EC

-

KAIST introduces microbial food as a strategy food production of the future

The global food crisis is increasing due to rapid population growth and declining food productivity to climate change. Moreover, today's food production and supply system emit a huge amount of carbon dioxide, reaching 30% of the total amount emitted by humanity, aggravating climate change. Sustainable and nutritious microbial food is attracting attention as a key to overcoming this impasse.

KAIST (President Kwang Hyung Lee) announced on April 12th that Research Professor Kyeong Rok Choi of the BioProcess Engineering Research Center and Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering published a paper that proposes a direction of research on ‘microbial food production from sustainable raw materials.’

Microbial food refers to various foods and food ingredients produced using microorganisms. Microbial biomass contains a large amount of protein per unit in dry mass, comparable to that of meat, and emits the smallest amount of carbon dioxide and is required to produce a unit mass compared to various livestock, fish, shellfish, and crops. Since the amount of water and space requirement is small, it can be an eco-friendly, sustainable and highly nutritious food resource.

Fermented foods are the most readily available microbial foods around us. Although the proportion of microbial biomass in fermented foods is small, compounds with relatively low nutritional value, such as carbohydrates, are consumed during the fermentation process, and as microorganisms proliferate, the content of nutrients with higher nutritional value, such as proteins and vitamins, increases.

Various food compounds isolated and purified from biomass or culture media obtained through microbial culture are also a branch of microbial food. Examples that can be found around us include various amino acids, including monosodium glutamate, food proteins, enzymes, flavoring compounds, food colorings, and bioactive substances.

< Figure 1. Schematic diagram portraying various microbial biomass production strategies utlizing sustainable feedstocks >

Lastly, the most ultimate and fundamental form of microbial food can be said to be microbial biomass or extracts produced through microbial culture and foods cooked using them. A representative example is single-cell protein, which collectively refers to microbial biomass or microbial proteins extracted from it.

In this paper, the researchers comprehensively covered various non-edible raw materials and strategies for using them that can be used to produce microbial food in a more sustainable way. Furthermore, it covers various microbial foods that are actually produced in the industry using the relevant raw materials and their characteristics, as well as prospects for the production and generalization of sustainable microbial foods.

Research Professor Kyeong Rok Choi, the first author of this paper, said, “Microbial foods produced from various sustainable raw materials will soon be commonly encountered at our tables.” Second author Seok Yeong Jung, a doctoral student, also said, “Microbial foods of the future will not be limited foods consumed only out of a sense of obligation to the environment, but will be complete foods that are consumed by choice because of their nutritional value and taste.” In addition, Distinguished Professor Sang Yup Lee said, “It is time for the industry and academia, as well as the public and private sectors, to cooperate more closely so that more diverse microbial foods can be developed and supplied in order to create a sustainable society for ourselves and our descendants.”

< Figure 2. Compositions and environmental footprints of animal, plant and microbial biomass. >

This paper was published online on April 9 in ‘Nature Microbiology’ published by Nature.

※ Paper title: From sustainable feedstocks to microbial foods

※ Author information: Kyeong Rok Choi (first author), Seok Yeong Jung (second author) and Sang Yup Lee (corresponding author)

This research was conducted under the development of platform technologies of microbial cell factories for the next-generation biorefineries project (project leader KAIST Distinguished Professor Sang Yup Lee) supported by the Ministry of Science and ICT and the Cooperative Research Program for Agriculture Science and Technology Development (Project leader KAIST Research Professor Kyeong Rok Choi) of the Agricultural Microbiology Project Group (Director, Professor Pahn-Shick Chang) supported by the Rural Development Administration.

2024.04.12 View 7409

KAIST introduces microbial food as a strategy food production of the future

The global food crisis is increasing due to rapid population growth and declining food productivity to climate change. Moreover, today's food production and supply system emit a huge amount of carbon dioxide, reaching 30% of the total amount emitted by humanity, aggravating climate change. Sustainable and nutritious microbial food is attracting attention as a key to overcoming this impasse.

KAIST (President Kwang Hyung Lee) announced on April 12th that Research Professor Kyeong Rok Choi of the BioProcess Engineering Research Center and Distinguished Professor Sang Yup Lee from the Department of Chemical and Biomolecular Engineering published a paper that proposes a direction of research on ‘microbial food production from sustainable raw materials.’

Microbial food refers to various foods and food ingredients produced using microorganisms. Microbial biomass contains a large amount of protein per unit in dry mass, comparable to that of meat, and emits the smallest amount of carbon dioxide and is required to produce a unit mass compared to various livestock, fish, shellfish, and crops. Since the amount of water and space requirement is small, it can be an eco-friendly, sustainable and highly nutritious food resource.

Fermented foods are the most readily available microbial foods around us. Although the proportion of microbial biomass in fermented foods is small, compounds with relatively low nutritional value, such as carbohydrates, are consumed during the fermentation process, and as microorganisms proliferate, the content of nutrients with higher nutritional value, such as proteins and vitamins, increases.

Various food compounds isolated and purified from biomass or culture media obtained through microbial culture are also a branch of microbial food. Examples that can be found around us include various amino acids, including monosodium glutamate, food proteins, enzymes, flavoring compounds, food colorings, and bioactive substances.

< Figure 1. Schematic diagram portraying various microbial biomass production strategies utlizing sustainable feedstocks >

Lastly, the most ultimate and fundamental form of microbial food can be said to be microbial biomass or extracts produced through microbial culture and foods cooked using them. A representative example is single-cell protein, which collectively refers to microbial biomass or microbial proteins extracted from it.

In this paper, the researchers comprehensively covered various non-edible raw materials and strategies for using them that can be used to produce microbial food in a more sustainable way. Furthermore, it covers various microbial foods that are actually produced in the industry using the relevant raw materials and their characteristics, as well as prospects for the production and generalization of sustainable microbial foods.

Research Professor Kyeong Rok Choi, the first author of this paper, said, “Microbial foods produced from various sustainable raw materials will soon be commonly encountered at our tables.” Second author Seok Yeong Jung, a doctoral student, also said, “Microbial foods of the future will not be limited foods consumed only out of a sense of obligation to the environment, but will be complete foods that are consumed by choice because of their nutritional value and taste.” In addition, Distinguished Professor Sang Yup Lee said, “It is time for the industry and academia, as well as the public and private sectors, to cooperate more closely so that more diverse microbial foods can be developed and supplied in order to create a sustainable society for ourselves and our descendants.”

< Figure 2. Compositions and environmental footprints of animal, plant and microbial biomass. >

This paper was published online on April 9 in ‘Nature Microbiology’ published by Nature.

※ Paper title: From sustainable feedstocks to microbial foods

※ Author information: Kyeong Rok Choi (first author), Seok Yeong Jung (second author) and Sang Yup Lee (corresponding author)

This research was conducted under the development of platform technologies of microbial cell factories for the next-generation biorefineries project (project leader KAIST Distinguished Professor Sang Yup Lee) supported by the Ministry of Science and ICT and the Cooperative Research Program for Agriculture Science and Technology Development (Project leader KAIST Research Professor Kyeong Rok Choi) of the Agricultural Microbiology Project Group (Director, Professor Pahn-Shick Chang) supported by the Rural Development Administration.

2024.04.12 View 7409 -

KAIST Develops Healthcare Device Tracking Chronic Diabetic Wounds

A KAIST research team has developed an effective wireless system that monitors the wound healing process by tracking the spatiotemporal temperature changes and heat transfer characteristics of damaged areas such as diabetic wounds.

On the 5th of March, KAIST (represented by President Kwang Hyung Lee) announced that the research team led by Professor Kyeongha Kwon from KAIST’s School of Electrical Engineering, in association with Chung-Ang University professor Hanjun Ryu, developed digital healthcare technology that tracks the wound healing process in real time, which allows appropriate treatments to be administered.

< Figure 1. Schematic illustrations and diagrams of real-time wound monitoring systems. >

The skin serves as a barrier protecting the body from harmful substances, therefore damage to the skin may cause severe health risks to patients in need of intensive care. Especially in the case of diabetic patients, chronic wounds are easily formed due to complications in normal blood circulation and the wound healing process. In the United States alone, hundreds of billions of dollars of medical costs stem from regenerating the skin from such wounds. While various methods exist to promote wound healing, personalized management is essential depending on the condition of each patient's wounds.

Accordingly, the research team tracked the heating response within the wound by utilizing the differences in temperature between the damaged area and the surrounding healthy skin. They then measured heat transfer characteristics to observe moisture changes near the skin surface, ultimately establishing a basis for understanding the formation process of scar tissue. The team conducted experiments using diabetic mice models regarding the delay in wound healing under pathological conditions, and it was demonstrated that the collected data accurately tracks the wound healing process and the formation of scar tissue.

To minimize the tissue damage that may occur in the process of removing the tracking device after healing, the system integrates biodegradable sensor modules capable of natural decomposition within the body. These biodegradable modules disintegrate within the body after use, thus reducing the risk of additional discomfort or tissue damage upon device removal. Furthermore, the device could one day be used for monitoring inside the wound area as there is no need for removal.

Professor Kyeongha Kwon, who led the research, anticipates that continuous monitoring of wound temperature and heat transfer characteristics will enable medical professionals to more accurately assess the status of diabetic patients' wounds and provide appropriate treatment. He further predicted that the implementation of biodegradable sensors allows for the safe decomposition of the device after wound healing without the need for removal, making live monitoring possible not only in hospitals but also at home.

The research team plans to integrate antimicrobial materials into this device, aiming to expand its technological capabilities to enable the observation and prevention of inflammatory responses, bacterial infections, and other complications. The goal is to provide a multi-purpose wound monitoring platform capable of real-time antimicrobial monitoring in hospitals or homes by detecting changes in temperature and heat transfer characteristics indicative of infection levels.

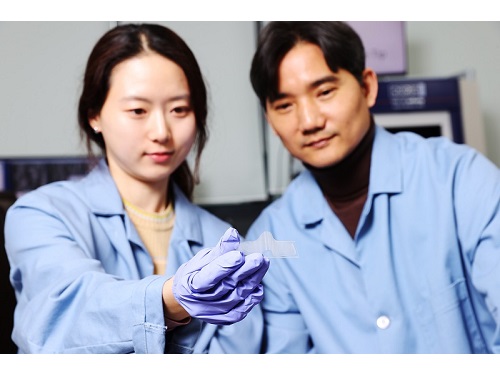

< Image 1. Image of the bioresorbable temperature sensor >

The results of this study were published on February 19th in the international journal Advanced Healthcare Materials and selected as the inside back cover article, titled "Materials and Device Designs for Wireless Monitoring of Temperature and Thermal Transport Properties of Wound Beds during Healing."

This research was conducted with support from the Basic Research Program, the Regional Innovation Center Program, and the BK21 Program.

2024.03.11 View 7246

KAIST Develops Healthcare Device Tracking Chronic Diabetic Wounds

A KAIST research team has developed an effective wireless system that monitors the wound healing process by tracking the spatiotemporal temperature changes and heat transfer characteristics of damaged areas such as diabetic wounds.

On the 5th of March, KAIST (represented by President Kwang Hyung Lee) announced that the research team led by Professor Kyeongha Kwon from KAIST’s School of Electrical Engineering, in association with Chung-Ang University professor Hanjun Ryu, developed digital healthcare technology that tracks the wound healing process in real time, which allows appropriate treatments to be administered.

< Figure 1. Schematic illustrations and diagrams of real-time wound monitoring systems. >

The skin serves as a barrier protecting the body from harmful substances, therefore damage to the skin may cause severe health risks to patients in need of intensive care. Especially in the case of diabetic patients, chronic wounds are easily formed due to complications in normal blood circulation and the wound healing process. In the United States alone, hundreds of billions of dollars of medical costs stem from regenerating the skin from such wounds. While various methods exist to promote wound healing, personalized management is essential depending on the condition of each patient's wounds.

Accordingly, the research team tracked the heating response within the wound by utilizing the differences in temperature between the damaged area and the surrounding healthy skin. They then measured heat transfer characteristics to observe moisture changes near the skin surface, ultimately establishing a basis for understanding the formation process of scar tissue. The team conducted experiments using diabetic mice models regarding the delay in wound healing under pathological conditions, and it was demonstrated that the collected data accurately tracks the wound healing process and the formation of scar tissue.

To minimize the tissue damage that may occur in the process of removing the tracking device after healing, the system integrates biodegradable sensor modules capable of natural decomposition within the body. These biodegradable modules disintegrate within the body after use, thus reducing the risk of additional discomfort or tissue damage upon device removal. Furthermore, the device could one day be used for monitoring inside the wound area as there is no need for removal.

Professor Kyeongha Kwon, who led the research, anticipates that continuous monitoring of wound temperature and heat transfer characteristics will enable medical professionals to more accurately assess the status of diabetic patients' wounds and provide appropriate treatment. He further predicted that the implementation of biodegradable sensors allows for the safe decomposition of the device after wound healing without the need for removal, making live monitoring possible not only in hospitals but also at home.

The research team plans to integrate antimicrobial materials into this device, aiming to expand its technological capabilities to enable the observation and prevention of inflammatory responses, bacterial infections, and other complications. The goal is to provide a multi-purpose wound monitoring platform capable of real-time antimicrobial monitoring in hospitals or homes by detecting changes in temperature and heat transfer characteristics indicative of infection levels.

< Image 1. Image of the bioresorbable temperature sensor >

The results of this study were published on February 19th in the international journal Advanced Healthcare Materials and selected as the inside back cover article, titled "Materials and Device Designs for Wireless Monitoring of Temperature and Thermal Transport Properties of Wound Beds during Healing."

This research was conducted with support from the Basic Research Program, the Regional Innovation Center Program, and the BK21 Program.

2024.03.11 View 7246 -

The World’s First Hacking-preventing Cryptographic Semiconductor Chip

With the dramatic increase in the amount of information exchanged between components or devices in the 5G/6G era, such as for the Internet of Things (IoT) and autonomous driving, hacking attacks are becoming more sophisticated. Consequently, enhancing security functions is essential for safely transmitting data between and among devices.

On February 29th, a KAIST research team led by Professors Yang-gyu Choi and Seung-tak Ryu from the School of Electrical Engineering announced the successful development of the world's first security cryptographic semiconductor.

The team has developed the Cryptoristor, a cryptographic transistor based on FinFET technology, produced through a 100% silicon-compatible process, for the first time in the world. Cryptoristor is a random number generator (RNG) with unparalleled characteristics, featuring a unique structure comprising a single transistor and a distinctive mechanism.

In all security environments, including artificial intelligence, the most crucial element is the RNG. In the most commonly used security chip, the Advanced Encryption Standard (AES), the RNG is a core component, occupying approximately 75% of the total chip area and more than 85% of its energy consumption. Hence, there is an urgent need for the development of low-power/ultra-small RNGs suitable for mobile or IoT devices.

Existing RNGs come with limitations as they lack compatibility with silicon CMOS processes and circuit-based RNGs occupy a large surface area.

In contrast, the team’s newly developed Cryptoristor, a cryptographic semiconductor based on a single-component structure, consumes and occupies less than .001 of the power and area compared to the current chips being used. Utilizing the inherent randomness of FinFETs, fabricated on a Silicon-on-Insulator (SOI) substrate with an insulating layer formed beneath the silicon, the team developed an RNG that unpredictably produces zeroes and ones.

< Figure 1. Conceptual diagram of the security cryptographic transistor device. >

Generally speaking, preventing hackers from predicting the encrypted algorithms during data exchanges through mobile devices is pivotal. Therefore, this method ensures unpredictability by generating random sequences of zeroes and ones that change every time.

Moreover, while the Cryptoristor-based RNG research is the world's first of its kind without any international implementation cases, it shares the same transistor structure as existing logic or memory components. This enables 100% production through rapid mass production processes using existing semiconductor facilities at a low cost.

Seung-il Kim, a PhD student who led the research, explained the significance of the study, stating, "As a cryptographic semiconductor, the ultra-small/low-power random number generator enhances security through its distinctive unpredictability, supporting safe hyperconnectivity with secure transmissions between chips or devices. Particularly, compared to previous research, it offers excellent advantages in terms of energy consumption, integration density, and cost, making it suitable for IoT device environments."

This research, with master’s student Hyung-jin Yoo as the co-author, was officially published in the online edition of Science Advances, a sister journal of Science, in February 2024 (research paper title: Cryptographic transistor for true random number generator with low power consumption).

This research received support from the Next-Generation Intelligent Semiconductor Technology Development Project and the Core Technology Development Project for the National Semiconductor Research Laboratory.

2024.03.07 View 8236

The World’s First Hacking-preventing Cryptographic Semiconductor Chip

With the dramatic increase in the amount of information exchanged between components or devices in the 5G/6G era, such as for the Internet of Things (IoT) and autonomous driving, hacking attacks are becoming more sophisticated. Consequently, enhancing security functions is essential for safely transmitting data between and among devices.

On February 29th, a KAIST research team led by Professors Yang-gyu Choi and Seung-tak Ryu from the School of Electrical Engineering announced the successful development of the world's first security cryptographic semiconductor.

The team has developed the Cryptoristor, a cryptographic transistor based on FinFET technology, produced through a 100% silicon-compatible process, for the first time in the world. Cryptoristor is a random number generator (RNG) with unparalleled characteristics, featuring a unique structure comprising a single transistor and a distinctive mechanism.

In all security environments, including artificial intelligence, the most crucial element is the RNG. In the most commonly used security chip, the Advanced Encryption Standard (AES), the RNG is a core component, occupying approximately 75% of the total chip area and more than 85% of its energy consumption. Hence, there is an urgent need for the development of low-power/ultra-small RNGs suitable for mobile or IoT devices.

Existing RNGs come with limitations as they lack compatibility with silicon CMOS processes and circuit-based RNGs occupy a large surface area.

In contrast, the team’s newly developed Cryptoristor, a cryptographic semiconductor based on a single-component structure, consumes and occupies less than .001 of the power and area compared to the current chips being used. Utilizing the inherent randomness of FinFETs, fabricated on a Silicon-on-Insulator (SOI) substrate with an insulating layer formed beneath the silicon, the team developed an RNG that unpredictably produces zeroes and ones.

< Figure 1. Conceptual diagram of the security cryptographic transistor device. >

Generally speaking, preventing hackers from predicting the encrypted algorithms during data exchanges through mobile devices is pivotal. Therefore, this method ensures unpredictability by generating random sequences of zeroes and ones that change every time.

Moreover, while the Cryptoristor-based RNG research is the world's first of its kind without any international implementation cases, it shares the same transistor structure as existing logic or memory components. This enables 100% production through rapid mass production processes using existing semiconductor facilities at a low cost.

Seung-il Kim, a PhD student who led the research, explained the significance of the study, stating, "As a cryptographic semiconductor, the ultra-small/low-power random number generator enhances security through its distinctive unpredictability, supporting safe hyperconnectivity with secure transmissions between chips or devices. Particularly, compared to previous research, it offers excellent advantages in terms of energy consumption, integration density, and cost, making it suitable for IoT device environments."

This research, with master’s student Hyung-jin Yoo as the co-author, was officially published in the online edition of Science Advances, a sister journal of Science, in February 2024 (research paper title: Cryptographic transistor for true random number generator with low power consumption).

This research received support from the Next-Generation Intelligent Semiconductor Technology Development Project and the Core Technology Development Project for the National Semiconductor Research Laboratory.

2024.03.07 View 8236 -

KAIST Team Develops an Insect-Mimicking Semiconductor to Detect Motion

The recent development of an “intelligent sensor” semiconductor that mimics the optic nerve of insects while operating at ultra-high speeds and low power offers extensive expandability into various innovative technologies. This technology is expected to be applied to various fields including transportation, safety, and security systems, contributing to both industry and society.

On February 19, a KAIST research team led by Professor Kyung Min Kim from the Department of Materials Science and Engineering (DMSE) announced the successful developed an intelligent motion detector by merging various memristor* devices to mimic the visual intelligence** of the optic nerve of insects.

*Memristor: a “memory resistor” whose state of resistance changes depending on the input signal

**Visual intelligence: the ability to interpret visual information and perform calculations within the optic nerve

With the recent advances in AI technology, vision systems are being improved by utilizing AI in various tasks such as image recognition, object detection, and motion analysis. However, existing vision systems typically recognize objects and their behaviour from the received image signals using complex algorithms. This method requires a significant amount of data traffic and higher power consumption, making it difficult to apply in mobile or IoT devices.

Meanwhile, insects are known to be able to effectively process visual information through an optic nerve circuit called the elementary motion detector, allowing them to detect objects and recognize their motion at an advanced level. However, mimicking this pathway using conventional silicon integrated circuit (CMOS) technology requires complex circuits, and its implementation into actual devices has thus been limited.

< Figure 1. Working principle of a biological elementary motion detection system. >

Professor Kyung Min Kim’s research team developed an intelligent motion detecting sensor that operates at a high level of efficiency and ultra-high speeds. The device has a simple structure consisting of only two types of memristors and a resistor developed by the team. The two different memristors each carry out a signal delay function and a signal integration and ignition function, respectively. Through them, the team could directly mimic the optic nerve of insects to analyze object movement.

< Figure 2. (Left) Optical image of the M-EMD device in the left panel (scale bar 200 μm) and SEM image of the device in the right panel (scale bar: 20 μm). (Middle) Responses of the M-EMD in positive direction. (Right) Responses of the M-EMD in negative direction. >

To demonstrate its potential for practical applications, the research team used the newly developed motion detector to design a neuromorphic computing system that can predict the path of a vehicle. The results showed that the device used 92.9% less energy compared to existing technology and predicted motion with more accuracy.

< Figure 3. Neuromorphic computing system configuration based on motion recognition devices >

Professor Kim said, “Insects make use of their very simple visual intelligence systems to detect the motion of objects at a surprising high speed. This research is significant in that we could mimic the functions of a nerve using a memristor device.” He added, “Edge AI devices, such as AI-topped mobile phones, are becoming increasingly important. This research can contribute to the integration of efficient vision systems for motion recognition, so we expect it to be applied to various fields such as autonomous vehicles, vehicle transportation systems, robotics, and machine vision.”

This research, conducted by co-first authors Hanchan Song and Min Gu Lee, both Ph.D. candidates at KAIST DMSE, was published in the online issue of Advanced Materials on January 29.

This research was supported by the Mid-Sized Research Project by the National Research Foundation of Korea, the Next-Generation Intelligent Semiconductor Technology Development Project, the PIM Artificial Intelligence Semiconductor Core Technology Development Project, the National Nano Fab Center, and the Leap Research Project by KAIST.

2024.02.29 View 7463

KAIST Team Develops an Insect-Mimicking Semiconductor to Detect Motion

The recent development of an “intelligent sensor” semiconductor that mimics the optic nerve of insects while operating at ultra-high speeds and low power offers extensive expandability into various innovative technologies. This technology is expected to be applied to various fields including transportation, safety, and security systems, contributing to both industry and society.

On February 19, a KAIST research team led by Professor Kyung Min Kim from the Department of Materials Science and Engineering (DMSE) announced the successful developed an intelligent motion detector by merging various memristor* devices to mimic the visual intelligence** of the optic nerve of insects.

*Memristor: a “memory resistor” whose state of resistance changes depending on the input signal

**Visual intelligence: the ability to interpret visual information and perform calculations within the optic nerve

With the recent advances in AI technology, vision systems are being improved by utilizing AI in various tasks such as image recognition, object detection, and motion analysis. However, existing vision systems typically recognize objects and their behaviour from the received image signals using complex algorithms. This method requires a significant amount of data traffic and higher power consumption, making it difficult to apply in mobile or IoT devices.

Meanwhile, insects are known to be able to effectively process visual information through an optic nerve circuit called the elementary motion detector, allowing them to detect objects and recognize their motion at an advanced level. However, mimicking this pathway using conventional silicon integrated circuit (CMOS) technology requires complex circuits, and its implementation into actual devices has thus been limited.

< Figure 1. Working principle of a biological elementary motion detection system. >

Professor Kyung Min Kim’s research team developed an intelligent motion detecting sensor that operates at a high level of efficiency and ultra-high speeds. The device has a simple structure consisting of only two types of memristors and a resistor developed by the team. The two different memristors each carry out a signal delay function and a signal integration and ignition function, respectively. Through them, the team could directly mimic the optic nerve of insects to analyze object movement.

< Figure 2. (Left) Optical image of the M-EMD device in the left panel (scale bar 200 μm) and SEM image of the device in the right panel (scale bar: 20 μm). (Middle) Responses of the M-EMD in positive direction. (Right) Responses of the M-EMD in negative direction. >

To demonstrate its potential for practical applications, the research team used the newly developed motion detector to design a neuromorphic computing system that can predict the path of a vehicle. The results showed that the device used 92.9% less energy compared to existing technology and predicted motion with more accuracy.

< Figure 3. Neuromorphic computing system configuration based on motion recognition devices >

Professor Kim said, “Insects make use of their very simple visual intelligence systems to detect the motion of objects at a surprising high speed. This research is significant in that we could mimic the functions of a nerve using a memristor device.” He added, “Edge AI devices, such as AI-topped mobile phones, are becoming increasingly important. This research can contribute to the integration of efficient vision systems for motion recognition, so we expect it to be applied to various fields such as autonomous vehicles, vehicle transportation systems, robotics, and machine vision.”

This research, conducted by co-first authors Hanchan Song and Min Gu Lee, both Ph.D. candidates at KAIST DMSE, was published in the online issue of Advanced Materials on January 29.

This research was supported by the Mid-Sized Research Project by the National Research Foundation of Korea, the Next-Generation Intelligent Semiconductor Technology Development Project, the PIM Artificial Intelligence Semiconductor Core Technology Development Project, the National Nano Fab Center, and the Leap Research Project by KAIST.

2024.02.29 View 7463 -

KAIST to begin Joint Research to Develop Next-Generation LiDAR System with Hyundai Motor Group

< (From left) Jong-Soo Lee, Executive Vice President at Hyundai Motor, Sang-Yup Lee, Senior Vice President for Research at KAIST >

The ‘Hyundai Motor Group-KAIST On-Chip LiDAR Joint Research Lab’ was opened at KAIST’s main campus in Daejeon to develop LiDAR sensors for advanced autonomous vehicles.

The joint research lab aims to develop high-performance and compact on-chip sensors and new signal detection technology, which are essential in the increasingly competitive autonomous driving market. On-chip sensors, which utilize semiconductor manufacturing technology to add various functions, can reduce the size of LiDAR systems compared to conventional methods and secure price competitiveness through mass production using semiconductor fabrication processes.

The joint research lab will consist of about 30 researchers, including the Hyundai-Kia Institute of Advanced Technology Development research team and KAIST professors Sanghyeon Kim, Sangsik Kim, Wanyeong Jung, and Hamza Kurt from KAIST’s School of Electrical Engineering, and will operate for four years until 2028.

KAIST will be leading the specialized work of each research team, such as for the development of silicon optoelectronic on-chip LiDAR components, the fabrication of high-speed, high-power integrated circuits to run the LiDAR systems, and the optimization and verification of LiDAR systems.

Hyundai Motor and Kia, together with Hyundai NGV, a specialized industry-academia cooperation institution, will oversee the operation of the joint research lab and provide support such as monitoring technological trends, suggesting research directions, deriving core ideas, and recommending technologies and experts to enhance research capabilities.

A Hyundai Motor Group official said, "We believe that this cooperation between Hyundai Motor Company and Kia, the leader in autonomous driving technology, and KAIST, the home of world-class technology, will hasten the achievement of fully autonomous driving." He added, "We will do our best to enable the lab to produce tangible results.”

Professor Sanghyeon Kim said, "The LiDAR sensor, which serves as the eyes of a car, is a core technology for future autonomous vehicle development that is essential for automobile companies to internalize."

2024.02.27 View 10358

KAIST to begin Joint Research to Develop Next-Generation LiDAR System with Hyundai Motor Group

< (From left) Jong-Soo Lee, Executive Vice President at Hyundai Motor, Sang-Yup Lee, Senior Vice President for Research at KAIST >

The ‘Hyundai Motor Group-KAIST On-Chip LiDAR Joint Research Lab’ was opened at KAIST’s main campus in Daejeon to develop LiDAR sensors for advanced autonomous vehicles.

The joint research lab aims to develop high-performance and compact on-chip sensors and new signal detection technology, which are essential in the increasingly competitive autonomous driving market. On-chip sensors, which utilize semiconductor manufacturing technology to add various functions, can reduce the size of LiDAR systems compared to conventional methods and secure price competitiveness through mass production using semiconductor fabrication processes.

The joint research lab will consist of about 30 researchers, including the Hyundai-Kia Institute of Advanced Technology Development research team and KAIST professors Sanghyeon Kim, Sangsik Kim, Wanyeong Jung, and Hamza Kurt from KAIST’s School of Electrical Engineering, and will operate for four years until 2028.

KAIST will be leading the specialized work of each research team, such as for the development of silicon optoelectronic on-chip LiDAR components, the fabrication of high-speed, high-power integrated circuits to run the LiDAR systems, and the optimization and verification of LiDAR systems.

Hyundai Motor and Kia, together with Hyundai NGV, a specialized industry-academia cooperation institution, will oversee the operation of the joint research lab and provide support such as monitoring technological trends, suggesting research directions, deriving core ideas, and recommending technologies and experts to enhance research capabilities.

A Hyundai Motor Group official said, "We believe that this cooperation between Hyundai Motor Company and Kia, the leader in autonomous driving technology, and KAIST, the home of world-class technology, will hasten the achievement of fully autonomous driving." He added, "We will do our best to enable the lab to produce tangible results.”

Professor Sanghyeon Kim said, "The LiDAR sensor, which serves as the eyes of a car, is a core technology for future autonomous vehicle development that is essential for automobile companies to internalize."

2024.02.27 View 10358 -

A Korean research team develops a new clinical candidate for fatty liver disease

A team of Korean researchers have succeeded in developing a new drug candidate for the treatment of non-alcoholic fatty liver disease (NAFLD) acting on peripheral tissues. To date, there has not been an optimal treatment for non-alcoholic steatohepatitis (NASH), and this discovery is expected to set the grounds for the development of new drugs that can safely suppress both liver fat accumulation and liver fibrosis at the same time.

A joint research team led by Professor Jin Hee Ahn from Gwangju Institute of Science and Technology (GIST) and Professor Hail Kim from the KAIST Graduate School of Medical Science and Engineering developed a new chemical that can suppress disease-specific protein (HTR2A) through years of basic research. The team also revealed to have verified its efficacy and safety through preclinical tests (animal tests) at JD Bioscience Inc., a start-up company founded by Professor Ahn.

Although NAFLD has a prevalence rate as high as 20-30%, and about 5% of the global adult population suffers from NASH, there are no commercial drugs targeting them to date. NAFLD is a chronic disease that starts from the fatty liver and progresses into steatohepatitis, fibrosis, cirrhosis, and liver cancer. The mortality rate of patients increases with accompanied cardiovascular diseases and liver-related complications, and appropriate treatment in the early stage is hence necessary.

< Figure 1. Strategy and history of 5HT2A antagonists. Library and rational design for the development of compound 11c as a potent 5HT2A antagonist. Previous research efforts were discontinued due to limited oral absorption and safety. A therapeutic candidate to overcome this problem was identified and phase 1 clinical trials are currently in progress. >

The new synthetic chemical developed by the joint GIST-KAIST research is an innovative drug candidate that shows therapeutic effects on NASH based on a dual action mechanism that inhibits the accumulation of fat in the liver and liver fibrosis by suppressing the serotonin receptor protein 5HT2A.

The research team confirmed its therapeutic effects in animal models for NAFLD and NASH, in which hepatic steatosis and liver fibrosis* caused by fat accumulation in the liver were suppressed simultaneously by 50-70%.

*fibrosis: stiffening of parts of the liver, also used as a major indicator to track the prognosis of steatosis

The research team explained that the material was designed with optimal polarity and lipid affinity to minimize its permeability across the blood-brain barrier. It therefore does not affect the brain, and causes little side effects in the central nervous system (CNS) such as depression and suicidal ideations, while demonstrating excellent inhibition on its target protein present in tissues outside brain (IC50* = 14 nM). The team also demonstrated its superior efficacy in improving liver fibrosis when compared to similar drugs in the phase 3 clinical trial.

*IC50 (half maximal inhibitory concentration): the concentration at which a chemical suppresses 50% of a particular biological function

< Figure 2. GM-60106 (11c)'s effect on obesity: When GM-60106 was administered to an obese animal model (mice) for 2 months, body weight, body fat mass, and blood sugar were significantly reduced (a-d). In addition, the steatohepatitis level (NAFLD Activity Score) and the expression of genes of the treated mice involved in adipogenesis along with blood/liver fat decreased (e-h) >

Based on the pharmacological data obtained through preclinical trials, the team evaluated the effects of the drug on 88 healthy adults as part of their phase 1 clinical trial, where the side effects and the safe dosage of a drug are tested against healthy adults. Results showed no serious side effects and a good level of drug safety.

In addition, a preliminary efficacy evaluation on eight adults with steatohepatitis is currently underway.

Professor Jin Hee Ahn said, “The aim of this research is to develop a treatment for NASH with little side effects and guaranteed safety by developing a new target. The developed chemical is currently going through phase 1 of the global clinical trial in Australia through JD Bioscience Inc., a bio venture company for innovative drug development.” he added, “The candidate material the research team is currently developing shows not only a high level of safety and preventative effects by suppressing fat accumulation in the liver, but also a direct therapeutic effect on liver fibrosis. This is a strength that distinguishes our material from other competing drugs.”

< Figure 3. Efficacy of GM-60106 (11c) on liver fibrosis: When GM-60106 was administered to a steatohepatitis model (mice) for 3 months, the expression of genes associated with tissue fibrosis was significantly reduced (b-c). As a result of a detailed analysis of the tissues of the animal model, it was confirmed that the rate of tissue fibrosis was reduced and the expression rate of genes related to tissue fibrosis and inflammation was also significantly reduced (e-h). >

Professor Hail Kim from KAIST said, “Until now, this disease did not have a method of treatment other than weight control, and there has been no attempt to develop a drug that can be used for non-obese patients.” He added, “Through this research, we look forward to the development of various treatment techniques targeting a range of metabolic diseases including NASH that do not affect the weight of the patient.”

This study, conducted together by the research teams led by Professor Ahn from GIST and Professor Kim from KAIST, as well as the research team from JD Bioscience Inc., was supported by the Ministry of Science and ICT, and the National New Drug Development Project. The results of this research were published by Nature Communications on January 20.

The team also presented the results of their clinical study on the candidate material coded GM-60106 targeting metabolic abnormality-related MASH* at NASH-TAG Conference 2024, which was held in Utah for three days starting on January 4, which was selected as an excellent abstract.

*MASH (Metabolic Dysfunction-Associated Steatohepatitis): new replacement term for NASH

2024.02.21 View 8988

A Korean research team develops a new clinical candidate for fatty liver disease

A team of Korean researchers have succeeded in developing a new drug candidate for the treatment of non-alcoholic fatty liver disease (NAFLD) acting on peripheral tissues. To date, there has not been an optimal treatment for non-alcoholic steatohepatitis (NASH), and this discovery is expected to set the grounds for the development of new drugs that can safely suppress both liver fat accumulation and liver fibrosis at the same time.

A joint research team led by Professor Jin Hee Ahn from Gwangju Institute of Science and Technology (GIST) and Professor Hail Kim from the KAIST Graduate School of Medical Science and Engineering developed a new chemical that can suppress disease-specific protein (HTR2A) through years of basic research. The team also revealed to have verified its efficacy and safety through preclinical tests (animal tests) at JD Bioscience Inc., a start-up company founded by Professor Ahn.

Although NAFLD has a prevalence rate as high as 20-30%, and about 5% of the global adult population suffers from NASH, there are no commercial drugs targeting them to date. NAFLD is a chronic disease that starts from the fatty liver and progresses into steatohepatitis, fibrosis, cirrhosis, and liver cancer. The mortality rate of patients increases with accompanied cardiovascular diseases and liver-related complications, and appropriate treatment in the early stage is hence necessary.

< Figure 1. Strategy and history of 5HT2A antagonists. Library and rational design for the development of compound 11c as a potent 5HT2A antagonist. Previous research efforts were discontinued due to limited oral absorption and safety. A therapeutic candidate to overcome this problem was identified and phase 1 clinical trials are currently in progress. >

The new synthetic chemical developed by the joint GIST-KAIST research is an innovative drug candidate that shows therapeutic effects on NASH based on a dual action mechanism that inhibits the accumulation of fat in the liver and liver fibrosis by suppressing the serotonin receptor protein 5HT2A.

The research team confirmed its therapeutic effects in animal models for NAFLD and NASH, in which hepatic steatosis and liver fibrosis* caused by fat accumulation in the liver were suppressed simultaneously by 50-70%.

*fibrosis: stiffening of parts of the liver, also used as a major indicator to track the prognosis of steatosis

The research team explained that the material was designed with optimal polarity and lipid affinity to minimize its permeability across the blood-brain barrier. It therefore does not affect the brain, and causes little side effects in the central nervous system (CNS) such as depression and suicidal ideations, while demonstrating excellent inhibition on its target protein present in tissues outside brain (IC50* = 14 nM). The team also demonstrated its superior efficacy in improving liver fibrosis when compared to similar drugs in the phase 3 clinical trial.

*IC50 (half maximal inhibitory concentration): the concentration at which a chemical suppresses 50% of a particular biological function

< Figure 2. GM-60106 (11c)'s effect on obesity: When GM-60106 was administered to an obese animal model (mice) for 2 months, body weight, body fat mass, and blood sugar were significantly reduced (a-d). In addition, the steatohepatitis level (NAFLD Activity Score) and the expression of genes of the treated mice involved in adipogenesis along with blood/liver fat decreased (e-h) >

Based on the pharmacological data obtained through preclinical trials, the team evaluated the effects of the drug on 88 healthy adults as part of their phase 1 clinical trial, where the side effects and the safe dosage of a drug are tested against healthy adults. Results showed no serious side effects and a good level of drug safety.

In addition, a preliminary efficacy evaluation on eight adults with steatohepatitis is currently underway.

Professor Jin Hee Ahn said, “The aim of this research is to develop a treatment for NASH with little side effects and guaranteed safety by developing a new target. The developed chemical is currently going through phase 1 of the global clinical trial in Australia through JD Bioscience Inc., a bio venture company for innovative drug development.” he added, “The candidate material the research team is currently developing shows not only a high level of safety and preventative effects by suppressing fat accumulation in the liver, but also a direct therapeutic effect on liver fibrosis. This is a strength that distinguishes our material from other competing drugs.”

< Figure 3. Efficacy of GM-60106 (11c) on liver fibrosis: When GM-60106 was administered to a steatohepatitis model (mice) for 3 months, the expression of genes associated with tissue fibrosis was significantly reduced (b-c). As a result of a detailed analysis of the tissues of the animal model, it was confirmed that the rate of tissue fibrosis was reduced and the expression rate of genes related to tissue fibrosis and inflammation was also significantly reduced (e-h). >

Professor Hail Kim from KAIST said, “Until now, this disease did not have a method of treatment other than weight control, and there has been no attempt to develop a drug that can be used for non-obese patients.” He added, “Through this research, we look forward to the development of various treatment techniques targeting a range of metabolic diseases including NASH that do not affect the weight of the patient.”

This study, conducted together by the research teams led by Professor Ahn from GIST and Professor Kim from KAIST, as well as the research team from JD Bioscience Inc., was supported by the Ministry of Science and ICT, and the National New Drug Development Project. The results of this research were published by Nature Communications on January 20.

The team also presented the results of their clinical study on the candidate material coded GM-60106 targeting metabolic abnormality-related MASH* at NASH-TAG Conference 2024, which was held in Utah for three days starting on January 4, which was selected as an excellent abstract.

*MASH (Metabolic Dysfunction-Associated Steatohepatitis): new replacement term for NASH

2024.02.21 View 8988 -

World-renowned Soprano Sumi Jo and Broadcom CEO Hock Tan awarded honorary doctorate from KAIST

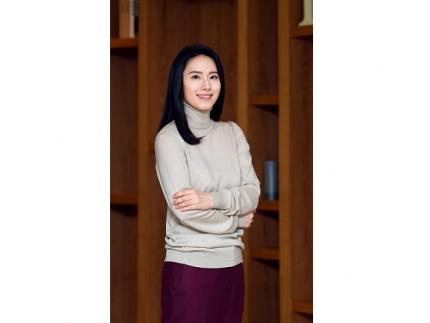

< (From left) Sumi Jo, Distinguished Visiting Professor at the Graduate School of Culture and Technology, and Broadcom President and CEO Hock Tan >

KAIST (President Kwang-Hyung Lee) announced that it awarded honorary doctorates to world-renowned soprano Sumi Jo, a distinguished visiting professor at the Graduate School of Culture and Technology, and the President and Chief Executive Officer of Broadcom Inc., Hock Tan, at the graduation ceremony held on the 16th of February, 2024.

Professor Sumi Jo, who received an honorary doctorate in science and technology, was appointed as a visiting professor at KAIST Graduate School of Culture and Technology in 2021 and established the "Sumi Jo Performing Arts Research Center" and have been involved in research providing valuable feedback on projects to put on stage performances utilizing AI-orchestrated musical ensemble technology and research on virtual voices using vocal synthesis technology, as well as participating in the demonstration of the technological performance showcased at KAIST. Also, she held a special lecture and a talk concert for KAIST students, sharing her experience as a celebrated soprano on the world stage and having honest conversations with students.

KAIST said, “The doctorate is being awarded in recognition of her contributions that is broadening the spectrum of research in the field of science and technology to lead the digital era by suggesting a direction for future

science and technology to take led by culture. Also, her significant contribution to promoting necessary internationalization capabilities helps KAIST as it is growing into a world-class university through new academic challenges.”

< Professor Sumi Jo (left), who received an honorary doctorate in science and technology, and President Kwang-Hyung Lee >

Professor Sumi Jo, who debuted as Gilda in the opera in 1986, has performed with world-class conductors such as Herbert von Karajan, Georg Solti, Zubin Mehta, and James Levine. She has released over 40 full-length albums and continues to excel in all areas of vocal performances, including film scores, songs, and musicals.

Professor Sumi Jo said, “When I received a proposal from President Kwang-Hyung Lee of KAIST to convey what I experienced and felt on the world stage to students of science at KAIST under the topic of ‘Music and My Life,’ questions started to swirl inside of me.”

She continued, “Singing on stage is about ‘expressing,’ and it is a comprehensive artistic process that unfolding the artist’s inner self (expression) and showing it (presentation) in a way that the audience can best feel it through

methods such as sound, lighting, and directing. And I realized that, I was singing all my life in an environment where science and technology coexisted with culture and art.”

“When I worked with the students here at KAIST, I came to realize that when scientific and technologically talented people are set free to really enjoy their ideas and explore them on their own terms, their insight become sharper and their creativity become richer,” she said. She went on to add, “I am proud to be able to join the graduates at the ceremony and would like to express my gratitude for awarding me the honorary doctorate.”

< (From left) President Hock Tan, who received the honorary doctorate in engineering, Mrs. Lya Trung Tan, and President Kwang-Hyung Lee >

Hock Tan received an honorary doctorate in engineering. He is a highly successful businessman who demonstrated entrepreneurship based on a profound understanding of science and technology, which transformed Broadcom into a global enterprise in technology that provides semiconductor and software solutions.

Broadcom has achieved advancement and technological innovation in the semiconductor industry tailored to computer and telecommunication networks, and is evaluated as having played a major role in bringing about the digital transformation movement that is now encompassing the global communities.

Tan attributes the secret to his success to ‘the considerate decision made by the university to award him the scholarship which enabled him to pursue his degree’ and ‘the great team members working with him’..’ Also, he is well-known as a person who considers giving back to society his most important mission.

To support effective medical treatment and identification of the cause of autism, Tan has made large donations to MIT and Harvard University since 2017 several times, and during the COVID-19 pandemic, he reinforced his support to improve the treatment of workers at community medical institutions and non-profit organizations. He also founded the Broadcom Foundation, which supports science, technology, engineering, and mathematics (STEM) education programs for students in and outside the United States.

KAIST said, “We are awarding CEO Hock Tan the honorary doctorate in recognition of his contribution to KAIST’s emergence as a world-class university, as he emphasized the importance of convergence research and

internationalization of KAIST during his time serving as an overseas member of the KAIST President's Advisory Council from 2006 to 2013, while providing policy advices built on his experiences of innovations from various parts around the world.”

Tan emphasized, “KAIST has been vital to Korea’s advancement in the global economy. (KAIST) remains a source of technological innovation,” and that, “It is truly an honor to be recognized by an institution with such a distinguished record of excellence in science, engineering and research.”

President Kwang-Hyung Lee said, “Professor Sumi Jo’s exploration into the future of performing arts through science and technology helps to expand KAIST’s scope and enhance our creative capabilities, while the dedication and humane efforts Hock Tan demonstrates as he contributes to digital innovation through corporate management and engages in various social contribution activities serves as a superb example to all members of KAIST.”

He continued, “These two have lived out the values of challenge and innovation and became examples for many, and we are very pleased to welcome them as the newest members of the KAIST family. On behalf of all members of KAIST, I deliver our sincere congratulations.”

2024.02.17 View 10787

World-renowned Soprano Sumi Jo and Broadcom CEO Hock Tan awarded honorary doctorate from KAIST

< (From left) Sumi Jo, Distinguished Visiting Professor at the Graduate School of Culture and Technology, and Broadcom President and CEO Hock Tan >

KAIST (President Kwang-Hyung Lee) announced that it awarded honorary doctorates to world-renowned soprano Sumi Jo, a distinguished visiting professor at the Graduate School of Culture and Technology, and the President and Chief Executive Officer of Broadcom Inc., Hock Tan, at the graduation ceremony held on the 16th of February, 2024.

Professor Sumi Jo, who received an honorary doctorate in science and technology, was appointed as a visiting professor at KAIST Graduate School of Culture and Technology in 2021 and established the "Sumi Jo Performing Arts Research Center" and have been involved in research providing valuable feedback on projects to put on stage performances utilizing AI-orchestrated musical ensemble technology and research on virtual voices using vocal synthesis technology, as well as participating in the demonstration of the technological performance showcased at KAIST. Also, she held a special lecture and a talk concert for KAIST students, sharing her experience as a celebrated soprano on the world stage and having honest conversations with students.

KAIST said, “The doctorate is being awarded in recognition of her contributions that is broadening the spectrum of research in the field of science and technology to lead the digital era by suggesting a direction for future

science and technology to take led by culture. Also, her significant contribution to promoting necessary internationalization capabilities helps KAIST as it is growing into a world-class university through new academic challenges.”

< Professor Sumi Jo (left), who received an honorary doctorate in science and technology, and President Kwang-Hyung Lee >

Professor Sumi Jo, who debuted as Gilda in the opera in 1986, has performed with world-class conductors such as Herbert von Karajan, Georg Solti, Zubin Mehta, and James Levine. She has released over 40 full-length albums and continues to excel in all areas of vocal performances, including film scores, songs, and musicals.

Professor Sumi Jo said, “When I received a proposal from President Kwang-Hyung Lee of KAIST to convey what I experienced and felt on the world stage to students of science at KAIST under the topic of ‘Music and My Life,’ questions started to swirl inside of me.”

She continued, “Singing on stage is about ‘expressing,’ and it is a comprehensive artistic process that unfolding the artist’s inner self (expression) and showing it (presentation) in a way that the audience can best feel it through

methods such as sound, lighting, and directing. And I realized that, I was singing all my life in an environment where science and technology coexisted with culture and art.”

“When I worked with the students here at KAIST, I came to realize that when scientific and technologically talented people are set free to really enjoy their ideas and explore them on their own terms, their insight become sharper and their creativity become richer,” she said. She went on to add, “I am proud to be able to join the graduates at the ceremony and would like to express my gratitude for awarding me the honorary doctorate.”

< (From left) President Hock Tan, who received the honorary doctorate in engineering, Mrs. Lya Trung Tan, and President Kwang-Hyung Lee >

Hock Tan received an honorary doctorate in engineering. He is a highly successful businessman who demonstrated entrepreneurship based on a profound understanding of science and technology, which transformed Broadcom into a global enterprise in technology that provides semiconductor and software solutions.

Broadcom has achieved advancement and technological innovation in the semiconductor industry tailored to computer and telecommunication networks, and is evaluated as having played a major role in bringing about the digital transformation movement that is now encompassing the global communities.

Tan attributes the secret to his success to ‘the considerate decision made by the university to award him the scholarship which enabled him to pursue his degree’ and ‘the great team members working with him’..’ Also, he is well-known as a person who considers giving back to society his most important mission.

To support effective medical treatment and identification of the cause of autism, Tan has made large donations to MIT and Harvard University since 2017 several times, and during the COVID-19 pandemic, he reinforced his support to improve the treatment of workers at community medical institutions and non-profit organizations. He also founded the Broadcom Foundation, which supports science, technology, engineering, and mathematics (STEM) education programs for students in and outside the United States.

KAIST said, “We are awarding CEO Hock Tan the honorary doctorate in recognition of his contribution to KAIST’s emergence as a world-class university, as he emphasized the importance of convergence research and

internationalization of KAIST during his time serving as an overseas member of the KAIST President's Advisory Council from 2006 to 2013, while providing policy advices built on his experiences of innovations from various parts around the world.”

Tan emphasized, “KAIST has been vital to Korea’s advancement in the global economy. (KAIST) remains a source of technological innovation,” and that, “It is truly an honor to be recognized by an institution with such a distinguished record of excellence in science, engineering and research.”

President Kwang-Hyung Lee said, “Professor Sumi Jo’s exploration into the future of performing arts through science and technology helps to expand KAIST’s scope and enhance our creative capabilities, while the dedication and humane efforts Hock Tan demonstrates as he contributes to digital innovation through corporate management and engages in various social contribution activities serves as a superb example to all members of KAIST.”

He continued, “These two have lived out the values of challenge and innovation and became examples for many, and we are very pleased to welcome them as the newest members of the KAIST family. On behalf of all members of KAIST, I deliver our sincere congratulations.”

2024.02.17 View 10787 -

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 7901

A KAIST Research Team Develops a Novel “Bone Bandage” Material for Cracked Bones

Bone regeneration is a complex process, and existing methods to aid regeneration including transplants and growth factor transmissions face limitations such as the high cost. But recently, a piezoelectric material that can promote the growth of bone tissue has been developed.

A KAIST research team led by Professor Seungbum Hong from the Department of Materials Science and Engineering (DMSE) announced on January 25 the development of a biomimetic scaffold that generates electrical signals upon the application of pressure by utilizing the unique osteogenic ability of hydroxyapatite (HAp). This research was conducted in collaboration with a team led by Professor Jangho Kim from the Department of Convergence Biosystems Engineering at Chonnam National University.

HAp is a basic calcium phosphate material found in bones and teeth. This biocompatible mineral substance is also known to prevent tooth decay and is often used in toothpaste.

Previous studies on piezoelectric scaffolds confirmed the effects of piezoelectricity on promoting bone regeneration and improving bone fusion in various polymer-based materials, but were limited in simulating the complex cellular environment required for optimal bone tissue regeneration. However, this research suggests a new method for utilizing the unique osteogenic abilities of HAp to develop a material that mimics the environment for bone tissue in a living body.

< Figure 1. Design and characterization of piezoelectrically and topographically originated biomimetic scaffolds. (a) Schematic representation of the enhanced bone regeneration mechanism through electrical and topographical cues provided by HAp-incorporated P(VDF-TrFE) scaffolds. (b) Schematic diagram of the fabrication process. >

The research team developed a manufacturing process that fuses HAp with a polymer film. The flexible and free-standing scaffold developed through this process demonstrated its remarkable potential for promoting bone regeneration through in-vitro and in-vivo experiments in rats.

The team also identified the principles of bone regeneration that their scaffold is based on. Using atomic force microscopy (AFM), they analysed the electrical properties of the scaffold and evaluated the detailed surface properties related to cell shape and cell skeletal protein formation. They also investigated the effects of piezoelectricity and surface properties on the expression of growth factors.

Professor Hong from KAIST’s DMSE said, “We have developed a HAp-based piezoelectric composite material that can act like a ‘bone bandage’ through its ability to accelerate bone regeneration.” He added, “This research not only suggests a new direction for designing biomaterials, but is also significant in having explored the effects of piezoelectricity and surface properties on bone regeneration.”

This research, conducted by co-first authors Soyun Joo and Soyeon Kim from Professor Hong’s group, was published on ACS Applied Materials & Interfaces on January 4 under the title “Piezoelectrically and Topographically Engineered Scaffolds for Accelerating Bone Regeneration”. From Professor Kim’s group, Ph.D. candidate Yonghyun Gwon also participated as co-first author, and Professor Kim himself as a corresponding author.

< Figure 2. Analysis of piezoelectric and surface properties of the biomimetic scaffolds using atomic force microscopy. (a) PFM amplitude and phase images of box-poled composite scaffolds. The white bar represents 2 μm. (b) 3D representations of composite scaffolds paired with typical 2D line sections. (c) In vivo bone regeneration micro-CT analysis, (d) schematic representation of filler-derived electrical origins in bone regeneration. >

This research was supported by the KAIST Research and Development Team, the KUSTAR-KAIST Joint Research Center, the KAIST Global Singularity Project, and the government-funded Basic Research Project by the National Research Foundation of Korea.

2024.02.01 View 7901 -

KAIST Research Team Develops Sweat-Resistant Wearable Robot Sensor

New electromyography (EMG) sensor technology that allows the long-term stable control of wearable robots and is not affected by the wearer’s sweat and dead skin has gained attention recently. Wearable robots are devices used across a variety of rehabilitation treatments for the elderly and patients recovering from stroke or trauma.

A joint research team led by Professor Jae-Woong Jung from the KAIST School of Electrical Engineering (EE) and Professor Jung Kim from the KAIST Department of Mechanical Engineering (ME) announced on January 23rd that they have successfully developed a stretchable and adhesive microneedle sensor that can electrically sense physiological signals at a high level without being affected by the state of the user’s skin.

For wearable robots to recognize the intentions behind human movement for their use in rehabilitation treatment, they require a wearable electrophysiological sensor that gives precise EMG measurements. However, existing sensors often show deteriorating signal quality over time and are greatly affected by the user’s skin conditions. Furthermore, the sensor’s higher mechanical hardness causes noise since the contact surface is unable to keep up with the deformation of the skin. These shortcomings limit the reliable, long-term control of wearable robots.

< Figure 1. Design and working concept of the Stretchable microNeedle Adhesive Patch (SNAP). (A) Schematic illustration showing the overall system configuration and application of SNAP. (B) Exploded view schematic diagram of a SNAP, consisting of stretchable serpentine interconnects, Au-coated Si microneedle, and ECA made of Ag flakes–silicone composite. (C) Optical images showing high mechanical compliance of SNAP. >

However, the recently developed technology is expected to allow long-term and high-quality EMG measurements as it uses a stretchable and adhesive conducting substrate integrated with microneedle arrays that can easily penetrate the stratum corneum without causing discomfort. Through its excellent performance, the sensor is anticipated to be able to stably control wearable robots over a long period of time regardless of the wearer’s changing skin conditions and without the need for a preparation step that removes sweat and dead cells from the surface of their skin.

The research team created a stretchable and adhesive microneedle sensor by integrating microneedles into a soft silicon polymer substrate. The hard microneedles penetrate through the stratum corneum, which has high electrical resistance. As a result, the sensor can effectively lower contact resistance with the skin and obtain high-quality electrophysiological signals regardless of contamination. At the same time, the soft and adhesive conducting substrate can adapt to the skin’s surface that stretches with the wearer’s movement, providing a comfortable fit and minimizing noise caused by movement.

< Figure 2. Demonstration of the wireless Stretchable microNeedle Adhesive Patch (SNAP) system as an Human-machine interfaces (HMI) for closed-loop control of an exoskeleton robot. (A) Illustration depicting the system architecture and control strategy of an exoskeleton robot. (B) The hardware configuration of the pneumatic back support exoskeleton system. (C) Comparison of root mean square (RMS) of electromyography (EMG) with and without robotic assistance of pretreated skin and non-pretreated skin. >

To verify the usability of the new patch, the research team conducted a motion assistance experiment using a wearable robot. They attached the microneedle patch on a user’s leg, where it could sense the electrical signals generated by the muscle. The sensor then sent the detected intention to a wearable robot, allowing the robot to help the wearer lift a heavy object more easily.

Professor Jae-Woong Jung, who led the research, said, “The developed stretchable and adhesive microneedle sensor can stability detect EMG signals without being affected by the state of a user’s skin. Through this, we will be able to control wearable robots with higher precision and stability, which will help the rehabilitation of patients who use robots.”

The results of this research, written by co-first authors Heesoo Kim and Juhyun Lee, who are both Ph.D. candidates in the KAIST School of EE, were published in Science Advances on January 17th under the title “Skin-preparation-free, stretchable microneedle adhesive patches for reliable electrophysiological sensing and exoskeleton robot control”.

This research was supported by the Bio-signal Sensor Integrated Technology Development Project by the National Research Foundation of Korea, the Electronic Medicinal Technology Development Project, and the Step 4 BK21 Project.

2024.01.30 View 8126

KAIST Research Team Develops Sweat-Resistant Wearable Robot Sensor

New electromyography (EMG) sensor technology that allows the long-term stable control of wearable robots and is not affected by the wearer’s sweat and dead skin has gained attention recently. Wearable robots are devices used across a variety of rehabilitation treatments for the elderly and patients recovering from stroke or trauma.

A joint research team led by Professor Jae-Woong Jung from the KAIST School of Electrical Engineering (EE) and Professor Jung Kim from the KAIST Department of Mechanical Engineering (ME) announced on January 23rd that they have successfully developed a stretchable and adhesive microneedle sensor that can electrically sense physiological signals at a high level without being affected by the state of the user’s skin.

For wearable robots to recognize the intentions behind human movement for their use in rehabilitation treatment, they require a wearable electrophysiological sensor that gives precise EMG measurements. However, existing sensors often show deteriorating signal quality over time and are greatly affected by the user’s skin conditions. Furthermore, the sensor’s higher mechanical hardness causes noise since the contact surface is unable to keep up with the deformation of the skin. These shortcomings limit the reliable, long-term control of wearable robots.

< Figure 1. Design and working concept of the Stretchable microNeedle Adhesive Patch (SNAP). (A) Schematic illustration showing the overall system configuration and application of SNAP. (B) Exploded view schematic diagram of a SNAP, consisting of stretchable serpentine interconnects, Au-coated Si microneedle, and ECA made of Ag flakes–silicone composite. (C) Optical images showing high mechanical compliance of SNAP. >