paclitaxel-resistant cancers remodel their stress response by first becoming more stem cell-like, evolving the ability to self-renew to adapt to more stressful conditions like drug exposures. More surprisingly, when the researchers characterized the metabolic state of the cells, EGFR-TKI persisters derived from paclitaxel-resistant cancer cells showed high dependencies to energy-producing processes such as glycolysis and glutaminolysis.

“We found that, without an energy stimulus like glucose, these cells transform to becoming more senescent, a characteristic of cells that have arrested cell division. However, this senescence is controlled by stem cell factors, which the paclitaxel-resistant cancers use to escape from this arrested state given a favorable condition to re-grow,” said Aldonza.

Professor Kim explained, “Before this research, there was no reason to expect that acquiring the cancer stem cell phenotype that dramatically leads to a cascade of changes in cellular states affecting metabolism and cell death is linked with drug-specific sequential resistance between two classes of therapies.”

He added, “The expansion of our work to other working models of drug resistance in a much more clinically-relevant setting, perhaps in clinical trials, will take on increasing importance, as sequential treatment strategies will continue to be adapted to various forms of anti-cancer therapy regimens.”

This study was supported by the Basic Science Research Program of the National Research Foundation of Korea (NRF-2016R1C1B2009886), and the KAIST Future Systems Healthcare Project (KAISTHEALTHCARE42) funded by the Korean Ministry of Science and ICT (MSIT). Undergraduate student Aldonza participated in this research project and presented the findings as the lead author as part of the Undergraduate Research Participation (URP) Program at KAIST.

< Figure 1. Schematic overview of the study. >

< Figure 2. Big data analysis revealing co-resistance signatures between classes of anti-cancer drugs. >

Publication:

Aldonza et al. (2020) Prior acquired resistance to paclitaxel relays diverse EGFR-targeted therapy persistence mechanisms. Science Advances, Vol. 6, No. 6, eaav7416. Available online at http://dx.doi.org/10.1126/sciadv.aav7416

Profile: Prof. Yoosik Kim, MA, PhD

ysyoosik@kaist.ac.kr

https://qcbio.kaist.ac.kr/

Assistant Professor

Bio Network Analysis Laboratory

Department of Chemical and Biomolecular Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Mark Borris D. Aldonza

borris@kaist.ac.kr

Undergraduate Student

Department of Biological Sciences

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.10 View 18561

What Fuels a “Domino Effect” in Cancer Drug Resistance?

KAIST researchers have identified mechanisms that relay prior acquired resistance to the first-line chemotherapy to the second-line targeted therapy, fueling a “domino effect” in cancer drug resistance. Their study featured in the February 7 edition of Science Advances suggests a new strategy for improving the second-line setting of cancer treatment for patients who showed resistance to anti-cancer drugs.

Resistance to cancer drugs is often managed in the clinic by chemotherapy and targeted therapy. Unlike chemotherapy that works by repressing fast-proliferating cells, targeted therapy blocks a single oncogenic pathway to halt tumor growth. In many cases, targeted therapy is engaged as a maintenance therapy or employed in the second-line after front-line chemotherapy.

A team of researchers led by Professor Yoosik Kim from the Department of Chemical and Biomolecular Engineering and the KAIST Institute for Health Science and Technology (KIHST) has discovered an unexpected resistance signature that occurs between chemotherapy and targeted therapy. The team further identified a set of integrated mechanisms that promotes this kind of sequential therapy resistance.

“There have been multiple clinical accounts reflecting that targeted therapies tend to be least successful in patients who have exhausted all standard treatments,” said the first author of the paper Mark Borris D. Aldonza. He continued, “These accounts ignited our hypothesis that failed responses to some chemotherapies might speed up the evolution of resistance to other drugs, particularly those with specific targets.”

Aldonza and his colleagues extracted large amounts of drug-resistance information from the open-source database the Genomics of Drug Sensitivity in Cancer (GDSC), which contains thousands of drug response data entries from various human cancer cell lines. Their big data analysis revealed that cancer cell lines resistant to chemotherapies classified as anti-mitotic drugs (AMDs), toxins that inhibit overacting cell division, are also resistant to a class of targeted therapies called epidermal growth factor receptor-tyrosine kinase inhibitors (EGFR-TKIs).

In all of the cancer types analyzed, more than 84 percent of those resistant to AMDs, representatively ‘paclitaxel’, were also resistant to at least nine EGFR-TKIs. In lung, pancreatic, and breast cancers where paclitaxel is often used as a first-line, standard-of-care regimen, greater than 92 percent showed resistance to EGFR-TKIs. Professor Kim said, “It is surprising to see that such collateral resistance can occur specifically between two chemically different classes of drugs.”

To figure out how failed responses to paclitaxel leads to resistance to EGFR-TKIs, the team validated co-resistance signatures that they found in the database by generating and analyzing a subset of slow-doubling, paclitaxel-resistant cancer models called ‘persisters’.

The results demonstrated that paclitaxel-resistant cancers remodel their stress response by first becoming more stem cell-like, evolving the ability to self-renew to adapt to more stressful conditions like drug exposures. More surprisingly, when the researchers characterized the metabolic state of the cells, EGFR-TKI persisters derived from paclitaxel-resistant cancer cells showed high dependencies to energy-producing processes such as glycolysis and glutaminolysis.

“We found that, without an energy stimulus like glucose, these cells transform to becoming more senescent, a characteristic of cells that have arrested cell division. However, this senescence is controlled by stem cell factors, which the paclitaxel-resistant cancers use to escape from this arrested state given a favorable condition to re-grow,” said Aldonza.

Professor Kim explained, “Before this research, there was no reason to expect that acquiring the cancer stem cell phenotype that dramatically leads to a cascade of changes in cellular states affecting metabolism and cell death is linked with drug-specific sequential resistance between two classes of therapies.”

He added, “The expansion of our work to other working models of drug resistance in a much more clinically-relevant setting, perhaps in clinical trials, will take on increasing importance, as sequential treatment strategies will continue to be adapted to various forms of anti-cancer therapy regimens.”

This study was supported by the Basic Science Research Program of the National Research Foundation of Korea (NRF-2016R1C1B2009886), and the KAIST Future Systems Healthcare Project (KAISTHEALTHCARE42) funded by the Korean Ministry of Science and ICT (MSIT). Undergraduate student Aldonza participated in this research project and presented the findings as the lead author as part of the Undergraduate Research Participation (URP) Program at KAIST.

< Figure 1. Schematic overview of the study. >

< Figure 2. Big data analysis revealing co-resistance signatures between classes of anti-cancer drugs. >

Publication:

Aldonza et al. (2020) Prior acquired resistance to paclitaxel relays diverse EGFR-targeted therapy persistence mechanisms. Science Advances, Vol. 6, No. 6, eaav7416. Available online at http://dx.doi.org/10.1126/sciadv.aav7416

Profile: Prof. Yoosik Kim, MA, PhD

ysyoosik@kaist.ac.kr

https://qcbio.kaist.ac.kr/

Assistant Professor

Bio Network Analysis Laboratory

Department of Chemical and Biomolecular Engineering

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

Profile: Mark Borris D. Aldonza

borris@kaist.ac.kr

Undergraduate Student

Department of Biological Sciences

Korea Advanced Institute of Science and Technology (KAIST)

http://kaist.ac.kr

Daejeon, Republic of Korea

(END)

2020.02.10 View 18561 -

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 13367

Blood-Based Multiplexed Diagnostic Sensor Helps to Accurately Detect Alzheimer’s Disease

A research team at KAIST reported clinically accurate multiplexed electrical biosensor for detecting Alzheimer’s disease by measuring its core biomarkers using densely aligned carbon nanotubes.

Alzheimer’s disease is the most prevalent neurodegenerative disorder, affecting one in ten aged over 65 years. Early diagnosis can reduce the risk of suffering the disease by one-third, according to recent reports. However, its early diagnosis remains challenging due to the low accuracy but high cost of diagnosis.

Research team led by Professors Chan Beum Park and Steve Park described an ultrasensitive detection of multiple Alzheimer's disease core biomarker in human plasma. The team have designed the sensor array by employing a densely aligned single-walled carbon nanotube thin films as a transducer.

The representative biomarkers of Alzheimer's disease are beta-amyloid42, beta-amyloid40, total tau protein, phosphorylated tau protein and the concentrations of these biomarkers in human plasma are directly correlated with the pathology of Alzheimer’s disease.

The research team developed a highly sensitive resistive biosensor based on densely aligned carbon nanotubes fabricated by Langmuir-Blodgett method with a low manufacturing cost.

Aligned carbon nanotubes with high density minimizes the tube-to-tube junction resistance compared with randomly distributed carbon nanotubes, which leads to the improvement of sensor sensitivity. To be more specific, this resistive sensor with densely aligned carbon nanotubes exhibits a sensitivity over 100 times higher than that of conventional carbon nanotube-based biosensors.

By measuring the concentrations of four Alzheimer’s disease biomarkers simultaneously Alzheimer patients can be discriminated from health controls with an average sensitivity of 90.0%, a selectivity of 90.0% and an average accuracy of 88.6%.

This work, titled “Clinically accurate diagnosis of Alzheimer’s disease via multiplexed sensing of core biomarkers in human plasma”, were published in Nature Communications on January 8th 2020. The authors include PhD candidate Kayoung Kim and MS candidate Min-Ji Kim.

Professor Steve Park said, “This study was conducted on patients who are already confirmed with Alzheimer’s Disease. For further use in practical setting, it is necessary to test the patients with mild cognitive impairment.” He also emphasized that, “It is essential to establish a nationwide infrastructure, such as mild cognitive impairment cohort study and a dementia cohort study. This would enable the establishment of world-wide research network, and will help various private and public institutions.”

This research was supported by the Ministry of Science and ICT, Human Resource Bank of Chungnam National University Hospital and Chungbuk National University Hospital.

< A schematic diagram of a high-density aligned carbon nanotube-based resistive sensor that distinguishes patients with Alzheimer’s Disease by measuring the concentration of four biomarkers in the blood. >

Profile:

Professor Steve Park

stevepark@kaist.ac.kr

Department of Materials Science and Engineering

http://steveparklab.kaist.ac.kr/

KAIST

Profile:

Professor Chan Beum Park

parkcb at kaist.ac.kr

Department of Materials Science and Engineering

http://biomaterials.kaist.ac.kr/

KAIST

2020.02.07 View 13367 -

Professor Sungyeol Choi Receives Science and ICT Ministerial Commendation

< Professor Sungyeol Choi >

Professor Sungyeol Choi from the Department of Nuclear and Quantum Engineering received the Science and ICT Ministerial Commendation on the 9th Annual Nuclear Safety and Promotion Day last month, in recognition of his contributions to the promotion of nuclear energy through the safe management of spent nuclear fuel and radioactive waste.

Professor Choi developed high-precision, multi-physics codes that can predict and prevent abnormal power fluctuations caused by boron hideout within nuclear fuel in a pressurized water reactor, solving the problem that has caused economic losses of tens of billions of won every year from industrial sites.

He is now developing a new technology that can reduce high-level waste by recycling spent nuclear fuel, while preventing nuclear material from being used for nuclear weapons, which is one of the biggest challenges faced by the nuclear industry.

In 2017, his first year in office as a KAIST professor, Professor Choi was selected as the youngest and the only member under 50 of the Standing Scientific Advisory Committee at the Information Exchange Meeting on Partitioning and Transmutation (IEMPT), an authoritative association on the disposal of high-level nuclear waste.

The following year, he became the first Korean to receive the Early Career Award, which is given to one person every two years by the International Youth Nuclear Congress.

2020.01.15 View 6626

Professor Sungyeol Choi Receives Science and ICT Ministerial Commendation

< Professor Sungyeol Choi >

Professor Sungyeol Choi from the Department of Nuclear and Quantum Engineering received the Science and ICT Ministerial Commendation on the 9th Annual Nuclear Safety and Promotion Day last month, in recognition of his contributions to the promotion of nuclear energy through the safe management of spent nuclear fuel and radioactive waste.

Professor Choi developed high-precision, multi-physics codes that can predict and prevent abnormal power fluctuations caused by boron hideout within nuclear fuel in a pressurized water reactor, solving the problem that has caused economic losses of tens of billions of won every year from industrial sites.

He is now developing a new technology that can reduce high-level waste by recycling spent nuclear fuel, while preventing nuclear material from being used for nuclear weapons, which is one of the biggest challenges faced by the nuclear industry.

In 2017, his first year in office as a KAIST professor, Professor Choi was selected as the youngest and the only member under 50 of the Standing Scientific Advisory Committee at the Information Exchange Meeting on Partitioning and Transmutation (IEMPT), an authoritative association on the disposal of high-level nuclear waste.

The following year, he became the first Korean to receive the Early Career Award, which is given to one person every two years by the International Youth Nuclear Congress.

2020.01.15 View 6626 -

Scientists Discover the Mechanism of DNA High-Order Structure Formation

(Molecular structures of Abo1 in different energy states (left), Demonstration of an Abo1-assisted histone loading onto DNA by the DNA curtain assay. )

The genetic material of our cells—DNA—exists in a high-order structure called “chromatin”. Chromatin consists of DNA wrapped around histone proteins and efficiently packs DNA into a small volume. Moreover, using a spool and thread analogy, chromatin allows DNA to be locally wound or unwound, thus enabling genes to be enclosed or exposed. The misregulation of chromatin structures results in aberrant gene expression and can ultimately lead to developmental disorders or cancers. Despite the importance of DNA high-order structures, the complexity of the underlying machinery has circumvented molecular dissection.

For the first time, molecular biologists have uncovered how one particular mechanism uses energy to ensure proper histone placement onto DNA to form chromatin. They published their results on Dec. 17 in Nature Communications.

The study focused on proteins called histone chaperones. Histone chaperones are responsible for adding and removing specific histones at specific times during the DNA packaging process. The wrong histone at the wrong time and place could result in the misregulation of gene expression or aberrant DNA replication. Thus, histone chaperones are key players in the assembly and disassembly of chromatin.

“In order to carefully control the assembly and disassembly of chromatin units, histone chaperones act as molecular escorts that prevent histone aggregation and undesired interactions,” said Professor Ji-Joon Song in the Department of Biological Sciences at KAIST. “We set out to understand how a unique histone chaperone uses chemical energy to assemble or disassemble chromatin.”

Song and his team looked to Abo1, the only known histone chaperone that utilizes cellular energy (ATP). While Abo1 is found in yeast, it has an analogous partner in other organisms, including humans, called ATAD2. Both use ATP, which is produced through a cellular process where enzymes break down a molecule’s phosphate bond. ATP energy is typically used to power other cellular processes, but it is a rare partner for histone chaperones.

“This was an interesting problem in the field because all other histone chaperones studied to date do not use ATP,” Song said.

By imaging Abo1 with a single-molecule fluorescence imaging technique known as the DNA curtain assay, the researchers could examine the protein interactions at the single-molecule level. The technique allows scientists to arrange the DNA molecules and proteins on a single layer of a microfluidic chamber and examine the layer with fluorescence microscopy.

The researchers found through real-time observation that Abo1 is ring-shaped and changes its structure to accommodate a specific histone and deposit it on DNA. Moreover, they found that the accommodating structural changes are powered by ADP.

“We discovered a mechanism by which Abo1 accommodates histone substrates, ultimately allowing it to function as a unique energy-dependent histone chaperone,” Song said. “We also found that despite looking like a protein disassembly machine, Abo1 actually loads histone substrates onto DNA to facilitate chromatin assembly.”

The researchers plan to continue exploring how energy-dependent histone chaperones bind and release histones, with the ultimate goal of developing therapeutics that can target cancer-causing misbehavior by Abo1’s analogous human counterpart, ATAD2.

-Profile

Professor Ji-Joon Song

Department of Biological Sciences KI for the BioCentury (https://kis.kaist.ac.kr/index.php?mid=KIB_O) KAIST

2020.01.07 View 12910

Scientists Discover the Mechanism of DNA High-Order Structure Formation

(Molecular structures of Abo1 in different energy states (left), Demonstration of an Abo1-assisted histone loading onto DNA by the DNA curtain assay. )

The genetic material of our cells—DNA—exists in a high-order structure called “chromatin”. Chromatin consists of DNA wrapped around histone proteins and efficiently packs DNA into a small volume. Moreover, using a spool and thread analogy, chromatin allows DNA to be locally wound or unwound, thus enabling genes to be enclosed or exposed. The misregulation of chromatin structures results in aberrant gene expression and can ultimately lead to developmental disorders or cancers. Despite the importance of DNA high-order structures, the complexity of the underlying machinery has circumvented molecular dissection.

For the first time, molecular biologists have uncovered how one particular mechanism uses energy to ensure proper histone placement onto DNA to form chromatin. They published their results on Dec. 17 in Nature Communications.

The study focused on proteins called histone chaperones. Histone chaperones are responsible for adding and removing specific histones at specific times during the DNA packaging process. The wrong histone at the wrong time and place could result in the misregulation of gene expression or aberrant DNA replication. Thus, histone chaperones are key players in the assembly and disassembly of chromatin.

“In order to carefully control the assembly and disassembly of chromatin units, histone chaperones act as molecular escorts that prevent histone aggregation and undesired interactions,” said Professor Ji-Joon Song in the Department of Biological Sciences at KAIST. “We set out to understand how a unique histone chaperone uses chemical energy to assemble or disassemble chromatin.”

Song and his team looked to Abo1, the only known histone chaperone that utilizes cellular energy (ATP). While Abo1 is found in yeast, it has an analogous partner in other organisms, including humans, called ATAD2. Both use ATP, which is produced through a cellular process where enzymes break down a molecule’s phosphate bond. ATP energy is typically used to power other cellular processes, but it is a rare partner for histone chaperones.

“This was an interesting problem in the field because all other histone chaperones studied to date do not use ATP,” Song said.

By imaging Abo1 with a single-molecule fluorescence imaging technique known as the DNA curtain assay, the researchers could examine the protein interactions at the single-molecule level. The technique allows scientists to arrange the DNA molecules and proteins on a single layer of a microfluidic chamber and examine the layer with fluorescence microscopy.

The researchers found through real-time observation that Abo1 is ring-shaped and changes its structure to accommodate a specific histone and deposit it on DNA. Moreover, they found that the accommodating structural changes are powered by ADP.

“We discovered a mechanism by which Abo1 accommodates histone substrates, ultimately allowing it to function as a unique energy-dependent histone chaperone,” Song said. “We also found that despite looking like a protein disassembly machine, Abo1 actually loads histone substrates onto DNA to facilitate chromatin assembly.”

The researchers plan to continue exploring how energy-dependent histone chaperones bind and release histones, with the ultimate goal of developing therapeutics that can target cancer-causing misbehavior by Abo1’s analogous human counterpart, ATAD2.

-Profile

Professor Ji-Joon Song

Department of Biological Sciences KI for the BioCentury (https://kis.kaist.ac.kr/index.php?mid=KIB_O) KAIST

2020.01.07 View 12910 -

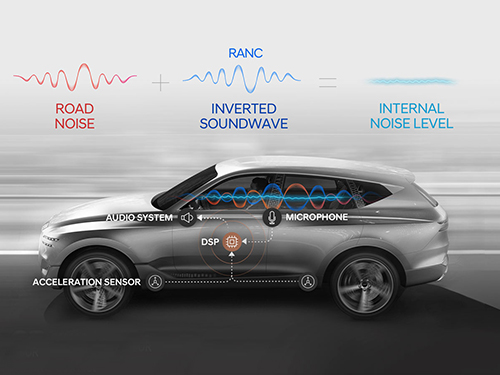

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 14506

A System Controlling Road Active Noise to Hit the Road

The research team led by Professor Youngjin Park of the Department of Mechanical Engineering has developed a road noise active noise control (RANC) system to be commercialized in partnership with Hyundai Motor Group.

On December 11, Hyundai Motor Group announced the successful development of the RANC system, which significantly reduces the road noise flowing into cars. The carmaker has completed the domestic and American patent applications for the location of sensors and the signal selection method, the core technology of RANC.

RANC is a technology for reducing road noise during driving. This system consists of an acceleration sensor, digital signal processor (the control computer to analyze sound signals), microphone, amplifier, and audio system. To make the system as simple as possible, the audio system utilizes the original audio system embedded in the car instead of a separate system.

The acceleration sensor first calculates the vibration from the road into the car. The location of the sensor is important for accurately identifying the vibration path. The research team was able to find the optimal sensor location through a number of tests.

The System Dynamics and Applied Control Laboratory of Professor Park researched ways to significantly reduce road noise with Hyundai Motor Group for four years from 1993 as a G7 national project and published the results in international journals. In 2002, the researchers published an article titled “Noise Quietens Driving” in Nature, where they announced the first success in reducing road noise in actual cars. The achievement did not lead to commercialization, however, due to the lack of auxiliary technologies at the time, digital amplifiers and DSP for cars for example, and pricing issues.

Since 2013, Professor Park’s research team has participated in one technology transfer and eight university-industry projects. Based on these efforts, the team was able to successfully develop the RANC system with domestic technology in partnership with Hyundai’s NVH Research Lab (Research Fellow, Dr. Gangdeok Lee; Ph.D. in aviation engineering, 1996), Optomech (Founder, Professor Gyeongsu Kim; Ph.D. in mechanical engineering, 1999), ARE (CEO Hyeonseok Kim; Ph.D. in mechanical engineering, 1998), WeAcom, and BurnYoung.

Professor Park’s team led the project by performing theory-based research during the commercialization stage in collaboration with Hyundai Motor Group.

For the commercialization of the RANC system, Hyundai Motor Group is planning to collaborate with the global car audio company Harman to increase the degree of completion and apply the RANC system to the GV 80, the first SUV model of the Genesis brand.

“I am very delighted as an engineer to see the research I worked on from my early days at KAIST be commercialized after 20 years,” noted Professor Park. “I am thrilled to make a contribution to such commercialization with my students in my lab.”

2019.12.27 View 14506 -

Professor Sung Yong Kim Elected as the Chair of PICES MONITOR

< Professor Sung Yong Kim >

Professor Sung Yong Kim from the Department of Mechanical Engineering was elected as the chair of the Technical Committee on Monitoring (MONITOR) of the North Pacific Marine Science Organization (PICES).

PICES is an intergovernmental marine science organization that was established in 1992 through a collaboration between six North Pacific nations including South Korea, Russia, the United States, Japan, China, and Canada to exchange and discuss research on the Pacific waters. Its headquarters is located in Canada and the organization consists of seven affiliated maritime science and marine technology committees.

Professor Kim was elected as the chair of the technical committee that focuses on monitoring and will be part of the Science Board as an ex-officio member. His term will last three years from November 2019.

Professor Kim was recognized for his academic excellence, expertise, and leadership among oceanographers both domestically and internationally.

Professor Kim will also participate as an academia civilian committee member of the Maritime and Fisheries Science and Technology Committee under the Korean Ministry of Oceans and Fisheries for two years from December 18, 2019.

He stated, “I will give my full efforts to broaden Korean oceanography research by participating in maritime leadership positions at home and abroad, and help South Korea become a maritime powerhouse.”

(END)

2019.12.22 View 12451

Professor Sung Yong Kim Elected as the Chair of PICES MONITOR

< Professor Sung Yong Kim >

Professor Sung Yong Kim from the Department of Mechanical Engineering was elected as the chair of the Technical Committee on Monitoring (MONITOR) of the North Pacific Marine Science Organization (PICES).

PICES is an intergovernmental marine science organization that was established in 1992 through a collaboration between six North Pacific nations including South Korea, Russia, the United States, Japan, China, and Canada to exchange and discuss research on the Pacific waters. Its headquarters is located in Canada and the organization consists of seven affiliated maritime science and marine technology committees.

Professor Kim was elected as the chair of the technical committee that focuses on monitoring and will be part of the Science Board as an ex-officio member. His term will last three years from November 2019.

Professor Kim was recognized for his academic excellence, expertise, and leadership among oceanographers both domestically and internationally.

Professor Kim will also participate as an academia civilian committee member of the Maritime and Fisheries Science and Technology Committee under the Korean Ministry of Oceans and Fisheries for two years from December 18, 2019.

He stated, “I will give my full efforts to broaden Korean oceanography research by participating in maritime leadership positions at home and abroad, and help South Korea become a maritime powerhouse.”

(END)

2019.12.22 View 12451 -

Professor Shin-Hyun Kim Receives the Young Scientist Award

Professor Shin-Hyun Kim from the Department of Chemical and Biomolecular Engineering received the Young Scientist Award from the Korean Academy of Science and Technology.

The Young Scientist Award is presented to a promising young Korean scientist under the age of 40 who shows significant potential, passion, and remarkable achievement.

Professor Kim was lauded for his research of intelligent soft materials. By applying his research, he developed a capsule sensor material that can not only be used for sensors, but also for displays, color aesthetics, anti-counterfeit technology, residual drug detection, and more.

The award ceremony took place on December 14 at the Gwacheon National Science Museum.

The Korean minister of Science and ICT delivered words of encouragement, reminding everyone that “the driving force behind creative performance of scientists is the provision of continuous support.” He added, “Researchers of Korea deserve greater public attention and support.”

(END)

2019.12.21 View 10110

Professor Shin-Hyun Kim Receives the Young Scientist Award

Professor Shin-Hyun Kim from the Department of Chemical and Biomolecular Engineering received the Young Scientist Award from the Korean Academy of Science and Technology.

The Young Scientist Award is presented to a promising young Korean scientist under the age of 40 who shows significant potential, passion, and remarkable achievement.

Professor Kim was lauded for his research of intelligent soft materials. By applying his research, he developed a capsule sensor material that can not only be used for sensors, but also for displays, color aesthetics, anti-counterfeit technology, residual drug detection, and more.

The award ceremony took place on December 14 at the Gwacheon National Science Museum.

The Korean minister of Science and ICT delivered words of encouragement, reminding everyone that “the driving force behind creative performance of scientists is the provision of continuous support.” He added, “Researchers of Korea deserve greater public attention and support.”

(END)

2019.12.21 View 10110 -

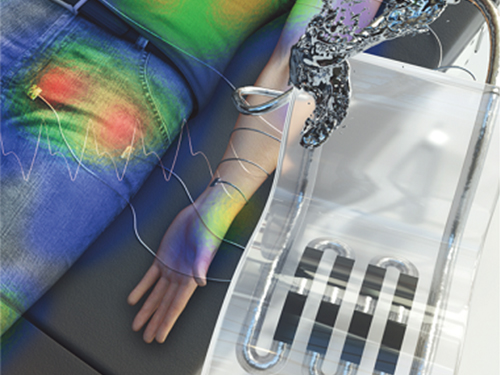

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 17690

New Liquid Metal Wearable Pressure Sensor Created for Health Monitoring Applications

Soft pressure sensors have received significant research attention in a variety of fields, including soft robotics, electronic skin, and wearable electronics. Wearable soft pressure sensors have great potential for the real-time health monitoring and for the early diagnosis of diseases.

A KAIST research team led by Professor Inkyu Park from the Department of Mechanical Engineering developed a highly sensitive wearable pressure sensor for health monitoring applications. This work was reported in Advanced Healthcare Materials on November 21 as a front cover article.

This technology is capable of sensitive, precise, and continuous measurement of physiological and physical signals and shows great potential for health monitoring applications and the early diagnosis of diseases.

A soft pressure sensor is required to have high compliance, high sensitivity, low cost, long-term performance stability, and environmental stability in order to be employed for continuous health monitoring. Conventional solid-state soft pressure sensors using functional materials including carbon nanotubes and graphene have showed great sensing performance. However, these sensors suffer from limited stretchability, signal drifting, and long-term instability due to the distance between the stretchable substrate and the functional materials.

To overcome these issues, liquid-state electronics using liquid metal have been introduced for various wearable applications. Of these materials, Galinstan, a eutectic metal alloy of gallium, indium, and tin, has great mechanical and electrical properties that can be employed in wearable applications. But today’s liquid metal-based pressure sensors have low-pressure sensitivity, limiting their applicability for health monitoring devices.

The research team developed a 3D-printed rigid microbump array-integrated, liquid metal-based soft pressure sensor. With the help of 3D printing, the integration of a rigid microbump array and the master mold for a liquid metal microchannel could be achieved simultaneously, reducing the complexity of the manufacturing process. Through the integration of the rigid microbump and the microchannel, the new pressure sensor has an extremely low detection limit and enhanced pressure sensitivity compared to previously reported liquid metal-based pressure sensors. The proposed sensor also has a negligible signal drift over 10,000 cycles of pressure, bending, and stretching and exhibited excellent stability when subjected to various environmental conditions.

These performance outcomes make it an excellent sensor for various health monitoring devices. First, the research team demonstrated a wearable wristband device that can continuously monitor one’s pulse during exercise and be employed in a noninvasive cuffless BP monitoring system based on PTT calculations. Then, they introduced a wireless wearable heel pressure monitoring system that integrates three 3D-BLiPS with a wireless communication module.

Professor Park said, “It was possible to measure health indicators including pulse and blood pressure continuously as well as pressure of body parts using our proposed soft pressure sensor. We expect it to be used in health care applications, such as the prevention and the monitoring of the pressure-driven diseases such as pressure ulcers in the near future. There will be more opportunities for future research including a whole-body pressure monitoring system related to other physical parameters.”

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT.

< Figure 1. The front cover image of Advanced Healthcare Materials, Volume 8, Issue 22. >

< Figure 2. Highly sensitive liquid metal-based soft pressure sensor integrated with 3D-printed microbump array. >

< Figure 3. High pressure sensitivity and reliable sensing performances of the proposed sensor and wireless heel pressure monitoring application. >

-ProfileProfessor Inkyu ParkMicro/Nano Transducers Laboratoryhttp://mintlab1.kaist.ac.kr/

Department of Mechanical EngineeringKAIST

2019.12.20 View 17690 -

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13552

Two Professors Receive Awards from the Korea Robotics Society

< Professor Jee-Hwan Ryu and Professor Ayoung Kim >

The Korea Robotics Society (KROS) conferred awards onto two KAIST professors from the Department of Civil and Environmental Engineering in recognition of their achievements and contributions to the development of the robotics industry in 2019. Professor Jee-Hwan Ryu has been actively engaged in researching the field of teleoperation, and this led him to win the KROS Robotics Innovation (KRI) Award. The KRI Award was newly established in 2019 by the KROS, in order to encourage researchers who have made innovative achievements in robotics. Professor Ryu shared the honor of being the first winner of this award with Professor Jaeheung Park of Seoul National University. Professor Ayoung Kim, from the same department, received the Young Investigator Award presented to emerging robitics researchers under 40 years of age. (END)

2019.12.19 View 13552