EC

-

Core Technology for Lithium Air Secondary Battery Developed

KAIST-Kyonggi University joint research team developed composite catalyst out of nano fiber and graphene

Five times improvement in capacity compared to lithium-ion secondary battery, driving 800 km at maximum

The core technology for lithium air secondary battery, the next generation high capacity battery, has been developed.

A research team formed by KAIST Department of Materials Science’s Professors Il-Doo Kim and Seokwoo Jeon, and Kyonggi University Department of Materials Science’s Professor Yong-Joon Park has created a lithium air secondary battery, with five times greater storage than the lithium-ion secondary battery, by developing a nano fiber-graphene composite catalyst. The research results are published in the August 8th online edition of Nano Letters.

A cathode of a lithium-ion battery consists of graphite and an anode of the battery consists of a lithium transition metal oxide. Lithium-ion batteries are widely used in mobile phones and laptops. However, lithium-ion batteries cannot support electric vehicles, providing energy for only 160 kilometers on one full charge. The lithium air secondary battery just developed by the research team uses lithium on the cathode and oxygen on the anode. It is earning a popular acknowledgement among the next generation secondary battery research community for having lightweight mass and high energy density.

However, lithium-ion batteries remain difficult to commercialize because of their short lifespan. Lithium and oxygen meet up to form lithium oxide (Li2O2) at discharge, and decompose again at charge. In a traditional lithium air battery, this cycle does not occur smoothly and results in high resistance, thereby reducing the lifespan of the battery. It is thus essential to develop high efficiency catalyst that facilitates the formation and decomposition of lithium oxides.

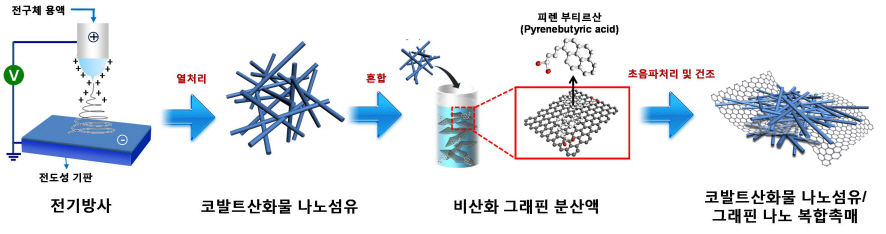

The research team used electric radiation to develop a nano composite catalyst by mixing cobalt oxide nano fiber and graphene. The performance of the battery has been maximized by settling nonoxidative graphene, which has high specific surface area and electrical conductivity, on catalyst active cobalt oxide nano fiber. Applying the nano composite catalyst on both poles of the lithium air battery resulted in an improved lifespan of over 80 recharge cycles with capacity greater than 100mAh/g, five times greater than a lithium ion battery. The newly discovered charge-discharge property is the highest among the reported performances of the lithium air battery so far.

The lithium air battery is cheap to make, as the main materials are metal oxide and graphene. “There are yet more issues to resolve such as stability, but we will collaborate with other organizations to open up the era of electronic vehicles,” said Professor Il-Doo Kim. “We hope to contribute to vitalizing the fields of next generation lithium air battery by leading nanocatalyst synthesis technology, one of the core materials in the fields of secondary battery,” Professor Kim spoke of his aspiration.

The graduate students participated in the research are Won-Hee Ryu, a postdoctorate at KAIST Department of Materials Science, Sungho Song, a PhD candidate at KAIST Department of Materials Science, and Taek-Han Yoon, a graduate student at Kyonggi University.

Picture I: Schematic Diagram of Lithium Air Battery Made of Nano Composite Catalysts

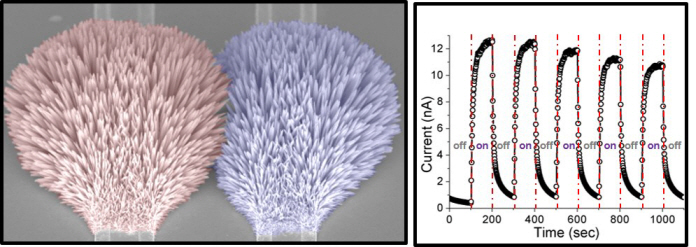

Picture II: Images of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts

Picture III: Images of Manufacturing Process of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts for Lithium Air Battery

2013.10.18 View 13038

Core Technology for Lithium Air Secondary Battery Developed

KAIST-Kyonggi University joint research team developed composite catalyst out of nano fiber and graphene

Five times improvement in capacity compared to lithium-ion secondary battery, driving 800 km at maximum

The core technology for lithium air secondary battery, the next generation high capacity battery, has been developed.

A research team formed by KAIST Department of Materials Science’s Professors Il-Doo Kim and Seokwoo Jeon, and Kyonggi University Department of Materials Science’s Professor Yong-Joon Park has created a lithium air secondary battery, with five times greater storage than the lithium-ion secondary battery, by developing a nano fiber-graphene composite catalyst. The research results are published in the August 8th online edition of Nano Letters.

A cathode of a lithium-ion battery consists of graphite and an anode of the battery consists of a lithium transition metal oxide. Lithium-ion batteries are widely used in mobile phones and laptops. However, lithium-ion batteries cannot support electric vehicles, providing energy for only 160 kilometers on one full charge. The lithium air secondary battery just developed by the research team uses lithium on the cathode and oxygen on the anode. It is earning a popular acknowledgement among the next generation secondary battery research community for having lightweight mass and high energy density.

However, lithium-ion batteries remain difficult to commercialize because of their short lifespan. Lithium and oxygen meet up to form lithium oxide (Li2O2) at discharge, and decompose again at charge. In a traditional lithium air battery, this cycle does not occur smoothly and results in high resistance, thereby reducing the lifespan of the battery. It is thus essential to develop high efficiency catalyst that facilitates the formation and decomposition of lithium oxides.

The research team used electric radiation to develop a nano composite catalyst by mixing cobalt oxide nano fiber and graphene. The performance of the battery has been maximized by settling nonoxidative graphene, which has high specific surface area and electrical conductivity, on catalyst active cobalt oxide nano fiber. Applying the nano composite catalyst on both poles of the lithium air battery resulted in an improved lifespan of over 80 recharge cycles with capacity greater than 100mAh/g, five times greater than a lithium ion battery. The newly discovered charge-discharge property is the highest among the reported performances of the lithium air battery so far.

The lithium air battery is cheap to make, as the main materials are metal oxide and graphene. “There are yet more issues to resolve such as stability, but we will collaborate with other organizations to open up the era of electronic vehicles,” said Professor Il-Doo Kim. “We hope to contribute to vitalizing the fields of next generation lithium air battery by leading nanocatalyst synthesis technology, one of the core materials in the fields of secondary battery,” Professor Kim spoke of his aspiration.

The graduate students participated in the research are Won-Hee Ryu, a postdoctorate at KAIST Department of Materials Science, Sungho Song, a PhD candidate at KAIST Department of Materials Science, and Taek-Han Yoon, a graduate student at Kyonggi University.

Picture I: Schematic Diagram of Lithium Air Battery Made of Nano Composite Catalysts

Picture II: Images of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts

Picture III: Images of Manufacturing Process of Cobalt Oxide Nano Fibers and Graphene Nano Composite Catalysts for Lithium Air Battery

2013.10.18 View 13038 -

Jellyfish Exterminator Robot Developed

Formation Control demonstrated by JEROS

- Trial performance successfully completed with three assembly robots -

A team led by KAIST Civil and Environmental Engineering Department’s Professor Hyeon Myeong has just finished testing the cooperative assembly robot for jellyfish population control, named JEROS, in the field.

The rising number of accidents and financial losses by fishing industry, estimated at 300 billion won per year, caused by the recent swarm of jellyfish in coastal waters has been a major problem for many years. The research team led by Prof. Hyeon Myeong began developing an unmanned automated system capable of eradicating jellyfishin in 2009, and has since completed field-tests last year with success.

This year, JEROS’s performance and speed has been improved with the ability to work in formation as a cooperative group to efficiently exterminate jellyfish.

An unmanned aquatic robot JEROS with a mountable grinding part is buoyed by two cylindrical bodies that utilizes propulsion motors to move forward and reverse, as well as rotate 360 degrees. Furthermore, GIS (geographic information system)-based map data is used to specify the region for jellyfish extermination, which automatically calculates the path for the task. JEROS then navigates autonomously using a GPS (Global Positioning System) receiver and an INS(inertial navigation system).

The assembly robots maintain a set formation pattern, while calculating its course to perform jellyfish extermination. The advantage of this method is that there is no need for individual control of the robots. Only the leader robot requires the calculated path, and the other robots can simply follow in a formation by exchanging their location information via wireless communication (ZigBee method).

JEROS uses its propulsion speed to capture jellyfish into the grinding part on the bottom, which then suctions the jellyfish toward the propeller to be exterminated.

The field test results show that three assembly robots operating at 4 knots (7.2km/h) disposes jellyfish at the rate of about 900kg/h.

The research team has currently completed testing JEROS at Gyeongnam Masan Bay and is expected to further experiment and improve the performance at various environment and conditions.

JEROS may also be utilized for other purposes including marine patrols, prevention of oil spills and waste removal in the sea.

JEROS research has been funded by Ministry of Science, ICT and Future Planning and Ministry of Trade, Industry and Energy.

2013.09.27 View 17889

Jellyfish Exterminator Robot Developed

Formation Control demonstrated by JEROS

- Trial performance successfully completed with three assembly robots -

A team led by KAIST Civil and Environmental Engineering Department’s Professor Hyeon Myeong has just finished testing the cooperative assembly robot for jellyfish population control, named JEROS, in the field.

The rising number of accidents and financial losses by fishing industry, estimated at 300 billion won per year, caused by the recent swarm of jellyfish in coastal waters has been a major problem for many years. The research team led by Prof. Hyeon Myeong began developing an unmanned automated system capable of eradicating jellyfishin in 2009, and has since completed field-tests last year with success.

This year, JEROS’s performance and speed has been improved with the ability to work in formation as a cooperative group to efficiently exterminate jellyfish.

An unmanned aquatic robot JEROS with a mountable grinding part is buoyed by two cylindrical bodies that utilizes propulsion motors to move forward and reverse, as well as rotate 360 degrees. Furthermore, GIS (geographic information system)-based map data is used to specify the region for jellyfish extermination, which automatically calculates the path for the task. JEROS then navigates autonomously using a GPS (Global Positioning System) receiver and an INS(inertial navigation system).

The assembly robots maintain a set formation pattern, while calculating its course to perform jellyfish extermination. The advantage of this method is that there is no need for individual control of the robots. Only the leader robot requires the calculated path, and the other robots can simply follow in a formation by exchanging their location information via wireless communication (ZigBee method).

JEROS uses its propulsion speed to capture jellyfish into the grinding part on the bottom, which then suctions the jellyfish toward the propeller to be exterminated.

The field test results show that three assembly robots operating at 4 knots (7.2km/h) disposes jellyfish at the rate of about 900kg/h.

The research team has currently completed testing JEROS at Gyeongnam Masan Bay and is expected to further experiment and improve the performance at various environment and conditions.

JEROS may also be utilized for other purposes including marine patrols, prevention of oil spills and waste removal in the sea.

JEROS research has been funded by Ministry of Science, ICT and Future Planning and Ministry of Trade, Industry and Energy.

2013.09.27 View 17889 -

Transparent Glass Wall as a Touch Game Media

Professor Woo-hoon Lee

- Selected as the “Highlight” at SIGGRAPH emerging technology conference

- “An excellent example of the transparent display panel in everyday life”

A joint research team led by KAIST Industrial Design Department’s Prof. Woo-hoon Lee and Computer Sciences Prof. Ki-hyuk Lee has developed a brand new concept game media “TransWall”, which utilizes both sides of the glass wall as the touch medium.

TransWall has been chosen as the “highlight” of 2013 SIGGRAPH emerging technology conference. SIGGRAPH is a world-renowned conference in the area of computer graphics and interaction technique, last held 21st-25th July at Anaheim, in the United States.

It all started with the thought, wouldn’t it be possible to turn the glass walls surrounding us into a medium for entertainment and communication?

TransWall utilizes holographic screen film inserted between two glass sheets with a multi-touch function, onto which the image can be projected using the beam projector from both sides. Furthermore, an additional Surface Transducer attached to the glass can deliver the sound and vibration.

What seemed as an ordinary glass wall has been transformed into a multi-sensory media that can transmit and receive visual, auditory and tactile information.

TransWall can be implemented at public places such as theme parks, large shopping malls and subway stations, providing the citizens with a new form of entertainment. This touch-interaction method can also be applied to developing a variety of cultural contents in the future.

Professor Lee said, “TransWall shows an example of near-future where touch-interaction method can be utilized with the soon-to-be commercialized transparent display panel in everyday lives.”

TransWall Introduction video (https://vimeo.com/70391422)

TransWall at SIGGRAPH 2013 Display (https://vimeo.com/71718874)

Picture 1. Both sides of the glass wall can be used as a touch platform for various medias, including games.

Picture 2. TransWall attracts the interests of the audience at SIGGRAPH emerging technology.

Picture 3. Structure of TransWall

Picture 4. Photo of TransWall from side

2013.09.19 View 11012

Transparent Glass Wall as a Touch Game Media

Professor Woo-hoon Lee

- Selected as the “Highlight” at SIGGRAPH emerging technology conference

- “An excellent example of the transparent display panel in everyday life”

A joint research team led by KAIST Industrial Design Department’s Prof. Woo-hoon Lee and Computer Sciences Prof. Ki-hyuk Lee has developed a brand new concept game media “TransWall”, which utilizes both sides of the glass wall as the touch medium.

TransWall has been chosen as the “highlight” of 2013 SIGGRAPH emerging technology conference. SIGGRAPH is a world-renowned conference in the area of computer graphics and interaction technique, last held 21st-25th July at Anaheim, in the United States.

It all started with the thought, wouldn’t it be possible to turn the glass walls surrounding us into a medium for entertainment and communication?

TransWall utilizes holographic screen film inserted between two glass sheets with a multi-touch function, onto which the image can be projected using the beam projector from both sides. Furthermore, an additional Surface Transducer attached to the glass can deliver the sound and vibration.

What seemed as an ordinary glass wall has been transformed into a multi-sensory media that can transmit and receive visual, auditory and tactile information.

TransWall can be implemented at public places such as theme parks, large shopping malls and subway stations, providing the citizens with a new form of entertainment. This touch-interaction method can also be applied to developing a variety of cultural contents in the future.

Professor Lee said, “TransWall shows an example of near-future where touch-interaction method can be utilized with the soon-to-be commercialized transparent display panel in everyday lives.”

TransWall Introduction video (https://vimeo.com/70391422)

TransWall at SIGGRAPH 2013 Display (https://vimeo.com/71718874)

Picture 1. Both sides of the glass wall can be used as a touch platform for various medias, including games.

Picture 2. TransWall attracts the interests of the audience at SIGGRAPH emerging technology.

Picture 3. Structure of TransWall

Picture 4. Photo of TransWall from side

2013.09.19 View 11012 -

Secondary, High Capacity Battery developed from Rice Husks

Rice husks, a waste product from rice polishing, has been successfully utilized as the silicon anode for use in high capacity lithium ion secondary batteries. The new silicon anode derived from rice husks exhibit superior output and lifespan.

Professor Choi Jang Wook (The Graduate School of Energy, Environment, Water and Sustainability (EEWS)) and Professor Park Seung Min (Department of Biochemistry) and their respective research teams separated naturally occurring, highly porous silica material within the rice husks and developed a 3-dimensional, highly porous silicon anode material.

The result of the research effort was published in the online edition of the Proceedings of the National Academy of Sciences (PNAS) journal, a world renowned journal in the field of natural sciences.

Silicon has attracted much attention as anode material for next generation lithium ion secondary batteries because it exhibits 3~5 times higher capacity than conventional graphene. The high capacity will pave the way to lithium secondary batteries with higher energy densities than conventional batteries. It is anticipated that the application of silicon batteries will yield electronic devices with a longer duration for use in addition to electronic vehicles boasting longer mileage.

The silicon anode is based on the 3-dimensional, highly porous structure of rice husks which remedies the problematic extreme volume expansion of conventional silicon anodes.

Utilization of inexpensive rice husks to create high value silicon anodes will cause a ripple effect on the industry and academia.

2013.08.23 View 11800

Secondary, High Capacity Battery developed from Rice Husks

Rice husks, a waste product from rice polishing, has been successfully utilized as the silicon anode for use in high capacity lithium ion secondary batteries. The new silicon anode derived from rice husks exhibit superior output and lifespan.

Professor Choi Jang Wook (The Graduate School of Energy, Environment, Water and Sustainability (EEWS)) and Professor Park Seung Min (Department of Biochemistry) and their respective research teams separated naturally occurring, highly porous silica material within the rice husks and developed a 3-dimensional, highly porous silicon anode material.

The result of the research effort was published in the online edition of the Proceedings of the National Academy of Sciences (PNAS) journal, a world renowned journal in the field of natural sciences.

Silicon has attracted much attention as anode material for next generation lithium ion secondary batteries because it exhibits 3~5 times higher capacity than conventional graphene. The high capacity will pave the way to lithium secondary batteries with higher energy densities than conventional batteries. It is anticipated that the application of silicon batteries will yield electronic devices with a longer duration for use in addition to electronic vehicles boasting longer mileage.

The silicon anode is based on the 3-dimensional, highly porous structure of rice husks which remedies the problematic extreme volume expansion of conventional silicon anodes.

Utilization of inexpensive rice husks to create high value silicon anodes will cause a ripple effect on the industry and academia.

2013.08.23 View 11800 -

KAIST unveils foldable micro electric car, Armadillo-T

The small and light electric car completely folds in half when parking, making it a perfect fit for public or private transportation in an urban environment.

Looking for a parking space for hours at a busy shopping mall or being stuck on roads jammed with cars releasing large amounts of carbon dioxide are all-too-familiar scenes for city dwellers.

A group of researchers at the Korea Advanced Institute of Science and Technology (KAIST) recently developed a possible solution to such problems: a foldable, compact electric vehicle that can be utilized either as a personal car or part of the public transit system to connect major transportation routes within a city.

In-Soo Suh, associate professor of the Graduate School for Green Transportation at KAIST, and his research team introduced a prototype micro electric car called "Armadillo-T," whose design is based on a native animal of South America, the armadillo, a placental mammal with a leathery armor shell.

The research team imitated the animal"s distinctive protection characteristic of rolling up into a ball when facing with threat from predators. Just as armadillos hide themselves inside the shell, Armadillo-T tucks its rear body away, shrinking its original size of 2.8 meters (110 inches) down to almost half, 1.65 meters (65 inches), when folding.

Armadillo-T is a four-wheel-drive, all-electric car with two seats and four in-wheel motors. Since the motors are installed inside the wheels, and the 13.6 kWh capacity of lithium-ion battery pack is housed on the front side, the battery and motors do not have to change their positions when the car folds. This not only optimizes the energy efficiency but also provides stability and ample room to drivers and passengers.

Once folded, the small and light (weighs 450 kg) electric vehicle takes up only one-third of a 5-meter parking space, the standard parking size in Korea, allowing three of its kind to be parked. With a smartphone-interfaced remote control on the wheels, the vehicle can turn 360 degrees, enhancing drivers" convenience to park the car, even in an odd space in a parking lot, the corner of a building, for example.

Professor In-Soo Suh said, "I expect that people living in cities will eventually shift their preferences from bulky, petro-engine cars to smaller and lighter electric cars. Armadillo-T can be one of the alternatives city drivers can opt for. Particularly, this car is ideal for urban travels, including car-sharing and transit transfer, to offer major transportation links in a city. In addition to the urban application, local near-distance travels such as tourist zones or large buildings can be another example of application."

The concept car has loads of smart features on board, too: the cameras installed inside the car eliminate the need for side mirrors and increase the driver"s ability to see the car"s right and left side, thereby reducing blind spots. With a smartphone, the driver can control Armadillo-T and enable remote folding control. The car has a maximum speed of 60 km/h, and with a ten-minute fast charge, it can run up to 100 km.

Professor Suh explained that the concept of Armadillo-T was originally initiated in 2011 as he focused his research interest on the sub-A segment of personal mobility vehicles (PMVs), which are smaller and lighter than the current compact cars, as a new personalized transport mode.

"In coming years, we will see more mega-size cities established and face more serious environmental problems. Throughout the world, the aging population is rapidly growing as well. To cope with climate, energy, and limited petroleum resources, we really need to think outside the box, once again, to find more convenient and eco-friendly transportation, just as the Ford Model T did in the early 1920s. A further level of R&D, technical standards, and regulatory reviews are required to have these types of micro vehicles or PMVs on the market through test-bed evaluations, but we believe that Armadillo-T is an icon toward the future transport system with technology innovation."

The research project has been supported by the Korean government, the Ministry of Land, Infrastructure and Transport and the Korea Agency for Infrastructure Technology Advancement, since December 2012.Youtube Link: http://www.youtube.com/watch?v=8DoZH7Y-sR0

2013.08.21 View 16440

KAIST unveils foldable micro electric car, Armadillo-T

The small and light electric car completely folds in half when parking, making it a perfect fit for public or private transportation in an urban environment.

Looking for a parking space for hours at a busy shopping mall or being stuck on roads jammed with cars releasing large amounts of carbon dioxide are all-too-familiar scenes for city dwellers.

A group of researchers at the Korea Advanced Institute of Science and Technology (KAIST) recently developed a possible solution to such problems: a foldable, compact electric vehicle that can be utilized either as a personal car or part of the public transit system to connect major transportation routes within a city.

In-Soo Suh, associate professor of the Graduate School for Green Transportation at KAIST, and his research team introduced a prototype micro electric car called "Armadillo-T," whose design is based on a native animal of South America, the armadillo, a placental mammal with a leathery armor shell.

The research team imitated the animal"s distinctive protection characteristic of rolling up into a ball when facing with threat from predators. Just as armadillos hide themselves inside the shell, Armadillo-T tucks its rear body away, shrinking its original size of 2.8 meters (110 inches) down to almost half, 1.65 meters (65 inches), when folding.

Armadillo-T is a four-wheel-drive, all-electric car with two seats and four in-wheel motors. Since the motors are installed inside the wheels, and the 13.6 kWh capacity of lithium-ion battery pack is housed on the front side, the battery and motors do not have to change their positions when the car folds. This not only optimizes the energy efficiency but also provides stability and ample room to drivers and passengers.

Once folded, the small and light (weighs 450 kg) electric vehicle takes up only one-third of a 5-meter parking space, the standard parking size in Korea, allowing three of its kind to be parked. With a smartphone-interfaced remote control on the wheels, the vehicle can turn 360 degrees, enhancing drivers" convenience to park the car, even in an odd space in a parking lot, the corner of a building, for example.

Professor In-Soo Suh said, "I expect that people living in cities will eventually shift their preferences from bulky, petro-engine cars to smaller and lighter electric cars. Armadillo-T can be one of the alternatives city drivers can opt for. Particularly, this car is ideal for urban travels, including car-sharing and transit transfer, to offer major transportation links in a city. In addition to the urban application, local near-distance travels such as tourist zones or large buildings can be another example of application."

The concept car has loads of smart features on board, too: the cameras installed inside the car eliminate the need for side mirrors and increase the driver"s ability to see the car"s right and left side, thereby reducing blind spots. With a smartphone, the driver can control Armadillo-T and enable remote folding control. The car has a maximum speed of 60 km/h, and with a ten-minute fast charge, it can run up to 100 km.

Professor Suh explained that the concept of Armadillo-T was originally initiated in 2011 as he focused his research interest on the sub-A segment of personal mobility vehicles (PMVs), which are smaller and lighter than the current compact cars, as a new personalized transport mode.

"In coming years, we will see more mega-size cities established and face more serious environmental problems. Throughout the world, the aging population is rapidly growing as well. To cope with climate, energy, and limited petroleum resources, we really need to think outside the box, once again, to find more convenient and eco-friendly transportation, just as the Ford Model T did in the early 1920s. A further level of R&D, technical standards, and regulatory reviews are required to have these types of micro vehicles or PMVs on the market through test-bed evaluations, but we believe that Armadillo-T is an icon toward the future transport system with technology innovation."

The research project has been supported by the Korean government, the Ministry of Land, Infrastructure and Transport and the Korea Agency for Infrastructure Technology Advancement, since December 2012.Youtube Link: http://www.youtube.com/watch?v=8DoZH7Y-sR0

2013.08.21 View 16440 -

2013 International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST)

The International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST) is a global forum organized by KAIST undergraduate students to promote the exchange of ideas and facilitate the discussion of issues that are important to science, technology, society, and higher education. The ICISTS-KAIST conference has been held annually every summer since 2005, inviting distinguished speakers and guests from all around the world to share their insights and expertise with students gathered from Korea and abroad. Last year alone, more than 300 students from 22 nations and 40 speakers participated in the event.

Originally, the ICISTS-KAIST was established by KAIST students who were inspired by the Harvard Project for Asian and International Relations (HPAIR), which is one of the Harvard’s largest annual student conferences in Asia.

This year, 335 students from 103 universities in 22 countries joined the conference that was held on August 5th-9th in Daejeon, making the 2013 ICISTS-KAIST the biggest science and engineering gathering hosted by university students in Asia. About 36% of the participants were international students.

The theme of the conference was “Perfect Alliance: Coexistence for Human Society,” in which students and speakers addressed issues on how to harmonize the speed of scientific progress with the development of important values in society, as well as to explore solutions to overcome the chasm, if any, between the boundaries of science and society.

In his opening remarks, President Steve Kang said, “Creativity and innovation are born out of openness. Therefore, it is essential for young scientists and engineers to communicate with people from different cultural and political backgrounds. Through this kind of global interaction and exchange of ideas and views, students will have an opportunity to deepen their understanding of the world and to better examine the purpose of their intellectual exploration in science and technology.” At the 2013 ICISTS-KAIST, 25 distinguished speakers participated including Walter Bender, a former director of the Media Lab at MIT and David Christian, a professor of Macquarie University in Australia.

2013.08.08 View 11711

2013 International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST)

The International Conference for the Integration of Science, Technology, and Society at KAIST (ICISTS-KAIST) is a global forum organized by KAIST undergraduate students to promote the exchange of ideas and facilitate the discussion of issues that are important to science, technology, society, and higher education. The ICISTS-KAIST conference has been held annually every summer since 2005, inviting distinguished speakers and guests from all around the world to share their insights and expertise with students gathered from Korea and abroad. Last year alone, more than 300 students from 22 nations and 40 speakers participated in the event.

Originally, the ICISTS-KAIST was established by KAIST students who were inspired by the Harvard Project for Asian and International Relations (HPAIR), which is one of the Harvard’s largest annual student conferences in Asia.

This year, 335 students from 103 universities in 22 countries joined the conference that was held on August 5th-9th in Daejeon, making the 2013 ICISTS-KAIST the biggest science and engineering gathering hosted by university students in Asia. About 36% of the participants were international students.

The theme of the conference was “Perfect Alliance: Coexistence for Human Society,” in which students and speakers addressed issues on how to harmonize the speed of scientific progress with the development of important values in society, as well as to explore solutions to overcome the chasm, if any, between the boundaries of science and society.

In his opening remarks, President Steve Kang said, “Creativity and innovation are born out of openness. Therefore, it is essential for young scientists and engineers to communicate with people from different cultural and political backgrounds. Through this kind of global interaction and exchange of ideas and views, students will have an opportunity to deepen their understanding of the world and to better examine the purpose of their intellectual exploration in science and technology.” At the 2013 ICISTS-KAIST, 25 distinguished speakers participated including Walter Bender, a former director of the Media Lab at MIT and David Christian, a professor of Macquarie University in Australia.

2013.08.08 View 11711 -

KAIST's wireless Online Electric Vehicle (OLEV) runs inner city roads

For the first time anywhere, electric buses provide public transportation services and are recharged right from the road.

The Online Electric Vehicle (OLEV), developed by the Korea Advanced Institute of Science and Technology (KAIST), is an electric vehicle that can be charged while stationary or driving, thus removing the need to stop at a charging station. Likewise, an OLEV tram does not require pantographs to feed power from electric wires strung above the tram route.

Following the development and operation of commercialized OLEV trams (at an amusement park in Seoul) and shuttle buses (at KAIST campus), respectively, the City of Gumi in South Korea, beginning on August 6th, is providing its citizens with OLEV public transportation services.

Two OLEV buses will run an inner city route between Gumi Train Station and In-dong district, for a total of 24 km roundtrip. The bus will receive 20 kHz and 100 kW (136 horsepower) electricity at an 85% maximum power transmission efficiency rate while maintaining a 17cm air gap between the underbody of the vehicle and the road surface.

OLEV is a groundbreaking technology that accelerates the development of purely electric vehicles as a viable option for future transportation systems, be they personal vehicles or public transit. This is accomplished by solving technological issues that limit the commercialization of electric vehicles such as price, weight, volume, driving distance, and lack of charging infrastructure.

OLEV receives power wirelessly through the application of the “Shaped Magnetic Field in Resonance (SMFIR)” technology. SMFIR is a new technology introduced by KAIST that enables electric vehicles to transfer electricity wirelessly from the road surface while moving. Power comes from the electrical cables buried under the surface of the road, creating magnetic fields. There is a receiving device installed on the underbody of the OLEV that converts these fields into electricity. The length of power strips installed under the road is generally 5%-15% of the entire road, requiring only a few sections of the road to be rebuilt with the embedded cables.

OLEV has a small battery (one-third of the size of the battery equipped with a regular electric car). The vehicle complies with the international electromagnetic fields (EMF) standards of 62.5 mG, within the margin of safety level necessary for human health. The road has a smart function as well, to distinguish OLEV buses from regular cars—the segment technology is employed to control the power supply by switching on the power strip when OLEV buses pass along, but switching it off for other vehicles, thereby preventing EMF exposure and standby power consumption. As of today, the SMFIR technology supplies 60 kHz and 180 kW of power remotely to transport vehicles at a stable, constant rate.

Dong-Ho Cho, a professor of the electrical engineering and the director of the Center for Wireless Power Transfer Technology Business Development at KAIST, said:

“It’s quite remarkable that we succeeded with the OLEV project so that buses are offering public transportation services to passengers. This is certainly a turning point for OLEV to become more commercialized and widely accepted for mass transportation in our daily living.”

After the successful operation of the two OLEV buses by the end of this year, Gumi City plans to provide ten more such buses by 2015.

2013.08.07 View 26623

KAIST's wireless Online Electric Vehicle (OLEV) runs inner city roads

For the first time anywhere, electric buses provide public transportation services and are recharged right from the road.

The Online Electric Vehicle (OLEV), developed by the Korea Advanced Institute of Science and Technology (KAIST), is an electric vehicle that can be charged while stationary or driving, thus removing the need to stop at a charging station. Likewise, an OLEV tram does not require pantographs to feed power from electric wires strung above the tram route.

Following the development and operation of commercialized OLEV trams (at an amusement park in Seoul) and shuttle buses (at KAIST campus), respectively, the City of Gumi in South Korea, beginning on August 6th, is providing its citizens with OLEV public transportation services.

Two OLEV buses will run an inner city route between Gumi Train Station and In-dong district, for a total of 24 km roundtrip. The bus will receive 20 kHz and 100 kW (136 horsepower) electricity at an 85% maximum power transmission efficiency rate while maintaining a 17cm air gap between the underbody of the vehicle and the road surface.

OLEV is a groundbreaking technology that accelerates the development of purely electric vehicles as a viable option for future transportation systems, be they personal vehicles or public transit. This is accomplished by solving technological issues that limit the commercialization of electric vehicles such as price, weight, volume, driving distance, and lack of charging infrastructure.

OLEV receives power wirelessly through the application of the “Shaped Magnetic Field in Resonance (SMFIR)” technology. SMFIR is a new technology introduced by KAIST that enables electric vehicles to transfer electricity wirelessly from the road surface while moving. Power comes from the electrical cables buried under the surface of the road, creating magnetic fields. There is a receiving device installed on the underbody of the OLEV that converts these fields into electricity. The length of power strips installed under the road is generally 5%-15% of the entire road, requiring only a few sections of the road to be rebuilt with the embedded cables.

OLEV has a small battery (one-third of the size of the battery equipped with a regular electric car). The vehicle complies with the international electromagnetic fields (EMF) standards of 62.5 mG, within the margin of safety level necessary for human health. The road has a smart function as well, to distinguish OLEV buses from regular cars—the segment technology is employed to control the power supply by switching on the power strip when OLEV buses pass along, but switching it off for other vehicles, thereby preventing EMF exposure and standby power consumption. As of today, the SMFIR technology supplies 60 kHz and 180 kW of power remotely to transport vehicles at a stable, constant rate.

Dong-Ho Cho, a professor of the electrical engineering and the director of the Center for Wireless Power Transfer Technology Business Development at KAIST, said:

“It’s quite remarkable that we succeeded with the OLEV project so that buses are offering public transportation services to passengers. This is certainly a turning point for OLEV to become more commercialized and widely accepted for mass transportation in our daily living.”

After the successful operation of the two OLEV buses by the end of this year, Gumi City plans to provide ten more such buses by 2015.

2013.08.07 View 26623 -

High Speed Nanomanufacturing Process Developed using Laser

Dr. Yeo Jun Yeop from KAIST’s Department of Mechanical Engineering, in a joint research project with Prof. Seung Hwan Ko, has developed a technology that speeds up the nanomanufacturing process by using lasers. Their research is published in the frontispiece of Advanced Functional Materials (July 9th issue).

Fig. The frontispiece of Advanced Functional Materials(July 9th issue)

The research group put a nanomaterial precursor on the board, illuminated it with a continuous-wave laser in the green wavelength range, and succeeded in synthesizing a nanowire at the point they wanted for the first time in the world.

Currently nanomaterials are difficult to mass produce and commercialize due to their complex and costly manufacturing processes which also use toxic gases. However, their new technology simplified the process and so reduced the manufacturing time from some hours to five minutes (1/10th times reduced).

Furthermore, this technology will apply regardless of the type of the board. Such nanometerials can be synthesized at any point on a flexible plastic board or even in three dimensional structures by illuminating them with a simple laser. Academics and industries expect mass production and commercialization of nanomaterials in near future.

Dr. Yeo said he intends to research further to promote early commercialization of multifunctional electronic devices by combining various nanomaterials

This research is sponsored by the National Research Foundation of Korea, the Ministry of Trade, Industry and Energy and KAIST EEWS

Fig. A nanomaterial synthesized after illuminated by lasers

Fig. A nanomaterial synthesized on a three dimensional structure using the developed technology

Fig. Functional electron device manufactured by using the synthesized nanomaterials

2013.08.02 View 9965

High Speed Nanomanufacturing Process Developed using Laser

Dr. Yeo Jun Yeop from KAIST’s Department of Mechanical Engineering, in a joint research project with Prof. Seung Hwan Ko, has developed a technology that speeds up the nanomanufacturing process by using lasers. Their research is published in the frontispiece of Advanced Functional Materials (July 9th issue).

Fig. The frontispiece of Advanced Functional Materials(July 9th issue)

The research group put a nanomaterial precursor on the board, illuminated it with a continuous-wave laser in the green wavelength range, and succeeded in synthesizing a nanowire at the point they wanted for the first time in the world.

Currently nanomaterials are difficult to mass produce and commercialize due to their complex and costly manufacturing processes which also use toxic gases. However, their new technology simplified the process and so reduced the manufacturing time from some hours to five minutes (1/10th times reduced).

Furthermore, this technology will apply regardless of the type of the board. Such nanometerials can be synthesized at any point on a flexible plastic board or even in three dimensional structures by illuminating them with a simple laser. Academics and industries expect mass production and commercialization of nanomaterials in near future.

Dr. Yeo said he intends to research further to promote early commercialization of multifunctional electronic devices by combining various nanomaterials

This research is sponsored by the National Research Foundation of Korea, the Ministry of Trade, Industry and Energy and KAIST EEWS

Fig. A nanomaterial synthesized after illuminated by lasers

Fig. A nanomaterial synthesized on a three dimensional structure using the developed technology

Fig. Functional electron device manufactured by using the synthesized nanomaterials

2013.08.02 View 9965 -

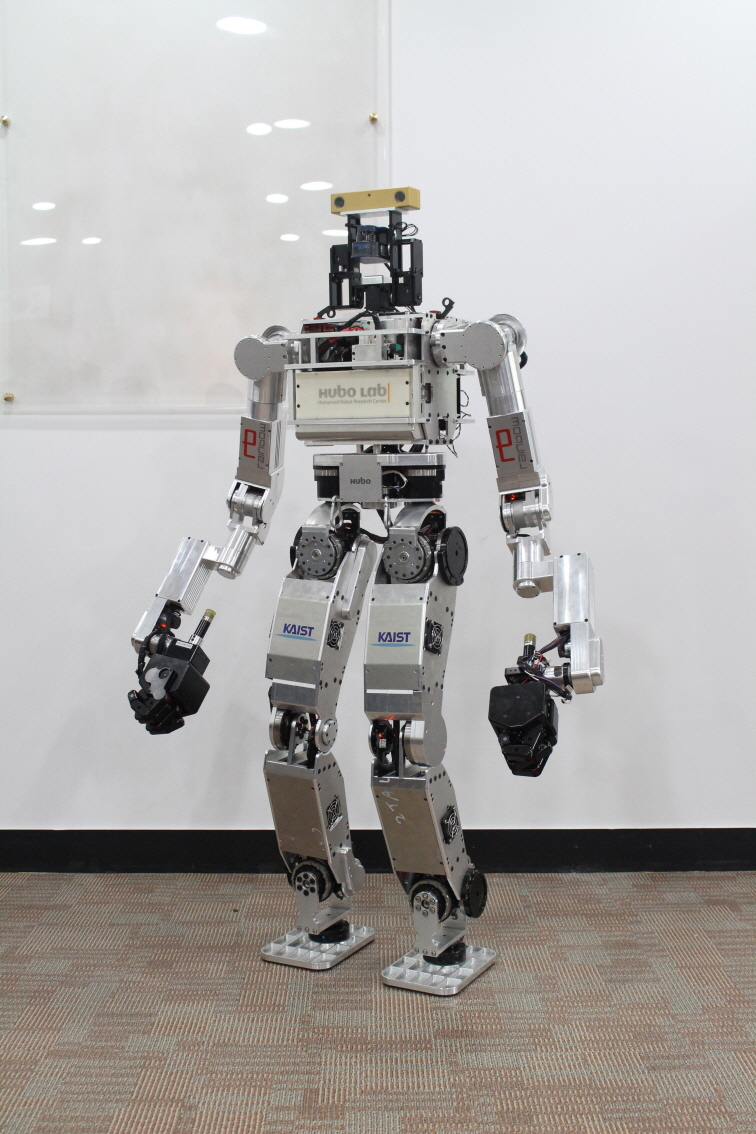

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 15461

KAIST's HUBO Ready for DARPA's Robotics Challenge Trials

When walking on muddy or bumpy roads, the two arms of DRC-HUBO become extra legs, enabling stable and agile movements.

The Humanoid Robot Research Center (HUBO Lab, http://hubolab.kaist.ac.kr) at the Korea Advanced Institute of Science and Technology (KAIST) and Rainbow Co., a spin-off venture company of the university, unveiled a new model of HUBO that will be entered in an international robotics competition scheduled later this year.

The competition is hosted and sponsored by the US Defense Advanced Research Projects Agency (DARPA), which is called the DARPA Robotics Challenge (DRC). Kicked off in October 2012, the DRC’s goal is to spur the development of advanced robots that can assist humans in mitigating and recovering from future natural and man-made disasters.

KAIST’s humanoid robot, HUBO, was originally created by Jun-Ho Oh, a distinguished professor of the Department of Mechanical Engineering, in 2004. Since then, the robot has gone through technological advancements, with the latest version of HUBO II released in 2012. So far, 12 HUBOs have been exported for further studies in robotics to universities, research institutes, and private companies in the US, China, and Singapore.

In tandem with Rainbow Co. (www.rainbow-robot.com), Professor Oh and his research team recently developed DRC-HUBO, which will compete as Team DRC-HUBO led by Drexel University at the DRC trials to be held in December 2013. Team DRC-HUBO is consisted of KAIST and nine US institutions.

DRC-HUBO is designed to perform difficult but essential activities required when responding to disaster scenes. The robot will have to fulfill eight tasks assigned by the DRC at the upcoming event such as driving a utility vehicle, walking across rough terrain, climbing a ladder, and using hand tools.

Unlike the previous models of HUBO, DRC-HUBO boasts several distinctive, enhanced features. Chief among them is the way the robot interacts with the external environment. Without complex sensors installed throughout the body, DRC-HUBO can control each joint of the arms and legs in compliance with the dynamics dictated by the external environment.

For example, when DRC-HUBO is faced with a rock falling from above while climbing up a ladder, the robot’s arms and legs naturally give in to the force of external changes. Accordingly, as the robot dodges the rock, its body and joints smoothly sway to absorb shock so that the fingers can keep a tight grip on the ladder, and the feet are planted firmly on the rail of the ladder, not losing balance.

In addition, DRC-HUBO can switch from bipedal to quadrupedal walking and vice versa. This provides the robot with greater stability to walk on uneven terrain or to climb up a hill. The robot’s arms and legs are elongated to better meet the challenges demanded by the DRC competition. DRC-HUBO’s two arms swing back and forth to form legs when necessary, thereby walking freely backwards and forwards.

The robot has gotten stronger grip as well. The right hand has four fingers (with one triggering finger that operates independently from the other three fingers), and the left hand has three fingers. All three fingers on both hands are actuated synchronously for gripping. The fingers are sophisticated enough to steer the wheel of a vehicle or grab a ladder to climb up, and strong enough to hold 15 lbs in one hand.

“With a full 34 degrees of freedom (DOF), DRC-HUBO stands 4.7 ft tall and weighs 120 lbs. All in all, the robot has been improved and extensively refurbished from the past models of HUBOs to compete at the DRC Trials. It has better vision and coordination. The legs and arms have become stronger,” said Professor Oh.

“Although the robot is still a prototype, it has important capabilities that can be utilized in advancing humanoid robots in general. One example is the way its arms can be used as extra legs to support the robot’s body, offering more flexibility in providing aid to humans.”

2013.07.25 View 15461 -

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

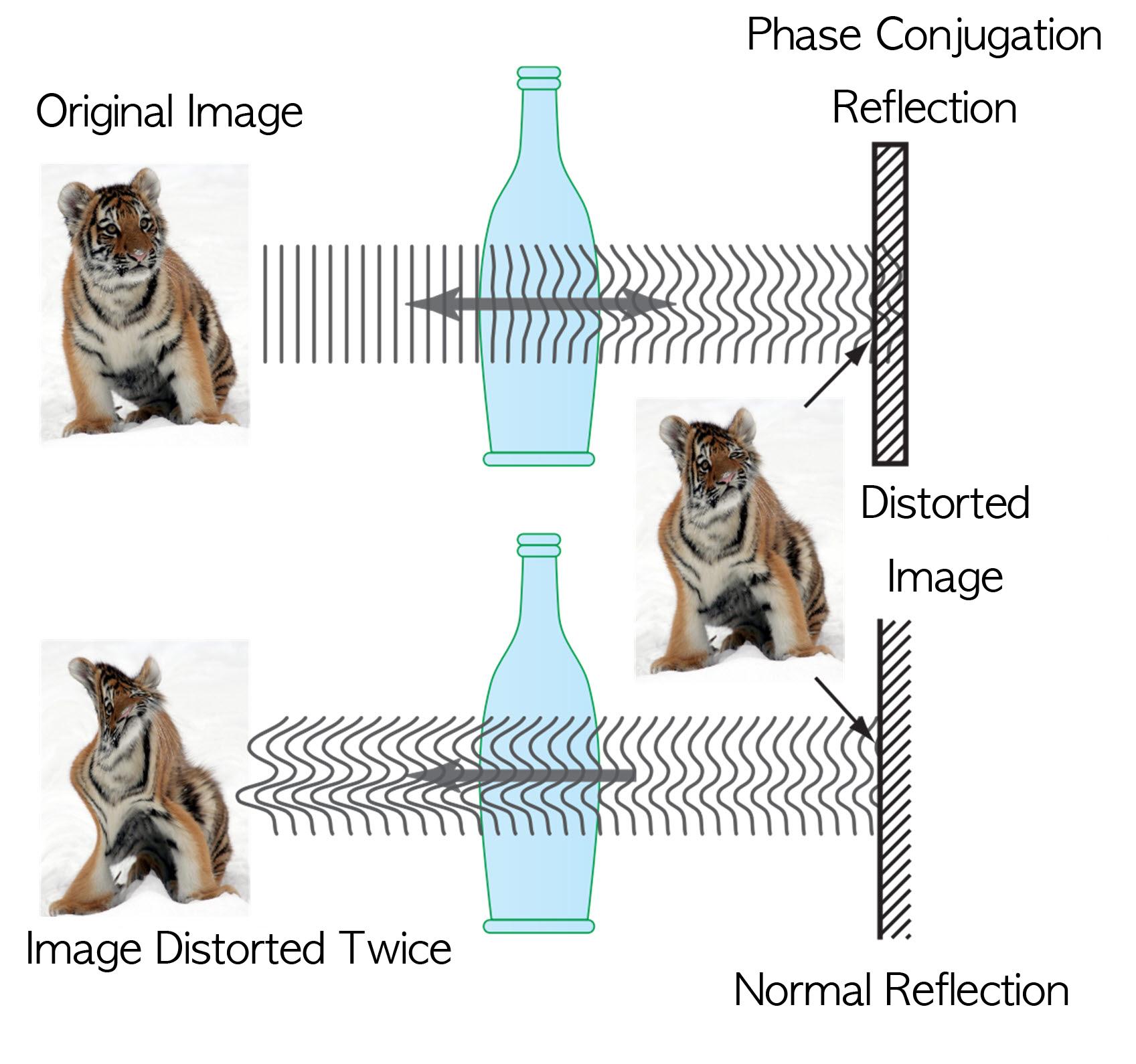

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 9717

Technology Developed to Control Light Scattering Using Holography

Published on May 29th Nature Scientific Reports online

Recently, a popular article demonstrated that an opaque glass becomes transparent as transparent tape is applied to the glass. The scientific principle is that light is less scattered as the rough surface of the opaque glass is filled by transparent tape, thereby making things behind the opaque glass look clearer.

Professor Yong-Keun Park from KAIST’s Department of Physics, in a joint research with MIT Spectroscopy Lab, has developed a technology to easily control light scattering using holography. Their results are published on Nature’s Scientific Reports May 29th online edition.

This technology allows us to see things behind visual obstructions such as cloud and smoke, or even human skin that is highly scattering, optically thick materials. The research team applied the holography technology that records both the direction and intensity of light, and controlled light scattering of obstacles lied between an observer and a target image. The team was able to retrieve the original image by recording the information of scattered light and reflecting the light precisely to the other side.This phenomenon is known as “phase conjugation” in physics. Professor Park’s team applied phase conjugation and digital holography to observe two-dimensional image behind a highly scattering wall. “This technology will be utilized in many fields of physics, optics, nanotechnology, medical science, and even military science,” said Professor Park. “This is different from what is commonly known as penetrating camera or invisible clothes.” He nevertheless drew the line at over-interpreting the technology, “Currently, the significance is on the development of the technology itself that allows us to accurately control the scattering of light."

Figure I. Observed Images

Figure II. Light Scattering Control

2013.07.19 View 9717 -

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 9963

Joint Research Center on EEWS with Hyundai Heavy Industries Plans to Open

The research center will conduct collaborative R&D projects on energy, environment, water, and sustainability for the next five years.Hyundai Heavy Industries (HHI), the world’s largest shipbuilding company, signed an MOU with KAIST for future business development and joint research collaboration.

KAIST and HHI signed an MOU as an agreement to establish the “HHI-KAIST EEWS Research Center (HK Research Center) on June 21st.”

The major mission of the HK Research Center is to build a strong base for creating future businesses through developing fundamental, core technology in the field of EEWS and designing business models based on the new technology.

Toward this goal, HHI will sponsor the R&D budget and operation expenses of the research center for the next five years.

Prior to the signing of the MOU, a delegation from HHI, led by the Vice President, Mr. Si-Young Hwang, visited the Office of EEWS Initiative at KAIST and held a workshop. During the workshop, HHI and KAIST agreed to collaborate in fields such as LNG-propelled ships, solar power generation, energy storage, fuel cells, and CO2 capture.

KAIST has run a EEWS graduate program that receives government grants over the last five years, with a research emphasis on energy, environment, water, and sustainability, which are crucial issues to humankind in the 21st century. The EEWS program achieved 24 core technological developments and educates more than 200 masters- and PhD-degree students annually.

The EEWS program also emphasizes commercializing its research outcomes. Through the annual Business Planning Competition and Investment Drive, there have been eight new companies founded by alumni and professors over the last five years of the program. The HK Research Center will be an excellent foundation for future education and research in EEWS.

Professor Jae-Kyu Lee, the head of the HK Research Center and the director of the EEWS Initiative, said, “This event is a benchmarking example of Industry-KAIST collaboration. We hope that the HK Research Center will be a place for disruptive innovations to translate into creative business opportunities.”

MOU signed for Hyundai Heavy Industries-KAIST EEWS Research Center

2013.07.15 View 9963 -

Foreign graduates donate to development fund for six years

International graduates of the Global IT Technology Graduate School at KAIST have continued a tradition of giving something back to their alma mater.

On May 10th, President Steve Kang held a donation ceremony with 12 donors.

Started in 2008, the graduates, mostly consisted of government officials from developing countries, have raised a development fund for KAIST, and in the past six years, a total of 81 graduates donated USD 10,000.

“KAIST provided me with an excellent education and research environment during my studies. I’m glad that I can have an opportunity to help my juniors and the university,” said Naryn Kenzhaliyev of Kazakhstan, a graduate present at the ceremony.

“Every year, these students voluntarily give when they are about to graduate. We feel proud and greatly appreciated for their philanthropic efforts,” said Professor Jae-Jung Noh, responsible for the global IT technology graduate program.

Established in 2006, the Global IT Technology Graduate School has attracted IT specialists from Korea and abroad, offering master’s and doctoral degrees. The school has invited many public servants in developing countries whose expertise lies in IT technology.

2013.07.04 View 6939

Foreign graduates donate to development fund for six years

International graduates of the Global IT Technology Graduate School at KAIST have continued a tradition of giving something back to their alma mater.

On May 10th, President Steve Kang held a donation ceremony with 12 donors.

Started in 2008, the graduates, mostly consisted of government officials from developing countries, have raised a development fund for KAIST, and in the past six years, a total of 81 graduates donated USD 10,000.

“KAIST provided me with an excellent education and research environment during my studies. I’m glad that I can have an opportunity to help my juniors and the university,” said Naryn Kenzhaliyev of Kazakhstan, a graduate present at the ceremony.

“Every year, these students voluntarily give when they are about to graduate. We feel proud and greatly appreciated for their philanthropic efforts,” said Professor Jae-Jung Noh, responsible for the global IT technology graduate program.

Established in 2006, the Global IT Technology Graduate School has attracted IT specialists from Korea and abroad, offering master’s and doctoral degrees. The school has invited many public servants in developing countries whose expertise lies in IT technology.

2013.07.04 View 6939